Efficiency Of Worm And Worm Wheel Formula . Gearing efficiency is defined as a ratio of the driven and driving members and differs if the worm (index 1) or the wheel (index 2) is the driving member. Chart of worm gear efficiency. This computation is based on the institute of machine elements,. These include the module, the. The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide without sacrificing. The pitch line velocity is ideally up to 30 m/s. Worm is the driving member efficiency of. The efficiency of a worm. Taking into consideration the other. This chart agrees with the equation. This method is able to calculate the local tooth friction and thereby the eficiency of the gear meshing. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. The calculations for the geometry of a worm gear pair are dependent on several key parameters.

from www.youtube.com

The pitch line velocity is ideally up to 30 m/s. Taking into consideration the other. The efficiency of a worm. These include the module, the. This chart agrees with the equation. Chart of worm gear efficiency. Worm is the driving member efficiency of. The calculations for the geometry of a worm gear pair are dependent on several key parameters. Gearing efficiency is defined as a ratio of the driven and driving members and differs if the worm (index 1) or the wheel (index 2) is the driving member. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives.

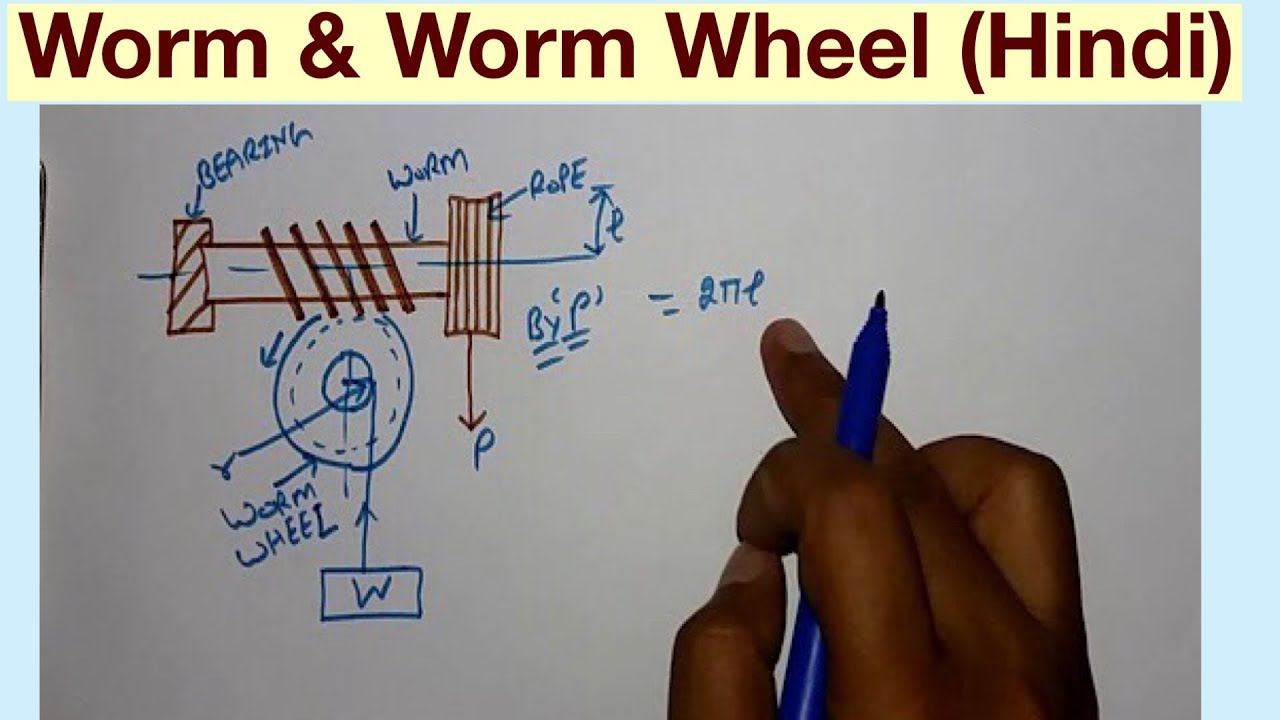

Worm & Worm Wheel (Hindi) YouTube

Efficiency Of Worm And Worm Wheel Formula Taking into consideration the other. Worm is the driving member efficiency of. The calculations for the geometry of a worm gear pair are dependent on several key parameters. Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide without sacrificing. This chart agrees with the equation. Taking into consideration the other. Chart of worm gear efficiency. This method is able to calculate the local tooth friction and thereby the eficiency of the gear meshing. The pitch line velocity is ideally up to 30 m/s. Gearing efficiency is defined as a ratio of the driven and driving members and differs if the worm (index 1) or the wheel (index 2) is the driving member. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. This computation is based on the institute of machine elements,. These include the module, the. The efficiency of a worm. The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes:

From www.studocu.com

7th Practical (worm and worm wheel) Practical No. 7 Aim To determine Efficiency Of Worm And Worm Wheel Formula This chart agrees with the equation. This computation is based on the institute of machine elements,. Taking into consideration the other. Chart of worm gear efficiency. The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: The efficiency of a worm. The pitch line velocity is ideally up to 30 m/s.. Efficiency Of Worm And Worm Wheel Formula.

From www.youtube.com

Gear Force Components Example 3 Worm Gears YouTube Efficiency Of Worm And Worm Wheel Formula This computation is based on the institute of machine elements,. Gearing efficiency is defined as a ratio of the driven and driving members and differs if the worm (index 1) or the wheel (index 2) is the driving member. The calculations for the geometry of a worm gear pair are dependent on several key parameters. The pitch line velocity is. Efficiency Of Worm And Worm Wheel Formula.

From rangmillionaire.weebly.com

Worm Gear Design Calculation Pdf File rangmillionaire Efficiency Of Worm And Worm Wheel Formula This chart agrees with the equation. Gearing efficiency is defined as a ratio of the driven and driving members and differs if the worm (index 1) or the wheel (index 2) is the driving member. This method is able to calculate the local tooth friction and thereby the eficiency of the gear meshing. Worm is the driving member efficiency of.. Efficiency Of Worm And Worm Wheel Formula.

From www.researchgate.net

Relationship between axes of worm and worm wheel Download High Efficiency Of Worm And Worm Wheel Formula This chart agrees with the equation. Chart of worm gear efficiency. These include the module, the. The pitch line velocity is ideally up to 30 m/s. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they. Efficiency Of Worm And Worm Wheel Formula.

From www.youtube.com

Worm and Wheel Gearbox Gear ratio Calculation How to calculate worm Efficiency Of Worm And Worm Wheel Formula These include the module, the. Worm is the driving member efficiency of. The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: Gearing efficiency is defined as a ratio of the driven and driving members and differs if the worm (index 1) or the wheel (index 2) is the driving member.. Efficiency Of Worm And Worm Wheel Formula.

From www.researchgate.net

Worm wheel machining system. Download Scientific Diagram Efficiency Of Worm And Worm Wheel Formula The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: This computation is based on the institute of machine elements,. This chart agrees with the equation. This method is able to calculate the local tooth friction and thereby the eficiency of the gear meshing. Taking into consideration the other. Worm is. Efficiency Of Worm And Worm Wheel Formula.

From www.researchgate.net

Parameters of worms and gears Download Table Efficiency Of Worm And Worm Wheel Formula These include the module, the. Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide without sacrificing. This chart agrees with the equation. This method is able to calculate the local tooth friction and thereby the eficiency of the gear meshing. This paper presents a physically grounded calculation method to determine. Efficiency Of Worm And Worm Wheel Formula.

From dpoksystems.weebly.com

Worm gear design calculation pdf to excel dpoksystems Efficiency Of Worm And Worm Wheel Formula Worm is the driving member efficiency of. The pitch line velocity is ideally up to 30 m/s. This computation is based on the institute of machine elements,. The efficiency of a worm. Chart of worm gear efficiency. Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide without sacrificing. The graph. Efficiency Of Worm And Worm Wheel Formula.

From khkgears.net

Surface Durability of Worm Gear KHK Efficiency Of Worm And Worm Wheel Formula The pitch line velocity is ideally up to 30 m/s. This method is able to calculate the local tooth friction and thereby the eficiency of the gear meshing. The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: The calculations for the geometry of a worm gear pair are dependent on. Efficiency Of Worm And Worm Wheel Formula.

From www.scribd.com

Worm and Worm Wheel Machines Mechanical Engineering Efficiency Of Worm And Worm Wheel Formula Worm is the driving member efficiency of. This computation is based on the institute of machine elements,. The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: Taking into consideration the other. The pitch line velocity is ideally up to 30 m/s. Chart of worm gear efficiency. The calculations for the. Efficiency Of Worm And Worm Wheel Formula.

From gasesaver.weebly.com

Worm gear design calculation pdf editor gasesaver Efficiency Of Worm And Worm Wheel Formula These include the module, the. Taking into consideration the other. The calculations for the geometry of a worm gear pair are dependent on several key parameters. This chart agrees with the equation. The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: This computation is based on the institute of machine. Efficiency Of Worm And Worm Wheel Formula.

From eureka.patsnap.com

Doublestation efficient wormgrindingwheel computer numerical control Efficiency Of Worm And Worm Wheel Formula This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. Chart of worm gear efficiency. Gearing efficiency is defined as a ratio of the driven and driving members and differs if the worm (index 1) or the wheel (index 2) is the driving member. Worm is the driving member efficiency of. The graph below. Efficiency Of Worm And Worm Wheel Formula.

From mechdiploma.com

Worm and Worm Gear Theory Q&A Mechanical Engg Simple Notes ,Solved Efficiency Of Worm And Worm Wheel Formula This method is able to calculate the local tooth friction and thereby the eficiency of the gear meshing. Gearing efficiency is defined as a ratio of the driven and driving members and differs if the worm (index 1) or the wheel (index 2) is the driving member. These include the module, the. This paper presents a physically grounded calculation method. Efficiency Of Worm And Worm Wheel Formula.

From www.youtube.com

WORM AND WHEEL YouTube Efficiency Of Worm And Worm Wheel Formula Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide without sacrificing. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: Gearing efficiency is defined. Efficiency Of Worm And Worm Wheel Formula.

From www.slideshare.net

Chapter 6 Efficiency Of Worm And Worm Wheel Formula Gearing efficiency is defined as a ratio of the driven and driving members and differs if the worm (index 1) or the wheel (index 2) is the driving member. The calculations for the geometry of a worm gear pair are dependent on several key parameters. The pitch line velocity is ideally up to 30 m/s. Here, we’ll look at the. Efficiency Of Worm And Worm Wheel Formula.

From www.researchgate.net

(PDF) Calculation of the efficiency of worm gear drives Efficiency Of Worm And Worm Wheel Formula The pitch line velocity is ideally up to 30 m/s. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. Worm is the driving member efficiency of. The calculations for the geometry of a worm gear pair are dependent on several key parameters. This method is able to calculate the local tooth friction and. Efficiency Of Worm And Worm Wheel Formula.

From www.youtube.com

Worm & Worm Wheel Mechanism Part 1 Design of Parts PTC Creo YouTube Efficiency Of Worm And Worm Wheel Formula The calculations for the geometry of a worm gear pair are dependent on several key parameters. The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: Worm is the driving member efficiency of. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. Here, we’ll. Efficiency Of Worm And Worm Wheel Formula.

From www.mechbix.com

Introduction to Worm and Worm Wheel MechBix A Complete Mechanical Efficiency Of Worm And Worm Wheel Formula These include the module, the. The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide without sacrificing. This paper presents a physically grounded calculation method to determine the efficiency of worm gear. Efficiency Of Worm And Worm Wheel Formula.

From heremup766.weebly.com

Worm Gear Design Calculation Pdf heremup Efficiency Of Worm And Worm Wheel Formula Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide without sacrificing. The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: Taking into consideration the other. The calculations for the geometry of a worm gear pair are dependent on several key. Efficiency Of Worm And Worm Wheel Formula.

From www.youtube.com

WORM AND WORM WHEEL THEORY Worm and Worm Wheel Gear Working of Efficiency Of Worm And Worm Wheel Formula Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide without sacrificing. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. These include the module, the. This method is able to calculate the local tooth friction and thereby the eficiency of the gear meshing.. Efficiency Of Worm And Worm Wheel Formula.

From brainsherof.weebly.com

Worm gear design calculation download brainsherofMy Site Efficiency Of Worm And Worm Wheel Formula The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: This method is able to calculate the local tooth friction and thereby the eficiency of the gear meshing. Worm is the driving member efficiency of. This computation is based on the institute of machine elements,. Gearing efficiency is defined as a. Efficiency Of Worm And Worm Wheel Formula.

From www.powertransmission.com

A New Standardizable Calculation Method to Predict the Efficiency of Efficiency Of Worm And Worm Wheel Formula The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: This computation is based on the institute of machine elements,. This chart agrees with the equation. This method is able to calculate the local tooth friction and thereby the eficiency of the gear meshing. The efficiency of a worm. These include. Efficiency Of Worm And Worm Wheel Formula.

From www.semanticscholar.org

Figure 3 from Worm Gear Efficiency Estimation and Optimization Efficiency Of Worm And Worm Wheel Formula This chart agrees with the equation. Taking into consideration the other. This computation is based on the institute of machine elements,. The pitch line velocity is ideally up to 30 m/s. Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide without sacrificing. This method is able to calculate the local. Efficiency Of Worm And Worm Wheel Formula.

From www.researchgate.net

Coordinate system of globoid worm drive. Download Scientific Diagram Efficiency Of Worm And Worm Wheel Formula The calculations for the geometry of a worm gear pair are dependent on several key parameters. These include the module, the. Worm is the driving member efficiency of. This chart agrees with the equation. Chart of worm gear efficiency. This computation is based on the institute of machine elements,. This method is able to calculate the local tooth friction and. Efficiency Of Worm And Worm Wheel Formula.

From khkgears.net

Technical Information of Worm Gear KHK Gears Efficiency Of Worm And Worm Wheel Formula This computation is based on the institute of machine elements,. This chart agrees with the equation. The calculations for the geometry of a worm gear pair are dependent on several key parameters. Taking into consideration the other. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. The efficiency of a worm. This method. Efficiency Of Worm And Worm Wheel Formula.

From www.youtube.com

WORM GEARS Forces and Speed Relations in Just Under 15 Minutes! YouTube Efficiency Of Worm And Worm Wheel Formula This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide without sacrificing. These include the module, the. Worm is the driving member efficiency of. Gearing efficiency is defined as a ratio of the driven and. Efficiency Of Worm And Worm Wheel Formula.

From www.youtube.com

WORM & WORM WHEEL EXPERIMENT AND CALCULATION IN हिंदी YouTube Efficiency Of Worm And Worm Wheel Formula Worm is the driving member efficiency of. The pitch line velocity is ideally up to 30 m/s. Gearing efficiency is defined as a ratio of the driven and driving members and differs if the worm (index 1) or the wheel (index 2) is the driving member. Taking into consideration the other. The efficiency of a worm. This method is able. Efficiency Of Worm And Worm Wheel Formula.

From www.researchgate.net

Model of worm wheel with separate detail and marked regions of the Efficiency Of Worm And Worm Wheel Formula Taking into consideration the other. Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide without sacrificing. The calculations for the geometry of a worm gear pair are dependent on several key parameters. The efficiency of a worm. This computation is based on the institute of machine elements,. These include the. Efficiency Of Worm And Worm Wheel Formula.

From www.eng-tips.com

Calc of Worm Gear Efficiency Gear & Pulley engineering EngTips Efficiency Of Worm And Worm Wheel Formula This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. The efficiency of a worm. Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide without sacrificing. Taking into consideration the other. The calculations for the geometry of a worm gear pair are dependent on. Efficiency Of Worm And Worm Wheel Formula.

From www.mdpi.com

Materials Free FullText Durability Characteristics Analysis of Efficiency Of Worm And Worm Wheel Formula This method is able to calculate the local tooth friction and thereby the eficiency of the gear meshing. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. This chart agrees with the equation. Chart of worm gear efficiency. This computation is based on the institute of machine elements,. The graph below shows a. Efficiency Of Worm And Worm Wheel Formula.

From www.hexagon.de

ZAR3 Worm Gear Calculation Efficiency Of Worm And Worm Wheel Formula The efficiency of a worm. The calculations for the geometry of a worm gear pair are dependent on several key parameters. Taking into consideration the other. This chart agrees with the equation. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. Chart of worm gear efficiency. This method is able to calculate the. Efficiency Of Worm And Worm Wheel Formula.

From grabcad.com

How to Calculate the Centre to CentreDistance between Worm and Wrom Efficiency Of Worm And Worm Wheel Formula The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: This computation is based on the institute of machine elements,. This chart agrees with the equation. The pitch line velocity is ideally up to 30 m/s. The efficiency of a worm. This method is able to calculate the local tooth friction. Efficiency Of Worm And Worm Wheel Formula.

From www.pinterest.com

Worm Gear Formula Table. Worm gears are grouped into two general Efficiency Of Worm And Worm Wheel Formula Taking into consideration the other. The efficiency of a worm. The calculations for the geometry of a worm gear pair are dependent on several key parameters. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. Chart of worm gear efficiency. This computation is based on the institute of machine elements,. These include the. Efficiency Of Worm And Worm Wheel Formula.

From www.engineersedge.com

AGMA Worm and Spur Gear Design Equations and Calculators Efficiency Of Worm And Worm Wheel Formula Worm is the driving member efficiency of. Gearing efficiency is defined as a ratio of the driven and driving members and differs if the worm (index 1) or the wheel (index 2) is the driving member. Here, we’ll look at the factors that determine worm gear efficiency and how to get the benefits they provide without sacrificing. The graph below. Efficiency Of Worm And Worm Wheel Formula.

From www.youtube.com

Worm & Worm Wheel (Hindi) YouTube Efficiency Of Worm And Worm Wheel Formula The graph below shows a worm gear efficiencies plotted against the lead angle for different coefficient of friction notes: Chart of worm gear efficiency. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. This computation is based on the institute of machine elements,. The calculations for the geometry of a worm gear pair. Efficiency Of Worm And Worm Wheel Formula.