Well Casing Vs Liner . This article will discuss the two main types of casings and liners that may be used in drilled shaft construction: In liner completions, both the liner and the intermediate casing function as the production string. The primary design consideration for liners is their ability to. So, if you have a well casing that leaks, your well experts may simply install a liner in the damaged portion of the casing. It also stabilizes the wellbore, so casing must be able to withstand especially high loads. Running and cementing liners is faster than full casings, meaning quicker completion times. If your liner is giving out, your well experts may simply replace it. Liner is a casing string that does not extend back to the wellhead, but is hung from another casing string. Casing lines the wellbore and thus protects the layers of soil and above all the groundwater from being contaminated by the drilling mud and/or frac fluids. Typically, a well liner is a repair part for a damaged well casing. The type of casing or liner that is used will depend on a number of factors, as described in depth below. Liners allow you to use larger tubing sizes for optimal production flow. Lighter liners mean less stress on your wellhead and surface piping.

from www.mdpi.com

If your liner is giving out, your well experts may simply replace it. Typically, a well liner is a repair part for a damaged well casing. Lighter liners mean less stress on your wellhead and surface piping. The primary design consideration for liners is their ability to. It also stabilizes the wellbore, so casing must be able to withstand especially high loads. Casing lines the wellbore and thus protects the layers of soil and above all the groundwater from being contaminated by the drilling mud and/or frac fluids. Running and cementing liners is faster than full casings, meaning quicker completion times. In liner completions, both the liner and the intermediate casing function as the production string. So, if you have a well casing that leaks, your well experts may simply install a liner in the damaged portion of the casing. Liners allow you to use larger tubing sizes for optimal production flow.

Processes Free FullText Study on Casing Safety Evaluation in High

Well Casing Vs Liner Liner is a casing string that does not extend back to the wellhead, but is hung from another casing string. If your liner is giving out, your well experts may simply replace it. The primary design consideration for liners is their ability to. Typically, a well liner is a repair part for a damaged well casing. It also stabilizes the wellbore, so casing must be able to withstand especially high loads. Running and cementing liners is faster than full casings, meaning quicker completion times. Lighter liners mean less stress on your wellhead and surface piping. This article will discuss the two main types of casings and liners that may be used in drilled shaft construction: The type of casing or liner that is used will depend on a number of factors, as described in depth below. So, if you have a well casing that leaks, your well experts may simply install a liner in the damaged portion of the casing. In liner completions, both the liner and the intermediate casing function as the production string. Liner is a casing string that does not extend back to the wellhead, but is hung from another casing string. Casing lines the wellbore and thus protects the layers of soil and above all the groundwater from being contaminated by the drilling mud and/or frac fluids. Liners allow you to use larger tubing sizes for optimal production flow.

From www.charlottepipe.com

PVC Well Casing Pipe Well Liner for Drinking Water Well Casing Vs Liner It also stabilizes the wellbore, so casing must be able to withstand especially high loads. In liner completions, both the liner and the intermediate casing function as the production string. If your liner is giving out, your well experts may simply replace it. Liner is a casing string that does not extend back to the wellhead, but is hung from. Well Casing Vs Liner.

From www.researchgate.net

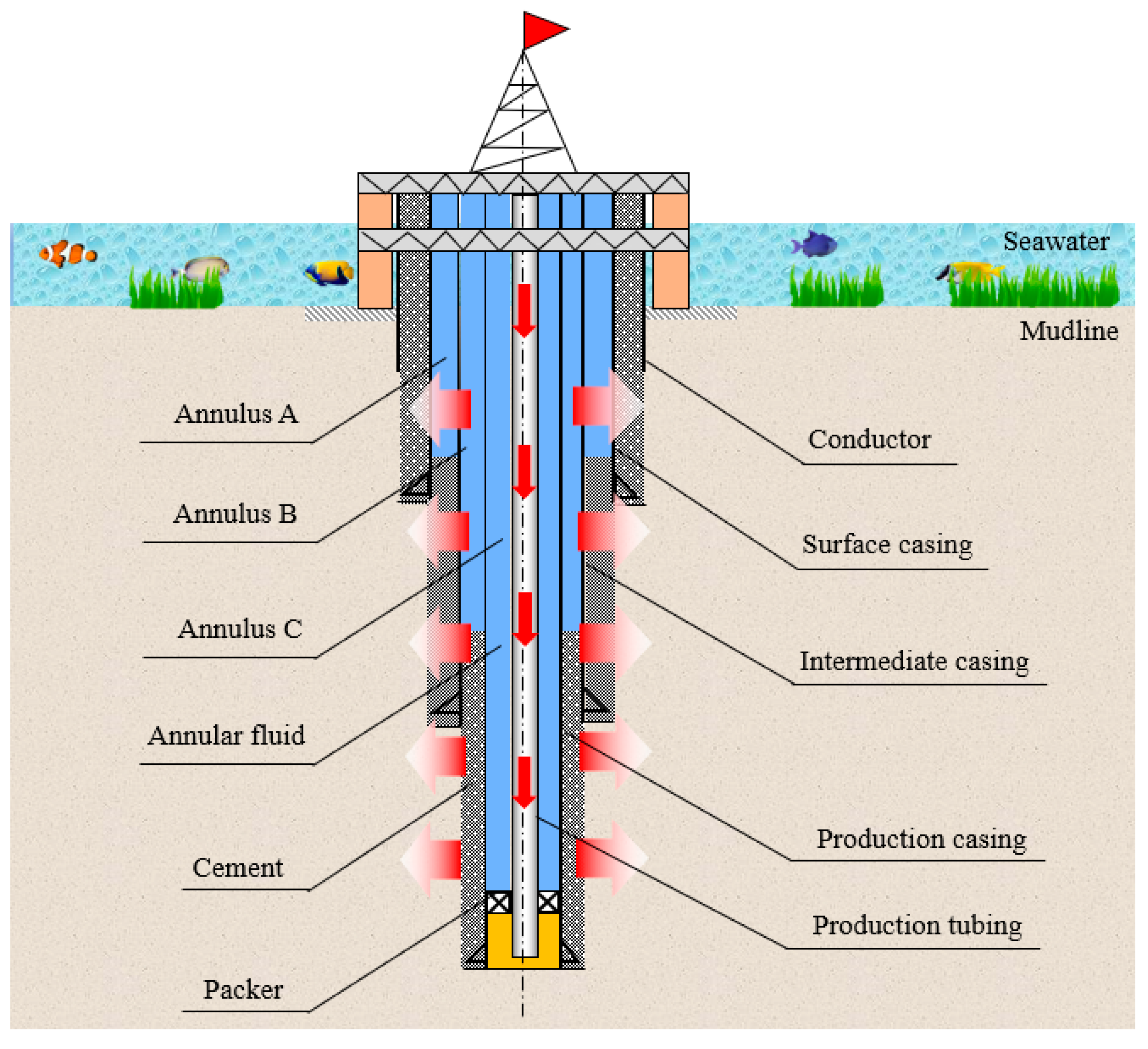

Casing and wellhead details of a pressurised well (left) and Well Casing Vs Liner So, if you have a well casing that leaks, your well experts may simply install a liner in the damaged portion of the casing. Liner is a casing string that does not extend back to the wellhead, but is hung from another casing string. Lighter liners mean less stress on your wellhead and surface piping. In liner completions, both the. Well Casing Vs Liner.

From rps-solar-pumps.zendesk.com

How to Measure a Well Casing & Well Seals vs Well Caps 24/7 RPS Well Casing Vs Liner Running and cementing liners is faster than full casings, meaning quicker completion times. The primary design consideration for liners is their ability to. This article will discuss the two main types of casings and liners that may be used in drilled shaft construction: Liners allow you to use larger tubing sizes for optimal production flow. Lighter liners mean less stress. Well Casing Vs Liner.

From www.drillingmanual.com

Drilling With Casing How, Why & Cementing Tips Drilling Manual Well Casing Vs Liner Liner is a casing string that does not extend back to the wellhead, but is hung from another casing string. This article will discuss the two main types of casings and liners that may be used in drilled shaft construction: The primary design consideration for liners is their ability to. Running and cementing liners is faster than full casings, meaning. Well Casing Vs Liner.

From nongferndaddy.com

Casing vs Liner มันต่างกันอย่างไร เคยสงสัยกันไหม ที่นี่มีคำตอบ Well Casing Vs Liner Casing lines the wellbore and thus protects the layers of soil and above all the groundwater from being contaminated by the drilling mud and/or frac fluids. So, if you have a well casing that leaks, your well experts may simply install a liner in the damaged portion of the casing. Lighter liners mean less stress on your wellhead and surface. Well Casing Vs Liner.

From www.ontario.ca

Wells Regulation New Construction of the Hole, Casing, Well Screen Well Casing Vs Liner Lighter liners mean less stress on your wellhead and surface piping. The type of casing or liner that is used will depend on a number of factors, as described in depth below. Liner is a casing string that does not extend back to the wellhead, but is hung from another casing string. In liner completions, both the liner and the. Well Casing Vs Liner.

From oilfieldteam.com

CasingSizesandName Well Casing Vs Liner Running and cementing liners is faster than full casings, meaning quicker completion times. So, if you have a well casing that leaks, your well experts may simply install a liner in the damaged portion of the casing. It also stabilizes the wellbore, so casing must be able to withstand especially high loads. This article will discuss the two main types. Well Casing Vs Liner.

From www.researchgate.net

Running and expansion process of expandable open hole liner system Well Casing Vs Liner The primary design consideration for liners is their ability to. Running and cementing liners is faster than full casings, meaning quicker completion times. Lighter liners mean less stress on your wellhead and surface piping. The type of casing or liner that is used will depend on a number of factors, as described in depth below. Liners allow you to use. Well Casing Vs Liner.

From ticladcopper.en.made-in-china.com

API Perforated Casing Pipe/ Slotted Liner Pipe/Water Well Sand Control Well Casing Vs Liner It also stabilizes the wellbore, so casing must be able to withstand especially high loads. This article will discuss the two main types of casings and liners that may be used in drilled shaft construction: If your liner is giving out, your well experts may simply replace it. Casing lines the wellbore and thus protects the layers of soil and. Well Casing Vs Liner.

From www.slideshare.net

Well design and construction i Well Casing Vs Liner So, if you have a well casing that leaks, your well experts may simply install a liner in the damaged portion of the casing. Liners allow you to use larger tubing sizes for optimal production flow. The primary design consideration for liners is their ability to. Typically, a well liner is a repair part for a damaged well casing. The. Well Casing Vs Liner.

From www.drillingcourse.com

Introduction to Cementing Drilling Course Well Casing Vs Liner Casing lines the wellbore and thus protects the layers of soil and above all the groundwater from being contaminated by the drilling mud and/or frac fluids. Liners allow you to use larger tubing sizes for optimal production flow. Lighter liners mean less stress on your wellhead and surface piping. Liner is a casing string that does not extend back to. Well Casing Vs Liner.

From pilebuck.com

Drilled Shafts Guide Casings & Liners Well Casing Vs Liner Typically, a well liner is a repair part for a damaged well casing. If your liner is giving out, your well experts may simply replace it. Liners allow you to use larger tubing sizes for optimal production flow. The primary design consideration for liners is their ability to. Lighter liners mean less stress on your wellhead and surface piping. This. Well Casing Vs Liner.

From marcelluscoalition.org

Well Casing Well Casing Vs Liner The primary design consideration for liners is their ability to. Liners allow you to use larger tubing sizes for optimal production flow. In liner completions, both the liner and the intermediate casing function as the production string. The type of casing or liner that is used will depend on a number of factors, as described in depth below. This article. Well Casing Vs Liner.

From www.drillingcontractor.org

Expandable casedhole liners assist integrated casing remediations Well Casing Vs Liner Liner is a casing string that does not extend back to the wellhead, but is hung from another casing string. So, if you have a well casing that leaks, your well experts may simply install a liner in the damaged portion of the casing. The primary design consideration for liners is their ability to. The type of casing or liner. Well Casing Vs Liner.

From www.youtube.com

Drilling Manual Expandable Casing Liners From Weatherford YouTube Well Casing Vs Liner Typically, a well liner is a repair part for a damaged well casing. So, if you have a well casing that leaks, your well experts may simply install a liner in the damaged portion of the casing. It also stabilizes the wellbore, so casing must be able to withstand especially high loads. The primary design consideration for liners is their. Well Casing Vs Liner.

From www.researchgate.net

Example HPHT well schematic. Download Scientific Diagram Well Casing Vs Liner In liner completions, both the liner and the intermediate casing function as the production string. Lighter liners mean less stress on your wellhead and surface piping. It also stabilizes the wellbore, so casing must be able to withstand especially high loads. So, if you have a well casing that leaks, your well experts may simply install a liner in the. Well Casing Vs Liner.

From books.gw-project.org

3.4 Components of a Domestic Well and Water System Domestic Wells Well Casing Vs Liner Casing lines the wellbore and thus protects the layers of soil and above all the groundwater from being contaminated by the drilling mud and/or frac fluids. If your liner is giving out, your well experts may simply replace it. Lighter liners mean less stress on your wellhead and surface piping. Typically, a well liner is a repair part for a. Well Casing Vs Liner.

From pilebuck.com

Chapter 6 Casings and Liners Pile Buck Magazine Well Casing Vs Liner Liners allow you to use larger tubing sizes for optimal production flow. Typically, a well liner is a repair part for a damaged well casing. It also stabilizes the wellbore, so casing must be able to withstand especially high loads. So, if you have a well casing that leaks, your well experts may simply install a liner in the damaged. Well Casing Vs Liner.

From mungfali.com

Water Well Casing Diagram Well Casing Vs Liner Lighter liners mean less stress on your wellhead and surface piping. The type of casing or liner that is used will depend on a number of factors, as described in depth below. This article will discuss the two main types of casings and liners that may be used in drilled shaft construction: So, if you have a well casing that. Well Casing Vs Liner.

From www.drillingformulas.com

Basic Understanding about Well Control with Pipe off Bottom Well Casing Vs Liner Running and cementing liners is faster than full casings, meaning quicker completion times. Typically, a well liner is a repair part for a damaged well casing. The type of casing or liner that is used will depend on a number of factors, as described in depth below. If your liner is giving out, your well experts may simply replace it.. Well Casing Vs Liner.

From www.beecavedrilling.com

Well Head Completion Options Bee Cave Drilling Well Casing Vs Liner The type of casing or liner that is used will depend on a number of factors, as described in depth below. Liner is a casing string that does not extend back to the wellhead, but is hung from another casing string. If your liner is giving out, your well experts may simply replace it. This article will discuss the two. Well Casing Vs Liner.

From www.researchgate.net

1 Typical well casing diagram. Download Scientific Diagram Well Casing Vs Liner Liners allow you to use larger tubing sizes for optimal production flow. If your liner is giving out, your well experts may simply replace it. Running and cementing liners is faster than full casings, meaning quicker completion times. The primary design consideration for liners is their ability to. Typically, a well liner is a repair part for a damaged well. Well Casing Vs Liner.

From pet-oil.blogspot.com

Chapter 2 Casing Design lec ( 6 ) petroleum Well Casing Vs Liner In liner completions, both the liner and the intermediate casing function as the production string. Running and cementing liners is faster than full casings, meaning quicker completion times. Liners allow you to use larger tubing sizes for optimal production flow. Lighter liners mean less stress on your wellhead and surface piping. If your liner is giving out, your well experts. Well Casing Vs Liner.

From horizonoilwell.com

Casing Design Horizon oil well academy Well Casing Vs Liner It also stabilizes the wellbore, so casing must be able to withstand especially high loads. Casing lines the wellbore and thus protects the layers of soil and above all the groundwater from being contaminated by the drilling mud and/or frac fluids. This article will discuss the two main types of casings and liners that may be used in drilled shaft. Well Casing Vs Liner.

From www.drillingformulas.com

Casing Design Drilling Formulas and Drilling Calculations Well Casing Vs Liner If your liner is giving out, your well experts may simply replace it. Typically, a well liner is a repair part for a damaged well casing. Liner is a casing string that does not extend back to the wellhead, but is hung from another casing string. The primary design consideration for liners is their ability to. So, if you have. Well Casing Vs Liner.

From www.drillingcourse.com

Introduction to Casing Drilling Course Well Casing Vs Liner The type of casing or liner that is used will depend on a number of factors, as described in depth below. If your liner is giving out, your well experts may simply replace it. So, if you have a well casing that leaks, your well experts may simply install a liner in the damaged portion of the casing. This article. Well Casing Vs Liner.

From www.pilebuck.com

Chapter 6 Casings and Liners Pile Buck Magazine Well Casing Vs Liner Typically, a well liner is a repair part for a damaged well casing. This article will discuss the two main types of casings and liners that may be used in drilled shaft construction: Running and cementing liners is faster than full casings, meaning quicker completion times. So, if you have a well casing that leaks, your well experts may simply. Well Casing Vs Liner.

From nongferndaddy.com

Casing vs Liner มันต่างกันอย่างไร เคยสงสัยกันไหม ที่นี่มีคำตอบ Well Casing Vs Liner The type of casing or liner that is used will depend on a number of factors, as described in depth below. Typically, a well liner is a repair part for a damaged well casing. So, if you have a well casing that leaks, your well experts may simply install a liner in the damaged portion of the casing. The primary. Well Casing Vs Liner.

From production-technology.org

Casing Specifications Production Technology Well Casing Vs Liner This article will discuss the two main types of casings and liners that may be used in drilled shaft construction: So, if you have a well casing that leaks, your well experts may simply install a liner in the damaged portion of the casing. Lighter liners mean less stress on your wellhead and surface piping. Running and cementing liners is. Well Casing Vs Liner.

From www.slideserve.com

PPT CHAPTER 6 WELL COMPLETION & STIMULATION PowerPoint Presentation Well Casing Vs Liner The primary design consideration for liners is their ability to. It also stabilizes the wellbore, so casing must be able to withstand especially high loads. Liner is a casing string that does not extend back to the wellhead, but is hung from another casing string. Lighter liners mean less stress on your wellhead and surface piping. This article will discuss. Well Casing Vs Liner.

From www.youtube.com

Well Design Introduction and API Standards of Casing YouTube Well Casing Vs Liner In liner completions, both the liner and the intermediate casing function as the production string. Casing lines the wellbore and thus protects the layers of soil and above all the groundwater from being contaminated by the drilling mud and/or frac fluids. So, if you have a well casing that leaks, your well experts may simply install a liner in the. Well Casing Vs Liner.

From baileylineroad.com

Understanding Water Wells Baileylineroad Well Casing Vs Liner This article will discuss the two main types of casings and liners that may be used in drilled shaft construction: The primary design consideration for liners is their ability to. Liners allow you to use larger tubing sizes for optimal production flow. Typically, a well liner is a repair part for a damaged well casing. Running and cementing liners is. Well Casing Vs Liner.

From www.researchgate.net

a—Schematic of well casing program Download Scientific Diagram Well Casing Vs Liner Typically, a well liner is a repair part for a damaged well casing. If your liner is giving out, your well experts may simply replace it. In liner completions, both the liner and the intermediate casing function as the production string. Casing lines the wellbore and thus protects the layers of soil and above all the groundwater from being contaminated. Well Casing Vs Liner.

From www.industrimigas.com

Drilling and Casing the Wellbore IndustriMigas 1 Oil and Gas Blog Well Casing Vs Liner Liners allow you to use larger tubing sizes for optimal production flow. So, if you have a well casing that leaks, your well experts may simply install a liner in the damaged portion of the casing. If your liner is giving out, your well experts may simply replace it. This article will discuss the two main types of casings and. Well Casing Vs Liner.

From www.mdpi.com

Processes Free FullText Study on Casing Safety Evaluation in High Well Casing Vs Liner Casing lines the wellbore and thus protects the layers of soil and above all the groundwater from being contaminated by the drilling mud and/or frac fluids. If your liner is giving out, your well experts may simply replace it. The primary design consideration for liners is their ability to. This article will discuss the two main types of casings and. Well Casing Vs Liner.