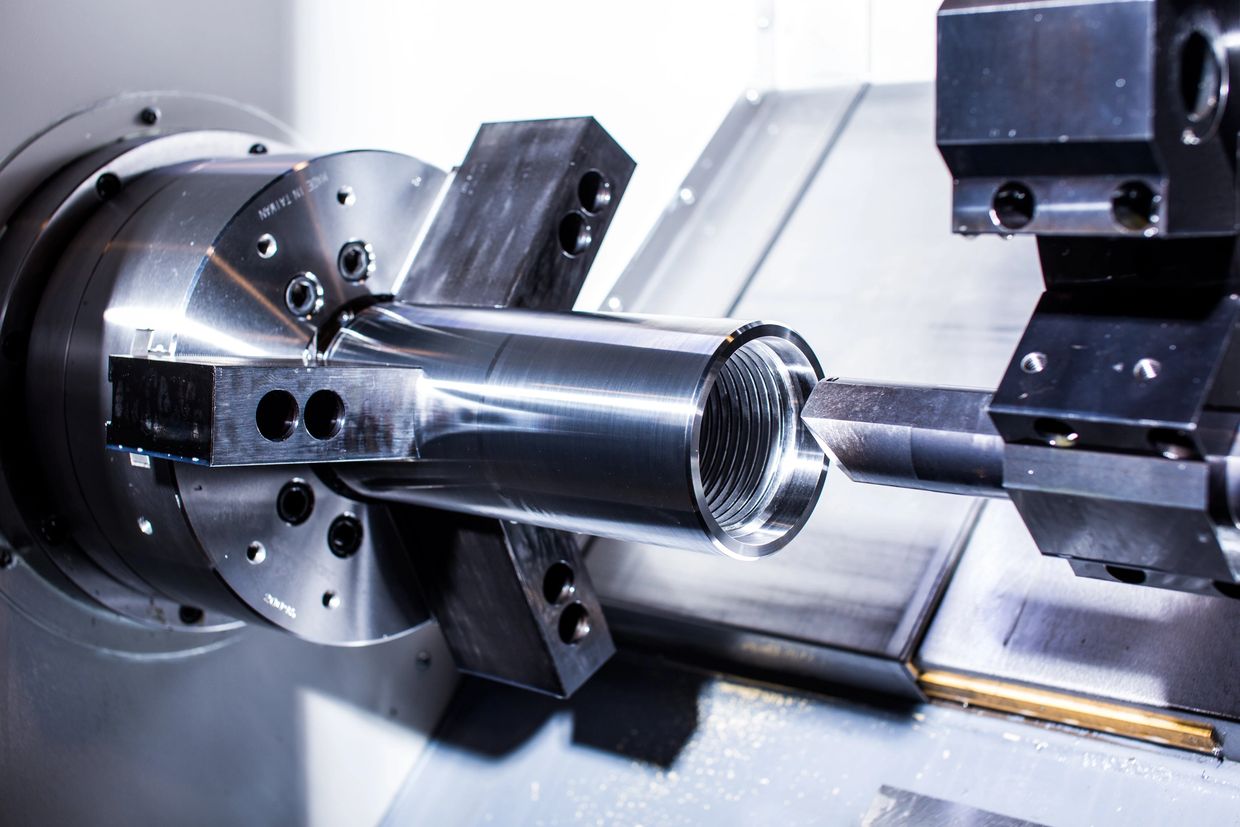

Threading Manufacturing Process . Suitable for all kind of. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. The method is used to create both internal threads (threads. V great tips for machining. The ability to specify, design, and manufacture these features effectively can drastically impact the functionality and longevity of a component or product. Covers the most common thread profiles; Productive and economical threading method, especially for smaller threads; Iii types of machining threads. Generally, it refers to the method of machining threads on the workpiece with forming tools. Ii main parameters for thread. Iv how to cut a machining thread? The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. I what is thread machining in part manufacturing?

from precimetal.ae

Suitable for all kind of. I what is thread machining in part manufacturing? The ability to specify, design, and manufacture these features effectively can drastically impact the functionality and longevity of a component or product. The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Iii types of machining threads. Covers the most common thread profiles; Generally, it refers to the method of machining threads on the workpiece with forming tools. Iv how to cut a machining thread? Productive and economical threading method, especially for smaller threads;

Threading Works Precimetal

Threading Manufacturing Process Iv how to cut a machining thread? I what is thread machining in part manufacturing? Suitable for all kind of. Iv how to cut a machining thread? V great tips for machining. Iii types of machining threads. Generally, it refers to the method of machining threads on the workpiece with forming tools. Productive and economical threading method, especially for smaller threads; The method is used to create both internal threads (threads. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. The ability to specify, design, and manufacture these features effectively can drastically impact the functionality and longevity of a component or product. Covers the most common thread profiles; Ii main parameters for thread. The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single.

From www.youtube.com

Shot of an automatic machine manufacturing thread Indian Stock Threading Manufacturing Process Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Productive and economical threading method, especially for smaller threads; Suitable for all kind of. Ii main parameters for thread. The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. The method is used to create. Threading Manufacturing Process.

From blog.csdn.net

Process, program, thread 的区别_process program algorithnCSDN博客 Threading Manufacturing Process Covers the most common thread profiles; The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. Generally, it refers to the method of machining threads on the workpiece with forming tools. V great tips for machining. The method is used to create both internal threads (threads. Thread machining is a vital subtractive. Threading Manufacturing Process.

From www.ganeshaecosphere.com

Manufacturing Process Threading Manufacturing Process Suitable for all kind of. Iii types of machining threads. Generally, it refers to the method of machining threads on the workpiece with forming tools. V great tips for machining. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. The method is used to create both internal threads (threads. The ability to specify,. Threading Manufacturing Process.

From www.sandvik.coromant.com

Tapping threads what is tapping? Threading Manufacturing Process I what is thread machining in part manufacturing? The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. V great tips for machining. Iv how to cut a machining thread? Iii types of machining threads. The ability to specify, design, and manufacture these features effectively can drastically impact the functionality and longevity. Threading Manufacturing Process.

From mechutopia.com

Hand Tapping How To Guide 2023 Mechutopia Threading Manufacturing Process Ii main parameters for thread. The method is used to create both internal threads (threads. I what is thread machining in part manufacturing? Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Iii types of machining threads. Iv how to cut a machining thread? Covers the most common thread profiles; Productive and. Threading Manufacturing Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Manufacturing Process Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. I what is thread machining in part manufacturing? Generally, it refers to the method of machining threads on the workpiece with forming tools. Ii main parameters for thread. The ability to specify, design, and manufacture these features effectively can drastically impact the functionality. Threading Manufacturing Process.

From issuu.com

Know the nut and bolt manufacturing process by superscrews Issuu Threading Manufacturing Process The method is used to create both internal threads (threads. Covers the most common thread profiles; Iii types of machining threads. Iv how to cut a machining thread? Productive and economical threading method, especially for smaller threads; Suitable for all kind of. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Generally,. Threading Manufacturing Process.

From www.scribd.com

Threading (Manufacturing) Threading Is The Process of Creating A Threading Manufacturing Process Suitable for all kind of. I what is thread machining in part manufacturing? The ability to specify, design, and manufacture these features effectively can drastically impact the functionality and longevity of a component or product. V great tips for machining. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Generally, it refers to. Threading Manufacturing Process.

From www.manufacturingguide.com

Electrical discharge threading Find suppliers, processes & material Threading Manufacturing Process Covers the most common thread profiles; Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. V great tips for machining. Productive and economical threading method, especially for smaller threads; The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. Iii types of machining threads. Thread. Threading Manufacturing Process.

From www.cpc-fasteners.com

THREADING MANUFACTURING Threading Manufacturing Process Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. The method is used to create both internal threads (threads. The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. Generally, it refers to the method of machining threads on the workpiece with forming tools.. Threading Manufacturing Process.

From www.huyett.com

Manufacturing Process Threading Threading Manufacturing Process Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. V great tips for machining. The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. The method is used to create both internal threads (threads. Generally, it refers to the method of machining threads on. Threading Manufacturing Process.

From www.manufacturingguide.com

Form Tapping Find suppliers, processes & material Threading Manufacturing Process Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Ii main parameters for thread. Generally, it refers to the method of machining threads on the workpiece with forming tools. Covers the most common thread profiles; The ability to specify, design, and manufacture these features effectively can drastically impact the functionality and longevity. Threading Manufacturing Process.

From www.dreamstime.com

Detail of Thread Factory Production Line Stock Photo Image of bobbin Threading Manufacturing Process The ability to specify, design, and manufacture these features effectively can drastically impact the functionality and longevity of a component or product. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Ii main parameters for thread. Covers the most common thread profiles; Iv how to cut a machining thread? V great tips for. Threading Manufacturing Process.

From www.youtube.com

Thread Taps Manufacturing YouTube Threading Manufacturing Process Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Iv how to cut a machining thread? Iii types of machining threads. The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. I what is thread machining in part manufacturing? The ability to specify, design, and. Threading Manufacturing Process.

From www.rolledthreads.com

What is the Difference Between Acme and Trapezoidal Threads? Threading Manufacturing Process The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. Generally, it refers to the method of machining threads on the workpiece with forming tools. Iv how to cut a machining thread? Suitable for all kind of. The method is used to create both internal threads (threads. Ii main parameters for thread.. Threading Manufacturing Process.

From proleantech.com

CNC Threading Process in Manufacturing A Comprehensive Guide CNC Threading Manufacturing Process Suitable for all kind of. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Ii main parameters for thread. Covers the most common thread profiles; I what is thread machining in part manufacturing? V great tips for machining. Iii types of machining threads. The major threading methods used in manufacturing include tapping, threading. Threading Manufacturing Process.

From www.youtube.com

Thread Making Process threading threadmill thread threadcutting Threading Manufacturing Process Iv how to cut a machining thread? The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. Generally, it refers to the method of machining threads on the workpiece with forming tools. Suitable for all kind of. V great tips for machining. The method is used to create both internal threads (threads.. Threading Manufacturing Process.

From www.cpc-fasteners.com

THREADING MANUFACTURING Threading Manufacturing Process Ii main parameters for thread. Iv how to cut a machining thread? Generally, it refers to the method of machining threads on the workpiece with forming tools. V great tips for machining. Suitable for all kind of. Productive and economical threading method, especially for smaller threads; Iii types of machining threads. Threading holds a critical position in manufacturing due to. Threading Manufacturing Process.

From www.youtube.com

How Thread Is Made Thread Production Line Thread Factory YouTube Threading Manufacturing Process V great tips for machining. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. The method is used to create both internal threads (threads. Covers the most common thread profiles; Productive and economical threading method, especially for smaller threads; I what is thread machining in part manufacturing? Suitable for all kind of.. Threading Manufacturing Process.

From dextutor.com

Threads in Operating System Dextutor Operating System Threading Manufacturing Process Iii types of machining threads. Generally, it refers to the method of machining threads on the workpiece with forming tools. The method is used to create both internal threads (threads. Iv how to cut a machining thread? The ability to specify, design, and manufacture these features effectively can drastically impact the functionality and longevity of a component or product. Ii. Threading Manufacturing Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Manufacturing Process Ii main parameters for thread. I what is thread machining in part manufacturing? The method is used to create both internal threads (threads. Productive and economical threading method, especially for smaller threads; Generally, it refers to the method of machining threads on the workpiece with forming tools. V great tips for machining. Thread machining is a vital subtractive process that. Threading Manufacturing Process.

From www.slideserve.com

PPT Topics PowerPoint Presentation, free download ID345512 Threading Manufacturing Process Productive and economical threading method, especially for smaller threads; The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. Suitable for all kind of. Iv how to cut a machining thread? Ii main parameters for thread. I what is thread machining in part manufacturing? Threading holds a critical position in manufacturing due. Threading Manufacturing Process.

From cnpipetool.en.made-in-china.com

Threading Manufacturing Machine China Electric Pipe Threading Machine Threading Manufacturing Process The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. Suitable for all kind of. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Covers the most common thread profiles; Productive and economical threading method, especially for smaller threads; The method is used to. Threading Manufacturing Process.

From precimetal.ae

Threading Works Precimetal Threading Manufacturing Process Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. Iv how to cut a machining thread? Productive and economical threading method, especially for smaller threads; Suitable for all kind of. Generally, it refers to the. Threading Manufacturing Process.

From radiantappliances.com

Manufacturing process analysis Steps & benefits you should know! Threading Manufacturing Process Ii main parameters for thread. I what is thread machining in part manufacturing? Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. V great tips for machining. The ability to specify, design, and manufacture these features. Threading Manufacturing Process.

From www.manufacturingguide.com

Thread Rolling Find suppliers, processes & material Threading Manufacturing Process Iv how to cut a machining thread? V great tips for machining. Ii main parameters for thread. Suitable for all kind of. Iii types of machining threads. Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. The method is used to create both internal threads (threads. Generally, it refers to the method of. Threading Manufacturing Process.

From mikehardware.com

Thread Rolling Process of Screws The Basics MIKEHARDWARE Threading Manufacturing Process The method is used to create both internal threads (threads. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Productive and economical threading method, especially for smaller threads; Ii main parameters for thread. The ability to specify, design, and manufacture these features effectively can drastically impact the functionality and longevity of a. Threading Manufacturing Process.

From jbcmachine.com

Threading Services JBC Machine, Inc. Threading Manufacturing Process The method is used to create both internal threads (threads. Generally, it refers to the method of machining threads on the workpiece with forming tools. V great tips for machining. I what is thread machining in part manufacturing? Covers the most common thread profiles; Suitable for all kind of. Threading holds a critical position in manufacturing due to its broad. Threading Manufacturing Process.

From www.practicalmachinist.com

A Guide to Tapping and Threading Practical Machinist Practical Threading Manufacturing Process I what is thread machining in part manufacturing? Suitable for all kind of. Ii main parameters for thread. Productive and economical threading method, especially for smaller threads; Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Iv how to cut a machining thread? V great tips for machining. The method is used. Threading Manufacturing Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Manufacturing Process Productive and economical threading method, especially for smaller threads; Covers the most common thread profiles; V great tips for machining. The ability to specify, design, and manufacture these features effectively can drastically impact the functionality and longevity of a component or product. Iv how to cut a machining thread? The method is used to create both internal threads (threads. Thread. Threading Manufacturing Process.

From mikehardware.com

From Raw Material to Precision Component a Deep Dive Into Screw Threading Manufacturing Process Iii types of machining threads. I what is thread machining in part manufacturing? The ability to specify, design, and manufacture these features effectively can drastically impact the functionality and longevity of a component or product. The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. Covers the most common thread profiles; Suitable. Threading Manufacturing Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Manufacturing Process The method is used to create both internal threads (threads. I what is thread machining in part manufacturing? Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Generally, it refers to the method of machining threads on the workpiece with forming tools. Suitable for all kind of. Ii main parameters for thread.. Threading Manufacturing Process.

From www.scribd.com

Thread manufacturing process ppt Screw Metalworking Threading Manufacturing Process Iv how to cut a machining thread? Productive and economical threading method, especially for smaller threads; Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Covers the most common thread profiles; Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Ii main parameters for thread.. Threading Manufacturing Process.

From www.researchgate.net

Schematic ¯ow diagram of the rubber thread manufacturing process Threading Manufacturing Process Suitable for all kind of. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Productive and economical threading method, especially for smaller threads; Iii types of machining threads. Covers the most common thread profiles; V great tips for machining. I what is thread machining in part manufacturing? Ii main parameters for thread.. Threading Manufacturing Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Manufacturing Process Iv how to cut a machining thread? Threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. The major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread rolling, and single. The ability to specify, design, and manufacture these features effectively can drastically impact the functionality and longevity of a. Threading Manufacturing Process.