Endoscope Welding Inspection . Asme b31.1 visual acceptance criteria. This makes it possible to directly detect any obvious defects or deviations in. A weld inspection is a key element of quality assurance in welding technology. Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints. Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. The visual examination as per asme b31.1 must adhere to the guidelines outlined in. Visible welding® weldwatch® hd weld camera with ultra dynamic range and zoom. The introduction of industrial endoscopes for welding inspection has brought about a significant revolution in manufacturing inspections. An endoscope, or a camera. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: A weld seam can be viewed.

from www.alibaba.com

Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. The visual examination as per asme b31.1 must adhere to the guidelines outlined in. An endoscope, or a camera. A weld seam can be viewed. A weld inspection is a key element of quality assurance in welding technology. Visible welding® weldwatch® hd weld camera with ultra dynamic range and zoom. Asme b31.1 visual acceptance criteria. This makes it possible to directly detect any obvious defects or deviations in. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints.

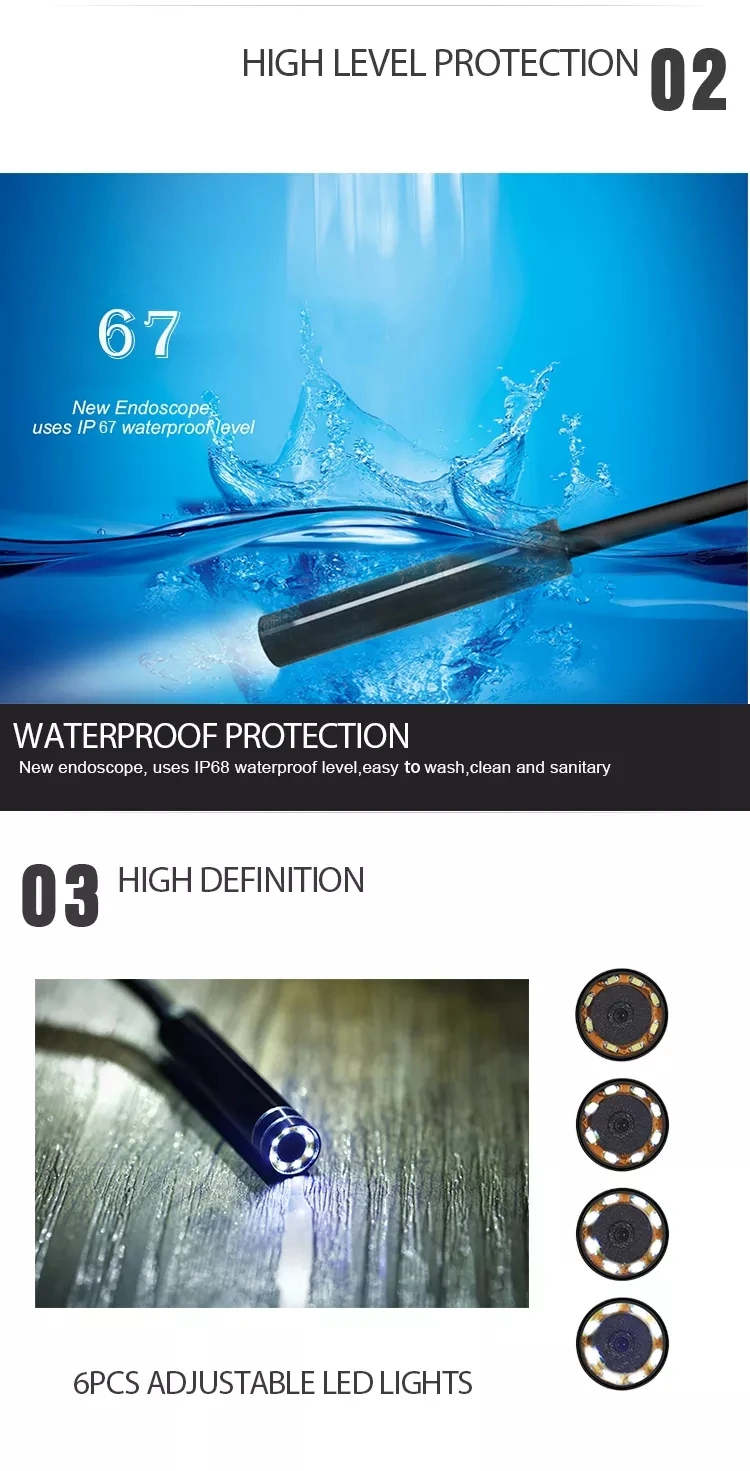

5m Hard Cable Sewer Endscope 7mm 3 In 1 Industrial Endoscopy Camera For

Endoscope Welding Inspection A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: The introduction of industrial endoscopes for welding inspection has brought about a significant revolution in manufacturing inspections. Visible welding® weldwatch® hd weld camera with ultra dynamic range and zoom. The visual examination as per asme b31.1 must adhere to the guidelines outlined in. Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints. An endoscope, or a camera. This makes it possible to directly detect any obvious defects or deviations in. Asme b31.1 visual acceptance criteria. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: A weld seam can be viewed. A weld inspection is a key element of quality assurance in welding technology.

From weldyard.com

The Rigid Borescopes EFER ENDOSCOPY Brand Weld أول متجر Endoscope Welding Inspection A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: A weld inspection is a key element of quality assurance in welding technology. Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints. Welding products that are exposed to high. Endoscope Welding Inspection.

From patcommedical.com

Distal Chip Endoscope Medical Inc. Endoscope Welding Inspection Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints. A weld inspection is a key element of quality assurance in welding technology. The visual examination as per asme b31.1 must adhere to the guidelines outlined in. This makes it possible to directly detect any obvious defects or deviations in.. Endoscope Welding Inspection.

From www.surgicalholdings.co.uk

Rigid Endoscope Repairs Surgical Holdings Endoscope Welding Inspection Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: An endoscope, or a camera. Various test methods can be used to identify weld defects such as cracks or lack of fusion. Endoscope Welding Inspection.

From weldyard.com

The Rigid Borescopes EFER ENDOSCOPY Brand Weld أول متجر Endoscope Welding Inspection The introduction of industrial endoscopes for welding inspection has brought about a significant revolution in manufacturing inspections. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints. An endoscope, or. Endoscope Welding Inspection.

From www.mig-welding.co.uk

Borescope/Endoscope MIG Welding Forum Endoscope Welding Inspection Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. A weld seam can be viewed. The introduction of industrial endoscopes for welding inspection has brought about a significant revolution in manufacturing inspections. Asme b31.1 visual acceptance criteria. A borescope weld inspection camera is an effective tool for quality control and inspection. Endoscope Welding Inspection.

From jscinspections.nl

Visual Inspections Endoscopy JSC Inspections Endoscope Welding Inspection Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: An endoscope, or a camera. Visible welding® weldwatch® hd weld camera with ultra dynamic range and zoom. A weld seam. Endoscope Welding Inspection.

From www.cctvcameradvrs.com

25M Meters 100 Feet FT 4 LED Waterproof Endoscope Borescope Snake Endoscope Welding Inspection This makes it possible to directly detect any obvious defects or deviations in. Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. A weld inspection is a key element of quality assurance in welding technology. Asme b31.1 visual acceptance criteria. A weld seam can be viewed. An endoscope, or a camera.. Endoscope Welding Inspection.

From www.alibaba.com

5m Hard Cable Sewer Endscope 7mm 3 In 1 Industrial Endoscopy Camera For Endoscope Welding Inspection A weld inspection is a key element of quality assurance in welding technology. An endoscope, or a camera. The visual examination as per asme b31.1 must adhere to the guidelines outlined in. This makes it possible to directly detect any obvious defects or deviations in. A weld seam can be viewed. Various test methods can be used to identify weld. Endoscope Welding Inspection.

From www.srirepairs.com

Rigid Endoscopes Repair Endoscope Repair Service Flexible Endoscope Endoscope Welding Inspection Asme b31.1 visual acceptance criteria. The visual examination as per asme b31.1 must adhere to the guidelines outlined in. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: This makes it possible to directly detect any obvious defects or deviations in. Various test methods can be used to identify. Endoscope Welding Inspection.

From www.ivt.be

Video endoscopy IVT Inspections Endoscope Welding Inspection Visible welding® weldwatch® hd weld camera with ultra dynamic range and zoom. This makes it possible to directly detect any obvious defects or deviations in. Asme b31.1 visual acceptance criteria. An endoscope, or a camera. A weld inspection is a key element of quality assurance in welding technology. A borescope weld inspection camera is an effective tool for quality control. Endoscope Welding Inspection.

From www.honorstand.com

5.5mm Industrial Endoscope AV Inspection Borescope Camera Honorstand Endoscope Welding Inspection This makes it possible to directly detect any obvious defects or deviations in. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: A weld inspection is a key element of quality assurance in welding technology. Various test methods can be used to identify weld defects such as cracks or. Endoscope Welding Inspection.

From www.ndt.net

Weld Root Inspection by Endoscopy as per ISO 5817 Class B Endoscope Welding Inspection An endoscope, or a camera. Asme b31.1 visual acceptance criteria. This makes it possible to directly detect any obvious defects or deviations in. A weld inspection is a key element of quality assurance in welding technology. The visual examination as per asme b31.1 must adhere to the guidelines outlined in. Welding products that are exposed to high pressure are unusable. Endoscope Welding Inspection.

From yateks.com

Borescope inspection used in Pharmaceutical Plants Pipe inspection Endoscope Welding Inspection A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints. The introduction. Endoscope Welding Inspection.

From stock.adobe.com

The video endoscope is used in the laboratory. Quality control of metal Endoscope Welding Inspection The introduction of industrial endoscopes for welding inspection has brought about a significant revolution in manufacturing inspections. Asme b31.1 visual acceptance criteria. A weld inspection is a key element of quality assurance in welding technology. Visible welding® weldwatch® hd weld camera with ultra dynamic range and zoom. An endoscope, or a camera. A borescope weld inspection camera is an effective. Endoscope Welding Inspection.

From www.youtube.com

Weld Inspection Video Endoscope INVIZ VUMAN RAY YouTube Endoscope Welding Inspection A weld inspection is a key element of quality assurance in welding technology. The introduction of industrial endoscopes for welding inspection has brought about a significant revolution in manufacturing inspections. Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints. Welding products that are exposed to high pressure are unusable. Endoscope Welding Inspection.

From ykinspection.en.made-in-china.com

Industry Endoscopy Camera Flexible Endoscope with for 4Way Tip Endoscope Welding Inspection This makes it possible to directly detect any obvious defects or deviations in. A weld inspection is a key element of quality assurance in welding technology. A weld seam can be viewed. An endoscope, or a camera. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: Welding products that. Endoscope Welding Inspection.

From www.starsyun.vip

Composition of rigid endoscopeendoscope parts and function Endoscope Welding Inspection The visual examination as per asme b31.1 must adhere to the guidelines outlined in. Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. An endoscope, or a camera. Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints. This makes it. Endoscope Welding Inspection.

From www.alibaba.com

5m Hard Cable Sewer Endscope 7mm 3 In 1 Industrial Endoscopy Camera For Endoscope Welding Inspection A weld inspection is a key element of quality assurance in welding technology. An endoscope, or a camera. Asme b31.1 visual acceptance criteria. Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded. Endoscope Welding Inspection.

From www.youtube.com

Laser cutting of endoscope devices, stainless steel tubes, engraving Endoscope Welding Inspection A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: This makes it possible to directly detect any obvious defects or deviations in. An endoscope, or a camera. A weld seam can be viewed. Welding products that are exposed to high pressure are unusable if the weld seam is not. Endoscope Welding Inspection.

From ykinspection.en.made-in-china.com

Portable Industrial Video Inspection Endoscope Snake Borescope for Endoscope Welding Inspection Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. Visible welding® weldwatch® hd weld camera with ultra dynamic range and zoom. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: This makes it possible to directly detect any obvious defects. Endoscope Welding Inspection.

From www.alibaba.com

Wholesale Engine Industrial Endoscope Automotive Borescope With 2way Endoscope Welding Inspection A weld seam can be viewed. This makes it possible to directly detect any obvious defects or deviations in. Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints. The introduction of industrial endoscopes for welding inspection has brought about a significant revolution in manufacturing inspections. A borescope weld inspection. Endoscope Welding Inspection.

From www.fyendoscopy.com

Types Of Flexible Endoscopes for Sale, Flexible Endoscope Manufacturer Endoscope Welding Inspection A weld inspection is a key element of quality assurance in welding technology. Asme b31.1 visual acceptance criteria. An endoscope, or a camera. A weld seam can be viewed. This makes it possible to directly detect any obvious defects or deviations in. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of. Endoscope Welding Inspection.

From www.gadgets4geeks.com.au

10m Industrial Endoscope Inspection Camera / Display Screen Endoscope Welding Inspection Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints. The introduction of industrial endoscopes for welding inspection has brought about a significant revolution in manufacturing inspections. The visual examination as per asme b31.1 must adhere to the guidelines outlined in. A borescope weld inspection camera is an effective tool. Endoscope Welding Inspection.

From www.gadgets4geeks.com.au

10m Industrial Endoscope Inspection Camera / Display Screen Endoscope Welding Inspection This makes it possible to directly detect any obvious defects or deviations in. Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. A weld inspection is a key element of quality assurance in welding technology. An endoscope, or a camera. Various test methods can be used to identify weld defects such. Endoscope Welding Inspection.

From bestweldinggears.com

Best 10 endoscopy Review BestWeldingGears Endoscope Welding Inspection The visual examination as per asme b31.1 must adhere to the guidelines outlined in. Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: A weld inspection is a key. Endoscope Welding Inspection.

From www.micro-epsilon.com

Optical weld seam inspection with industrial endoscope MicroEpsilon Endoscope Welding Inspection Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. This makes it possible to directly detect any obvious defects or deviations in. An endoscope, or a camera. Asme b31.1 visual acceptance criteria. The introduction of industrial endoscopes for welding inspection has brought about a significant revolution in manufacturing inspections. A borescope. Endoscope Welding Inspection.

From www.amphibear.com

Amphibear Weldings quality control Endoscope Welding Inspection Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. A weld inspection is a key element of quality assurance in welding technology. The visual examination as per asme b31.1 must adhere to the guidelines outlined in. An endoscope, or a camera. Asme b31.1 visual acceptance criteria. This makes it possible to. Endoscope Welding Inspection.

From www.alibaba.com

5m Hard Cable Sewer Endscope 7mm 3 In 1 Industrial Endoscopy Camera For Endoscope Welding Inspection This makes it possible to directly detect any obvious defects or deviations in. A weld seam can be viewed. An endoscope, or a camera. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: The visual examination as per asme b31.1 must adhere to the guidelines outlined in. The introduction. Endoscope Welding Inspection.

From ykinspection.en.made-in-china.com

3mm Side View Lens 5 Inch Portable Industrial Video Inspection Endoscope Welding Inspection The introduction of industrial endoscopes for welding inspection has brought about a significant revolution in manufacturing inspections. The visual examination as per asme b31.1 must adhere to the guidelines outlined in. This makes it possible to directly detect any obvious defects or deviations in. A borescope weld inspection camera is an effective tool for quality control and inspection in a. Endoscope Welding Inspection.

From sib7.com

Teslong NTS200 Portable LCD Snake eye Borescope and Endoscope Endoscope Welding Inspection A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: Asme b31.1 visual acceptance criteria. The introduction of industrial endoscopes for welding inspection has brought about a significant revolution in manufacturing inspections. A weld seam can be viewed. An endoscope, or a camera. Visible welding® weldwatch® hd weld camera with. Endoscope Welding Inspection.

From ykinspection.en.made-in-china.com

Flexible Joystick Video Endoscope for Engine Repair, Welding Inspection Endoscope Welding Inspection The introduction of industrial endoscopes for welding inspection has brought about a significant revolution in manufacturing inspections. Visible welding® weldwatch® hd weld camera with ultra dynamic range and zoom. A weld seam can be viewed. A weld inspection is a key element of quality assurance in welding technology. This makes it possible to directly detect any obvious defects or deviations. Endoscope Welding Inspection.

From www.alibaba.com

5m Hard Cable Sewer Endscope 7mm 3 In 1 Industrial Endoscopy Camera For Endoscope Welding Inspection Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints. Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. The visual examination as per asme b31.1 must adhere to the guidelines outlined in. Visible welding® weldwatch® hd weld camera with ultra. Endoscope Welding Inspection.

From inchbyinch.de

INCH Technical English pictorial inspection camera/endoscope Endoscope Welding Inspection Asme b31.1 visual acceptance criteria. Welding products that are exposed to high pressure are unusable if the weld seam is not welded through. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: An endoscope, or a camera. The visual examination as per asme b31.1 must adhere to the guidelines. Endoscope Welding Inspection.

From www.miqias.com

Visual Test Instrument MIQIAS Endoscope Welding Inspection A weld seam can be viewed. The visual examination as per asme b31.1 must adhere to the guidelines outlined in. Various test methods can be used to identify weld defects such as cracks or lack of fusion in welded joints. Visible welding® weldwatch® hd weld camera with ultra dynamic range and zoom. An endoscope, or a camera. A weld inspection. Endoscope Welding Inspection.

From www.walmart.com

VEVOR Sewer Camera 150ft Pipe Pipeline Inspection Camera 9 inch Color Endoscope Welding Inspection The visual examination as per asme b31.1 must adhere to the guidelines outlined in. The introduction of industrial endoscopes for welding inspection has brought about a significant revolution in manufacturing inspections. A borescope weld inspection camera is an effective tool for quality control and inspection in a variety of industries, including: Welding products that are exposed to high pressure are. Endoscope Welding Inspection.