Knife Blade Tempering . Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. So, to relieve internal stresses and improve toughness, heat the. Between cycles, the blade should be cool down to room temperature. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and 316°c) to. Tempering is the final stage of the heat treating process, performed after hardening and quenching. In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Although blacksmiths and knife manufacturers primarily do the tempering as part of an elaborate blade production process, you. Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain growth. After the second tempering cycle, the blade is usually fully tempered and ready to finish into a knife. Note that the temperature must be controlled. Quenching can introduce excess hardness and undesirable brittleness to your knife.

from www.youtube.com

Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain growth. Note that the temperature must be controlled. After the second tempering cycle, the blade is usually fully tempered and ready to finish into a knife. In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Between cycles, the blade should be cool down to room temperature. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and 316°c) to. Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. So, to relieve internal stresses and improve toughness, heat the. Tempering is the final stage of the heat treating process, performed after hardening and quenching. Although blacksmiths and knife manufacturers primarily do the tempering as part of an elaborate blade production process, you.

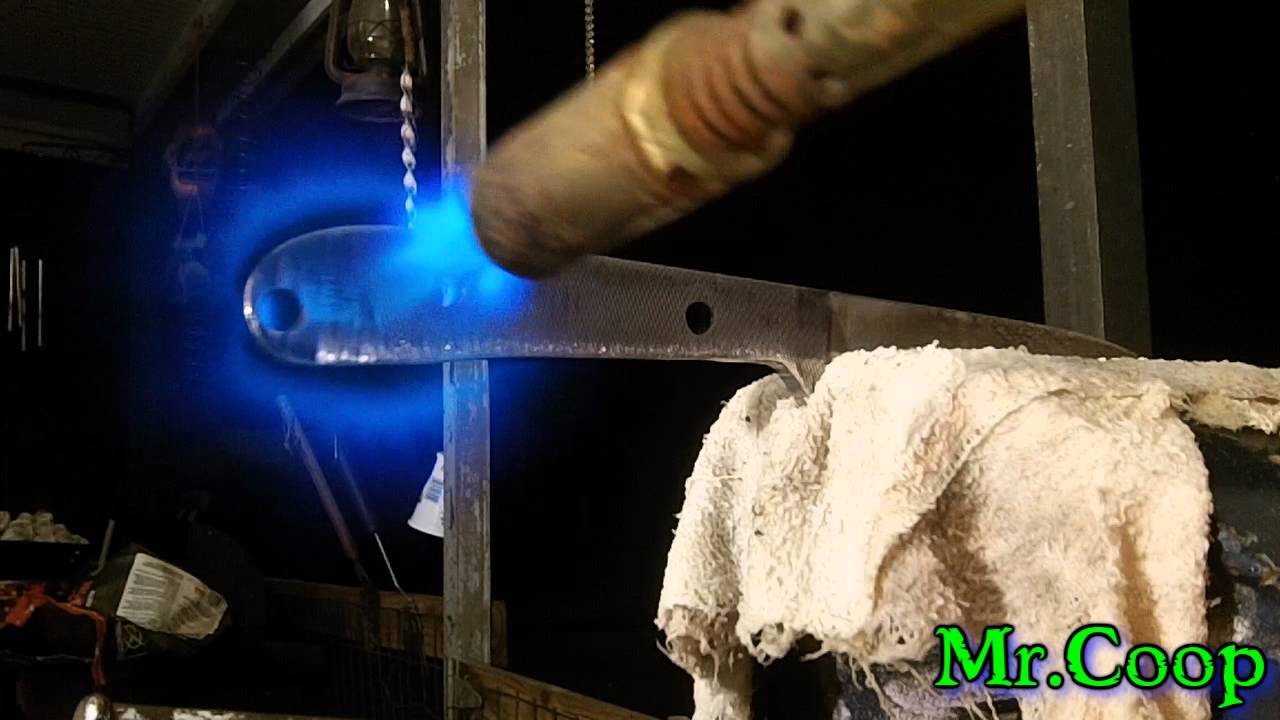

Tempering File Knife With Torch . YouTube

Knife Blade Tempering Quenching can introduce excess hardness and undesirable brittleness to your knife. Although blacksmiths and knife manufacturers primarily do the tempering as part of an elaborate blade production process, you. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and 316°c) to. Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. Between cycles, the blade should be cool down to room temperature. So, to relieve internal stresses and improve toughness, heat the. After the second tempering cycle, the blade is usually fully tempered and ready to finish into a knife. In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Quenching can introduce excess hardness and undesirable brittleness to your knife. Tempering is the final stage of the heat treating process, performed after hardening and quenching. Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain growth. Note that the temperature must be controlled.

From thetilessam.blogspot.com

How To A Knife Blade Hand Allround Cooking Knife With 13 Knife Blade Tempering So, to relieve internal stresses and improve toughness, heat the. Note that the temperature must be controlled. Tempering is the final stage of the heat treating process, performed after hardening and quenching. Between cycles, the blade should be cool down to room temperature. Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain growth.. Knife Blade Tempering.

From www.pinterest.com

knifemaking, hardening and tempering the blade Blade, Temper, Hardened Knife Blade Tempering Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and 316°c) to. Tempering is the final stage of the heat treating process, performed after hardening and quenching. Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain growth. Between cycles, the blade should be cool down. Knife Blade Tempering.

From www.pinterest.com

How to Temper Knife Blades Knife making, Diy knife, Knife Knife Blade Tempering Although blacksmiths and knife manufacturers primarily do the tempering as part of an elaborate blade production process, you. After the second tempering cycle, the blade is usually fully tempered and ready to finish into a knife. Tempering is the final stage of the heat treating process, performed after hardening and quenching. Tempering involves reheating the hardened steel to a lower. Knife Blade Tempering.

From recipes.net

How To Temper A Knife Blade In Toaster Oven Knife Blade Tempering Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain growth. In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. So, to relieve internal stresses and improve toughness, heat the. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and. Knife Blade Tempering.

From www.reddit.com

For everyone asking how to temper by color, here's the chart you need Knife Blade Tempering So, to relieve internal stresses and improve toughness, heat the. Quenching can introduce excess hardness and undesirable brittleness to your knife. Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. Note that the temperature must be controlled. Although blacksmiths and knife manufacturers primarily do. Knife Blade Tempering.

From www.pinterest.com

How to Heat Treat Stainless Steel for Knife Making Knife making Knife Blade Tempering Note that the temperature must be controlled. In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Tempering is the final stage of the heat treating process, performed after hardening and quenching. Between cycles, the blade should be cool down to room temperature. Quenching can introduce excess hardness and undesirable brittleness to your knife. Some. Knife Blade Tempering.

From www.youtube.com

How to make a knife? After Tempering (2/2) YouTube Knife Blade Tempering After the second tempering cycle, the blade is usually fully tempered and ready to finish into a knife. Between cycles, the blade should be cool down to room temperature. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and 316°c) to. Some knifemakers are afraid of holding too long at austenitizing temperature. Knife Blade Tempering.

From www.sst.net

Knife Heat Treating Services Knife Tempering Specialty Steel Knife Blade Tempering In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Between cycles, the blade should be cool down to room temperature. Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. After the second tempering cycle, the blade is usually. Knife Blade Tempering.

From www.pinterest.com

Knife Blade Steel Guide Composition Best Steels Comparison Chart Knife Blade Tempering After the second tempering cycle, the blade is usually fully tempered and ready to finish into a knife. In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Quenching can introduce excess hardness and undesirable brittleness to your knife. Between cycles, the blade should be cool down to room temperature. Note that the temperature must. Knife Blade Tempering.

From recipes.net

How To Temper Knife Blade In Kitchen Oven Knife Blade Tempering Although blacksmiths and knife manufacturers primarily do the tempering as part of an elaborate blade production process, you. Between cycles, the blade should be cool down to room temperature. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and 316°c) to. Quenching can introduce excess hardness and undesirable brittleness to your knife.. Knife Blade Tempering.

From www.pinterest.com

Viking 's axe blade of 4.93" in 1075 carbon steel with selective Knife Blade Tempering Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. Quenching can introduce excess hardness and undesirable brittleness to your knife. So, to relieve internal stresses and improve toughness, heat the. After the second tempering cycle, the blade is usually fully tempered and ready to. Knife Blade Tempering.

From www.pinterest.com

1000+ images about Gun & Knife Gallery on Pinterest Custom knives Knife Blade Tempering Although blacksmiths and knife manufacturers primarily do the tempering as part of an elaborate blade production process, you. Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain growth. In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Blade quenching is the process of rapidly cooling your blade. Knife Blade Tempering.

From www.youtube.com

Tempering & Heat Treating a 1095 Steel Knife Blade YouTube Knife Blade Tempering Between cycles, the blade should be cool down to room temperature. Although blacksmiths and knife manufacturers primarily do the tempering as part of an elaborate blade production process, you. Note that the temperature must be controlled. So, to relieve internal stresses and improve toughness, heat the. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and. Knife Blade Tempering.

From www.iforgeiron.com

Tempering 1095 blades to blue Heat Treating Knives, Blades etc I Knife Blade Tempering Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain growth. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and 316°c) to. Although blacksmiths and knife manufacturers primarily do the tempering as part of an elaborate blade production process, you. Between cycles, the blade should. Knife Blade Tempering.

From www.youtube.com

How to Temper Knife In Oven! YouTube Knife Blade Tempering In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. So, to relieve internal stresses and improve toughness, heat the. Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. Some knifemakers are afraid of holding too long at austenitizing. Knife Blade Tempering.

From jayfisher.com

Custom Knife Blades, Blade Grinds, Geometry, Steel Types, Finishes Knife Blade Tempering In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Quenching can introduce excess hardness and undesirable brittleness to your knife. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and 316°c) to. Blade quenching is the process of rapidly cooling your blade after heat treating, locking. Knife Blade Tempering.

From www.pinterest.com

File knife blanks made from old files ready for tempering Railroad Knife Blade Tempering Note that the temperature must be controlled. Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and 316°c) to. Tempering is the final stage of the heat. Knife Blade Tempering.

From www.iforgeiron.com

Tempering 1095 blades to blue Heat Treating Knives, Blades etc I Knife Blade Tempering In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Quenching can introduce excess hardness and undesirable brittleness to your knife. Note that the temperature must be controlled. After the second tempering cycle, the blade is usually fully tempered and ready to finish into a knife. Some knifemakers are afraid of holding too long at. Knife Blade Tempering.

From www.bladesmithsforum.com

Tempering Problem? Beginners Place Bladesmith's Forum Board Knife Blade Tempering Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and 316°c) to. Between cycles, the blade should be cool down to room temperature. In most cases, you. Knife Blade Tempering.

From www.pinterest.com

8 inches Blade Hand kukrikhukuriIraqi Angkhola kukrikhukuri Knife Blade Tempering Although blacksmiths and knife manufacturers primarily do the tempering as part of an elaborate blade production process, you. Quenching can introduce excess hardness and undesirable brittleness to your knife. Between cycles, the blade should be cool down to room temperature. Note that the temperature must be controlled. After the second tempering cycle, the blade is usually fully tempered and ready. Knife Blade Tempering.

From www.pinterest.es

Pin on My knives Knife Blade Tempering Note that the temperature must be controlled. Quenching can introduce excess hardness and undesirable brittleness to your knife. In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. After the. Knife Blade Tempering.

From fashionhedge.com

Bloodroot Blades Artisan Knives Knife Blade Tempering After the second tempering cycle, the blade is usually fully tempered and ready to finish into a knife. Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Note that. Knife Blade Tempering.

From www.pinterest.com

How to Temper Knife Blades Knife making, Knife making tools, Knife Knife Blade Tempering Quenching can introduce excess hardness and undesirable brittleness to your knife. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and 316°c) to. Between cycles, the blade should be cool down to room temperature. After the second tempering cycle, the blade is usually fully tempered and ready to finish into a knife.. Knife Blade Tempering.

From www.shootersforum.com

Making knife with hamon temper line Shooters Forum Knife Blade Tempering After the second tempering cycle, the blade is usually fully tempered and ready to finish into a knife. Although blacksmiths and knife manufacturers primarily do the tempering as part of an elaborate blade production process, you. Between cycles, the blade should be cool down to room temperature. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f. Knife Blade Tempering.

From www.pinterest.com

How to Temper Knife Blades in 2020 (With images) Metal working Knife Blade Tempering Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain growth. In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Between cycles, the. Knife Blade Tempering.

From www.youtube.com

Tempering File Knife With Torch . YouTube Knife Blade Tempering Tempering is the final stage of the heat treating process, performed after hardening and quenching. Quenching can introduce excess hardness and undesirable brittleness to your knife. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and 316°c) to. Between cycles, the blade should be cool down to room temperature. So, to relieve. Knife Blade Tempering.

From www.youtube.com

How To Make A Knife How I Temper A Knife. YouTube Knife Blade Tempering Note that the temperature must be controlled. Quenching can introduce excess hardness and undesirable brittleness to your knife. Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain growth. In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Blade quenching is the process of rapidly cooling your blade. Knife Blade Tempering.

From huntinglot.com

Knife Blade Grind Guide Types and Uses Hunting Lot Knife Blade Tempering Tempering is the final stage of the heat treating process, performed after hardening and quenching. In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain growth. After the second tempering cycle, the blade is usually fully tempered and ready. Knife Blade Tempering.

From morethanjustsurviving.com

Knife Blade Steel Guide Composition Best Steels Comparison Chart Knife Blade Tempering In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain growth. Tempering involves reheating. Knife Blade Tempering.

From www.youtube.com

Heat Treat Testing the Knife After Quench/Temper Process YouTube Knife Blade Tempering Note that the temperature must be controlled. Tempering is the final stage of the heat treating process, performed after hardening and quenching. After the second tempering cycle, the blade is usually fully tempered and ready to finish into a knife. Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating. Knife Blade Tempering.

From www.bladeforums.com

Tempering Chart for Common Knife Steels? Knife Blade Tempering Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and 316°c) to. After the second tempering cycle, the blade is usually fully tempered and ready to finish. Knife Blade Tempering.

From paddlemaking.blogspot.com

Paddle Making (and other canoe stuff) Crooked Knife Making Part 2 Knife Blade Tempering Quenching can introduce excess hardness and undesirable brittleness to your knife. In most cases, you should do 2 tempering cycles lasting 2 hours at around 400°f. After the second tempering cycle, the blade is usually fully tempered and ready to finish into a knife. Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain. Knife Blade Tempering.

From www.dreamstime.com

MACRO, DOF Burning Knife Blade Getting Dipped into Oil during Knife Blade Tempering After the second tempering cycle, the blade is usually fully tempered and ready to finish into a knife. Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain growth. Quenching can introduce excess hardness and undesirable brittleness to your knife. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and. Knife Blade Tempering.

From www.pinterest.ca

Full Tang Hand Tempered Steel Chef's Knife Butcher knife, Chef Knife Blade Tempering Tempering is the final stage of the heat treating process, performed after hardening and quenching. Some knifemakers are afraid of holding too long at austenitizing temperature because of concerns about grain growth. Between cycles, the blade should be cool down to room temperature. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c. Knife Blade Tempering.

From www.reddit.com

Hand blade with tempering patina. Hand cut and finished scales Knife Blade Tempering Between cycles, the blade should be cool down to room temperature. Blade quenching is the process of rapidly cooling your blade after heat treating, locking in the desired properties and creating a harder, more durable blade. Tempering involves reheating the hardened steel to a lower temperature (typically between 300°f and 600°f / 149°c and 316°c) to. Some knifemakers are afraid. Knife Blade Tempering.