Types Of Vacuum Forming . Vacuum forming is the simplest method to make repeatable plastic parts economically. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Vacuum forming uses a single mold and a vacuum pump. Unlike other molding techniques that rely on high. Explore the versatile world of vacuum forming in our comprehensive guide. Vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. It uses vacuum pressure and. Three common machines among them include; What are the types of vacuum forming machines?

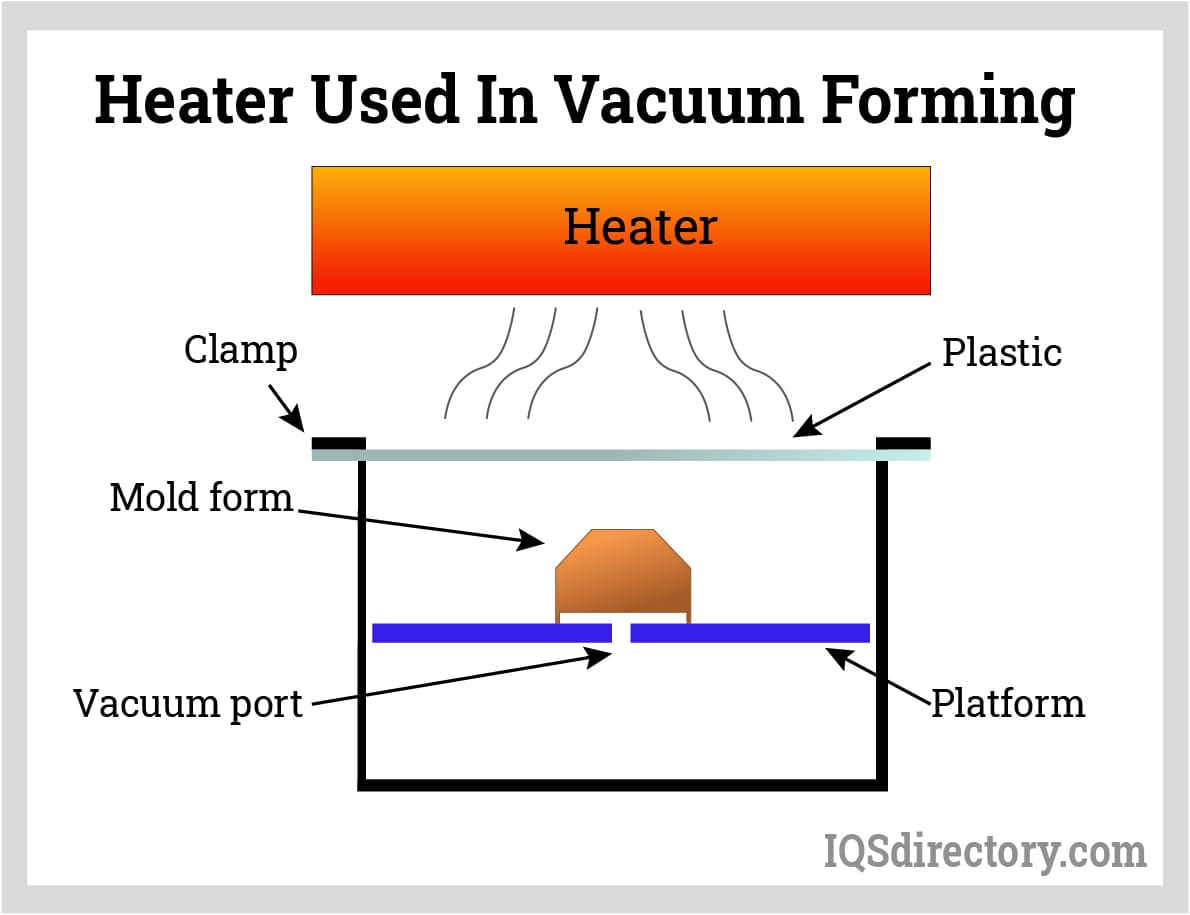

from www.iqsdirectory.com

It uses vacuum pressure and. A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. Three common machines among them include; What are the types of vacuum forming machines? Explore the versatile world of vacuum forming in our comprehensive guide. Vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. Unlike other molding techniques that rely on high. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Vacuum forming uses a single mold and a vacuum pump.

Vacuum Forming Types, Uses, Features and Benefits

Types Of Vacuum Forming Vacuum forming is the simplest method to make repeatable plastic parts economically. Vacuum forming uses a single mold and a vacuum pump. Vacuum forming is the simplest method to make repeatable plastic parts economically. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Three common machines among them include; Unlike other molding techniques that rely on high. A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. What are the types of vacuum forming machines? Explore the versatile world of vacuum forming in our comprehensive guide. It uses vacuum pressure and.

From formlabs.com

Introduction to Vacuum Forming Types Of Vacuum Forming Vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Vacuum forming is the simplest method to make repeatable plastic parts economically. What are. Types Of Vacuum Forming.

From www.brayplastics.co.uk

Vacuum forming for thermoplastic products,Bray Plastics Limited Types Of Vacuum Forming Explore the versatile world of vacuum forming in our comprehensive guide. Vacuum forming uses a single mold and a vacuum pump. Unlike other molding techniques that rely on high. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. What are the types of vacuum forming machines? Vacuum forming, the. Types Of Vacuum Forming.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages Types Of Vacuum Forming This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over. Types Of Vacuum Forming.

From www.madearia.com

Vacuum Forming Process, Materials & Benefit Aria Manufacturing Limited Types Of Vacuum Forming Three common machines among them include; What are the types of vacuum forming machines? A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Vacuum forming, the simplest thermoforming method, uses vacuum pressure. Types Of Vacuum Forming.

From www.youtube.com

Introduction To Vacuum Forming What is vacuum Forming and What Can I Types Of Vacuum Forming Vacuum forming is the simplest method to make repeatable plastic parts economically. It uses vacuum pressure and. What are the types of vacuum forming machines? A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in. Types Of Vacuum Forming.

From www.iqsdirectory.com

Vacuum Forming Types, Uses, Features and Benefits Types Of Vacuum Forming Explore the versatile world of vacuum forming in our comprehensive guide. Unlike other molding techniques that rely on high. Three common machines among them include; This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Vacuum forming uses a single mold and a vacuum pump. Discover how vacuum forming is. Types Of Vacuum Forming.

From www.sourcifychina.com

Vacuum Forming Process Guide Sourcing, Types, Applications, Benefits Types Of Vacuum Forming Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. Vacuum forming uses a single mold and a vacuum pump. It uses vacuum pressure and. Explore the versatile world of vacuum forming in our comprehensive guide. What are the types of vacuum forming machines? A heated plastic sheet is placed over. Types Of Vacuum Forming.

From www.sourcifychina.com

Vacuum Forming Process Guide Sourcing, Types, Applications, Benefits Types Of Vacuum Forming Vacuum forming is the simplest method to make repeatable plastic parts economically. A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. This method is favored for its ability to create detailed and large. Types Of Vacuum Forming.

From warringah-plastics.com.au

Industry Leaders in Vacuum Forming in Sydney Warringah Plastics Types Of Vacuum Forming Explore the versatile world of vacuum forming in our comprehensive guide. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. Vacuum forming is a type of thermoforming process where a plastic sheet is. Types Of Vacuum Forming.

From formlabs.com

Introduction to Vacuum Forming Formlabs Types Of Vacuum Forming Explore the versatile world of vacuum forming in our comprehensive guide. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. Three common machines among them include; Unlike other molding techniques that rely. Types Of Vacuum Forming.

From www.atiplastics.com

Vacuum Forming — Ati plastics Types Of Vacuum Forming Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. Three common machines among them include; This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Explore the versatile world of vacuum forming in our comprehensive guide. Vacuum forming is the. Types Of Vacuum Forming.

From www.sourcifychina.com

Vacuum Forming Process Guide Sourcing, Types, Applications, Benefits Types Of Vacuum Forming What are the types of vacuum forming machines? Vacuum forming uses a single mold and a vacuum pump. Explore the versatile world of vacuum forming in our comprehensive guide. Unlike other molding techniques that rely on high. Three common machines among them include; Vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes. Types Of Vacuum Forming.

From www.iqsdirectory.com

Vacuum Forming Types, Uses, Features and Benefits Types Of Vacuum Forming What are the types of vacuum forming machines? This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. Vacuum forming uses a single mold and a vacuum pump. Unlike other molding techniques that. Types Of Vacuum Forming.

From www.sourcifychina.com

Vacuum Forming Process Guide Sourcing, Types, Applications, Benefits Types Of Vacuum Forming Unlike other molding techniques that rely on high. Three common machines among them include; What are the types of vacuum forming machines? Vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. It uses vacuum pressure and. Vacuum forming, the simplest thermoforming method, uses. Types Of Vacuum Forming.

From kb.chambermaster.com

Vacuum Forming Types, Uses, Features And Benefits, 58 OFF Types Of Vacuum Forming Vacuum forming uses a single mold and a vacuum pump. Vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. It uses vacuum pressure. Types Of Vacuum Forming.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research Types Of Vacuum Forming A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. It uses vacuum pressure and. Vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. Vacuum forming uses a single mold and a vacuum pump. Vacuum forming,. Types Of Vacuum Forming.

From www.la-plastic.com

What is the Vacuum Forming Process? Types Of Vacuum Forming It uses vacuum pressure and. A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. Vacuum forming is the simplest method to make repeatable plastic parts economically. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. Explore the versatile world of vacuum forming. Types Of Vacuum Forming.

From www.madearia.com

Vacuum Forming Process, Materials & Benefit Aria Manufacturing Limited Types Of Vacuum Forming Explore the versatile world of vacuum forming in our comprehensive guide. It uses vacuum pressure and. Three common machines among them include; Vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. A heated plastic sheet is placed over the mold, and the vacuum. Types Of Vacuum Forming.

From www.youtube.com

How To Vacuum Form in 3 Easy Steps YouTube Types Of Vacuum Forming This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Unlike other molding techniques that rely on high. Explore the versatile world of vacuum forming in our comprehensive guide. Vacuum forming uses a single mold and a vacuum pump. What are the types of vacuum forming machines? Three common machines. Types Of Vacuum Forming.

From www.iqsdirectory.com

Vacuum Forming Types, Uses, Features and Benefits Types Of Vacuum Forming Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. What are the types of vacuum forming machines? Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. A heated plastic sheet is placed over the mold, and the vacuum pulls it. Types Of Vacuum Forming.

From www.vacforming.uk.com

What Is Vacuum Forming? Process And The Practical Uses Types Of Vacuum Forming Three common machines among them include; This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. Unlike other molding techniques that rely on high. Vacuum forming uses a single mold and a vacuum. Types Of Vacuum Forming.

From www.weetect.com

Plastic Fabrication The Complete Guide In 2018 Wee Tect Types Of Vacuum Forming Vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. Explore the versatile world of vacuum forming in our comprehensive guide. Vacuum forming is the simplest method to make repeatable plastic parts economically. Unlike other molding techniques that rely on high. It uses vacuum. Types Of Vacuum Forming.

From www.la-plastic.com

What Causes bing in Vacuum Forming? Types Of Vacuum Forming Explore the versatile world of vacuum forming in our comprehensive guide. A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. It uses vacuum pressure and. Unlike other molding techniques that rely on high. Three common machines among them include; What are the types of vacuum forming machines? Discover how vacuum forming is. Types Of Vacuum Forming.

From foammolders.com

Vacuum Forming The Processes Foam Molders Uses To Create HighQuality Types Of Vacuum Forming Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. Three common machines among them include; A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. Vacuum forming uses a single mold and a vacuum pump. This method is favored for its ability to. Types Of Vacuum Forming.

From www.pinterest.se

vacuum forming GCSE_Graphics_Packaging Exam revision, Vacuum Types Of Vacuum Forming Unlike other molding techniques that rely on high. Vacuum forming is the simplest method to make repeatable plastic parts economically. Three common machines among them include; A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. Explore the versatile world of vacuum forming in our comprehensive guide. Discover how vacuum forming is utilized. Types Of Vacuum Forming.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research Types Of Vacuum Forming Vacuum forming uses a single mold and a vacuum pump. Vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. Explore the versatile world of vacuum forming. Types Of Vacuum Forming.

From www.sourcifychina.com

The Ultimate Guide to Plastics Vacuum Forming Types, Applications Types Of Vacuum Forming Explore the versatile world of vacuum forming in our comprehensive guide. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. What are the types of vacuum forming machines? Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Vacuum forming. Types Of Vacuum Forming.

From www.slideserve.com

PPT VACUUM FORMING PowerPoint Presentation, free download ID6902792 Types Of Vacuum Forming What are the types of vacuum forming machines? This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Vacuum forming uses a single mold and a vacuum pump. Unlike other molding. Types Of Vacuum Forming.

From prestigetooling.com

Vacuum Forming Mold Types Thermoforming Molds Solid Surface Molds Types Of Vacuum Forming What are the types of vacuum forming machines? Unlike other molding techniques that rely on high. A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. This method is favored for its ability to. Types Of Vacuum Forming.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages Types Of Vacuum Forming This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Unlike other molding techniques that rely on high. A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. Vacuum forming uses a single mold and a vacuum pump. Vacuum forming is the simplest. Types Of Vacuum Forming.

From www.sourcifychina.com

Vacuum Forming Process Guide Sourcing, Types, Applications, Benefits Types Of Vacuum Forming Three common machines among them include; This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Explore the versatile world of vacuum forming in our comprehensive guide. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. Vacuum forming is a. Types Of Vacuum Forming.

From www.belovac.com

Vacuum Forming Machine, Vacuum Forming Machinery, Vacuum Forming Types Of Vacuum Forming Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. Vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing. Types Of Vacuum Forming.

From www.ansini.co.uk

What is Vacuum Forming? A Complete Guide to Vacuum Forming Ansini Types Of Vacuum Forming This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. It uses vacuum pressure and. Vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. Vacuum forming uses a single mold and a vacuum. Types Of Vacuum Forming.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages Types Of Vacuum Forming Unlike other molding techniques that rely on high. It uses vacuum pressure and. Vacuum forming is the simplest method to make repeatable plastic parts economically. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility. Types Of Vacuum Forming.

From www.iqsdirectory.com

Vacuum Forming Types, Uses, Features and Benefits Types Of Vacuum Forming This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. A heated plastic sheet is placed over the mold, and the vacuum pulls it into the desired. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. Three common machines among. Types Of Vacuum Forming.