Sheet Metal Parts Means . Foils, sheets and plates are pretty much the same, with the only difference being in thickness. Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. There are other measurement units used to categorise metals by thickness, though. Learn how to effectively design sheet metal parts. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the shapes and forms metal can be bought in. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two.

from www.ivymachine.com

There are other measurement units used to categorise metals by thickness, though. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Learn how to effectively design sheet metal parts. Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. Sheet metal is one of the shapes and forms metal can be bought in. Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two. Foils, sheets and plates are pretty much the same, with the only difference being in thickness.

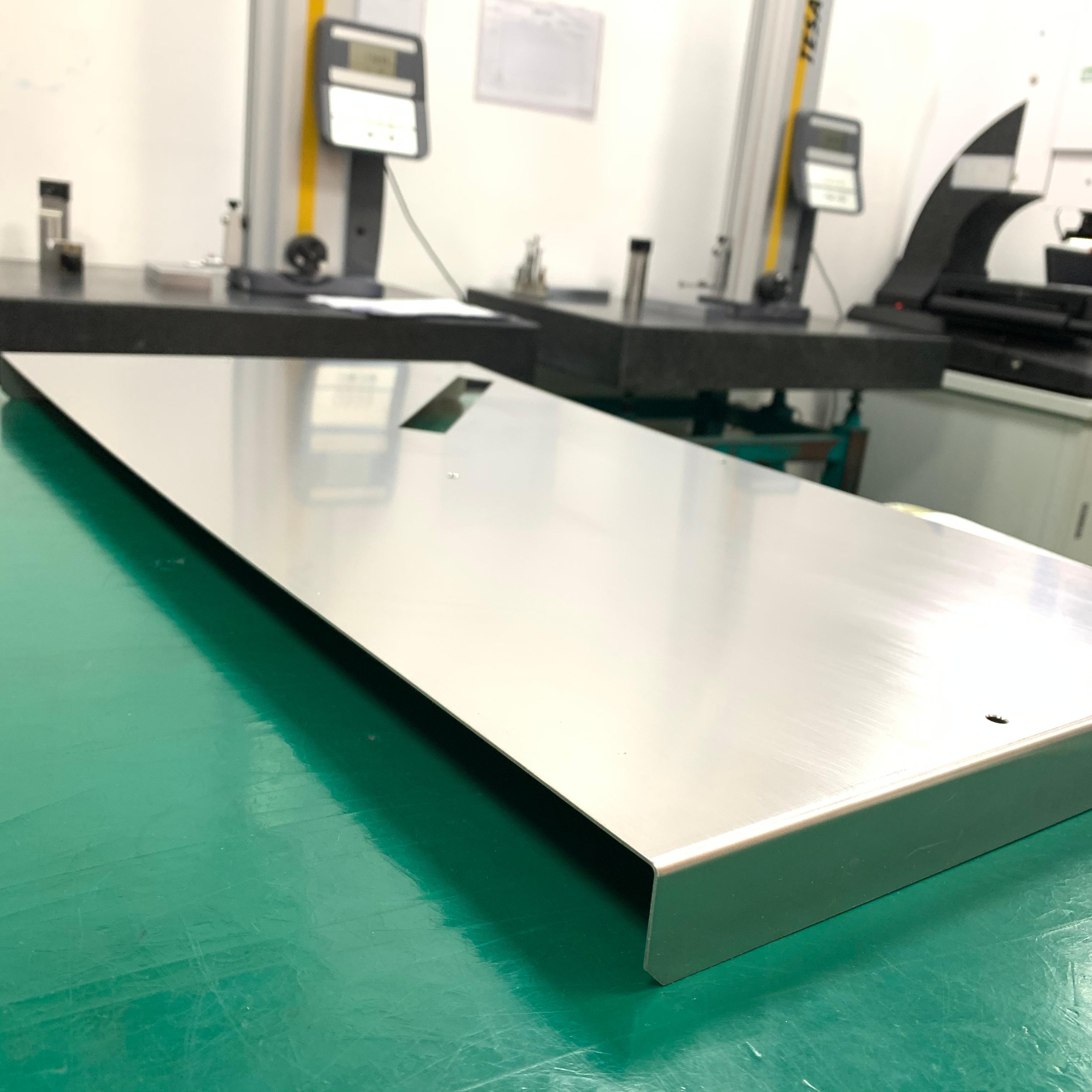

Sheet Metal Parts, Chute, Discharge, SUS304 ivy machining

Sheet Metal Parts Means These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Foils, sheets and plates are pretty much the same, with the only difference being in thickness. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two. Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. Learn how to effectively design sheet metal parts. Sheet metal is one of the shapes and forms metal can be bought in. There are other measurement units used to categorise metals by thickness, though.

From www.yufar-precision.com

Sheet Metal Fabrication (Parts) Yufar Precision Engineering Pte. Ltd Sheet Metal Parts Means This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two. There are other measurement units used to categorise metals by thickness, though. Learn how to effectively design sheet metal parts. Sheet metal is one of the shapes and forms metal can be bought in. Sheet. Sheet Metal Parts Means.

From neuronicworks.com

Design for Manufacturing Sheet Metal Deep Dive NeuronicWorks Sheet Metal Parts Means Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Foils, sheets and plates are pretty much the same, with the only difference being in thickness. These basic sheet metal fabrication guidelines include important design considerations to. Sheet Metal Parts Means.

From www.hymetalproducts.com

News Application of Precision Sheet Metal parts Sheet Metal Parts Means There are other measurement units used to categorise metals by thickness, though. Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. This guide. Sheet Metal Parts Means.

From www.dreamstime.com

Laser Cutting of Sheet Metal at the Factory. Storage of Finished Parts Sheet Metal Parts Means These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. There are other measurement units used to categorise metals by thickness, though. Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. Sheet metal is metal formed into thin, flat pieces, usually by an. Sheet Metal Parts Means.

From www.alibaba.com

Sheet Metal Fabrication Galvanized Metal Sheet Parts Professional Sheet Metal Parts Means Foils, sheets and plates are pretty much the same, with the only difference being in thickness. Sheet metal is one of the shapes and forms metal can be bought in. Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. There are other measurement units used to categorise metals by thickness,. Sheet Metal Parts Means.

From www.hymetalproducts.com

China Sheet metal prototype with short turnaround Manufacturer and Sheet Metal Parts Means Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. There are other measurement units used to categorise metals by thickness, though. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. This guide starts with the basics and moves toward design best. Sheet Metal Parts Means.

From www.sgewjaipur.com

Sheet Metal Parts S.G. Engineering Works Jaipur Sheet Metal Parts Means Learn how to effectively design sheet metal parts. Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. There are other measurement units used to categorise metals by thickness, though. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. This guide starts with the basics and. Sheet Metal Parts Means.

From fractory.com

Sheet Metal Hemming Hem Types & Processes Explained Fractory Sheet Metal Parts Means These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two. Foils, sheets and plates are pretty much the same, with the only. Sheet Metal Parts Means.

From www.approvedsheetmetal.com

Custom Sheet Metal Frames Precision Fabrication ASM Sheet Metal Parts Means Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Foils, sheets and plates are pretty much the same, with the only difference being in thickness. These basic sheet metal fabrication guidelines include important design considerations to. Sheet Metal Parts Means.

From www.globalsources.com

Oem Dongguan Sheet Metal Processing Highquality Sheet Metal Supplier Sheet Metal Parts Means These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Learn how to effectively design sheet metal parts. Foils, sheets and plates are pretty much the same, with the only difference being in thickness. This guide starts with the basics and moves toward design best practices and. Sheet Metal Parts Means.

From www.engineersrule.com

How to Define the MBD Data of Sheet Metal Parts Engineers Rule Sheet Metal Parts Means Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Learn how to effectively design. Sheet Metal Parts Means.

From wmitcsteel.en.made-in-china.com

SF028 Custom Processing Steel metal Parts Laser Cutting Service Sheet Sheet Metal Parts Means Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. Foils, sheets and plates are pretty much the same, with the only difference being in thickness. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. There are other measurement units used to categorise metals by thickness, though. Sheet metal is one of. Sheet Metal Parts Means.

From www.facebook.com

Tech Tip How to Easily Remove Holes in Sheet Metal Parts in Onshape Sheet Metal Parts Means Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. Foils, sheets and plates are pretty much the same, with the only difference being in thickness. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two.. Sheet Metal Parts Means.

From bankinfabtech.in

Sheet Metal Parts Bankin Fabtech LLP Sheet Metal Parts Means Foils, sheets and plates are pretty much the same, with the only difference being in thickness. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Sheet metal is one of the shapes and forms metal can be bought in. Many processes are utilized to form parts. Sheet Metal Parts Means.

From www.micro-industries.com

Sheet Metal Parts / Components Manufacturer in Mumbai, India Sheet Metal Parts Means Foils, sheets and plates are pretty much the same, with the only difference being in thickness. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two. Sheet metal is metal formed into thin, flat pieces, usually by. Sheet Metal Parts Means.

From bankinfabtech.in

Sheet Metal Parts Bankin Fabtech LLP Sheet Metal Parts Means Sheet metal is one of the shapes and forms metal can be bought in. Foils, sheets and plates are pretty much the same, with the only difference being in thickness. Learn how to effectively design sheet metal parts. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production. Sheet Metal Parts Means.

From sheetmetal.wiki

How to correctly and quickly distinguish the quality of automobile Sheet Metal Parts Means There are other measurement units used to categorise metals by thickness, though. Sheet metal is one of the shapes and forms metal can be bought in. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two. Many processes are utilized to form parts from sheet. Sheet Metal Parts Means.

From www.precismachinery.com

Sheet Metal Parts Sheet Metal Parts Means Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. Sheet metal is one of the shapes and forms metal can be bought in. Foils, sheets and plates are pretty much the same, with the only difference being in thickness. There are other measurement units used to categorise metals by thickness, though. Many processes are utilized to. Sheet Metal Parts Means.

From qddaao.en.made-in-china.com

Custom Precision Sheet Metal Parts by Stamping Bending Welding China Sheet Metal Parts Means Foils, sheets and plates are pretty much the same, with the only difference being in thickness. Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two. There are other measurement units used. Sheet Metal Parts Means.

From www.ivymachine.com

Sheet Metal Parts, Chute, Discharge, SUS304 ivy machining Sheet Metal Parts Means Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two. Foils, sheets and plates are pretty much the same, with the only difference being in thickness. These basic sheet metal fabrication guidelines include important design considerations to. Sheet Metal Parts Means.

From www.exportersindia.com

Automotive Sheet Metal Components Buy Automotive Sheet Metal Components Sheet Metal Parts Means Learn how to effectively design sheet metal parts. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Sheet metal is one of the shapes and forms metal can be bought in. This. Sheet Metal Parts Means.

From bankinfabtech.in

Sheet Metal Parts Bankin Fabtech LLP Sheet Metal Parts Means Sheet metal is one of the shapes and forms metal can be bought in. Foils, sheets and plates are pretty much the same, with the only difference being in thickness. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. There are other measurement units used to categorise metals by thickness, though. These basic sheet metal. Sheet Metal Parts Means.

From www.creatingway.com

Sheet Metal Parts CREATINGWAY Sheet Metal Parts Means This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two. There are other measurement units used to categorise metals by thickness, though. Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. These basic sheet metal. Sheet Metal Parts Means.

From stamping.en.made-in-china.com

Sheet Metal Parts Services Sheetmetal Bending Stamping Sheet Metal Sheet Metal Parts Means Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. There are other measurement units used to categorise metals by thickness, though. Sheet metal is any metal that. Sheet Metal Parts Means.

From dir.indiamart.com

Sheet Metal Parts Sheet Metal Components Latest Price, Manufacturers Sheet Metal Parts Means This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two. Foils, sheets and plates are pretty much the same, with the only difference being in thickness. Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. Sheet metal is one of the. Sheet Metal Parts Means.

From unique-part.net

Sheet Metal Parts,Sheet Metal Sheet Metal Parts Means Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the shapes and forms metal can be bought in. There are other measurement units used to categorise metals by thickness, though. Foils, sheets and plates are pretty much the same, with the only difference being in thickness. Sheet metal is any. Sheet Metal Parts Means.

From sheetmetal.wiki

Highquality car sheet metal parts are a technical means of car repair Sheet Metal Parts Means Sheet metal is one of the shapes and forms metal can be bought in. Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Sheet metal is metal. Sheet Metal Parts Means.

From www.indiamart.com

Fabricated Sheet Metal Parts at best price in Pune by Onyx Technology Sheet Metal Parts Means Foils, sheets and plates are pretty much the same, with the only difference being in thickness. Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. There are other measurement units used to categorise metals by thickness, though. Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending.. Sheet Metal Parts Means.

From www.indiamart.com

Cutting Material Automotive Sheet Metal Parts, Packaging Type Box at Sheet Metal Parts Means Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. There are other measurement units used to categorise metals by thickness, though. Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. Foils, sheets and plates are pretty much the same, with the only difference being in thickness. This guide starts with the. Sheet Metal Parts Means.

From www.indiamart.com

Silver Stainless Steel Sheet Metal Parts, for Industrial, Packaging Sheet Metal Parts Means Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the shapes and forms metal can be bought in. These basic sheet metal fabrication guidelines include important design considerations to help improve. Sheet Metal Parts Means.

From kalenkalip.com

Sheet Metal Parts Kalen Kalıp Sheet Metal Parts Means Sheet metal is one of the shapes and forms metal can be bought in. Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. There are other measurement units used to categorise metals by thickness, though. These basic. Sheet Metal Parts Means.

From in.pinterest.com

Different Types of Sheet Metal Operations [Explained] Sheet metal Sheet Metal Parts Means Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. Learn how to effectively design sheet metal parts. There are other measurement units used to categorise metals by thickness, though. Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. Foils, sheets and plates are pretty much the. Sheet Metal Parts Means.

From kieind.com

SHEET METAL PARTS Kie Industries Sheet Metal Parts Means There are other measurement units used to categorise metals by thickness, though. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. This guide starts with the basics and moves toward design best. Sheet Metal Parts Means.

From www.globalsources.com

Buy Wholesale China Oem Dongguan Sheet Metal Fabrication Supplier Sheet Sheet Metal Parts Means Sheet metal is any metal that has a thickness in between 0.5…6 millimetres. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Sheet metal is one of the shapes and forms metal can be bought in. Learn how to effectively design sheet metal parts. Sheet metal. Sheet Metal Parts Means.

From deepri.com

Sheet metal stamped parts Deep Sheet Metal Parts Means Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Sheet metal is one of the shapes and forms metal can be bought in. Foils, sheets and plates. Sheet Metal Parts Means.