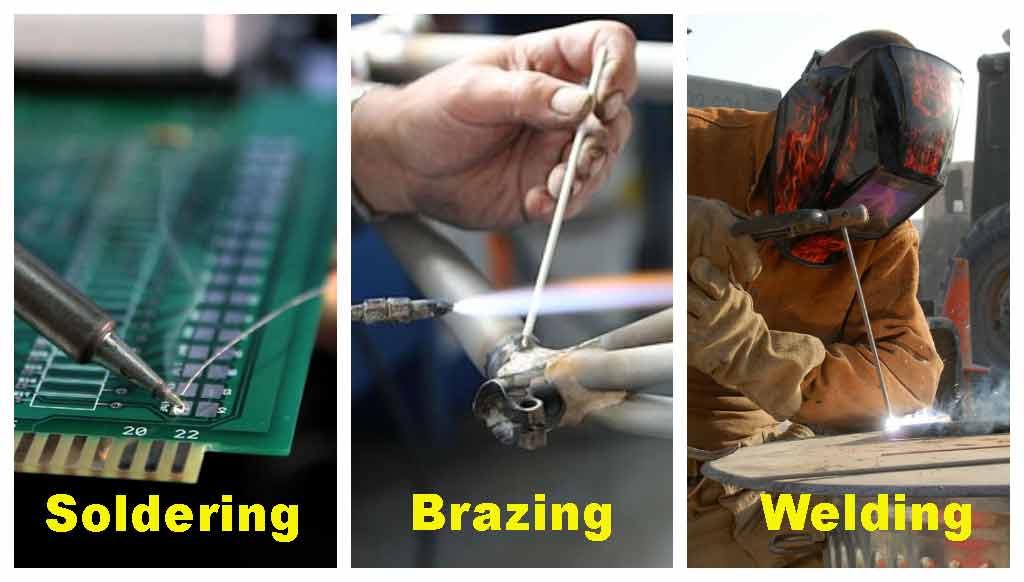

Braze In Materials . The brazing filler metal has a melting point above 450 °c. brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. brazing uses capillary action to join different metal surfaces. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Soldering uses filler metals that have a melting point below 450 °c. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. Brazing is similar to soldering but at higher. there are four main types of brazing heating methods: It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material.

from exownvsyp.blob.core.windows.net

Soldering uses filler metals that have a melting point below 450 °c. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. brazing uses capillary action to join different metal surfaces. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. there are four main types of brazing heating methods: The brazing filler metal has a melting point above 450 °c. Brazing is similar to soldering but at higher.

Brazing Iron Welding at Bruce Heffington blog

Braze In Materials brazing uses capillary action to join different metal surfaces. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. there are four main types of brazing heating methods: Soldering uses filler metals that have a melting point below 450 °c. brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. brazing uses capillary action to join different metal surfaces. Brazing is similar to soldering but at higher. The brazing filler metal has a melting point above 450 °c.

From exohjqeiv.blob.core.windows.net

What Is The Definition Of A Brazed Joint at James Zimmerman blog Braze In Materials brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. there are four main types of brazing heating methods: brazing is a joining process traditionally applied to metals (but also to. Braze In Materials.

From dxokxxkuh.blob.core.windows.net

Brazing In Welding at Bonnie Wert blog Braze In Materials The brazing filler metal has a melting point above 450 °c. there are four main types of brazing heating methods: Brazing is similar to soldering but at higher. Soldering uses filler metals that have a melting point below 450 °c. brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. . Braze In Materials.

From shahab-co.com

What is Induction brazing Brazing uses heat and a filler metal (alloy Braze In Materials brazing uses capillary action to join different metal surfaces. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. there are four main types of brazing heating methods: brazing is a group of welding processes which produces coalescence. Braze In Materials.

From exonvuqsf.blob.core.windows.net

Braze Welding Copper at Frank Orosco blog Braze In Materials The brazing filler metal has a melting point above 450 °c. brazing uses capillary action to join different metal surfaces. brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. there are four main types of brazing heating methods: Brazing is similar to soldering but at higher. brazing is. Braze In Materials.

From blog.thepipingmart.com

How to Braze Mild Steel A Complete Guide Braze In Materials Brazing is similar to soldering but at higher. brazing uses capillary action to join different metal surfaces. brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. The brazing filler metal has. Braze In Materials.

From www.globalspec.com

Braze and Brazing Alloys Selection Guide Types, Features, Applications Braze In Materials there are four main types of brazing heating methods: The brazing filler metal has a melting point above 450 °c. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. Brazing is similar to soldering but at higher. Torch or manual brazing, induction. Braze In Materials.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications Braze In Materials The brazing filler metal has a melting point above 450 °c. brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze. Braze In Materials.

From www.forgeweld.co.uk

Silver Brazing Alloys Silver Brazing Filler Materials Ltd Braze In Materials brazing uses capillary action to join different metal surfaces. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. there are four main types of brazing heating methods: Brazing is similar to soldering but at higher. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy). Braze In Materials.

From www.animalia-life.club

Brazing Metal Braze In Materials Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing is similar to soldering but at higher. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. Soldering uses filler metals that have a melting point below 450 °c. brazing uses capillary action to join different metal surfaces. . Braze In Materials.

From www.youtube.com

Brazing welding process How to Braze Weld To Know Everything YouTube Braze In Materials Soldering uses filler metals that have a melting point below 450 °c. The brazing filler metal has a melting point above 450 °c. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. there are four main types of brazing heating. Braze In Materials.

From exocheqgp.blob.core.windows.net

Brazing Or Soldering Which Is Better at Nelly Scott blog Braze In Materials brazing uses capillary action to join different metal surfaces. Brazing is similar to soldering but at higher. The brazing filler metal has a melting point above 450 °c. Soldering uses filler metals that have a melting point below 450 °c. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. brazing is a joining process traditionally applied to. Braze In Materials.

From exozgyfnw.blob.core.windows.net

What Is Brazing Welding Rod Used For at Alicia Porter blog Braze In Materials brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. Brazing is similar to soldering but at higher. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. Soldering uses filler metals that have a melting. Braze In Materials.

From www.youtube.com

How to Braze Aluminum to Copper YouTube Braze In Materials brazing uses capillary action to join different metal surfaces. brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. there are four main types of brazing heating methods: Soldering uses filler metals that have a melting point below 450 °c. Brazing is similar to soldering but at higher. Torch or. Braze In Materials.

From www.cpvmfg.com

Joining Metals Your Frequently Asked Questions About Brazing, Answered Braze In Materials Soldering uses filler metals that have a melting point below 450 °c. brazing uses capillary action to join different metal surfaces. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. It makes use of a process called wetting, wherein the base metals. Braze In Materials.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications Braze In Materials Torch or manual brazing, induction brazing, resistance brazing, and vacuum. there are four main types of brazing heating methods: Brazing is similar to soldering but at higher. brazing uses capillary action to join different metal surfaces. Soldering uses filler metals that have a melting point below 450 °c. brazing is a joining process traditionally applied to metals. Braze In Materials.

From www.pinterest.com

How to Weld Aluminum Without a Welder Brazing, Welding projects Braze In Materials The brazing filler metal has a melting point above 450 °c. brazing uses capillary action to join different metal surfaces. there are four main types of brazing heating methods: brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. It. Braze In Materials.

From weldingpros.net

Brazing Filler Metals And Fluxes Explained In Detail Braze In Materials there are four main types of brazing heating methods: Torch or manual brazing, induction brazing, resistance brazing, and vacuum. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. brazing uses capillary action to join different metal surfaces. Soldering uses filler metals that have a melting point below 450. Braze In Materials.

From blog.thepipingmart.com

What Is Metal Brazing And How Does It Work? Braze In Materials brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. there are four main types of brazing heating methods: It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. brazing uses capillary action. Braze In Materials.

From dxokxxkuh.blob.core.windows.net

Brazing In Welding at Bonnie Wert blog Braze In Materials Brazing is similar to soldering but at higher. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. brazing uses capillary action to join different metal surfaces. there are four main types of brazing heating methods: It makes use of a process. Braze In Materials.

From blog.thepipingmart.com

Brazing Copper with Mapp Gas Process Braze In Materials brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. Brazing is similar to soldering but at higher. there are four main types of brazing heating methods: It makes use of a process called wetting, wherein the base metals are bonded with a. Braze In Materials.

From exownvsyp.blob.core.windows.net

Brazing Iron Welding at Bruce Heffington blog Braze In Materials Torch or manual brazing, induction brazing, resistance brazing, and vacuum. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. Soldering uses filler metals that have a melting point below 450 °c. The brazing filler metal has a melting point above 450 °c. Brazing is similar to soldering but at higher.. Braze In Materials.

From www.globalspec.com

Braze and Brazing Alloys Information Engineering360 Braze In Materials Brazing is similar to soldering but at higher. Soldering uses filler metals that have a melting point below 450 °c. brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. brazing uses. Braze In Materials.

From www.kaizanaero.com

Brazing and Welding Kaizan Aero Manufacturing Sdn. Bhd. Braze In Materials there are four main types of brazing heating methods: The brazing filler metal has a melting point above 450 °c. brazing uses capillary action to join different metal surfaces. brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. brazing is a joining process traditionally applied to metals (but. Braze In Materials.

From www.mdpi.com

Metals Free FullText Recent Advances in Brazing Fillers for Braze In Materials there are four main types of brazing heating methods: Brazing is similar to soldering but at higher. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. The brazing filler metal has a melting point above 450 °c. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. brazing. Braze In Materials.

From www.youtube.com

How To Braze Copper Fittings For An Air Conditioner Full Video Of Braze In Materials brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. there are four main types of brazing heating methods: Brazing is similar to soldering but at higher. It makes use of a process called wetting, wherein the base metals are bonded with a. Braze In Materials.

From www.youtube.com

Brazing Process Animation YouTube Braze In Materials The brazing filler metal has a melting point above 450 °c. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze. Braze In Materials.

From fractory.com

Brazing Explained Definition, Process, Types Fractory Braze In Materials there are four main types of brazing heating methods: The brazing filler metal has a melting point above 450 °c. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Soldering uses filler metals that have a melting point below 450 °c. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten. Braze In Materials.

From dxoxtbbxd.blob.core.windows.net

Brazing Magnesium Alloys at Marion Mays blog Braze In Materials brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. The brazing filler metal has a melting point above 450 °c. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. Soldering uses filler metals that. Braze In Materials.

From www.youtube.com

Brazing Brass With Silver YouTube Braze In Materials brazing uses capillary action to join different metal surfaces. Brazing is similar to soldering but at higher. there are four main types of brazing heating methods: Torch or manual brazing, induction brazing, resistance brazing, and vacuum. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. The brazing filler. Braze In Materials.

From dxokxxkuh.blob.core.windows.net

Brazing In Welding at Bonnie Wert blog Braze In Materials Brazing is similar to soldering but at higher. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. brazing uses capillary action to join different metal surfaces. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Soldering uses filler metals that have a melting point below 450 °c. . Braze In Materials.

From www.youtube.com

Fundamentals of Brazing 5 Brazing the Assembly YouTube Braze In Materials Soldering uses filler metals that have a melting point below 450 °c. there are four main types of brazing heating methods: brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. It makes use of a process called wetting, wherein the base metals. Braze In Materials.

From shahab-co.com

What is Induction brazing Brazing uses heat and a filler metal (alloy Braze In Materials Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing is similar to soldering but at higher. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. brazing uses capillary action to join different metal surfaces. brazing is a group of welding processes which produces coalescence of materials. Braze In Materials.

From dxoonxmgb.blob.core.windows.net

Brass To Copper Brazing Rod at Barbara McGowan blog Braze In Materials Torch or manual brazing, induction brazing, resistance brazing, and vacuum. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. brazing is a group. Braze In Materials.

From www.harrisproductsgroup.com.au

How Brazing Works Capillary Action Harris Products Group Braze In Materials Soldering uses filler metals that have a melting point below 450 °c. there are four main types of brazing heating methods: The brazing filler metal has a melting point above 450 °c. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing is similar to soldering but at higher. brazing is a joining process traditionally applied to. Braze In Materials.

From blog.thepipingmart.com

Brazing vs Silver Soldering What's the Difference Braze In Materials Brazing is similar to soldering but at higher. brazing uses capillary action to join different metal surfaces. The brazing filler metal has a melting point above 450 °c. Soldering uses filler metals that have a melting point below 450 °c. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal. Braze In Materials.