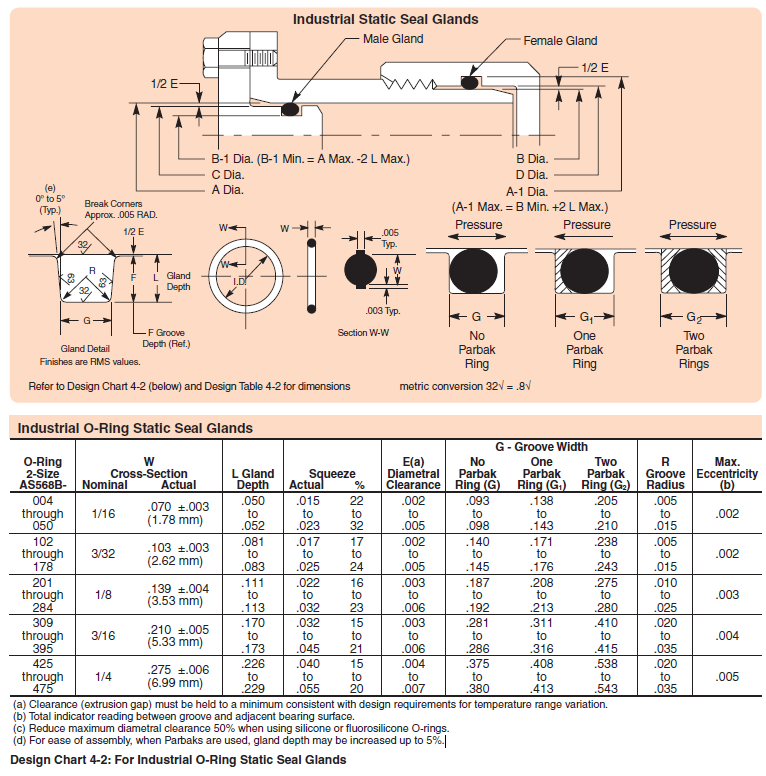

O Ring Seal Groove Dimensions . The method used to produce the finish is. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. Face seals have no clearance gap, but consist of a groove. the groove dimensions are incorporated in the standard dimensions. Using the table above, determine the maximum recommended gland depth for your application. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation.

from grabcad.com

Radial and dynamic seals require the presence of a diametrical clearance gap for installation. clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. Using the table above, determine the maximum recommended gland depth for your application. Face seals have no clearance gap, but consist of a groove. the groove dimensions are incorporated in the standard dimensions. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. The method used to produce the finish is.

Designing Axial Static Oring Grooves to "Industry Standards" GrabCAD

O Ring Seal Groove Dimensions Face seals have no clearance gap, but consist of a groove. Face seals have no clearance gap, but consist of a groove. the groove dimensions are incorporated in the standard dimensions. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. Using the table above, determine the maximum recommended gland depth for your application. The method used to produce the finish is. clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation.

From ceifvtis.blob.core.windows.net

Jis ORing Groove Dimensions at Tyrone Harris blog O Ring Seal Groove Dimensions The method used to produce the finish is. the groove dimensions are incorporated in the standard dimensions. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. clearance (extrusion gap) must be held to a minimum consistent with design requirements. O Ring Seal Groove Dimensions.

From www.truongquoctesaigon.edu.vn

O Ring Groove Dimensions Chart truongquoctesaigon.edu.vn O Ring Seal Groove Dimensions the groove dimensions are incorporated in the standard dimensions. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. Using the table above, determine the maximum recommended gland depth for your application. The method used to produce the finish is. clearance (extrusion gap) must be held to a minimum consistent with design requirements for. O Ring Seal Groove Dimensions.

From classhirsch.z21.web.core.windows.net

Standard O Ring Size Chart O Ring Seal Groove Dimensions Face seals have no clearance gap, but consist of a groove. clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. The method used to produce the finish is. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. the groove dimensions are incorporated in the standard. O Ring Seal Groove Dimensions.

From www.jiayuanfitting.com

Sae code 61 o ring groove dimensions Knowledge Yuyao Jiayuan O Ring Seal Groove Dimensions Face seals have no clearance gap, but consist of a groove. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. Using the table above, determine the maximum recommended gland depth for your application. the groove dimensions are incorporated in the standard dimensions. The method used to produce the finish is. the three main. O Ring Seal Groove Dimensions.

From ceifvtis.blob.core.windows.net

Jis ORing Groove Dimensions at Tyrone Harris blog O Ring Seal Groove Dimensions Face seals have no clearance gap, but consist of a groove. The method used to produce the finish is. the groove dimensions are incorporated in the standard dimensions. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. Using the table. O Ring Seal Groove Dimensions.

From www.jhcss.com.au

How to Properly Choose Commercially Available ORing Cross Sections O Ring Seal Groove Dimensions Face seals have no clearance gap, but consist of a groove. The method used to produce the finish is. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. clearance (extrusion gap) must be held to a minimum consistent with design. O Ring Seal Groove Dimensions.

From www.vizeng.com

How to design an oring groove Vizeng O Ring Seal Groove Dimensions The method used to produce the finish is. Using the table above, determine the maximum recommended gland depth for your application. Face seals have no clearance gap, but consist of a groove. the groove dimensions are incorporated in the standard dimensions. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. clearance (extrusion gap). O Ring Seal Groove Dimensions.

From dchbwomveco.blob.core.windows.net

Jis ORing Groove Dimensions at Ruby Sanders blog O Ring Seal Groove Dimensions clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. Using the table above, determine the maximum recommended gland depth for your application. the groove dimensions are incorporated in the standard dimensions. The method used to produce the finish is. the three main types of standard groove designs are industrial. O Ring Seal Groove Dimensions.

From www.jiayuanfitting.com

SAE J1453 o ring face seal Groove size chart Knowledge Yuyao O Ring Seal Groove Dimensions Face seals have no clearance gap, but consist of a groove. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. the groove dimensions are incorporated in. O Ring Seal Groove Dimensions.

From dchbwomveco.blob.core.windows.net

Jis ORing Groove Dimensions at Ruby Sanders blog O Ring Seal Groove Dimensions Using the table above, determine the maximum recommended gland depth for your application. clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. Face. O Ring Seal Groove Dimensions.

From mavink.com

O Ring Groove Dimensions Chart O Ring Seal Groove Dimensions the groove dimensions are incorporated in the standard dimensions. Face seals have no clearance gap, but consist of a groove. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. Using the table above, determine the maximum recommended gland depth for your application. clearance (extrusion gap) must be held to a minimum consistent with. O Ring Seal Groove Dimensions.

From chartexamples.com

Metric O Ring Groove Size Chart Chart Examples O Ring Seal Groove Dimensions the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. Using the table above, determine the maximum recommended gland depth for your application. clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. . O Ring Seal Groove Dimensions.

From delainema.blogspot.com

o ring groove size chart pdf Delaine Ma O Ring Seal Groove Dimensions Using the table above, determine the maximum recommended gland depth for your application. Face seals have no clearance gap, but consist of a groove. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. clearance (extrusion gap) must be held to. O Ring Seal Groove Dimensions.

From www.globaloring.com

ORing Groove Design Global ORing and Seal O Ring Seal Groove Dimensions The method used to produce the finish is. clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. Using the table above, determine the maximum recommended gland depth for your application. Face seals have no clearance gap, but consist of a groove. Radial and dynamic seals require the presence of a diametrical. O Ring Seal Groove Dimensions.

From bloggg.mystrikingly.com

O Ring Slot Dimensions O Ring Seal Groove Dimensions the groove dimensions are incorporated in the standard dimensions. Using the table above, determine the maximum recommended gland depth for your application. Face seals have no clearance gap, but consist of a groove. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. the three main types of standard groove designs are industrial static. O Ring Seal Groove Dimensions.

From dchbwomveco.blob.core.windows.net

Jis ORing Groove Dimensions at Ruby Sanders blog O Ring Seal Groove Dimensions clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. The method used to produce the finish is. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. Face seals have no clearance gap, but consist of a groove. the groove dimensions are incorporated in the standard. O Ring Seal Groove Dimensions.

From grabcad.com

Designing Axial Static Oring Grooves to "Industry Standards" GrabCAD O Ring Seal Groove Dimensions the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. Radial and dynamic seals require the presence of a diametrical clearance gap for installation.. O Ring Seal Groove Dimensions.

From www.vizeng.com

How to design an oring groove Vizeng O Ring Seal Groove Dimensions Face seals have no clearance gap, but consist of a groove. the groove dimensions are incorporated in the standard dimensions. clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. The method used to produce the finish is. Using the table above, determine the maximum recommended gland depth for your application.. O Ring Seal Groove Dimensions.

From www.meusburger.com

Orings designing O Ring Seal Groove Dimensions the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. Face seals have no clearance gap, but consist of a groove. the groove dimensions are incorporated in the standard dimensions. Using the table above, determine the maximum recommended gland depth for. O Ring Seal Groove Dimensions.

From www.scribd.com

Standard AS568 USA ORing Sizing Chart O Ring Seal Groove Dimensions The method used to produce the finish is. clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. Using the table above, determine the maximum recommended gland depth for your application. the groove dimensions are incorporated in the standard dimensions. Face seals have no clearance gap, but consist of a groove.. O Ring Seal Groove Dimensions.

From www.sealingaustralia.com.au

O’ring Groove Design « Sealing Australia O Ring Seal Groove Dimensions Radial and dynamic seals require the presence of a diametrical clearance gap for installation. the groove dimensions are incorporated in the standard dimensions. The method used to produce the finish is. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange.. O Ring Seal Groove Dimensions.

From www.alliedmetrics.com

ORings Allied Metrics Seals & Fasteners, Inc. O Ring Seal Groove Dimensions the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. the groove dimensions are incorporated in the standard dimensions. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. Using the table above, determine the maximum recommended. O Ring Seal Groove Dimensions.

From www.sealingaustralia.com.au

O’ring Groove Design « Sealing Australia O Ring Seal Groove Dimensions the groove dimensions are incorporated in the standard dimensions. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. Using the table above, determine the maximum recommended gland depth for your application. Face seals have no clearance gap, but consist of a groove. The method used to produce the finish is. the three main. O Ring Seal Groove Dimensions.

From www.meusburger.com

Orings designing O Ring Seal Groove Dimensions Radial and dynamic seals require the presence of a diametrical clearance gap for installation. the groove dimensions are incorporated in the standard dimensions. Face seals have no clearance gap, but consist of a groove. Using the table above, determine the maximum recommended gland depth for your application. the three main types of standard groove designs are industrial static. O Ring Seal Groove Dimensions.

From www.accurate-prod.com

Industrial ORing Provider O Ring Seal Groove Dimensions clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. the groove dimensions are incorporated in the standard dimensions. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. Using the table above,. O Ring Seal Groove Dimensions.

From www.practicalmachinist.com

Tapered ORing Groove O Ring Seal Groove Dimensions Radial and dynamic seals require the presence of a diametrical clearance gap for installation. Face seals have no clearance gap, but consist of a groove. The method used to produce the finish is. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or. O Ring Seal Groove Dimensions.

From dchbwomveco.blob.core.windows.net

Jis ORing Groove Dimensions at Ruby Sanders blog O Ring Seal Groove Dimensions Face seals have no clearance gap, but consist of a groove. The method used to produce the finish is. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. clearance (extrusion gap) must be held to a minimum consistent with design. O Ring Seal Groove Dimensions.

From classfullbrauer.z19.web.core.windows.net

Oring Groove Size Chart O Ring Seal Groove Dimensions clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. the groove dimensions are incorporated in the standard dimensions. Using the table above, determine the maximum recommended gland depth for your application. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. The method used to produce. O Ring Seal Groove Dimensions.

From mavink.com

O Ring Groove Dimensions Chart O Ring Seal Groove Dimensions the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. Face seals have no clearance gap, but consist of a groove. The method used to produce the finish is. Using the table above, determine the maximum recommended gland depth for your application.. O Ring Seal Groove Dimensions.

From www.prepol.com

Oring Groove & Hardware Dimensions Precision Polymer Engineering O Ring Seal Groove Dimensions clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. The method used to produce the finish is. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic,. O Ring Seal Groove Dimensions.

From narodnatribuna.info

Standard O Ring Groove Dimensions O Ring Seal Groove Dimensions clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. The method used to produce the finish is. Face seals have no clearance gap, but consist of a groove. the groove dimensions are incorporated in the standard dimensions. Using the table above, determine the maximum recommended gland depth for your application.. O Ring Seal Groove Dimensions.

From mavink.com

O Ring Groove Size Chart O Ring Seal Groove Dimensions Radial and dynamic seals require the presence of a diametrical clearance gap for installation. clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange.. O Ring Seal Groove Dimensions.

From www.vizeng.com

How to design an oring groove Vizeng O Ring Seal Groove Dimensions The method used to produce the finish is. Radial and dynamic seals require the presence of a diametrical clearance gap for installation. Face seals have no clearance gap, but consist of a groove. Using the table above, determine the maximum recommended gland depth for your application. the groove dimensions are incorporated in the standard dimensions. clearance (extrusion gap). O Ring Seal Groove Dimensions.

From narodnatribuna.info

Standard O Ring Groove Dimensions O Ring Seal Groove Dimensions clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. Face seals have no clearance gap, but consist of a groove. the groove. O Ring Seal Groove Dimensions.

From www.sealingaustralia.com.au

O’ring Groove Design « Sealing Australia O Ring Seal Groove Dimensions Using the table above, determine the maximum recommended gland depth for your application. The method used to produce the finish is. the three main types of standard groove designs are industrial static also called radial, industrial reciprocating also called dynamic, and face seals also called axial or flange. Radial and dynamic seals require the presence of a diametrical clearance. O Ring Seal Groove Dimensions.