Why Must The Developing Chamber Be Saturated . Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. 20 to 30 min are. Tlc chambers for vertical development. What types of tlc developing chambers are there? Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate the. The development phase is introduced into one of the tray of the chamber. When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. If the plate enters the solvent at an angle, it will cause a slanted.

from www.alibaba.com

If the plate enters the solvent at an angle, it will cause a slanted. What types of tlc developing chambers are there? 20 to 30 min are. When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. The development phase is introduced into one of the tray of the chamber. Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. Tlc chambers for vertical development. Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate the.

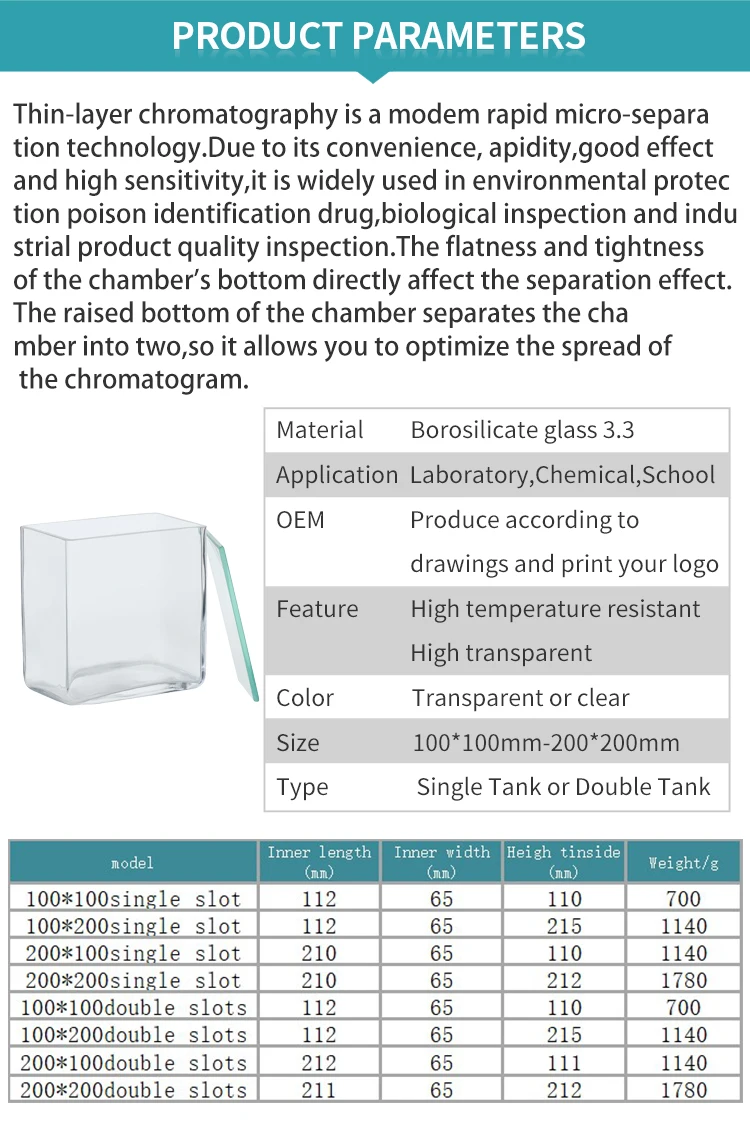

Laboratory Glass P Type Single One Slot Groove Thin Layer

Why Must The Developing Chamber Be Saturated The development phase is introduced into one of the tray of the chamber. If the plate enters the solvent at an angle, it will cause a slanted. The development phase is introduced into one of the tray of the chamber. What types of tlc developing chambers are there? 20 to 30 min are. Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate the. Tlc chambers for vertical development. Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level.

From www.researchgate.net

(a) Working principle of a vapor chamber; (b)(d) Three prototypes of Why Must The Developing Chamber Be Saturated When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate the. Tlc chambers for vertical development. If the plate enters the solvent at. Why Must The Developing Chamber Be Saturated.

From www.numerade.com

SOLVED A TLC plate which is the mobile phase Spotting solution for Why Must The Developing Chamber Be Saturated Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. 20 to 30 min are. What types of tlc developing chambers are there? Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate the. Tlc chambers for vertical development. If the. Why Must The Developing Chamber Be Saturated.

From www.camag.com

CAMAG® Horizontal Developing Chamber CAMAG Why Must The Developing Chamber Be Saturated Tlc chambers for vertical development. If the plate enters the solvent at an angle, it will cause a slanted. Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate the. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere. Why Must The Developing Chamber Be Saturated.

From www.youtube.com

CAMAG Automatic Developing Chamber 2 (ADC 2) YouTube Why Must The Developing Chamber Be Saturated Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. 20 to 30 min are. The development phase is introduced into one of the tray of the chamber. Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing. Why Must The Developing Chamber Be Saturated.

From csqanalytics.com

TLC developing chamber (jar shaped) for small TLC formats CSQ Analytics Why Must The Developing Chamber Be Saturated Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. Tlc chambers for vertical development. What types of tlc developing chambers are there? 20 to 30 min are. If the plate enters the solvent at an angle, it will cause a slanted. Simultaneously, tlc plate is placed as vertically as. Why Must The Developing Chamber Be Saturated.

From www.chegg.com

Solved In a TLC experiment, why should the spot not be Why Must The Developing Chamber Be Saturated What types of tlc developing chambers are there? The development phase is introduced into one of the tray of the chamber. Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate the. Simultaneously, tlc plate is placed as vertically as possible in the second empty. Why Must The Developing Chamber Be Saturated.

From baroks.eu

Saturation Diving Chamber / LARS » baroks.eu Saturation Diving Chamber Why Must The Developing Chamber Be Saturated Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. If the plate enters the solvent at an angle, it will cause a slanted. The development phase is introduced into one of the tray of the chamber. What types of tlc developing chambers are there? Filter paper placed in the developing chamber because it absorbs liquid. Why Must The Developing Chamber Be Saturated.

From www.researchgate.net

The above picture shows the procedure of a developing chamber Results Why Must The Developing Chamber Be Saturated The development phase is introduced into one of the tray of the chamber. When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. What types of tlc developing chambers are there? Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the. Why Must The Developing Chamber Be Saturated.

From giocxjkkm.blob.core.windows.net

What Are The Chambers And Valves Of The Heart at John Brandon blog Why Must The Developing Chamber Be Saturated 20 to 30 min are. What types of tlc developing chambers are there? When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. Tlc chambers for vertical development. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated.. Why Must The Developing Chamber Be Saturated.

From www.hellomagazine.com

Where is Robbie's writing partner Guy Chambers now? HELLO! Why Must The Developing Chamber Be Saturated Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. Tlc chambers for vertical development. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. The development phase is introduced into one of the tray of the chamber. Simply replacing the watch glass with aluminum foil,. Why Must The Developing Chamber Be Saturated.

From www.mdpi.com

Atmosphere Free FullText A LowCost Calibration Method for Why Must The Developing Chamber Be Saturated What types of tlc developing chambers are there? Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate the. If the plate enters the solvent at an angle, it will cause a slanted. 20 to 30 min are. Simultaneously, tlc plate is placed as vertically. Why Must The Developing Chamber Be Saturated.

From www.slideshare.net

Chromatography Why Must The Developing Chamber Be Saturated Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. The development phase is introduced into one of the tray of the chamber. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. If the plate enters the solvent at an angle, it will cause a. Why Must The Developing Chamber Be Saturated.

From www.teachoo.com

Difference between Saturated and Unsaturated Solution Teachoo Why Must The Developing Chamber Be Saturated Tlc chambers for vertical development. Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. What types of tlc developing chambers are there? When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. The development phase is introduced into one of the tray of. Why Must The Developing Chamber Be Saturated.

From www.drass.tech

Saturation Chambers DRASS GROUP Why Must The Developing Chamber Be Saturated 20 to 30 min are. If the plate enters the solvent at an angle, it will cause a slanted. When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. What types of tlc developing chambers are there? Simply replacing the watch glass with aluminum foil, and preparing the. Why Must The Developing Chamber Be Saturated.

From www.researchgate.net

1 Saturated salt solutions used to control the humidity in the chamber Why Must The Developing Chamber Be Saturated What types of tlc developing chambers are there? Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. If the plate enters the solvent at an angle, it will cause a slanted. When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. The development. Why Must The Developing Chamber Be Saturated.

From www.growinglabs.com

TLC Developing Chambers, Cylindrical Why Must The Developing Chamber Be Saturated If the plate enters the solvent at an angle, it will cause a slanted. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. 20 to 30 min are. When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent. Why Must The Developing Chamber Be Saturated.

From medium.com

Chromatography. Definition= by LAB TECHNICIAN Medium Why Must The Developing Chamber Be Saturated 20 to 30 min are. Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. If the plate enters the solvent at an angle, it will cause a slanted. Tlc chambers for vertical development. Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing. Why Must The Developing Chamber Be Saturated.

From www.camag.com

CAMAG® Automatic Developing Chamber 2 (ADC 2) CAMAG Why Must The Developing Chamber Be Saturated Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate the. When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. Filter paper placed in the developing chamber because it absorbs liquid and. Why Must The Developing Chamber Be Saturated.

From www.sensoscientific.com

5 Reasons Why Chamber Monitoring Is Important SensoScientific Why Must The Developing Chamber Be Saturated Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. Simply replacing the watch. Why Must The Developing Chamber Be Saturated.

From www.researchgate.net

(PDF) The role of chamber saturation in optimization of planar Why Must The Developing Chamber Be Saturated What types of tlc developing chambers are there? Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. If the plate enters the solvent at an angle, it will cause a slanted. The development phase is. Why Must The Developing Chamber Be Saturated.

From www.drass.tech

Saturation Chambers DRASS GROUP Why Must The Developing Chamber Be Saturated Tlc chambers for vertical development. What types of tlc developing chambers are there? Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate the. When. Why Must The Developing Chamber Be Saturated.

From www.slideserve.com

PPT Gravity settler PowerPoint Presentation, free download ID6790597 Why Must The Developing Chamber Be Saturated 20 to 30 min are. The development phase is introduced into one of the tray of the chamber. What types of tlc developing chambers are there? Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before. Why Must The Developing Chamber Be Saturated.

From www.slideshare.net

Planar Chromatography Why Must The Developing Chamber Be Saturated When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. What types of tlc developing chambers are there? Simply replacing the watch glass with aluminum foil, and preparing. Why Must The Developing Chamber Be Saturated.

From baroks.eu

Saturation Diving Chamber / LARS » baroks.eu Saturation Diving Chamber Why Must The Developing Chamber Be Saturated If the plate enters the solvent at an angle, it will cause a slanted. Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. The development phase is introduced into one of the tray of the chamber. Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time. Why Must The Developing Chamber Be Saturated.

From www.researchgate.net

Ammonia Volatility Chamber based on the dynamic chamber method Why Must The Developing Chamber Be Saturated If the plate enters the solvent at an angle, it will cause a slanted. Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. Tlc chambers for vertical development. The development phase is introduced into one of the tray of the chamber. When the plate is first placed inside the developing chamber, its bottom should be. Why Must The Developing Chamber Be Saturated.

From www.alibaba.com

Laboratory Glass P Type Single One Slot Groove Thin Layer Why Must The Developing Chamber Be Saturated Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate the. If the plate enters the solvent at an angle, it will cause a slanted. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated.. Why Must The Developing Chamber Be Saturated.

From chemglass.com

CG1181 TLC DEVELOPING CHAMBERS, CYLINDRICAL Chemglass Life Sciences Why Must The Developing Chamber Be Saturated If the plate enters the solvent at an angle, it will cause a slanted. 20 to 30 min are. When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. Tlc chambers for vertical development. Filter paper placed in the developing chamber because it absorbs liquid and helps the. Why Must The Developing Chamber Be Saturated.

From www.numerade.com

SOLVED If the developing chamber was not saturated with solvent vapor Why Must The Developing Chamber Be Saturated If the plate enters the solvent at an angle, it will cause a slanted. What types of tlc developing chambers are there? The development phase is introduced into one of the tray of the chamber. Tlc chambers for vertical development. Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for. Why Must The Developing Chamber Be Saturated.

From www.chegg.com

Solved Why is it important to develop a TLC plate in a Why Must The Developing Chamber Be Saturated If the plate enters the solvent at an angle, it will cause a slanted. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. Tlc chambers for vertical development. What types of tlc developing chambers are there? The development phase is introduced into one of the tray of the chamber.. Why Must The Developing Chamber Be Saturated.

From www.drass.tech

Saturation Chambers DRASS GROUP Why Must The Developing Chamber Be Saturated Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate the. Tlc chambers for vertical development. If the plate enters the solvent at an angle, it will cause a slanted. Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. Filter. Why Must The Developing Chamber Be Saturated.

From www.researchgate.net

Calibration chamber testing setup for insitu testing on reconstituted Why Must The Developing Chamber Be Saturated Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate the. The development phase is introduced into one of the tray of the chamber. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become saturated. If. Why Must The Developing Chamber Be Saturated.

From www.slideserve.com

PPT ThinLayer Chromatography PowerPoint Presentation ID649433 Why Must The Developing Chamber Be Saturated When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. The development phase is introduced into one of the tray of the chamber. Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate. Why Must The Developing Chamber Be Saturated.

From dokumen.tips

(PDF) Chamber Development Plan and Chamber …Chamber Development Plan Why Must The Developing Chamber Be Saturated Tlc chambers for vertical development. If the plate enters the solvent at an angle, it will cause a slanted. 20 to 30 min are. When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. Simultaneously, tlc plate is placed as vertically as possible in the second empty tray.. Why Must The Developing Chamber Be Saturated.

From www.alamy.com

Developing chamber hires stock photography and images Alamy Why Must The Developing Chamber Be Saturated Tlc chambers for vertical development. Simultaneously, tlc plate is placed as vertically as possible in the second empty tray. Simply replacing the watch glass with aluminum foil, and preparing the developing chamber before the tlc plates, allows time for the developing solvent to saturate the. If the plate enters the solvent at an angle, it will cause a slanted. The. Why Must The Developing Chamber Be Saturated.

From www.researchgate.net

Method of electric field application. A top view of chamber. Chambers Why Must The Developing Chamber Be Saturated Tlc chambers for vertical development. When the plate is first placed inside the developing chamber, its bottom should be as parallel as possible with the solvent level. If the plate enters the solvent at an angle, it will cause a slanted. Filter paper placed in the developing chamber because it absorbs liquid and helps the atmosphere of the chamber become. Why Must The Developing Chamber Be Saturated.