Brazing Rod Cast Iron . The first step is crucial for achieving a solid bond between the two cast iron pieces. Clean and prepare the surface. Due to significantly lower temperatures compared to welding, brittleness and the likelihood of cracking of the welded material are reduced considerably. braze welding is a process used to join cast iron parts by heating them to a high temperature and using a filler metal to bond the pieces together. Using a cutting torch and brass filler. yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. brazing cast iron is one of the best solutions. here is how to braze an old cast iron part. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. brazing is often the preferred method to repair cast iron parts. The nickel content in the brazing rod provides a. In this article, we’ll explain.

from www.alibaba.com

The first step is crucial for achieving a solid bond between the two cast iron pieces. In this article, we’ll explain. yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. brazing is often the preferred method to repair cast iron parts. Clean and prepare the surface. here is how to braze an old cast iron part. The nickel content in the brazing rod provides a. brazing cast iron is one of the best solutions. Using a cutting torch and brass filler.

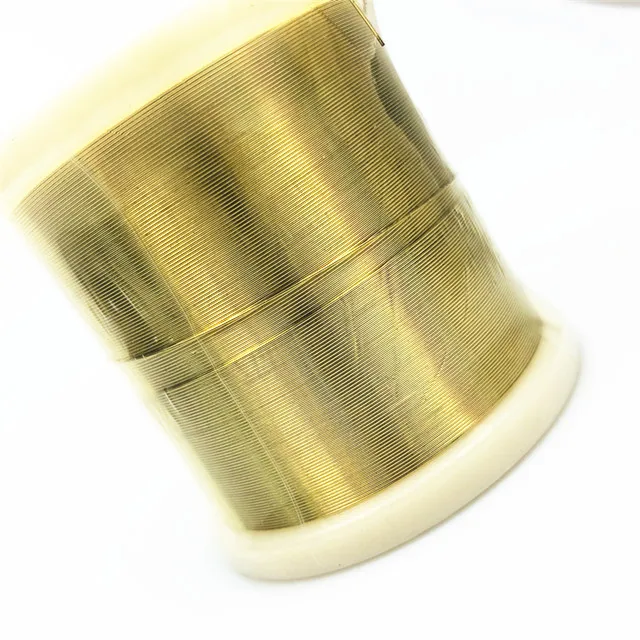

Rbcuznc Brass Brazing Alloy Mig Welding Wire 0.8mm Buy Mig Brass

Brazing Rod Cast Iron Due to significantly lower temperatures compared to welding, brittleness and the likelihood of cracking of the welded material are reduced considerably. yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. Using a cutting torch and brass filler. brazing is often the preferred method to repair cast iron parts. The first step is crucial for achieving a solid bond between the two cast iron pieces. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. In this article, we’ll explain. braze welding is a process used to join cast iron parts by heating them to a high temperature and using a filler metal to bond the pieces together. The nickel content in the brazing rod provides a. brazing cast iron is one of the best solutions. here is how to braze an old cast iron part. Due to significantly lower temperatures compared to welding, brittleness and the likelihood of cracking of the welded material are reduced considerably. Clean and prepare the surface.

From www.hotzxgirl.com

Cast Iron Rods Hot Sex Picture Brazing Rod Cast Iron braze welding is a process used to join cast iron parts by heating them to a high temperature and using a filler metal to bond the pieces together. here is how to braze an old cast iron part. brazing is often the preferred method to repair cast iron parts. The first step is crucial for achieving a. Brazing Rod Cast Iron.

From www.indiamart.com

Flux Coated Brass Brazing Rods, Size 2.00mm ALFA501FC, Size 500 mm at Brazing Rod Cast Iron Using a cutting torch and brass filler. here is how to braze an old cast iron part. Due to significantly lower temperatures compared to welding, brittleness and the likelihood of cracking of the welded material are reduced considerably. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. brazing is often the. Brazing Rod Cast Iron.

From weldingpros.net

Brazing cast iron HowTo Guide, Tips & Techniques Brazing Rod Cast Iron The nickel content in the brazing rod provides a. yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. Using a cutting torch and brass filler. The first step is crucial for achieving a. Brazing Rod Cast Iron.

From www.youtube.com

Always learning Brazing Cast Iron YouTube Brazing Rod Cast Iron In this article, we’ll explain. braze welding is a process used to join cast iron parts by heating them to a high temperature and using a filler metal to bond the pieces together. yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. Due to significantly lower temperatures compared. Brazing Rod Cast Iron.

From www.offshoresupply.co.uk

Bronze Brazing Rods Unitor Bronze264 Brazing Rods Brazing Rod Cast Iron brazing is often the preferred method to repair cast iron parts. Clean and prepare the surface. Using a cutting torch and brass filler. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. The nickel content in the brazing rod provides a. yes, you can braze weld cast iron using a brazing. Brazing Rod Cast Iron.

From carlsonmfg.com

Braze Cast Iron Free Information From 1 Source Brazing Rod Cast Iron Clean and prepare the surface. The nickel content in the brazing rod provides a. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. braze welding is a process used to join cast iron parts by heating them to a high temperature and using a filler metal to bond the pieces together. Using. Brazing Rod Cast Iron.

From exyhoaupa.blob.core.windows.net

Tig Brazing Cast Iron at Lily Cavin blog Brazing Rod Cast Iron Due to significantly lower temperatures compared to welding, brittleness and the likelihood of cracking of the welded material are reduced considerably. In this article, we’ll explain. yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. The nickel content in the brazing rod provides a. The first step is crucial. Brazing Rod Cast Iron.

From hxeyjgyzc.blob.core.windows.net

Bronze Brazing Rod Cast Iron at Hector West blog Brazing Rod Cast Iron braze welding is a process used to join cast iron parts by heating them to a high temperature and using a filler metal to bond the pieces together. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. Using a cutting torch and brass filler. The nickel content in the brazing rod provides. Brazing Rod Cast Iron.

From korweld.com.ph

Welding Rod Cast Iron Korweld PH Brazing Rod Cast Iron The nickel content in the brazing rod provides a. Due to significantly lower temperatures compared to welding, brittleness and the likelihood of cracking of the welded material are reduced considerably. Using a cutting torch and brass filler. brazing is often the preferred method to repair cast iron parts. Clean and prepare the surface. The first step is crucial for. Brazing Rod Cast Iron.

From www.youtube.com

Tig Welding/Brazing Cast Iron to 409 Stainless YouTube Brazing Rod Cast Iron brazing cast iron is one of the best solutions. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. brazing is often the preferred method to repair cast iron parts. In this. Brazing Rod Cast Iron.

From weldingpros.net

Brazing cast iron HowTo Guide, Tips & Techniques Brazing Rod Cast Iron Using a cutting torch and brass filler. Due to significantly lower temperatures compared to welding, brittleness and the likelihood of cracking of the welded material are reduced considerably. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. yes, you can braze weld cast iron using a brazing rod with a nickel content. Brazing Rod Cast Iron.

From giosgpbcv.blob.core.windows.net

What Is Mig Brazing Used For at Mary Butts blog Brazing Rod Cast Iron brazing is often the preferred method to repair cast iron parts. braze welding is a process used to join cast iron parts by heating them to a high temperature and using a filler metal to bond the pieces together. In this article, we’ll explain. yes, you can braze weld cast iron using a brazing rod with a. Brazing Rod Cast Iron.

From www.indiamart.com

Brass Brazing Rods, Size 2 Mm at Rs 440/kilogram in Agra ID 17701260330 Brazing Rod Cast Iron brazing cast iron is one of the best solutions. The nickel content in the brazing rod provides a. here is how to braze an old cast iron part. The first step is crucial for achieving a solid bond between the two cast iron pieces. brazing cast iron has proven successful in cast iron repair, maintenance, and casting. Brazing Rod Cast Iron.

From www.bernzomatic.com

How To Braze Metal Together Brazing Metal Bernzomatic Brazing Rod Cast Iron In this article, we’ll explain. yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. Due to significantly lower temperatures compared to welding, brittleness and the likelihood of cracking of the welded material are reduced considerably. here is how to braze an old cast iron part. brazing is. Brazing Rod Cast Iron.

From www.pinterest.com

Pin on Moms who weld Brazing Rod Cast Iron The first step is crucial for achieving a solid bond between the two cast iron pieces. The nickel content in the brazing rod provides a. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. In this article, we’ll explain. braze welding is a process used to join cast iron parts by heating. Brazing Rod Cast Iron.

From www.alibaba.com

Rbcuznc Brass Brazing Alloy Mig Welding Wire 0.8mm Buy Mig Brass Brazing Rod Cast Iron braze welding is a process used to join cast iron parts by heating them to a high temperature and using a filler metal to bond the pieces together. brazing is often the preferred method to repair cast iron parts. yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or. Brazing Rod Cast Iron.

From duroweld.co.nz

Aluminium Low Temp Brazing rod PRICE PER ROD Duroweld Brazing Rod Cast Iron The first step is crucial for achieving a solid bond between the two cast iron pieces. brazing is often the preferred method to repair cast iron parts. brazing cast iron is one of the best solutions. Clean and prepare the surface. Due to significantly lower temperatures compared to welding, brittleness and the likelihood of cracking of the welded. Brazing Rod Cast Iron.

From detroittorch.com

Cast Iron Rod Detroit Torch Brazing Rod Cast Iron brazing cast iron is one of the best solutions. yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. brazing is often the preferred method to repair cast iron parts. Using a cutting torch and brass filler. brazing cast iron has proven successful in cast iron repair,. Brazing Rod Cast Iron.

From www.made-in-china.com

Rbcuzna S223 Braze Welding of Copper, Steel and Cast Iron Cu59 Brass Brazing Rod Cast Iron The first step is crucial for achieving a solid bond between the two cast iron pieces. Due to significantly lower temperatures compared to welding, brittleness and the likelihood of cracking of the welded material are reduced considerably. brazing is often the preferred method to repair cast iron parts. The nickel content in the brazing rod provides a. Using a. Brazing Rod Cast Iron.

From www.weldingdirect.co.uk

Super SG Cast Iron Repair TIG & Gas Welding Rods SIF Brazing Rod Cast Iron Clean and prepare the surface. Using a cutting torch and brass filler. brazing is often the preferred method to repair cast iron parts. In this article, we’ll explain. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. brazing cast iron is one of the best solutions. Due to significantly lower temperatures. Brazing Rod Cast Iron.

From www.reddit.com

First time brazing malleable cast iron to mild steel. TIG Brazing is Brazing Rod Cast Iron The first step is crucial for achieving a solid bond between the two cast iron pieces. yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. Clean and prepare the surface. brazing cast iron is one of the best solutions. brazing cast iron has proven successful in cast. Brazing Rod Cast Iron.

From www.practicalmachinist.com

Brazing Cast Iron? Brazing Rod Cast Iron brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. brazing cast iron is one of the best solutions. Clean and prepare the surface. Using a cutting torch and brass filler. The first step is crucial for achieving a solid bond between the two cast iron pieces. Due to significantly lower temperatures compared. Brazing Rod Cast Iron.

From www.youtube.com

Cast Iron Brazing Demo Wood Stove Door with Vulcan 320 YouTube Brazing Rod Cast Iron In this article, we’ll explain. braze welding is a process used to join cast iron parts by heating them to a high temperature and using a filler metal to bond the pieces together. The nickel content in the brazing rod provides a. Due to significantly lower temperatures compared to welding, brittleness and the likelihood of cracking of the welded. Brazing Rod Cast Iron.

From www.ebay.com.au

1.6mm x 5kg Pack Nickel Bronze Bare TIG / OXY Brazing Rods Cast Iron Brazing Rod Cast Iron yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. In this article, we’ll explain. The nickel content in the brazing rod provides a. here is how to braze an old cast iron part. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation. Brazing Rod Cast Iron.

From www.practicalmachinist.com

Brazing Cast Iron? Brazing Rod Cast Iron yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. The nickel content in the brazing rod provides a. here is how to braze an old cast iron part. The first step is crucial for achieving a solid bond between the two cast iron pieces. In this article, we’ll. Brazing Rod Cast Iron.

From www.reddit.com

Brazing rod for cast iron? (2000x2000) r/Weldingporn Brazing Rod Cast Iron brazing is often the preferred method to repair cast iron parts. The nickel content in the brazing rod provides a. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. brazing cast iron is one of the best solutions. The first step is crucial for achieving a solid bond between the two. Brazing Rod Cast Iron.

From twobabox.com

“Casting Iron with Braze A HowTo Guide” Brazing Rod Cast Iron brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. brazing cast iron is one of the best solutions. Clean and prepare the surface. In this article, we’ll explain. here is how. Brazing Rod Cast Iron.

From 10bestreviewz.com

Top 10 Best Brazing Rod For Cast Iron in 2024 Reviews by Experts Brazing Rod Cast Iron here is how to braze an old cast iron part. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. brazing is often the preferred method to repair cast iron parts. In. Brazing Rod Cast Iron.

From www.youtube.com

Silver Brazing Demo Stainless Steel, Brass, & Copper YouTube Brazing Rod Cast Iron brazing cast iron is one of the best solutions. yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. Using a cutting torch and brass filler. brazing is often the preferred method to repair cast iron parts. braze welding is a process used to join cast iron. Brazing Rod Cast Iron.

From www.weldingtipsandtricks.com

TIG Welding Cast Iron Brazing Rod Cast Iron The nickel content in the brazing rod provides a. brazing is often the preferred method to repair cast iron parts. In this article, we’ll explain. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. The first step is crucial for achieving a solid bond between the two cast iron pieces. braze. Brazing Rod Cast Iron.

From www.weldingdirect.co.uk

10mm SIF Super SG Cast Iron Repair TIG & Gas Welding Rods Brazing Rod Cast Iron brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. Due to significantly lower temperatures compared to welding, brittleness and the likelihood of cracking of the welded material are reduced considerably. In this article, we’ll explain. The nickel content in the brazing rod provides a. The first step is crucial for achieving a solid. Brazing Rod Cast Iron.

From practicalmachinist.com

Brazing Cast Iron? Brazing Rod Cast Iron yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. Clean and prepare the surface. The first step is crucial for achieving a solid bond between the two cast iron pieces. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. Due to significantly. Brazing Rod Cast Iron.

From www.weldingtipsandtricks.com

Tig Welding Cast Iron Vise Repair Brazing Rod Cast Iron braze welding is a process used to join cast iron parts by heating them to a high temperature and using a filler metal to bond the pieces together. The first step is crucial for achieving a solid bond between the two cast iron pieces. brazing cast iron is one of the best solutions. Due to significantly lower temperatures. Brazing Rod Cast Iron.

From www.indiamart.com

Brass Brazing Rod, Size 2.5 Mm at Rs 20/piece in Pune ID 20136017648 Brazing Rod Cast Iron yes, you can braze weld cast iron using a brazing rod with a nickel content of 55% or higher. In this article, we’ll explain. brazing cast iron has proven successful in cast iron repair, maintenance, and casting reclamation applications. The nickel content in the brazing rod provides a. The first step is crucial for achieving a solid bond. Brazing Rod Cast Iron.

From www.weldaidalloys.com

Silver Brazing Rods Latest Price, Silver Brazing Rods Manufacturer Brazing Rod Cast Iron Clean and prepare the surface. The nickel content in the brazing rod provides a. In this article, we’ll explain. Due to significantly lower temperatures compared to welding, brittleness and the likelihood of cracking of the welded material are reduced considerably. here is how to braze an old cast iron part. braze welding is a process used to join. Brazing Rod Cast Iron.