Pump Failure Report Example . Mechanical seal problems from initial startup, seals failed (replaced) every three to six months (both ib. The basics of root cause failure analysis. Also, the most common analysing and diagnosing. Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and how to root them out through. Find out why a system failed and what could be done to prevent repeated failures. Using the bfwp example, we identified several modes of failure: This work will examine how hydraulic pumps fail as well as what their causes and effects are. This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure.

from www.dexform.com

Find out why a system failed and what could be done to prevent repeated failures. Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. The basics of root cause failure analysis. Also, the most common analysing and diagnosing. This work will examine how hydraulic pumps fail as well as what their causes and effects are. Mechanical seal problems from initial startup, seals failed (replaced) every three to six months (both ib. Using the bfwp example, we identified several modes of failure: With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and how to root them out through.

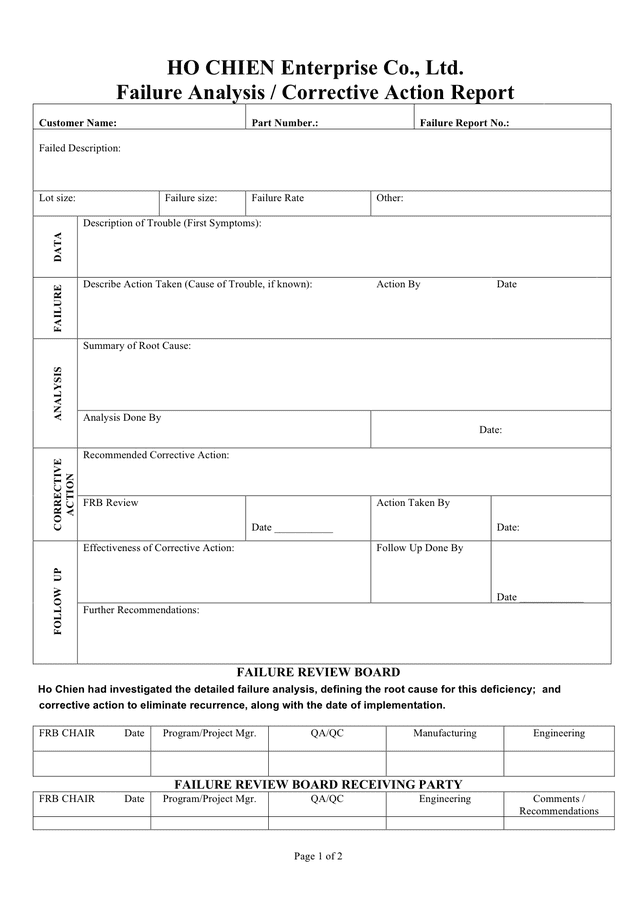

Failure report form in Word and Pdf formats

Pump Failure Report Example Using the bfwp example, we identified several modes of failure: This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and how to root them out through. Mechanical seal problems from initial startup, seals failed (replaced) every three to six months (both ib. Also, the most common analysing and diagnosing. This work will examine how hydraulic pumps fail as well as what their causes and effects are. Find out why a system failed and what could be done to prevent repeated failures. The basics of root cause failure analysis. Using the bfwp example, we identified several modes of failure:

From www.inpaspages.com

Failure Analysis Report Pump Failure Report Example Using the bfwp example, we identified several modes of failure: This work will examine how hydraulic pumps fail as well as what their causes and effects are. Find out why a system failed and what could be done to prevent repeated failures. Mechanical seal problems from initial startup, seals failed (replaced) every three to six months (both ib. Also, the. Pump Failure Report Example.

From www.heritagechristiancollege.com

48 Failure Analysis Report Template Free Heritagechristiancollege Pump Failure Report Example Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. Mechanical seal problems from initial startup, seals failed (replaced) every three to six months (both ib. With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and. Pump Failure Report Example.

From www.template.net

9+ Editable Failure Analysis Templates PDF, Word, Google Docs, Apple Pump Failure Report Example This work will examine how hydraulic pumps fail as well as what their causes and effects are. Find out why a system failed and what could be done to prevent repeated failures. With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and how to root them out. Pump Failure Report Example.

From coderedconsultants.com

Fire Pump Flow Test Reports Code Red Consultants Pump Failure Report Example With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and how to root them out through. Also, the most common analysing and diagnosing. Find out why a system failed and what could be done to prevent repeated failures. The basics of root cause failure analysis. Mechanical seal. Pump Failure Report Example.

From cloudflare.itsnudimension.com

Failure Investigation Report Template Creative Sample Templates Pump Failure Report Example The basics of root cause failure analysis. This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. Using the bfwp example, we identified several modes of failure: Mechanical seal. Pump Failure Report Example.

From www.heritagechristiancollege.com

Failure Analysis Report Template Free Of Sample Failure Analysis Report Pump Failure Report Example This work will examine how hydraulic pumps fail as well as what their causes and effects are. Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. The basics of root cause failure analysis. With so much at stake, it is crucial that professionals learn to recognize and detect. Pump Failure Report Example.

From www.studypool.com

SOLUTION Pump seal failure report sample Studypool Pump Failure Report Example Also, the most common analysing and diagnosing. With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and how to root them out through. This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. Subsequent to major overhaul. Pump Failure Report Example.

From www.sampletemplatess.com

Failure Analysis Report Template Free SampleTemplatess SampleTemplatess Pump Failure Report Example Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. The basics of root cause failure analysis. This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. Also, the most common analysing and diagnosing. Find out why a system. Pump Failure Report Example.

From www.pumpsandsystems.com

Common Pump Failure Factors Pumps & Systems Pump Failure Report Example The basics of root cause failure analysis. This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. Find out why a system failed and what could be done to prevent repeated failures. With so much at stake, it is crucial that professionals learn to recognize and detect the most common. Pump Failure Report Example.

From www.pumpindustry.com.au

Four common causes of pump failure Pump Industry Magazine Pump Failure Report Example The basics of root cause failure analysis. Mechanical seal problems from initial startup, seals failed (replaced) every three to six months (both ib. Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. This paper represents the generic process of fmeca for centrifugal pump failures and a case study. Pump Failure Report Example.

From www.studypool.com

SOLUTION Pump seal failure report sample Studypool Pump Failure Report Example Using the bfwp example, we identified several modes of failure: Also, the most common analysing and diagnosing. The basics of root cause failure analysis. This work will examine how hydraulic pumps fail as well as what their causes and effects are. This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump. Pump Failure Report Example.

From pray.gelorailmu.com

How To Write An Effective Incident Report [Examples + Within Failure Pump Failure Report Example This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. Find out why a system failed and what could be done to prevent repeated failures. The basics of root cause failure analysis. Also, the most common analysing and diagnosing. Mechanical seal problems from initial startup, seals failed (replaced) every three. Pump Failure Report Example.

From shootersjournal.net

Failure Analysis Report Template Pump Failure Report Example Also, the most common analysing and diagnosing. With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and how to root them out through. This work will examine how hydraulic pumps fail as well as what their causes and effects are. This paper represents the generic process of. Pump Failure Report Example.

From mavink.com

Equipment Failure Report Template Pump Failure Report Example Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes. Pump Failure Report Example.

From www.studypool.com

SOLUTION Pump seal failure report sample Studypool Pump Failure Report Example Also, the most common analysing and diagnosing. Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. Mechanical seal problems from initial startup, seals failed (replaced) every three to six months (both ib. The basics of root cause failure analysis. With so much at stake, it is crucial that. Pump Failure Report Example.

From www.dexform.com

Equipment failure report form in Word and Pdf formats Pump Failure Report Example Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and how to root them out through. This paper represents the generic process of fmeca for centrifugal. Pump Failure Report Example.

From www.template.net

9+ Editable Failure Analysis Templates PDF, Word, Google Docs, Apple Pump Failure Report Example Also, the most common analysing and diagnosing. Find out why a system failed and what could be done to prevent repeated failures. Using the bfwp example, we identified several modes of failure: Mechanical seal problems from initial startup, seals failed (replaced) every three to six months (both ib. With so much at stake, it is crucial that professionals learn to. Pump Failure Report Example.

From www.slideserve.com

PPT PUMP FAILURE MODES PowerPoint Presentation, free download ID389705 Pump Failure Report Example Using the bfwp example, we identified several modes of failure: Also, the most common analysing and diagnosing. This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and. Pump Failure Report Example.

From dremelmicro.com

40 Effective Root Cause Analysis Templates Forms & Examples Failure Pump Failure Report Example Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. The basics of root cause failure analysis. Mechanical seal problems from initial startup, seals failed (replaced) every three to six months (both ib. Also, the most common analysing and diagnosing. Using the bfwp example, we identified several modes of. Pump Failure Report Example.

From pumpgroup.co.uk

test report 1 Pump Supply & Repair Group Pump Failure Report Example Find out why a system failed and what could be done to prevent repeated failures. This work will examine how hydraulic pumps fail as well as what their causes and effects are. With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and how to root them out. Pump Failure Report Example.

From www.heritagechristiancollege.com

48 Failure Analysis Report Template Free Heritagechristiancollege Pump Failure Report Example The basics of root cause failure analysis. With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and how to root them out through. Using the bfwp example, we identified several modes of failure: Find out why a system failed and what could be done to prevent repeated. Pump Failure Report Example.

From www.scribd.com

An Overview of Pumps Report Pump Piston Free 30day Trial Scribd Pump Failure Report Example This work will examine how hydraulic pumps fail as well as what their causes and effects are. With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and how to root them out through. Using the bfwp example, we identified several modes of failure: Also, the most common. Pump Failure Report Example.

From www.researchgate.net

(PDF) Failure Investigation Report on Different Components of an Pump Failure Report Example The basics of root cause failure analysis. Also, the most common analysing and diagnosing. Using the bfwp example, we identified several modes of failure: Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. Mechanical seal problems from initial startup, seals failed (replaced) every three to six months (both. Pump Failure Report Example.

From www.template.net

43+ Incident Report Formats PDF, Word, Pages Pump Failure Report Example This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. Using the bfwp example, we identified several modes of failure: Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. Mechanical seal problems from initial startup, seals failed (replaced). Pump Failure Report Example.

From www.examples.com

Damage Report 16+ Examples, Format, How To Draft, Pdf Pump Failure Report Example Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. The basics of root cause failure analysis. Find out why a system failed and what could be done to prevent repeated failures. With so much at stake, it is crucial that professionals learn to recognize and detect the most. Pump Failure Report Example.

From www.scribd.com

A Report on Pumps Pump Gases Pump Failure Report Example Mechanical seal problems from initial startup, seals failed (replaced) every three to six months (both ib. This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. Also, the most common analysing and diagnosing. The basics of root cause failure analysis. With so much at stake, it is crucial that professionals. Pump Failure Report Example.

From fiixsoftware.com

What Is Fault Tree Analysis (FTA)? Fiix Pump Failure Report Example This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. The basics of root cause failure analysis. This work will examine how hydraulic pumps fail as well as what their causes and effects are. Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started. Pump Failure Report Example.

From www.slideshare.net

Pump report Pump Failure Report Example This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. The basics of root cause failure analysis. Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. With so much at stake, it is crucial that professionals learn to. Pump Failure Report Example.

From www.dexform.com

Failure report form in Word and Pdf formats Pump Failure Report Example With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and how to root them out through. Using the bfwp example, we identified several modes of failure: Find out why a system failed and what could be done to prevent repeated failures. Also, the most common analysing and. Pump Failure Report Example.

From www.researchgate.net

2 An example of failure mode and effect analysis (FMEA) Download Pump Failure Report Example Find out why a system failed and what could be done to prevent repeated failures. This work will examine how hydraulic pumps fail as well as what their causes and effects are. This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. Also, the most common analysing and diagnosing. Subsequent. Pump Failure Report Example.

From es.scribd.com

Equipment Failure Report PDF Pump Failure Report Example This paper represents the generic process of fmeca for centrifugal pump failures and a case study on centrifugal pump failure. Also, the most common analysing and diagnosing. Find out why a system failed and what could be done to prevent repeated failures. Using the bfwp example, we identified several modes of failure: Mechanical seal problems from initial startup, seals failed. Pump Failure Report Example.

From www.allbusinesstemplates.com

Product Failure Analysis Templates at Pump Failure Report Example Mechanical seal problems from initial startup, seals failed (replaced) every three to six months (both ib. With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and how to root them out through. Using the bfwp example, we identified several modes of failure: This work will examine how. Pump Failure Report Example.

From support.theboogaloo.org

Failure Analysis Report Template Free Product Example Regarding Failure Pump Failure Report Example The basics of root cause failure analysis. With so much at stake, it is crucial that professionals learn to recognize and detect the most common causes of pump failure and how to root them out through. This work will examine how hydraulic pumps fail as well as what their causes and effects are. Also, the most common analysing and diagnosing.. Pump Failure Report Example.

From safetyculture.com

Free Heat Pump Maintenance Checklists PDF SafetyCulture Pump Failure Report Example Subsequent to major overhaul of a pump by a pump vendor, the pump installed and started with high drive end bearing. Find out why a system failed and what could be done to prevent repeated failures. Also, the most common analysing and diagnosing. The basics of root cause failure analysis. This paper represents the generic process of fmeca for centrifugal. Pump Failure Report Example.

From www.studypool.com

SOLUTION Pump seal failure report sample Studypool Pump Failure Report Example Using the bfwp example, we identified several modes of failure: The basics of root cause failure analysis. Find out why a system failed and what could be done to prevent repeated failures. This work will examine how hydraulic pumps fail as well as what their causes and effects are. Mechanical seal problems from initial startup, seals failed (replaced) every three. Pump Failure Report Example.