Electrodes With Powdered Iron In Their Flux Belong To The . Dcep for flat, vertical, overhead,. Iron powder content in the coating to enhance metal deposition and productivity; Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. The flux material provides the shielding gases and the protective slag. The iron powder not only melts in the heat of the arc to increase deposition rate but also enables the electrode to carry a higher welding current. E6010 = high cellulose sodium flux. Some of the most popular electrodes and their meaning are given below: In stick welding there are a number of welding electrode types to weld different materials, varied purposes and welding rod characteristics. So what are the main types of. However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. The wire acts as both the electrode and the filler metal for the process.

from www.goodscience.com.au

So what are the main types of. Some of the most popular electrodes and their meaning are given below: E6010 = high cellulose sodium flux. Dcep for flat, vertical, overhead,. In stick welding there are a number of welding electrode types to weld different materials, varied purposes and welding rod characteristics. Iron powder content in the coating to enhance metal deposition and productivity; The flux material provides the shielding gases and the protective slag. Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. The iron powder not only melts in the heat of the arc to increase deposition rate but also enables the electrode to carry a higher welding current. However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18.

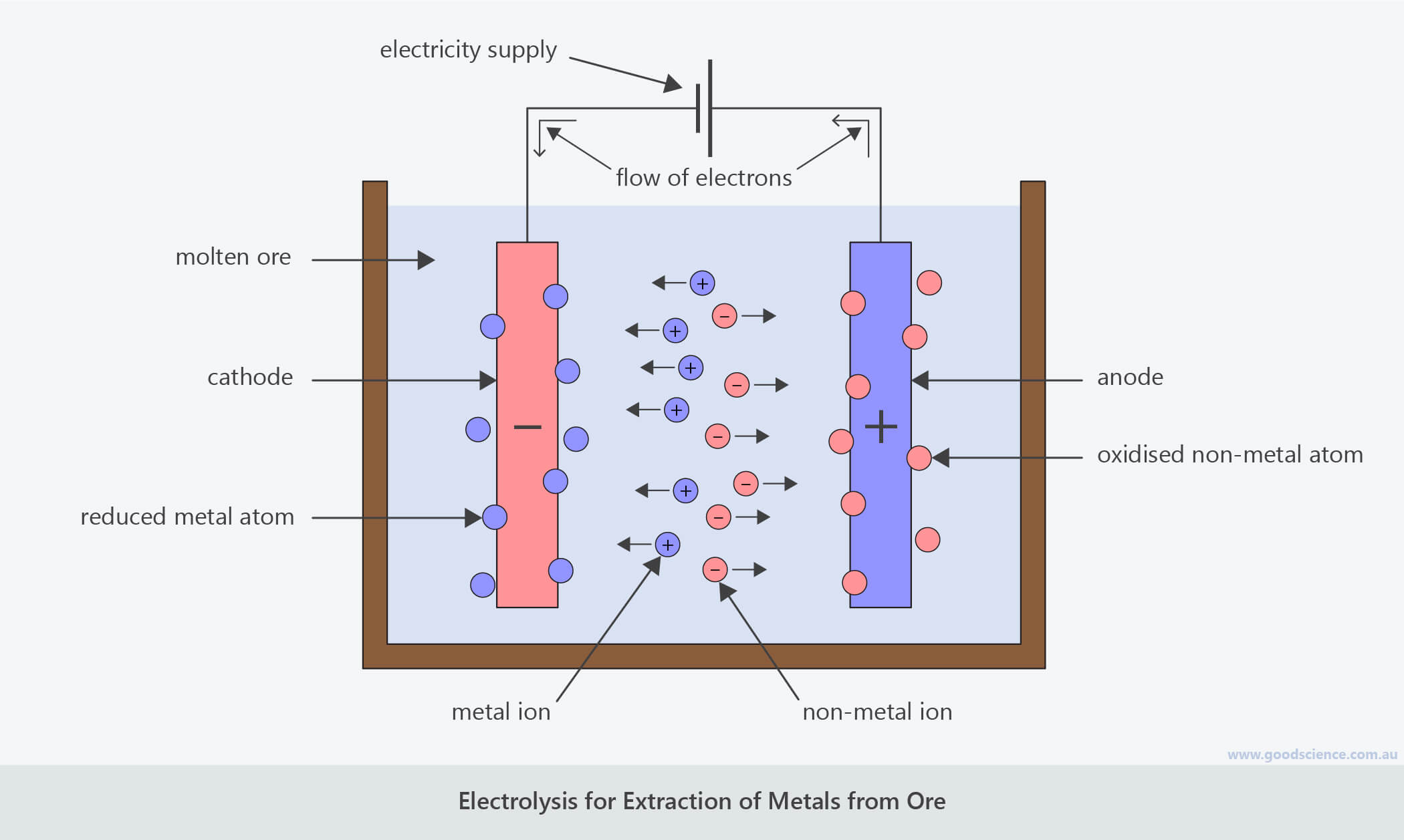

Extraction of Metals Good Science

Electrodes With Powdered Iron In Their Flux Belong To The However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. The flux material provides the shielding gases and the protective slag. In stick welding there are a number of welding electrode types to weld different materials, varied purposes and welding rod characteristics. The wire acts as both the electrode and the filler metal for the process. Some of the most popular electrodes and their meaning are given below: Dcep for flat, vertical, overhead,. However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. Iron powder content in the coating to enhance metal deposition and productivity; Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. The iron powder not only melts in the heat of the arc to increase deposition rate but also enables the electrode to carry a higher welding current. E6010 = high cellulose sodium flux. So what are the main types of.

From www.facebook.com

Facebook Electrodes With Powdered Iron In Their Flux Belong To The Dcep for flat, vertical, overhead,. The flux material provides the shielding gases and the protective slag. So what are the main types of. In stick welding there are a number of welding electrode types to weld different materials, varied purposes and welding rod characteristics. Iron powder content in the coating to enhance metal deposition and productivity; E6010 = high cellulose. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.alibaba.com

510mm Ges Graphite Electrodes Scrap / Powder With High Quality Electrodes With Powdered Iron In Their Flux Belong To The The wire acts as both the electrode and the filler metal for the process. E6010 = high cellulose sodium flux. Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. Dcep for flat, vertical, overhead,. Iron powder content in the coating to enhance metal deposition and productivity; However, iron. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.pinterest.ca

Welding electrodes for thermal power plantss Electrodes With Powdered Iron In Their Flux Belong To The E6010 = high cellulose sodium flux. Dcep for flat, vertical, overhead,. The wire acts as both the electrode and the filler metal for the process. The flux material provides the shielding gases and the protective slag. However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as. Electrodes With Powdered Iron In Their Flux Belong To The.

From clydesdaleengineering.co.za

Afrox Afrolux High Iron Powder Electrodes Clydesdale Engineering Supplies Electrodes With Powdered Iron In Their Flux Belong To The Dcep for flat, vertical, overhead,. However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. The wire acts as both the electrode and the filler metal for the process. E6010 = high cellulose sodium flux. Iron powder content in the coating to enhance metal. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.nsrp.org

Flux Cored Electrode for Welding HY100 and HSLA100 NSRP Electrodes With Powdered Iron In Their Flux Belong To The In stick welding there are a number of welding electrode types to weld different materials, varied purposes and welding rod characteristics. E6010 = high cellulose sodium flux. So what are the main types of. Dcep for flat, vertical, overhead,. Some of the most popular electrodes and their meaning are given below: The wire acts as both the electrode and the. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.researchgate.net

Characterization of the powdered electrolyte and electrode materials Electrodes With Powdered Iron In Their Flux Belong To The Some of the most popular electrodes and their meaning are given below: E6010 = high cellulose sodium flux. However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. The wire acts as both the electrode and the filler metal for the process. Dcep for. Electrodes With Powdered Iron In Their Flux Belong To The.

From kowelding.com.au

E7018 Low Hydrogen Stick Electrodes 3.2mm KO Welding Electrodes With Powdered Iron In Their Flux Belong To The So what are the main types of. Iron powder content in the coating to enhance metal deposition and productivity; Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. The iron powder not only melts in the heat of the arc to increase deposition rate but also enables the. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.alibaba.com

Hiflux Toroidal Cores Iron Powder/nanocrystalline/amorphous Electrodes With Powdered Iron In Their Flux Belong To The Iron powder content in the coating to enhance metal deposition and productivity; However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. So what are the main types of. The wire acts as both the electrode and the filler metal for the process. In. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.researchgate.net

Schematic illustration of the freestanding electrode fabrication Electrodes With Powdered Iron In Their Flux Belong To The However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. E6010 = high cellulose sodium flux. Iron powder content in the coating to enhance metal deposition and productivity; The flux material provides the shielding gases and the protective slag. The iron powder not only. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.mdpi.com

Batteries Free FullText Liion Electrode Microstructure Evolution Electrodes With Powdered Iron In Their Flux Belong To The So what are the main types of. The flux material provides the shielding gases and the protective slag. Iron powder content in the coating to enhance metal deposition and productivity; Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. The iron powder not only melts in the heat. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.weldingandndt.com

Welding electrodes Understanding the SMAW electrode symbols Welding Electrodes With Powdered Iron In Their Flux Belong To The Dcep for flat, vertical, overhead,. However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. So what are the main types of. E6010 = high cellulose sodium flux. In stick welding there are a number of welding electrode types to weld different materials, varied. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.homedepot.com

Lincoln Electric 3.375 in. 1 lb. Powder Flux600FX01 The Home Depot Electrodes With Powdered Iron In Their Flux Belong To The E6010 = high cellulose sodium flux. Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. Dcep for flat, vertical, overhead,. The wire acts as both the electrode and the filler metal for the process. The iron powder not only melts in the heat of the arc to increase. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.frontiersin.org

Frontiers Prospects and challenges of the electrochemical reduction Electrodes With Powdered Iron In Their Flux Belong To The Some of the most popular electrodes and their meaning are given below: Dcep for flat, vertical, overhead,. E6010 = high cellulose sodium flux. In stick welding there are a number of welding electrode types to weld different materials, varied purposes and welding rod characteristics. The wire acts as both the electrode and the filler metal for the process. However, iron. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.indiamart.com

Iron Powder Electrodes at best price in Hosur by Johan Wire Electrodes With Powdered Iron In Their Flux Belong To The Iron powder content in the coating to enhance metal deposition and productivity; Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. Some of the most popular electrodes and their meaning are given below: The iron powder not only melts in the heat of the arc to increase deposition. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.alibaba.com

Basic Iron Powder Type Electrode Iso 2560be4918 A Thj506fe (e7018 Electrodes With Powdered Iron In Their Flux Belong To The E6010 = high cellulose sodium flux. In stick welding there are a number of welding electrode types to weld different materials, varied purposes and welding rod characteristics. The iron powder not only melts in the heat of the arc to increase deposition rate but also enables the electrode to carry a higher welding current. Some of the most popular electrodes. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.pinterest.com

27 best images about Welding Electrodes on Pinterest Welding Electrodes With Powdered Iron In Their Flux Belong To The The flux material provides the shielding gases and the protective slag. So what are the main types of. The iron powder not only melts in the heat of the arc to increase deposition rate but also enables the electrode to carry a higher welding current. In stick welding there are a number of welding electrode types to weld different materials,. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.alibaba.com

Best Quality Welding Flux Welding Mix Powder For Making Welding Electrodes With Powdered Iron In Their Flux Belong To The Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. The wire acts as both the electrode and the filler metal for the process. The flux material provides the shielding gases and the protective slag. E6010 = high cellulose sodium flux. The iron powder not only melts in the. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.weldingandndt.com

Welding electrodes Understanding the SMAW electrode symbols Welding Electrodes With Powdered Iron In Their Flux Belong To The Some of the most popular electrodes and their meaning are given below: However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. In stick welding there are a number of welding electrode types to weld different materials, varied purposes and welding rod characteristics. The. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.researchgate.net

Brushing method for the stretchable electrode and the fabrication Electrodes With Powdered Iron In Their Flux Belong To The The flux material provides the shielding gases and the protective slag. Some of the most popular electrodes and their meaning are given below: The iron powder not only melts in the heat of the arc to increase deposition rate but also enables the electrode to carry a higher welding current. Iron powder content in the coating to enhance metal deposition. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.mdpi.com

Metals Free FullText Crystallization of FeWB Amorphous Powder Electrodes With Powdered Iron In Their Flux Belong To The Dcep for flat, vertical, overhead,. Some of the most popular electrodes and their meaning are given below: Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. E6010 = high cellulose sodium flux. In stick welding there are a number of welding electrode types to weld different materials, varied. Electrodes With Powdered Iron In Their Flux Belong To The.

From blog.rheosense.com

Characterize Your Battery Slurry with the Right Tools Electrodes With Powdered Iron In Their Flux Belong To The Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. Dcep for flat, vertical, overhead,. However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. Iron powder content in the coating to enhance. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.sciencenewsforstudents.org

Explainer What is an electrode? Science News for Students Electrodes With Powdered Iron In Their Flux Belong To The Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. In stick welding there are a number of welding electrode types to weld different materials, varied purposes and welding rod characteristics. So what are the main types of. The flux material provides the shielding gases and the protective slag.. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.goodscience.com.au

Extraction of Metals Good Science Electrodes With Powdered Iron In Their Flux Belong To The So what are the main types of. The iron powder not only melts in the heat of the arc to increase deposition rate but also enables the electrode to carry a higher welding current. Dcep for flat, vertical, overhead,. Iron powder content in the coating to enhance metal deposition and productivity; Some of the most popular electrodes and their meaning. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.desertcart.ae

Buy Z208 cast Iron Electrode, Electrode, Universal Electrode for Electrodes With Powdered Iron In Their Flux Belong To The So what are the main types of. In stick welding there are a number of welding electrode types to weld different materials, varied purposes and welding rod characteristics. However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. Iron powder content in the coating. Electrodes With Powdered Iron In Their Flux Belong To The.

From shlaiwu.en.made-in-china.com

Welding Electrodes Powder Iron Powder for Core Wires China Iron Electrodes With Powdered Iron In Their Flux Belong To The So what are the main types of. However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. The flux material provides the shielding gases and the protective slag. In stick welding there are a number of welding electrode types to weld different materials, varied. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.fowkes.co.za

ELECTRODE LH 7018 4.0MM 4KG AFROX 4.0KG BOXSOLD PER KGLOW HYDROGEN Electrodes With Powdered Iron In Their Flux Belong To The In stick welding there are a number of welding electrode types to weld different materials, varied purposes and welding rod characteristics. Dcep for flat, vertical, overhead,. The flux material provides the shielding gases and the protective slag. The wire acts as both the electrode and the filler metal for the process. Stick welding electrodes are consumable composite short rods with. Electrodes With Powdered Iron In Their Flux Belong To The.

From shlaiwu.en.made-in-china.com

Sponge Electrode Welding Flux Reduced Iron Powder Electrodes Electrodes With Powdered Iron In Their Flux Belong To The The iron powder not only melts in the heat of the arc to increase deposition rate but also enables the electrode to carry a higher welding current. The wire acts as both the electrode and the filler metal for the process. Some of the most popular electrodes and their meaning are given below: In stick welding there are a number. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.aliexpress.com

Copper Flux Copper Gas Solder Flux Flux Silver Paste Powder Aluminum Electrodes With Powdered Iron In Their Flux Belong To The Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. E6010 = high cellulose sodium flux. In stick welding there are a number of welding electrode types to weld different materials, varied purposes and welding rod characteristics. The iron powder not only melts in the heat of the arc. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.youtube.com

6 Different Types of Electrodes & their Reactions in Electrochemistry Electrodes With Powdered Iron In Their Flux Belong To The However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. So what are the main types of. Dcep for flat, vertical, overhead,. The flux material provides the shielding gases and the protective slag. Some of the most popular electrodes and their meaning are given. Electrodes With Powdered Iron In Their Flux Belong To The.

From weldingzilla.com

Why Welding Electrodes Are Coated With Flux? Electrodes With Powdered Iron In Their Flux Belong To The The iron powder not only melts in the heat of the arc to increase deposition rate but also enables the electrode to carry a higher welding current. The wire acts as both the electrode and the filler metal for the process. However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent,. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.cell.com

Dry electrode technology, the rising star in solidstate battery Electrodes With Powdered Iron In Their Flux Belong To The In stick welding there are a number of welding electrode types to weld different materials, varied purposes and welding rod characteristics. Dcep for flat, vertical, overhead,. So what are the main types of. Some of the most popular electrodes and their meaning are given below: E6010 = high cellulose sodium flux. Stick welding electrodes are consumable composite short rods with. Electrodes With Powdered Iron In Their Flux Belong To The.

From parweld.com

Magmaweld E7024 Iron Powder Electrodes Parweld Electrodes With Powdered Iron In Their Flux Belong To The In stick welding there are a number of welding electrode types to weld different materials, varied purposes and welding rod characteristics. The wire acts as both the electrode and the filler metal for the process. The flux material provides the shielding gases and the protective slag. Dcep for flat, vertical, overhead,. Stick welding electrodes are consumable composite short rods with. Electrodes With Powdered Iron In Their Flux Belong To The.

From saylordotorg.github.io

Electrochemistry Electrodes With Powdered Iron In Their Flux Belong To The Dcep for flat, vertical, overhead,. Some of the most popular electrodes and their meaning are given below: Iron powder content in the coating to enhance metal deposition and productivity; However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. The flux material provides the. Electrodes With Powdered Iron In Their Flux Belong To The.

From www.researchgate.net

Schematic of the composite electrode fabrication process with sample Electrodes With Powdered Iron In Their Flux Belong To The Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a covering of flux material. The wire acts as both the electrode and the filler metal for the process. Iron powder content in the coating to enhance metal deposition and productivity; In stick welding there are a number of welding electrode types to weld. Electrodes With Powdered Iron In Their Flux Belong To The.

From shlaiwu.en.made-in-china.com

Welding Electrode Flux Sponge Reduced Iron Powder Thermite Welding Electrodes With Powdered Iron In Their Flux Belong To The However, iron powder is added to the electrode, and if the content is higher than 35 to 40 percent, the electrode is classified as an exx18. Dcep for flat, vertical, overhead,. Iron powder content in the coating to enhance metal deposition and productivity; Stick welding electrodes are consumable composite short rods with a core of solid metal wire and a. Electrodes With Powdered Iron In Their Flux Belong To The.