Brinell Lead Hardness Chart . The test is achieved by. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. Downloadable chart of lead hardness by use, orville deutchman 2019. A 10 mm steel ball was used for 450. According to iso 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to determine the brinell. The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. Page 30 of glen fryxell’s book ( referenced below) has an. We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number.

from pdfslide.net

53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. A 10 mm steel ball was used for 450. The test is achieved by. The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. According to iso 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to determine the brinell. We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. Downloadable chart of lead hardness by use, orville deutchman 2019. Page 30 of glen fryxell’s book ( referenced below) has an. These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number.

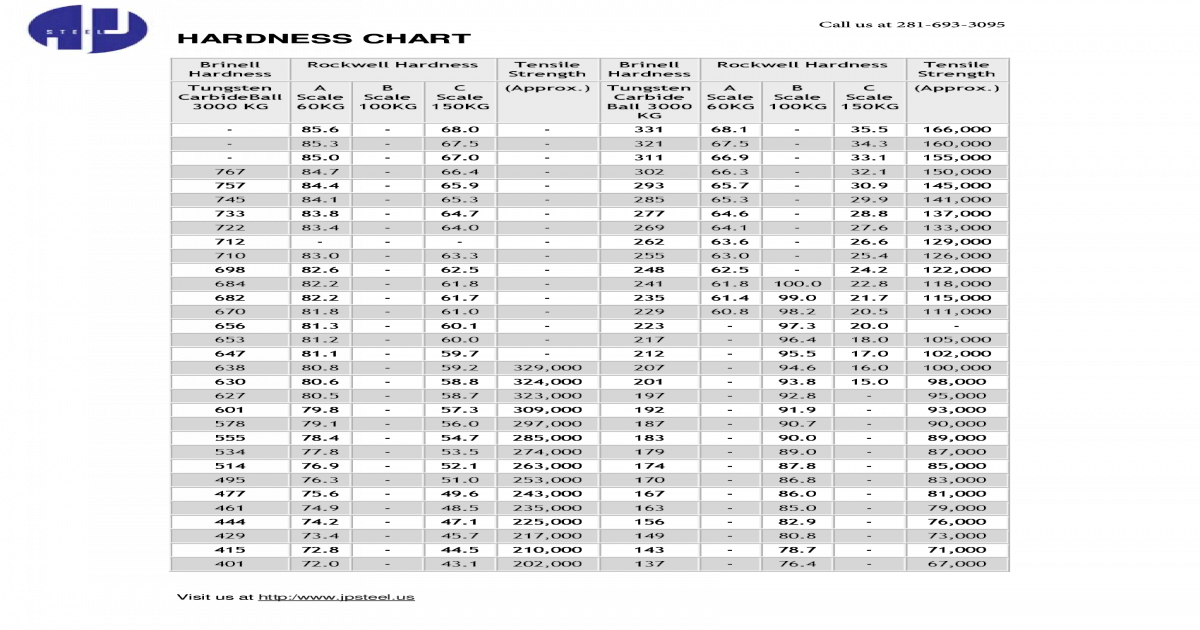

BrinellRockwell Hardness Chart JP CHART Visit us at http/ Brinell

Brinell Lead Hardness Chart The test is achieved by. According to iso 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to determine the brinell. Downloadable chart of lead hardness by use, orville deutchman 2019. A 10 mm steel ball was used for 450. These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number. We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. The test is achieved by. Page 30 of glen fryxell’s book ( referenced below) has an. The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys.

From writersneed.com

Mechanical Pencil Lead Grades and Hardness Explained WRITER'S NEED Brinell Lead Hardness Chart 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. According to iso 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed. Brinell Lead Hardness Chart.

From colorscale.z28.web.core.windows.net

hardness scale charts Wood reference charts Brinell Lead Hardness Chart 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. Downloadable chart of lead hardness by use, orville deutchman 2019. The test is achieved by. We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. These corrections. Brinell Lead Hardness Chart.

From mungfali.com

Metal Hardness Scale Chart Brinell Lead Hardness Chart Downloadable chart of lead hardness by use, orville deutchman 2019. Page 30 of glen fryxell’s book ( referenced below) has an. The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. 53 rows the brinell hardness test is commonly used to determine the hardness. Brinell Lead Hardness Chart.

From samanthalong.z19.web.core.windows.net

Brinell Hardness Chart For Metals Brinell Lead Hardness Chart The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. Downloadable chart of lead hardness by use, orville deutchman 2019. A 10 mm steel ball was used for 450. The test is achieved by. According to iso 6506, the spherical indenter made of hard. Brinell Lead Hardness Chart.

From forums.sassnet.com

Testing hardness of lead alloys. SASS Wire SASS Wire Forum Brinell Lead Hardness Chart The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. According to iso 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to determine the brinell.. Brinell Lead Hardness Chart.

From preppersvoice.com

Pencil hardness test versus Brinell hardness of lead alloys The Brinell Lead Hardness Chart The test is achieved by. The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. Page 30 of glen fryxell’s book ( referenced below) has an. These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number. We work with. Brinell Lead Hardness Chart.

From mavink.com

Brinell Hardness Chart Printable Brinell Lead Hardness Chart These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number. We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. Page 30. Brinell Lead Hardness Chart.

From www.iqualitrol.com

China Dongguan Quality Control Technology Co., Ltd. latest company news Brinell Lead Hardness Chart These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. A 10 mm steel ball was used for 450. We work with certified analysis foundry alloy in two hardnesses in order to provide you with the. Brinell Lead Hardness Chart.

From www.tessshebaylo.com

Brinell Hardness Tensile Strength Equation Tessshebaylo Brinell Lead Hardness Chart A 10 mm steel ball was used for 450. The test is achieved by. Downloadable chart of lead hardness by use, orville deutchman 2019. These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number. The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify. Brinell Lead Hardness Chart.

From exotpsphk.blob.core.windows.net

Lead Hardness Brinell at Sarah Nevarez blog Brinell Lead Hardness Chart The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. The test is achieved by. We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. Page 30 of glen fryxell’s. Brinell Lead Hardness Chart.

From www.gbu-taganskij.ru

Hardness Conversion Chart For Brinell, Rockwell, Vickers,, 46 OFF Brinell Lead Hardness Chart Downloadable chart of lead hardness by use, orville deutchman 2019. According to iso 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to determine the brinell. These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number. The. Brinell Lead Hardness Chart.

From learningeichelberger.z13.web.core.windows.net

Pencil Lead Hardness Chart Brinell Lead Hardness Chart Downloadable chart of lead hardness by use, orville deutchman 2019. A 10 mm steel ball was used for 450. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the. Brinell Lead Hardness Chart.

From www.floridareloading.com

Hardness Testing Lead A series of TIPS from my recent Cast Lead Brinell Lead Hardness Chart 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. A 10 mm steel ball was used for 450. According to iso 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to determine. Brinell Lead Hardness Chart.

From www.scribd.com

Brinell Scale HBW 10/3000 Chart PDF Chemical Product Engineering Brinell Lead Hardness Chart These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number. We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. A 10 mm steel ball was used for 450. Page 30 of glen fryxell’s book ( referenced below) has an. According. Brinell Lead Hardness Chart.

From www.researchgate.net

Brinell hardness values for all samples Download Scientific Diagram Brinell Lead Hardness Chart 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. According to iso 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed. Brinell Lead Hardness Chart.

From exopraclw.blob.core.windows.net

Lead Alloy Hardness Calculator at Tamara Riggs blog Brinell Lead Hardness Chart These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number. We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. The test is achieved by. A 10 mm steel ball was used for 450. 53 rows the brinell hardness test is. Brinell Lead Hardness Chart.

From mungfali.com

Metal Hardness Scale Chart Brinell Lead Hardness Chart Downloadable chart of lead hardness by use, orville deutchman 2019. We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. Page 30 of glen fryxell’s book ( referenced below) has an. These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number.. Brinell Lead Hardness Chart.

From www.bostoncenterless.com

Hardness Conversion Chart Boston Centerless Brinell Lead Hardness Chart 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. Downloadable chart of lead hardness by use, orville deutchman 2019. These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number. The test is achieved by. We work with certified analysis foundry alloy in two hardnesses in. Brinell Lead Hardness Chart.

From chordcharts.z28.web.core.windows.net

rockwell hardness scale indenter load chart Metal hardness Brinell Lead Hardness Chart The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. According to iso 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to determine the brinell.. Brinell Lead Hardness Chart.

From www.researchgate.net

Brinell hardness measurement along the simulated sample Download Brinell Lead Hardness Chart A 10 mm steel ball was used for 450. We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. Page 30 of glen fryxell’s book ( referenced below) has an. The system we use today was invented in 1900 by johan august brinell and we still. Brinell Lead Hardness Chart.

From slashk.blogspot.com

Slash K Reloading Lead Bullet Hardness Brinell Lead Hardness Chart Page 30 of glen fryxell’s book ( referenced below) has an. Downloadable chart of lead hardness by use, orville deutchman 2019. A 10 mm steel ball was used for 450. These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number. We work with certified analysis foundry alloy in two hardnesses in order to provide you. Brinell Lead Hardness Chart.

From pdfslide.net

BrinellRockwell Hardness Chart JP CHART Visit us at http/ Brinell Brinell Lead Hardness Chart Page 30 of glen fryxell’s book ( referenced below) has an. These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number. The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. According to iso 6506, the spherical indenter made. Brinell Lead Hardness Chart.

From mavink.com

Brinell Hardness Chart Printable Brinell Lead Hardness Chart According to iso 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to determine the brinell. Downloadable chart of lead hardness by use, orville deutchman 2019. The system we use today was invented in 1900 by johan august brinell and we still. Brinell Lead Hardness Chart.

From mavink.com

Brinell Hardness Chart Printable Brinell Lead Hardness Chart 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. A 10 mm steel ball was used for 450. Page 30 of glen fryxell’s book ( referenced below) has an. Downloadable chart of lead hardness by use, orville deutchman 2019. These corrections are approximate only and represent the averages to the. Brinell Lead Hardness Chart.

From www.scribd.com

Brinell Hardness Conversion Chart Brinell Lead Hardness Chart Downloadable chart of lead hardness by use, orville deutchman 2019. We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. According to iso 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1. Brinell Lead Hardness Chart.

From exyhufqwr.blob.core.windows.net

Brinell Hardness Number Chart at Ronald Fields blog Brinell Lead Hardness Chart The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number.. Brinell Lead Hardness Chart.

From mungfali.com

ASTM Hardness Conversion Chart Brinell Lead Hardness Chart 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. Downloadable chart of lead hardness by use, orville deutchman 2019. According to iso 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to. Brinell Lead Hardness Chart.

From www.chegg.com

Solved Data For Brinell Hardness Reading (kg/mm^2) Of Har... Brinell Lead Hardness Chart We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. These corrections are approximate only and represent the averages to. Brinell Lead Hardness Chart.

From exotpsphk.blob.core.windows.net

Lead Hardness Brinell at Sarah Nevarez blog Brinell Lead Hardness Chart These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number. We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. The test is achieved by. The system we use today was invented in 1900 by johan august brinell and we still. Brinell Lead Hardness Chart.

From exoxiuepc.blob.core.windows.net

Brinell Hardness Chart For Aluminum at Kevin Mast blog Brinell Lead Hardness Chart We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number. Downloadable chart of lead hardness by use, orville deutchman 2019. A 10 mm steel ball was used for 450. 53 rows. Brinell Lead Hardness Chart.

From www.scribd.com

Printable Brinell Hardness Chart Firearms Ammunition Brinell Lead Hardness Chart Downloadable chart of lead hardness by use, orville deutchman 2019. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. These corrections are approximate only and represent the averages to the nearest 1/2 rockwell number. The test is achieved by. According to iso 6506, the spherical indenter made of hard metal. Brinell Lead Hardness Chart.

From www.myxxgirl.com

Piano Surichinmoi Render Brinell Hardness Of Carbon Steel Build Duck Brinell Lead Hardness Chart Page 30 of glen fryxell’s book ( referenced below) has an. According to iso 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to determine the brinell. A 10 mm steel ball was used for 450. The system we use today was. Brinell Lead Hardness Chart.

From www.gordonengland.co.uk

Brinell and Vickers Hardness and Tensile Strength Equivalent Chart Brinell Lead Hardness Chart The test is achieved by. Page 30 of glen fryxell’s book ( referenced below) has an. Downloadable chart of lead hardness by use, orville deutchman 2019. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. According to iso 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed. Brinell Lead Hardness Chart.

From exoxiuepc.blob.core.windows.net

Brinell Hardness Chart For Aluminum at Kevin Mast blog Brinell Lead Hardness Chart The test is achieved by. A 10 mm steel ball was used for 450. We work with certified analysis foundry alloy in two hardnesses in order to provide you with the bullet hardness that works best for you. 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. These corrections are. Brinell Lead Hardness Chart.

From www.cnccookbook.com.s3-website-us-east-1.amazonaws.com

Hardness Conversion Chart for Brinell, Rockwell, Vickers, Shore Brinell Lead Hardness Chart 53 rows the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. Downloadable chart of lead hardness by use, orville deutchman 2019. The system we use today was invented in 1900 by johan august brinell and we still use it today to quantify the hardness of various materials. A 10 mm steel ball. Brinell Lead Hardness Chart.