Drill Milling Adapter . It features an 11 inch cross feed and a 6.5 inch in and out feed. These jaws will hold your workpiece securely in place as you mill it down. Mills are a huge investment, and for hobbyists without the space to install their own. Converting a drill press into a milling machine. Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. Featuring heavy steel construction and smooth. A drill press machine is quicker yet less accurate compared to the milling machines. A drill press is mainly used for drilling holes and other basic tasks, while a milling machine is used to perform more complex. This ellis milling table fits 9400 and 12000 model drill press. First and foremost, you’ll need a set of milling jaws that can attach to your drill press. The head of the milling machine is. Learn how to use your drill press as a mill and unlock its full potential.

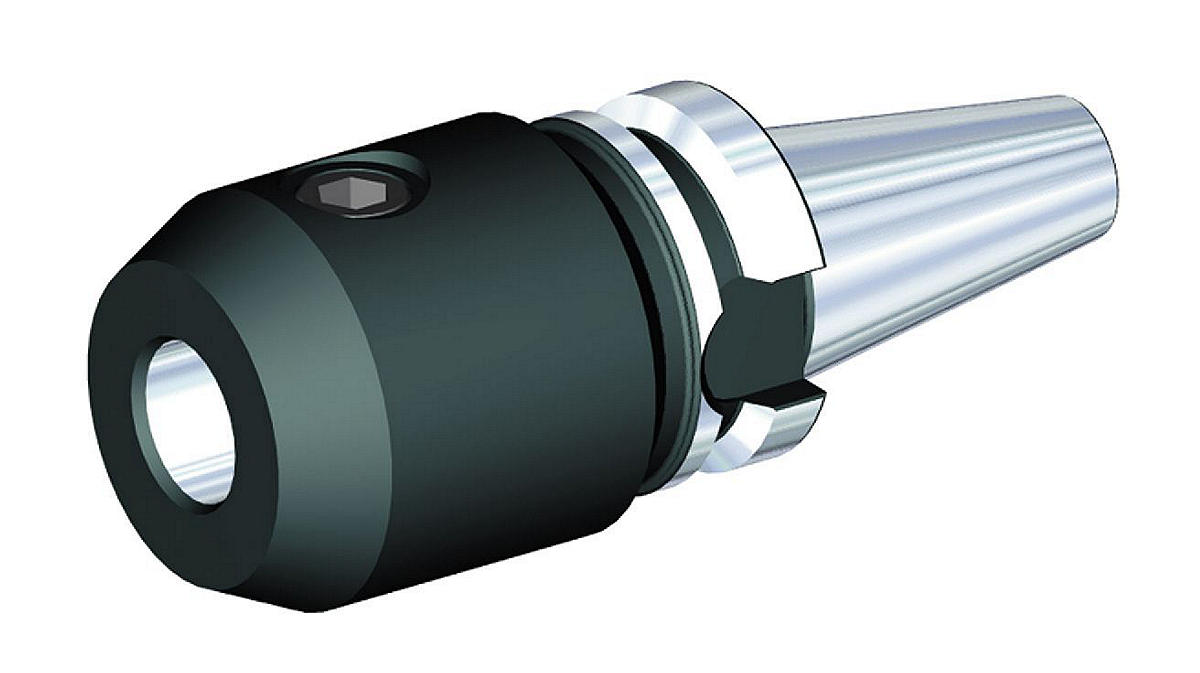

from www.kennametal.com

It features an 11 inch cross feed and a 6.5 inch in and out feed. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. Converting a drill press into a milling machine. These jaws will hold your workpiece securely in place as you mill it down. First and foremost, you’ll need a set of milling jaws that can attach to your drill press. Featuring heavy steel construction and smooth. The head of the milling machine is. Learn how to use your drill press as a mill and unlock its full potential. This ellis milling table fits 9400 and 12000 model drill press.

End Mill Adapters

Drill Milling Adapter Learn how to use your drill press as a mill and unlock its full potential. Learn how to use your drill press as a mill and unlock its full potential. These jaws will hold your workpiece securely in place as you mill it down. A drill press is mainly used for drilling holes and other basic tasks, while a milling machine is used to perform more complex. Converting a drill press into a milling machine. This ellis milling table fits 9400 and 12000 model drill press. It features an 11 inch cross feed and a 6.5 inch in and out feed. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. Mills are a huge investment, and for hobbyists without the space to install their own. Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. Featuring heavy steel construction and smooth. First and foremost, you’ll need a set of milling jaws that can attach to your drill press. The head of the milling machine is. A drill press machine is quicker yet less accurate compared to the milling machines.

From ebonyedmondstone.blogspot.com

Drillpro 1.513mm Drill Chuck Drill Adapter 1/220UNF Thread Changed Drill Milling Adapter The head of the milling machine is. Mills are a huge investment, and for hobbyists without the space to install their own. A drill press is mainly used for drilling holes and other basic tasks, while a milling machine is used to perform more complex. Featuring heavy steel construction and smooth. It features an 11 inch cross feed and a. Drill Milling Adapter.

From www.amazon.com

7/8" R8 End Mill Adapter for Bridgeport Type milling Machines / 7/8 Drill Milling Adapter Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. These jaws will hold your workpiece securely in place as you mill it down. It features an 11 inch cross feed and a 6.5. Drill Milling Adapter.

From dansdiscounttools.com

SPI Quick Change End Mill Adapter 3/4″ U300EC3/4 Dan's Discount Tools Drill Milling Adapter Mills are a huge investment, and for hobbyists without the space to install their own. Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. The head of the milling machine is. Learn how to use your drill press as a mill and unlock its full potential. Featuring heavy steel construction and smooth. Additionally, you’ll. Drill Milling Adapter.

From www.knuth.com

Extension Sleeve MT 3/4 Milling & Drilling Adapters KNUTH USA Drill Milling Adapter It features an 11 inch cross feed and a 6.5 inch in and out feed. This ellis milling table fits 9400 and 12000 model drill press. A drill press machine is quicker yet less accurate compared to the milling machines. A drill press is mainly used for drilling holes and other basic tasks, while a milling machine is used to. Drill Milling Adapter.

From primebuy.com

Buy Michigan Drill HR4030, 40 to 30 Drawbar Milling Machine Adapter Drill Milling Adapter Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. It features an 11 inch cross feed and a 6.5 inch in and out feed. Learn how to use your drill press as a mill and unlock its full potential. Converting a drill press into a milling machine. Additionally, you’ll need a milling vise that. Drill Milling Adapter.

From www.aliexpress.com

MT3 to B18 Drill Chuck Arbor Adapter Flat Tail Shank Morse Taper 3MT Drill Milling Adapter First and foremost, you’ll need a set of milling jaws that can attach to your drill press. Converting a drill press into a milling machine. Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. Featuring heavy steel construction and smooth. This ellis milling table fits 9400 and 12000 model drill press. Additionally, you’ll need. Drill Milling Adapter.

From www.penntoolco.com

Micro Drill Adapters Penn Tool Co., Inc Drill Milling Adapter Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. Mills are a huge investment, and for hobbyists without the space to install their own. The head of the milling machine is. This ellis milling table fits 9400 and 12000 model drill press. Learn how to use your drill. Drill Milling Adapter.

From www.carbideanddiamondtooling.com

Milling Machine Adapters, Drill Drifts NMTB NST R8 Drill Milling Adapter Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. Mills are a huge investment, and for hobbyists without the space to install their own. Featuring heavy steel construction and smooth. A drill press machine is quicker yet less accurate compared to the milling machines. The head of the milling machine is. Additionally, you’ll need. Drill Milling Adapter.

From www.kennametal.com

End Mill Adapters Drill Milling Adapter It features an 11 inch cross feed and a 6.5 inch in and out feed. Learn how to use your drill press as a mill and unlock its full potential. Featuring heavy steel construction and smooth. Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. Mills are a huge investment, and for hobbyists without. Drill Milling Adapter.

From alexnld.com

1.513mm Drill Chuck Drill Adapter 1/2 Inch Changed Impact Wrench Into Drill Milling Adapter Converting a drill press into a milling machine. Learn how to use your drill press as a mill and unlock its full potential. The head of the milling machine is. Mills are a huge investment, and for hobbyists without the space to install their own. This ellis milling table fits 9400 and 12000 model drill press. A drill press is. Drill Milling Adapter.

From www.indiamart.com

Stainless Steel BT30 Milling Adapter, Rs 500 /piece Radhey Enterprise Drill Milling Adapter Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. Learn how to use your drill press as a mill and unlock its full potential. Mills are a huge investment, and for hobbyists without the space to install their own. Featuring heavy steel construction and smooth. This ellis milling. Drill Milling Adapter.

From www.trick-tools.com

Ellis Drill Press Milling Table and Adapter Drill Milling Adapter Learn how to use your drill press as a mill and unlock its full potential. Converting a drill press into a milling machine. First and foremost, you’ll need a set of milling jaws that can attach to your drill press. The head of the milling machine is. This ellis milling table fits 9400 and 12000 model drill press. These jaws. Drill Milling Adapter.

From www.ebay.es

MT2 to MT3 Morse Taper Reduction Adapter Drill Sleeve for Lathe Milling Drill Milling Adapter Converting a drill press into a milling machine. Featuring heavy steel construction and smooth. A drill press machine is quicker yet less accurate compared to the milling machines. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. Learn how to use your drill press as a mill and. Drill Milling Adapter.

From www.amazon.com

11/4" R8 End Mill Adapter Power Milling Machines Drill Milling Adapter Mills are a huge investment, and for hobbyists without the space to install their own. A drill press machine is quicker yet less accurate compared to the milling machines. Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. The head of the milling machine is. Additionally, you’ll need a milling vise that will clamp. Drill Milling Adapter.

From www.aliexpress.com

Buy 1 16mm Alloy Self locking Click Keyless Drill Drill Milling Adapter Mills are a huge investment, and for hobbyists without the space to install their own. A drill press is mainly used for drilling holes and other basic tasks, while a milling machine is used to perform more complex. The head of the milling machine is. First and foremost, you’ll need a set of milling jaws that can attach to your. Drill Milling Adapter.

From www.knuth.com

Milling & Drilling Adapters KNUTH Drill Milling Adapter Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. This ellis milling table fits 9400 and 12000 model drill press. A drill press is mainly used for drilling holes and other basic tasks, while a milling machine is used to perform more complex. A drill press machine is quicker yet less accurate compared to. Drill Milling Adapter.

From www.knuth.com

Adapter BT 40 / MT 4 Milling & Drilling Adapters KNUTH Drill Milling Adapter A drill press machine is quicker yet less accurate compared to the milling machines. The head of the milling machine is. This ellis milling table fits 9400 and 12000 model drill press. First and foremost, you’ll need a set of milling jaws that can attach to your drill press. Mills are a huge investment, and for hobbyists without the space. Drill Milling Adapter.

From pogsinc.org

Micro Fine Drill Mill Adaptor Miniature Quill 1/2 ShankJT0 Taper to Drill Milling Adapter It features an 11 inch cross feed and a 6.5 inch in and out feed. Featuring heavy steel construction and smooth. The head of the milling machine is. These jaws will hold your workpiece securely in place as you mill it down. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more. Drill Milling Adapter.

From www.amazon.com

R8 11/4'' End Mill Adapter Holder For Bridgeport Machines Adaptor Tool Drill Milling Adapter It features an 11 inch cross feed and a 6.5 inch in and out feed. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. The head of the milling machine is. Featuring heavy steel construction and smooth. These jaws will hold your workpiece securely in place as you. Drill Milling Adapter.

From www.aliexpress.com

1pc 1 16mm Alloy Self locking Click Keyless Drill Chuck Adapter for CNC Drill Milling Adapter Mills are a huge investment, and for hobbyists without the space to install their own. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. Learn how to use your drill press as a mill and unlock its full potential. It features an 11 inch cross feed and a. Drill Milling Adapter.

From flavored.ph

Business 0.66mm Electric Drill Chuck B10 Thread with Key Adapter for Drill Milling Adapter Mills are a huge investment, and for hobbyists without the space to install their own. A drill press machine is quicker yet less accurate compared to the milling machines. Converting a drill press into a milling machine. It features an 11 inch cross feed and a 6.5 inch in and out feed. This ellis milling table fits 9400 and 12000. Drill Milling Adapter.

From www.aliexpress.com

MT2 to B16 Drill Chuck Arbor Adapter Flat Tail Shank Morse Taper 2MT Drill Milling Adapter These jaws will hold your workpiece securely in place as you mill it down. Converting a drill press into a milling machine. Learn how to use your drill press as a mill and unlock its full potential. The head of the milling machine is. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you. Drill Milling Adapter.

From www.jiffyairtool.com

90 Degree Modular Drill Attachments Jiffy Air Tool Drill Milling Adapter Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. Mills are a huge investment, and for hobbyists without the space to install their own. Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. First and foremost, you’ll need a set of milling. Drill Milling Adapter.

From www.wish.com

1.513MM B16 Drill Chuck Adapter Milling Tool Kit Key Type Drill Chuck Drill Milling Adapter First and foremost, you’ll need a set of milling jaws that can attach to your drill press. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. A drill press machine is quicker yet less accurate compared to the milling machines. Featuring heavy steel construction and smooth. The head. Drill Milling Adapter.

From kalead.en.made-in-china.com

Bt/Sph Drill Chuck Adapter Integrated Type for CNC Lathe Machine Tools Drill Milling Adapter Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. The head of the milling machine is. These jaws will hold your workpiece securely in place as you mill it down. Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. This ellis milling. Drill Milling Adapter.

From primebuy.com

Buy Michigan Drill HPD403, 3MT to 40 Drawbar End Milling Machine Drill Milling Adapter First and foremost, you’ll need a set of milling jaws that can attach to your drill press. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. Featuring heavy steel construction and smooth. Converting a drill press into a milling machine. These jaws will hold your workpiece securely in. Drill Milling Adapter.

From www.ebay.com

Precision Fine Micro Drill Mill Adapter Miniature Quill 1/2" Shank with Drill Milling Adapter Mills are a huge investment, and for hobbyists without the space to install their own. First and foremost, you’ll need a set of milling jaws that can attach to your drill press. A drill press machine is quicker yet less accurate compared to the milling machines. It features an 11 inch cross feed and a 6.5 inch in and out. Drill Milling Adapter.

From adt-diamondtools.com

Drill bit adapter DDBI Hilti to 1 ¼” Drill Milling Adapter A drill press machine is quicker yet less accurate compared to the milling machines. This ellis milling table fits 9400 and 12000 model drill press. Learn how to use your drill press as a mill and unlock its full potential. A drill press is mainly used for drilling holes and other basic tasks, while a milling machine is used to. Drill Milling Adapter.

From www.youtube.com

Milling machine drill adapter Part 2 of 2 YouTube Drill Milling Adapter This ellis milling table fits 9400 and 12000 model drill press. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. Mills are a huge investment, and for hobbyists without the space to install their own. Featuring heavy steel construction and smooth. Converting a drill press into a milling. Drill Milling Adapter.

From www.aliexpress.com

Electric Drill Converter Drill Bit Interface Adapters M22 Diamond Core Drill Milling Adapter It features an 11 inch cross feed and a 6.5 inch in and out feed. The head of the milling machine is. These jaws will hold your workpiece securely in place as you mill it down. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. Learn how to. Drill Milling Adapter.

From www.amazon.com

Spindle Morse Taper Adapter Sleeve, Drill Adapters, Taper Adapter Drill Milling Adapter Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. A drill press is mainly used for drilling holes and other basic tasks, while a milling machine is used to perform more complex. Learn how to use your drill press as a mill and unlock its full potential. Mills. Drill Milling Adapter.

From www.indiamart.com

Milling Adapter at Rs 2000 /piece मिलिंग टूल Kakamari Enterprises Drill Milling Adapter Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. Learn how to use your drill press as a mill and unlock its full potential. First and foremost, you’ll need a set of milling jaws that can attach to your drill press. It features an 11 inch cross feed. Drill Milling Adapter.

From tillescenter.org

MT2 to MT3 Taper Drill Sleeve Reducing Adapter For Lathe Milling Drill Milling Adapter A drill press machine is quicker yet less accurate compared to the milling machines. The head of the milling machine is. Featuring heavy steel construction and smooth. Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. Converting a drill press into a milling machine. First and foremost, you’ll need a set of milling jaws. Drill Milling Adapter.

From www.desertcart.ae

Buy CNBTR 40 Chrome Steel MT2 Morse Taper Drill Sleeve Adapter Holder Drill Milling Adapter These jaws will hold your workpiece securely in place as you mill it down. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. The head of the milling machine is. A drill press. Drill Milling Adapter.

From www.knuth.com

Adapter Sleeve BT30xMT1 Milling & Drilling Adapters KNUTH Drill Milling Adapter These jaws will hold your workpiece securely in place as you mill it down. Additionally, you’ll need a milling vise that will clamp onto your drill press table, giving you even more control and precision. Connect a variety of bits to drills, powered screwdrivers, ratchet wrenches, and other turning tools. Learn how to use your drill press as a mill. Drill Milling Adapter.