Conveyor Belts Justification . The primary function of a conveyor belt is to move materials from one location to another. One pulley, known as the drive pulley, drives or tows the belt, moving. Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: Cleaning the conveyor belt after the discharge point is essential to prevent misalignment, minimize material spillage and increase. This function is integral to. Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. The belt forms a closed loop around the pulleys so it can continually rotate. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. With this in mind, there are six key considerations to evaluate during the conveyor selection process:

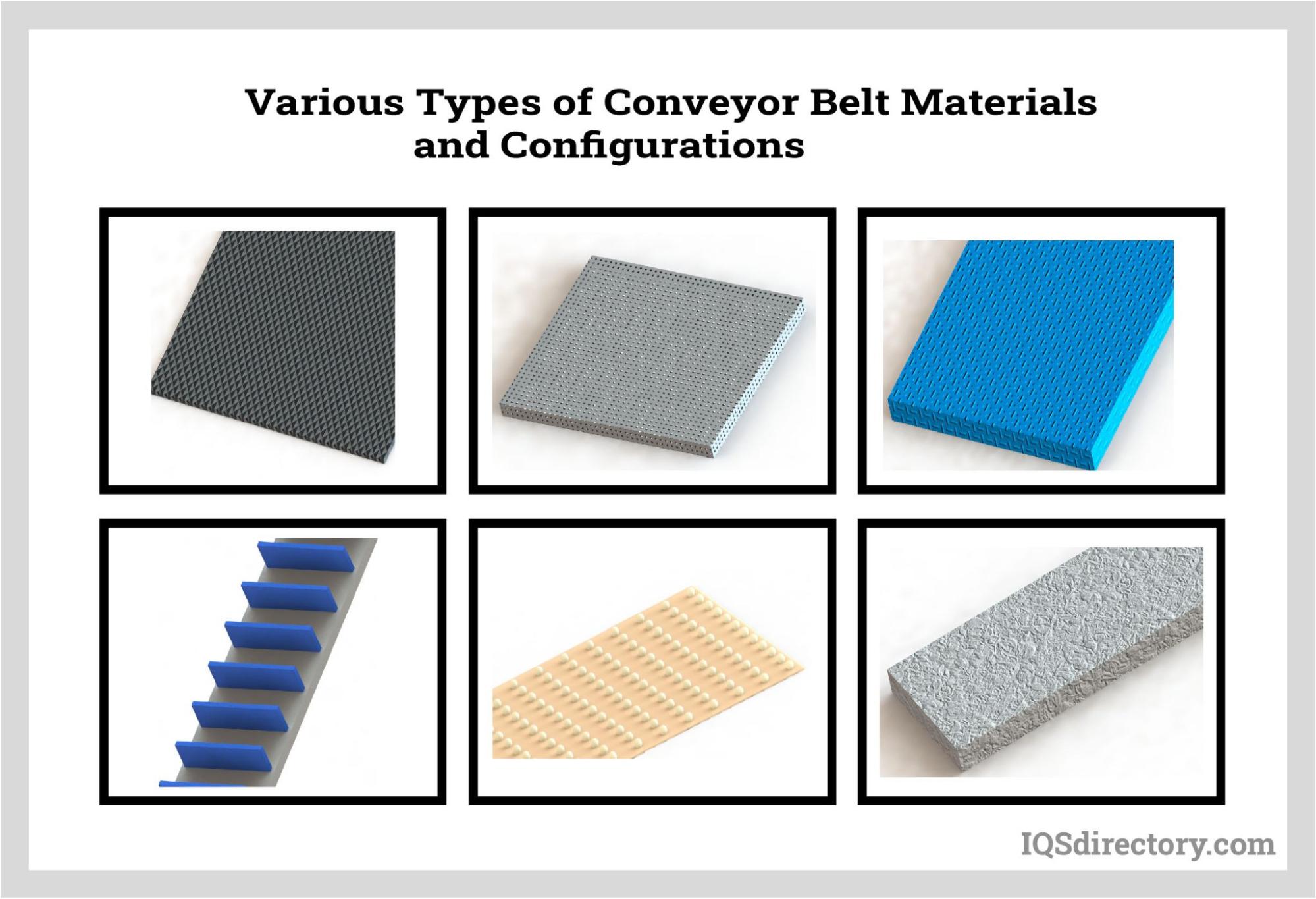

from www.iqsdirectory.com

One pulley, known as the drive pulley, drives or tows the belt, moving. Cleaning the conveyor belt after the discharge point is essential to prevent misalignment, minimize material spillage and increase. The primary function of a conveyor belt is to move materials from one location to another. Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: This function is integral to. With this in mind, there are six key considerations to evaluate during the conveyor selection process: Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. The belt forms a closed loop around the pulleys so it can continually rotate.

Conveyor Belts What Is It? How Does It Work? Types, Parts

Conveyor Belts Justification With this in mind, there are six key considerations to evaluate during the conveyor selection process: Cleaning the conveyor belt after the discharge point is essential to prevent misalignment, minimize material spillage and increase. This function is integral to. With this in mind, there are six key considerations to evaluate during the conveyor selection process: Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: The primary function of a conveyor belt is to move materials from one location to another. Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. The belt forms a closed loop around the pulleys so it can continually rotate. One pulley, known as the drive pulley, drives or tows the belt, moving.

From dfe.com

Conveyor Belt Tension Measurement & Monitoring Dover Flexo Conveyor Belts Justification With this in mind, there are six key considerations to evaluate during the conveyor selection process: The belt forms a closed loop around the pulleys so it can continually rotate. One pulley, known as the drive pulley, drives or tows the belt, moving. Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: Cleaning the. Conveyor Belts Justification.

From www.iqsdirectory.com

Conveyor Belt What Is It? How Does It Work? Types, Parts Conveyor Belts Justification Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. The belt forms a closed loop around the pulleys so it can continually rotate. Cleaning the conveyor belt after. Conveyor Belts Justification.

From www.dornerconveyors.com

Intralox Activated Roller Belt™ (ARB) Technology Dorner Conveyors Conveyor Belts Justification The belt forms a closed loop around the pulleys so it can continually rotate. Cleaning the conveyor belt after the discharge point is essential to prevent misalignment, minimize material spillage and increase. This function is integral to. Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: Belt conveyors are the most widely used and. Conveyor Belts Justification.

From www.youtube.com

Conveyor Belt Conveyor belt length calculation in Roll YouTube Conveyor Belts Justification Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. With this in mind, there are six key considerations to evaluate during the conveyor selection process: This function is integral to. One pulley, known as the drive pulley, drives or tows the belt, moving.. Conveyor Belts Justification.

From www.jingjinequipment.com

Belt Conveyors Types, Uses And Things To Consider When Choosing A Conveyor Belts Justification The belt forms a closed loop around the pulleys so it can continually rotate. One pulley, known as the drive pulley, drives or tows the belt, moving. The primary function of a conveyor belt is to move materials from one location to another. Cleaning the conveyor belt after the discharge point is essential to prevent misalignment, minimize material spillage and. Conveyor Belts Justification.

From www.youtube.com

Belt conveyor Power calculation YouTube Conveyor Belts Justification This function is integral to. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. The primary function of a conveyor belt is to move materials from one location to another. The belt forms a closed loop around the pulleys so it can continually. Conveyor Belts Justification.

From www.conveyorbelting.net

Sampla Belting Conveyor Belting Conveyor Belts Justification The primary function of a conveyor belt is to move materials from one location to another. With this in mind, there are six key considerations to evaluate during the conveyor selection process: The belt forms a closed loop around the pulleys so it can continually rotate. Belt conveyors are the most widely used and versatile mode of mechanical conveying systems. Conveyor Belts Justification.

From www.bloggerconnect.com.au

8 Basic Types of Conveyor Belts and Their Applications Conveyor Belts Justification Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. The belt forms a closed loop around the pulleys so it can continually rotate. Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: The primary function of a. Conveyor Belts Justification.

From www.iqsdirectory.com

Conveyor Belts What Is It? How Does It Work? Types, Parts Conveyor Belts Justification With this in mind, there are six key considerations to evaluate during the conveyor selection process: Cleaning the conveyor belt after the discharge point is essential to prevent misalignment, minimize material spillage and increase. Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: Belt conveyors are the most widely used and versatile mode of. Conveyor Belts Justification.

From www.youtube.com

Belt Conveyor Types of conveyor belt different Types of industrial Conveyor Belts Justification Cleaning the conveyor belt after the discharge point is essential to prevent misalignment, minimize material spillage and increase. Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: The primary function of a conveyor belt. Conveyor Belts Justification.

From www.iqsdirectory.com

Conveyor Belts What Is It? How Does It Work? Types, Parts Conveyor Belts Justification Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice. Conveyor Belts Justification.

From www.rubberconveyorbeltindian.com

How to choose a Heat Resistant Conveyor Belt Latest Blog Conveyor Belts Justification Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. This function is integral to. The primary function of a conveyor belt is to. Conveyor Belts Justification.

From www.youtube.com

Inclined Conveyor Belt with Flights YouTube Conveyor Belts Justification The primary function of a conveyor belt is to move materials from one location to another. One pulley, known as the drive pulley, drives or tows the belt, moving. Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. With this in mind, there are six key considerations to evaluate. Conveyor Belts Justification.

From denbydirect.com

7 Basic Types of Belt Conveyors One For Every Industry Denby Direct Conveyor Belts Justification With this in mind, there are six key considerations to evaluate during the conveyor selection process: The primary function of a conveyor belt is to move materials from one location to another. Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: Belt conveyors are available up to 72” wide and can operate at speeds. Conveyor Belts Justification.

From www.elixirphil.com

8 Basic Types of Conveyor Belts and Their Applications Blog Conveyor Belts Justification Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. The belt forms a closed loop around the pulleys so it can continually rotate. The primary function of a conveyor belt is to move materials from one location to another. With this in mind,. Conveyor Belts Justification.

From conveyors.lewcoinc.com

Chain Driven Roller Conveyor with Skewed Rollers for Product Conveyor Belts Justification One pulley, known as the drive pulley, drives or tows the belt, moving. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. With this in mind, there are six key considerations to evaluate during the conveyor selection process: Belt conveyors are the most. Conveyor Belts Justification.

From www.youtube.com

Conveyor Belt Installation Overview YouTube Conveyor Belts Justification Cleaning the conveyor belt after the discharge point is essential to prevent misalignment, minimize material spillage and increase. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. With this in mind, there are six key considerations to evaluate during the conveyor selection process:. Conveyor Belts Justification.

From www.iqsdirectory.com

Conveyor Belt What Is It? How Does It Work? Types, Parts Conveyor Belts Justification This function is integral to. One pulley, known as the drive pulley, drives or tows the belt, moving. The belt forms a closed loop around the pulleys so it can continually rotate. Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. Cleaning the conveyor belt after the discharge point. Conveyor Belts Justification.

From www.engineersdatabase.com

Conveyor Components The Engineers Database Conveyor Belts Justification Cleaning the conveyor belt after the discharge point is essential to prevent misalignment, minimize material spillage and increase. This function is integral to. The belt forms a closed loop around the pulleys so it can continually rotate. The primary function of a conveyor belt is to move materials from one location to another. Belt conveyors are available up to 72”. Conveyor Belts Justification.

From www.iqsdirectory.com

Conveyor Belts What Is It? How Does It Work? Types, Parts Conveyor Belts Justification Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. With this in mind, there are six key considerations to evaluate during the conveyor selection process: The primary function of a conveyor belt is to move materials from one location to another. This function. Conveyor Belts Justification.

From www.jmindustrial.com

Popular Methods and Procedure of Conveyor Belt Splicing JM Industrial Conveyor Belts Justification The primary function of a conveyor belt is to move materials from one location to another. With this in mind, there are six key considerations to evaluate during the conveyor selection process: Cleaning the conveyor belt after the discharge point is essential to prevent misalignment, minimize material spillage and increase. This function is integral to. Belt conveyors are available up. Conveyor Belts Justification.

From www.iqsdirectory.com

Belt Conveyors Components, Types, Design, and Applications Conveyor Belts Justification Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. Cleaning the conveyor belt after the discharge point is essential to prevent misalignment, minimize material spillage and increase. This function is integral to. One pulley, known as the drive pulley, drives or tows the. Conveyor Belts Justification.

From www.iqsdirectory.com

Conveyor Belt What Is It? How Does It Work? Types, Parts Conveyor Belts Justification One pulley, known as the drive pulley, drives or tows the belt, moving. Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. Belt conveyors are the most widely. Conveyor Belts Justification.

From www.iqsdirectory.com

Conveyor Belts What Is It? How Does It Work? Types, Parts Conveyor Belts Justification With this in mind, there are six key considerations to evaluate during the conveyor selection process: Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred. Conveyor Belts Justification.

From www.iqsdirectory.com

Belt Conveyors Components, Types, Design, and Applications Conveyor Belts Justification Cleaning the conveyor belt after the discharge point is essential to prevent misalignment, minimize material spillage and increase. Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. This function is integral to. The primary function of a conveyor belt is to move materials from one location to another. Iso. Conveyor Belts Justification.

From easy-systems.eu

Incline belt conveyor Belt conveyors Conveyor Belts Justification This function is integral to. One pulley, known as the drive pulley, drives or tows the belt, moving. Cleaning the conveyor belt after the discharge point is essential to prevent misalignment, minimize material spillage and increase. With this in mind, there are six key considerations to evaluate during the conveyor selection process: Belt conveyors are the most widely used and. Conveyor Belts Justification.

From www.dornerconveyors.com

Intralox Activated Roller Belt™ (ARB) Technology Dorner Conveyors Conveyor Belts Justification Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: This function is integral to. One pulley, known as the drive pulley, drives or tows the belt, moving. Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. Cleaning the conveyor belt after the discharge. Conveyor Belts Justification.

From baktisurabaya.com

10 Tipe Belt Conveyor Dan Material Belt Conveyor CV BAKTI Conveyor Belts Justification The belt forms a closed loop around the pulleys so it can continually rotate. The primary function of a conveyor belt is to move materials from one location to another. Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. Cleaning the conveyor belt after the discharge point is essential. Conveyor Belts Justification.

From www.researchgate.net

1. Basic components of a conveyor belt. Download Scientific Diagram Conveyor Belts Justification Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. One pulley, known as the drive pulley, drives or tows the belt, moving. This function is integral to. The belt forms a closed loop around the pulleys so it can continually rotate. Belt conveyors are available up to 72” wide. Conveyor Belts Justification.

From www.iqsdirectory.com

Conveyor Belts What Is It? How Does It Work? Types, Parts Conveyor Belts Justification This function is integral to. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making them the preferred choice for. With this in mind, there are six key considerations to evaluate during the conveyor selection process: The belt forms a closed loop around the pulleys so it can continually. Conveyor Belts Justification.

From clickmyemails.com

Choosing the right material for your conveyor belt Digital Marketing Conveyor Belts Justification The primary function of a conveyor belt is to move materials from one location to another. The belt forms a closed loop around the pulleys so it can continually rotate. Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. Iso 15236 consists of the following parts, under the general. Conveyor Belts Justification.

From rolmasterconveyors.ca

Belt Conveyors Rolmaster Conveyors Conveyor Belts Justification Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: The belt forms a closed loop around the pulleys so it can continually rotate. The primary function of a conveyor belt is to move materials. Conveyor Belts Justification.

From southquip.com

Plastic Modular Belt Conveyors Southquip Industrial Conveyor Belts Justification The belt forms a closed loop around the pulleys so it can continually rotate. Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. This function is integral to. Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (fpm), making. Conveyor Belts Justification.

From www.fnsheppard.com

What Are the Functions of the Conveyor Belt? • F.N. Sheppard Conveyor Belts Justification Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or. The belt forms a closed loop around the pulleys so it can continually rotate. The primary function of a conveyor belt is to move materials from one location to another. Iso 15236 consists of the following parts, under the general. Conveyor Belts Justification.

From www.econveyors.in

Optimizing Tracking of Belt Conveyor 5 Tips by Excel Conveyors Conveyor Belts Justification The primary function of a conveyor belt is to move materials from one location to another. One pulley, known as the drive pulley, drives or tows the belt, moving. This function is integral to. Iso 15236 consists of the following parts, under the general title steel cord conveyor belts: Belt conveyors are the most widely used and versatile mode of. Conveyor Belts Justification.