Materials In Car Body Engineering . Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical state during. Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. The main elements of selecting material especially for the body is involved in a wide variety of characteristics such as thermal, chemical or mechanical resistance, manufacturing efficiency and durability. General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and.

from procon.com.pk

Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical state during. Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. The main elements of selecting material especially for the body is involved in a wide variety of characteristics such as thermal, chemical or mechanical resistance, manufacturing efficiency and durability. Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest.

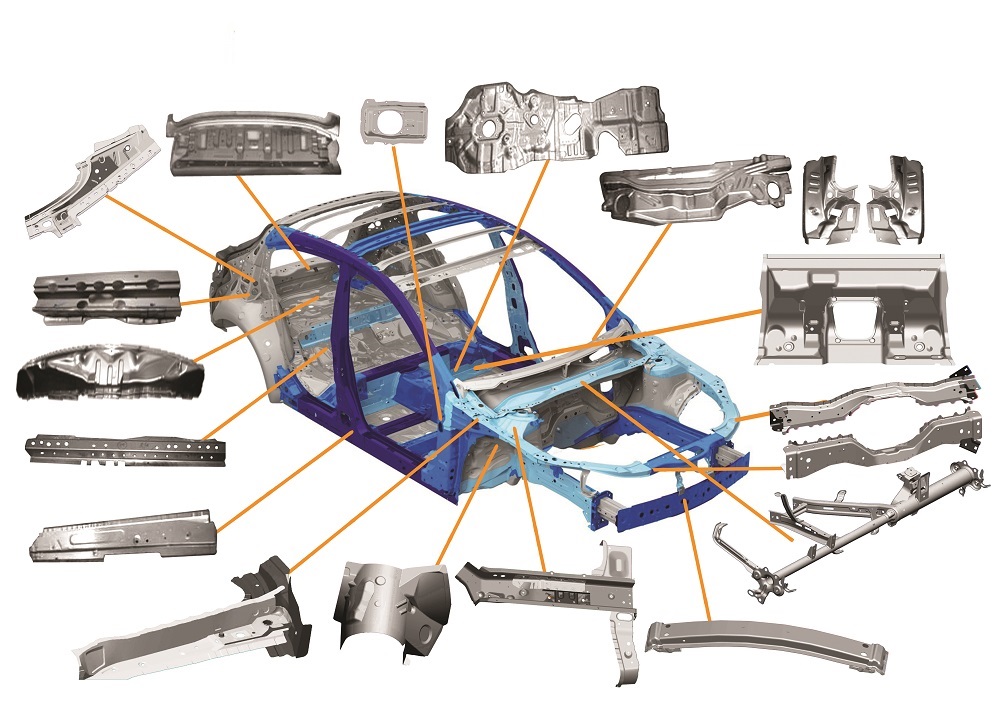

Sheet Metal Body Parts PROCON

Materials In Car Body Engineering Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical state during. The main elements of selecting material especially for the body is involved in a wide variety of characteristics such as thermal, chemical or mechanical resistance, manufacturing efficiency and durability. Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest.

From bargainsanyoprojectors.blogspot.com

How To Build A Custom Car Body INSPIRING BODYBUILDING Materials In Car Body Engineering Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical state during. Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. Based on a review of key factors bringing about change, three major trends in material usage for. Materials In Car Body Engineering.

From www.automotiveengineeringhq.com

The Automotive Design Engineer From A Z Materials In Car Body Engineering Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. Most of the polymers. Materials In Car Body Engineering.

From www.academia.edu

(PDF) Utilization of textile fabric waste as reinforcement for Materials In Car Body Engineering General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. The main elements of selecting material especially for the body is involved in a wide variety of characteristics such as thermal, chemical or mechanical resistance, manufacturing efficiency and durability. Most of the polymers used in car body engineering and manufacturing are reactive. Materials In Car Body Engineering.

From www.automotive-circle.com

Car Body Parts Materials and Forming Processes 2024 AutomotiveCircle Materials In Car Body Engineering Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical state during. Based. Materials In Car Body Engineering.

From newsroom.porsche.com

The body Intelligent mix of materials for maximum strength Porsche Materials In Car Body Engineering Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical state during. Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and.. Materials In Car Body Engineering.

From www.boronextrication.com

2015 Audi A3 Body Structure and Safety Systems Boron Extrication Materials In Car Body Engineering Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. General. Materials In Car Body Engineering.

From ahssinsights.org

Benefits of Tailored Products in Automotive Body Construction AHSS Materials In Car Body Engineering Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. The main elements of. Materials In Car Body Engineering.

From www.elastomer.kuraray.com

Advanced automotive polymer applications and plastics Kuraray Materials In Car Body Engineering Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. The main elements of selecting material especially for the body is involved in a wide variety of. Materials In Car Body Engineering.

From knaufautomotive.com

Automotive industry manufacturing of car components from environment Materials In Car Body Engineering Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. General. Materials In Car Body Engineering.

From www.aptgroup.com.cn

AP&T’s focus on highstrength aluminum at Automotive Circle — Materials Materials In Car Body Engineering General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical state during. Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw. Materials In Car Body Engineering.

From www.automotive-aluminium.com

Car Body Sheet Metal Haomei Aluminum Materials In Car Body Engineering Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. The main elements of selecting material especially for the body is involved in a wide variety of characteristics such as thermal, chemical or. Materials In Car Body Engineering.

From www.researchgate.net

Percentage use of various materials in car manufacturing and cost Materials In Car Body Engineering General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical state during. Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. Based on a review. Materials In Car Body Engineering.

From www.team-bhp.com

Different materials used in the making of our cars! TeamBHP Materials In Car Body Engineering Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. General. Materials In Car Body Engineering.

From www.youtube.com

L 09 Different types of Material Used in Car BodyAutomobile Chassis Materials In Car Body Engineering Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. The main elements of selecting material especially for the body is involved in a wide variety of characteristics such as thermal, chemical or mechanical resistance, manufacturing efficiency and durability. Most of the polymers used in car body engineering and. Materials In Car Body Engineering.

From www.mentorworks.ca

Future Automotive Manufacturing Process & Materials Mentor Works Materials In Car Body Engineering Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical. Materials In Car Body Engineering.

From www.linkedin.com

Lightweighting in car body engineering material substitution Materials In Car Body Engineering Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical state during. Based on a review. Materials In Car Body Engineering.

From engineering.report

Materials in Car Body Engineering 2020 Materials In Car Body Engineering Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. The main elements of selecting material especially for the body is involved in a wide variety of characteristics such as thermal, chemical. Materials In Car Body Engineering.

From autocomponentsindia.com

Lightweighting lies heavy on automotive industry Auto Components India Materials In Car Body Engineering Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical state during. General requirements for the new unisteel concept to become a viable material solution for steel car. Materials In Car Body Engineering.

From www.team-bhp.com

Different materials used in the making of our cars! TeamBHP Materials In Car Body Engineering Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. The main elements of selecting material especially for the body is involved in a wide variety of characteristics such as thermal, chemical or mechanical resistance, manufacturing efficiency and durability. General requirements for the new unisteel concept to become a viable material solution for steel. Materials In Car Body Engineering.

From www.mdpi.com

Materials Free FullText Current Trends in Automotive Materials In Car Body Engineering General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. The main elements of selecting. Materials In Car Body Engineering.

From www.pallkornmayer.com

Tesla Model 3 body in white — Pall Kornmayer Materials In Car Body Engineering Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical state during. General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. Here, we propose a. Materials In Car Body Engineering.

From procon.com.pk

Sheet Metal Body Parts PROCON Materials In Car Body Engineering General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. The main elements of selecting material especially for the body is involved in a wide variety of characteristics such as thermal,. Materials In Car Body Engineering.

From advtechconsultants.com

CompositeMaterial Materials In Car Body Engineering Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. Here, we propose a. Materials In Car Body Engineering.

From www.lightmetalage.com

New Gordon Murray Aluminum and Composite Auto Body Design Cuts Weight Materials In Car Body Engineering Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. Based on a review of. Materials In Car Body Engineering.

From baopusteel.com

Application Of Steel In The Automotive Industry Baopu Steel Materials In Car Body Engineering Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their. Materials In Car Body Engineering.

From carwow.co.uk

Car materials what they are and what they're good for carwow Materials In Car Body Engineering Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical state during. Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. General requirements for the new unisteel concept to become a viable material solution for steel car body. Materials In Car Body Engineering.

From www.carbodydesign.com

Audi A3 Materials in the body structure Car Body Design Materials In Car Body Engineering Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical state during. Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and.. Materials In Car Body Engineering.

From findcarsolution.com

Volkswagen Polo Review Specifications, Features and Price Find Car Materials In Car Body Engineering Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. The. Materials In Car Body Engineering.

From www.cf-composites.toray

Automotive Parts Processed Composites PRODUCTS Carbon Fiber Materials In Car Body Engineering Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical state during. General requirements for the new unisteel concept to become a viable material solution for steel car body. Materials In Car Body Engineering.

From www.pinterest.com

Materials for Automobile Bodies (eBook) The body book, Automobile Materials In Car Body Engineering Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. The main elements of selecting material especially for the body is involved in a wide variety of characteristics such as thermal, chemical or mechanical resistance, manufacturing efficiency and durability. Based on a review of key factors bringing about change, three major trends in material. Materials In Car Body Engineering.

From www.media.volvocars.com

Illustration of the body's metal construction in the V60 (safety cage Materials In Car Body Engineering Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. The main elements of selecting material especially for the body is involved in a wide variety of characteristics such as thermal, chemical or. Materials In Car Body Engineering.

From buzztum.com

Benefits of Injection Molding for Automotive Parts Manufacturing Materials In Car Body Engineering The main elements of selecting material especially for the body is involved in a wide variety of characteristics such as thermal, chemical or mechanical resistance, manufacturing efficiency and durability. Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. Most of the polymers used in car body engineering and manufacturing are reactive polymers that. Materials In Car Body Engineering.

From automotive.arcelormittal.com

Double door ring at Materials in Car Body Engineering 2021 Materials In Car Body Engineering Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. Most of the polymers. Materials In Car Body Engineering.

From automotive.arcelormittal.com

Materials in Car Body Engineering 2018 Materials In Car Body Engineering Materials in car body engineering is automotive circle’s annual expert conference in bad nauheim/germany, discussing latest. Here, we propose a novel metallurgy solution to accomplish the goal of unifying the sheet steel grades for automotive biw manufacturing. Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. General. Materials In Car Body Engineering.

From www.carsguide.com.au

Materials in Motion Metal CarsGuide OverSteer Materials In Car Body Engineering General requirements for the new unisteel concept to become a viable material solution for steel car body manufacturing. Based on a review of key factors bringing about change, three major trends in material usage for car bodies are identified and. Most of the polymers used in car body engineering and manufacturing are reactive polymers that change their chemical and physical. Materials In Car Body Engineering.