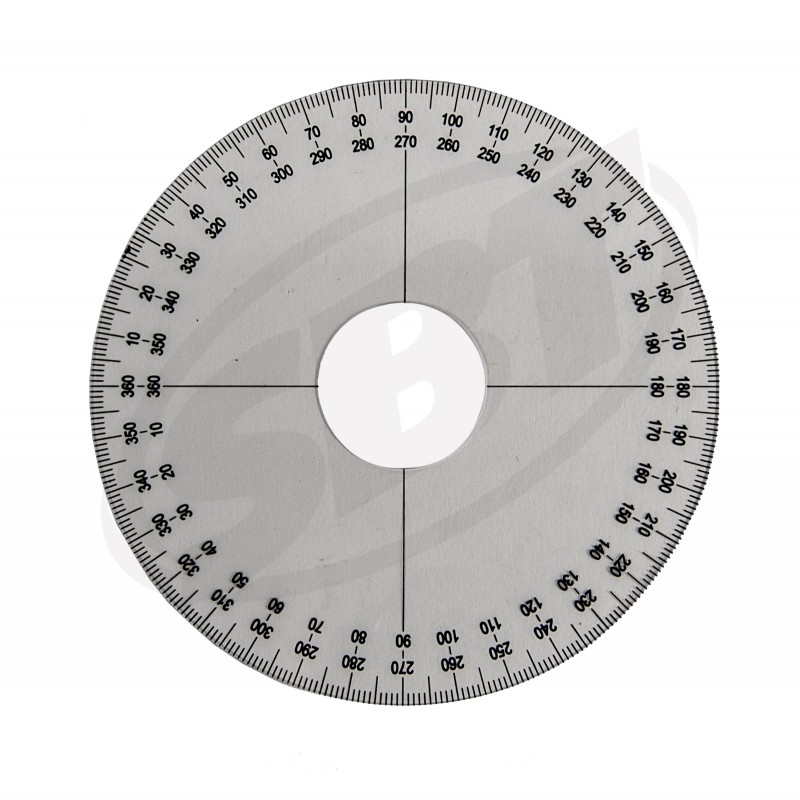

Timing Degree Wheel . In the end, there are a couple of ways to degree a cam. Learn what a camshaft degree wheel is and how to use it to synchronize the cam and crank positions in an engine. Having trouble degreeing your camshafts? With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. Learn how to accurately measure valve timing events with a degree wheel, dial indicator, cam card. Count the degrees from tdc to your. Most degree wheels allow you to measure in degrees from tdc (the zero mark) in both directions. A good old fashioned coat hanger, looped around one of the timing cover bolts and sharpened to a point on the opposite end works perfectly. Degree wheels are easy to find. Truing up the degree wheel. There're several ways to degree the camshaft position, but the most accurate and commonly used procedure is called the intake centerline method. The first step in degreeing a camshaft is to true up the degree wheel. We will need a few. A pointer can be purchased or easily fabricated.

from www.matosimport.com

Having trouble degreeing your camshafts? Truing up the degree wheel. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. We will need a few. Count the degrees from tdc to your. The first step in degreeing a camshaft is to true up the degree wheel. There're several ways to degree the camshaft position, but the most accurate and commonly used procedure is called the intake centerline method. Most degree wheels allow you to measure in degrees from tdc (the zero mark) in both directions. In the end, there are a couple of ways to degree a cam. Learn what a camshaft degree wheel is and how to use it to synchronize the cam and crank positions in an engine.

ENGINE DEGREE TIMING WHEEL, SEADOO

Timing Degree Wheel In the end, there are a couple of ways to degree a cam. Most degree wheels allow you to measure in degrees from tdc (the zero mark) in both directions. Learn what a camshaft degree wheel is and how to use it to synchronize the cam and crank positions in an engine. In the end, there are a couple of ways to degree a cam. Truing up the degree wheel. We will need a few. Degree wheels are easy to find. The first step in degreeing a camshaft is to true up the degree wheel. Count the degrees from tdc to your. Having trouble degreeing your camshafts? A good old fashioned coat hanger, looped around one of the timing cover bolts and sharpened to a point on the opposite end works perfectly. There're several ways to degree the camshaft position, but the most accurate and commonly used procedure is called the intake centerline method. Learn how to accurately measure valve timing events with a degree wheel, dial indicator, cam card. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. A pointer can be purchased or easily fabricated.

From sideways-technologies.co.uk

Printable Degree Wheel for ECU/MEGAJOLT ETC Ignition, ECU and Fuel Timing Degree Wheel Having trouble degreeing your camshafts? In the end, there are a couple of ways to degree a cam. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. Degree wheels are easy to find. The first step in degreeing. Timing Degree Wheel.

From jetskiparts.com

SeaDoo Rotary Valve Timing Degree Wheel 580 587 650 657 717 720 787 80 Timing Degree Wheel Learn what a camshaft degree wheel is and how to use it to synchronize the cam and crank positions in an engine. Degree wheels are easy to find. Truing up the degree wheel. A good old fashioned coat hanger, looped around one of the timing cover bolts and sharpened to a point on the opposite end works perfectly. We will. Timing Degree Wheel.

From printable.conaresvirtual.edu.sv

Printable Degree Wheel Timing Degree Wheel Count the degrees from tdc to your. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. Learn how to accurately measure valve timing events with a degree wheel, dial indicator, cam card. Most degree wheels allow you to. Timing Degree Wheel.

From www.opelgt.com

Cam timing degree wheel Timing Degree Wheel A good old fashioned coat hanger, looped around one of the timing cover bolts and sharpened to a point on the opposite end works perfectly. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. A pointer can be. Timing Degree Wheel.

From www.motorcycleid.com

Motion Pro® 080092 Engine Timing Degree Wheel Timing Degree Wheel Most degree wheels allow you to measure in degrees from tdc (the zero mark) in both directions. We will need a few. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. There're several ways to degree the camshaft. Timing Degree Wheel.

From www.cardinalsracing.com

Camshaft Timing Degree Wheel Cardinals Racing Timing Degree Wheel Having trouble degreeing your camshafts? With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. We will need a few. In the end, there are a couple of ways to degree a cam. There're several ways to degree the. Timing Degree Wheel.

From pwrdrvndsl1de1.wpenginepowered.com

Degree Wheel for Timing Adjustment Power Driven Diesel Timing Degree Wheel Having trouble degreeing your camshafts? Truing up the degree wheel. We will need a few. Most degree wheels allow you to measure in degrees from tdc (the zero mark) in both directions. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to. Timing Degree Wheel.

From www.pinterest.com

DOO ROTARY VALVE TIMING DEGREE WHEEL TOOL SP SPI SPX GTI GTS GTX HX XP Timing Degree Wheel Degree wheels are easy to find. Having trouble degreeing your camshafts? A pointer can be purchased or easily fabricated. The first step in degreeing a camshaft is to true up the degree wheel. There're several ways to degree the camshaft position, but the most accurate and commonly used procedure is called the intake centerline method. Count the degrees from tdc. Timing Degree Wheel.

From racetoolsdirect.com

Moroso Camshaft Degree Wheel 11 inch incar Race Tools Direct Timing Degree Wheel Most degree wheels allow you to measure in degrees from tdc (the zero mark) in both directions. Learn how to accurately measure valve timing events with a degree wheel, dial indicator, cam card. Count the degrees from tdc to your. A pointer can be purchased or easily fabricated. A good old fashioned coat hanger, looped around one of the timing. Timing Degree Wheel.

From www.onallcylinders.com

Tool Tech An Overview of Camshaft Degree Wheels Timing Degree Wheel A pointer can be purchased or easily fabricated. Learn how to accurately measure valve timing events with a degree wheel, dial indicator, cam card. Truing up the degree wheel. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center.. Timing Degree Wheel.

From www.unitedtools.com.my

Precision TDC Timing Degree Wheel for Engine Timing Functions Timing Degree Wheel With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. A pointer can be purchased or easily fabricated. There're several ways to degree the camshaft position, but the most accurate and commonly used procedure is called the intake centerline. Timing Degree Wheel.

From shopee.com.my

CARDINALS Camshaft Timing Degree Wheel Shopee Malaysia Timing Degree Wheel A pointer can be purchased or easily fabricated. Degree wheels are easy to find. In the end, there are a couple of ways to degree a cam. Most degree wheels allow you to measure in degrees from tdc (the zero mark) in both directions. Learn how to accurately measure valve timing events with a degree wheel, dial indicator, cam card.. Timing Degree Wheel.

From www.printablee.com

7 Best Images of Printable Degree Templates College Degree Diploma Timing Degree Wheel A pointer can be purchased or easily fabricated. In the end, there are a couple of ways to degree a cam. Having trouble degreeing your camshafts? Count the degrees from tdc to your. We will need a few. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need. Timing Degree Wheel.

From ubicaciondepersonas.cdmx.gob.mx

Subaru Engine Timing Degree Disc Wheel Black Anodised Aluminium Timing Degree Wheel Learn how to accurately measure valve timing events with a degree wheel, dial indicator, cam card. Having trouble degreeing your camshafts? With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. Most degree wheels allow you to measure in. Timing Degree Wheel.

From www.cardinalsracing.com

Camshaft Timing Degree Wheel Cardinals Racing Timing Degree Wheel In the end, there are a couple of ways to degree a cam. Truing up the degree wheel. The first step in degreeing a camshaft is to true up the degree wheel. Most degree wheels allow you to measure in degrees from tdc (the zero mark) in both directions. Having trouble degreeing your camshafts? We will need a few. Degree. Timing Degree Wheel.

From www.lowbrowcustoms.com

British Standard Triumph Ignition Timing Degree Wheel Early Up to Timing Degree Wheel A pointer can be purchased or easily fabricated. Learn how to accurately measure valve timing events with a degree wheel, dial indicator, cam card. A good old fashioned coat hanger, looped around one of the timing cover bolts and sharpened to a point on the opposite end works perfectly. The first step in degreeing a camshaft is to true up. Timing Degree Wheel.

From www.ebay.co.uk

TDC Timing Degree Wheel T&E Tools 4096 eBay Timing Degree Wheel Most degree wheels allow you to measure in degrees from tdc (the zero mark) in both directions. A pointer can be purchased or easily fabricated. We will need a few. There're several ways to degree the camshaft position, but the most accurate and commonly used procedure is called the intake centerline method. A good old fashioned coat hanger, looped around. Timing Degree Wheel.

From www.pinterest.com

Printable+360+Degree+Protractor Degrees, 360 degree, Printables Timing Degree Wheel Learn what a camshaft degree wheel is and how to use it to synchronize the cam and crank positions in an engine. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. In the end, there are a couple. Timing Degree Wheel.

From powerdrivendiesel.com

Degree Wheel for Timing Adjustment Power Driven Diesel Timing Degree Wheel Degree wheels are easy to find. A pointer can be purchased or easily fabricated. In the end, there are a couple of ways to degree a cam. Count the degrees from tdc to your. There're several ways to degree the camshaft position, but the most accurate and commonly used procedure is called the intake centerline method. The first step in. Timing Degree Wheel.

From printable.mist-bd.org

Printable Degree Wheel Timing Degree Wheel Having trouble degreeing your camshafts? Truing up the degree wheel. A pointer can be purchased or easily fabricated. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. The first step in degreeing a camshaft is to true up. Timing Degree Wheel.

From www.ebay.co.uk

Triumph Degree Wheel 500 650 Timing Tool 196368 Points Models T100 Timing Degree Wheel Degree wheels are easy to find. Having trouble degreeing your camshafts? Learn what a camshaft degree wheel is and how to use it to synchronize the cam and crank positions in an engine. A good old fashioned coat hanger, looped around one of the timing cover bolts and sharpened to a point on the opposite end works perfectly. In the. Timing Degree Wheel.

From www.motionpro.com

Degree Wheel, Eng. Timing Motion Pro Timing Degree Wheel With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. The first step in degreeing a camshaft is to true up the degree wheel. Most degree wheels allow you to measure in degrees from tdc (the zero mark) in. Timing Degree Wheel.

From www.matosimport.com

ENGINE DEGREE TIMING WHEEL, SEADOO Timing Degree Wheel Having trouble degreeing your camshafts? In the end, there are a couple of ways to degree a cam. Most degree wheels allow you to measure in degrees from tdc (the zero mark) in both directions. The first step in degreeing a camshaft is to true up the degree wheel. A pointer can be purchased or easily fabricated. Learn how to. Timing Degree Wheel.

From mossmotors.com

Engine Timing Degree Wheel Moss Motors Timing Degree Wheel Degree wheels are easy to find. A good old fashioned coat hanger, looped around one of the timing cover bolts and sharpened to a point on the opposite end works perfectly. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top. Timing Degree Wheel.

From www.summitracing.com

BikeMaster 151639 BikeMaster Timing Degree Wheels Summit Racing Timing Degree Wheel Learn what a camshaft degree wheel is and how to use it to synchronize the cam and crank positions in an engine. Count the degrees from tdc to your. Truing up the degree wheel. A good old fashioned coat hanger, looped around one of the timing cover bolts and sharpened to a point on the opposite end works perfectly. Learn. Timing Degree Wheel.

From www.americanmototire.com

Motion Pro Degree Wheel (080092) American Moto Tire Timing Degree Wheel The first step in degreeing a camshaft is to true up the degree wheel. Degree wheels are easy to find. In the end, there are a couple of ways to degree a cam. Learn what a camshaft degree wheel is and how to use it to synchronize the cam and crank positions in an engine. Having trouble degreeing your camshafts?. Timing Degree Wheel.

From www.baxtercycle.com

Timing Degree Wheel Kit 1968 and Earlier Baxter Cycle Timing Degree Wheel Learn how to accurately measure valve timing events with a degree wheel, dial indicator, cam card. Count the degrees from tdc to your. A pointer can be purchased or easily fabricated. Most degree wheels allow you to measure in degrees from tdc (the zero mark) in both directions. There're several ways to degree the camshaft position, but the most accurate. Timing Degree Wheel.

From printablejd.com

Printable Compass Degrees Printable JD Timing Degree Wheel With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. The first step in degreeing a camshaft is to true up the degree wheel. Degree wheels are easy to find. In the end, there are a couple of ways. Timing Degree Wheel.

From www.mgexp.com

[Solved] Cam timing wheel info MGA Forum The MG Experience Timing Degree Wheel Degree wheels are easy to find. The first step in degreeing a camshaft is to true up the degree wheel. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. We will need a few. Truing up the degree. Timing Degree Wheel.

From printable.mist-bd.org

Printable Degree Wheel Timing Degree Wheel A pointer can be purchased or easily fabricated. Count the degrees from tdc to your. Truing up the degree wheel. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. The first step in degreeing a camshaft is to. Timing Degree Wheel.

From mail.squarebirds.org

Degreeing your CAM Timing Degree Wheel Count the degrees from tdc to your. The first step in degreeing a camshaft is to true up the degree wheel. A good old fashioned coat hanger, looped around one of the timing cover bolts and sharpened to a point on the opposite end works perfectly. Having trouble degreeing your camshafts? We will need a few. Learn what a camshaft. Timing Degree Wheel.

From garage.grumpysperformance.com

finding top dead center 1 for timing ignition & cam Grumpys Timing Degree Wheel In the end, there are a couple of ways to degree a cam. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted to the crankshaft, you need to set piston number one to top dead center. A pointer can be purchased or easily fabricated. Most degree wheels allow you to measure in. Timing Degree Wheel.

From www.pinterest.com

Timing Degree Wheel Timing Degree Wheel Learn how to accurately measure valve timing events with a degree wheel, dial indicator, cam card. Having trouble degreeing your camshafts? The first step in degreeing a camshaft is to true up the degree wheel. A good old fashioned coat hanger, looped around one of the timing cover bolts and sharpened to a point on the opposite end works perfectly.. Timing Degree Wheel.

From www.onallcylinders.com

Tool Tech An Overview of Camshaft Degree Wheels Timing Degree Wheel Learn how to accurately measure valve timing events with a degree wheel, dial indicator, cam card. Having trouble degreeing your camshafts? There're several ways to degree the camshaft position, but the most accurate and commonly used procedure is called the intake centerline method. With the timing set adjusted to zero degrees of advance or retard and the degree wheel bolted. Timing Degree Wheel.

From mungfali.com

Printable Degree Wheel For Engines Timing Degree Wheel The first step in degreeing a camshaft is to true up the degree wheel. We will need a few. A pointer can be purchased or easily fabricated. There're several ways to degree the camshaft position, but the most accurate and commonly used procedure is called the intake centerline method. A good old fashioned coat hanger, looped around one of the. Timing Degree Wheel.