End Mill Milling Process . the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps: This is not a very complicated process and you can carry end milling out using the following. end milling is an exceptional cnc milling process you can use to make a variety of contours and specific designs not. end milling is a cutting process that uses rotating tools to remove material from a workpiece. End milling is a versatile type. end milling process. we will cover the different types of end mills and feature the advantages of the process. They come in various types,. end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal.

from www.hobby-machinist.com

end milling process. end milling is a cutting process that uses rotating tools to remove material from a workpiece. end milling is an exceptional cnc milling process you can use to make a variety of contours and specific designs not. End milling is a versatile type. They come in various types,. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps: end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. we will cover the different types of end mills and feature the advantages of the process. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. This is not a very complicated process and you can carry end milling out using the following.

What end mill for brass? Copper? Page 2 The HobbyMachinist

End Mill Milling Process This is not a very complicated process and you can carry end milling out using the following. This is not a very complicated process and you can carry end milling out using the following. end milling process. end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. we will cover the different types of end mills and feature the advantages of the process. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. end milling is an exceptional cnc milling process you can use to make a variety of contours and specific designs not. They come in various types,. end milling is a cutting process that uses rotating tools to remove material from a workpiece. End milling is a versatile type. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps:

From www.dreamstime.com

The Press Die Manufacturing Process by CNC Milling Machine with Ball End Mill Milling Process end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. we will cover the different types of end mills and feature the advantages of the process. end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. the best accuracy and productivity will. End Mill Milling Process.

From www.dreamstime.com

The Press Die Manufacturing Process by CNC Milling Machine with Ball End Mill Milling Process This is not a very complicated process and you can carry end milling out using the following. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps: They come in various types,. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal.. End Mill Milling Process.

From www.youtube.com

Crash Course in Milling Chapter 8 Choosing & Using Endmills, by End Mill Milling Process End milling is a versatile type. end milling process. This is not a very complicated process and you can carry end milling out using the following. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and. End Mill Milling Process.

From www.youtube.com

VERTICAL MILLING OPERATION USE OF END MILL CUTTER . YouTube End Mill Milling Process end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. End milling is a versatile type. end milling is an exceptional cnc milling process you can use to make a variety of contours and specific designs not. end milling is a cutting process that uses rotating tools to remove material from a workpiece.. End Mill Milling Process.

From www.dreamstime.com

Milling Metalworking Process. Industrial CNC Metal Machining by End Mill Milling Process end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. end milling is an exceptional cnc milling process you can use to make a variety of contours and specific designs not. we will cover the different types of end mills and feature the advantages of the process.. End Mill Milling Process.

From www.cnccookbook.com

Ball Nose End Mill [Easy Guide to Ball Cutters] CNCCookbook Be A End Mill Milling Process This is not a very complicated process and you can carry end milling out using the following. end milling is an exceptional cnc milling process you can use to make a variety of contours and specific designs not. end milling is a cutting process that uses rotating tools to remove material from a workpiece. End milling is a. End Mill Milling Process.

From www.speedtigertools.com

End Mill Size Standards Chart & IntroductionSPEED TIGER End Mill Milling Process end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. end milling process. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps: This is not a very complicated process and you can carry end milling out using the following. . End Mill Milling Process.

From advancedtool.com

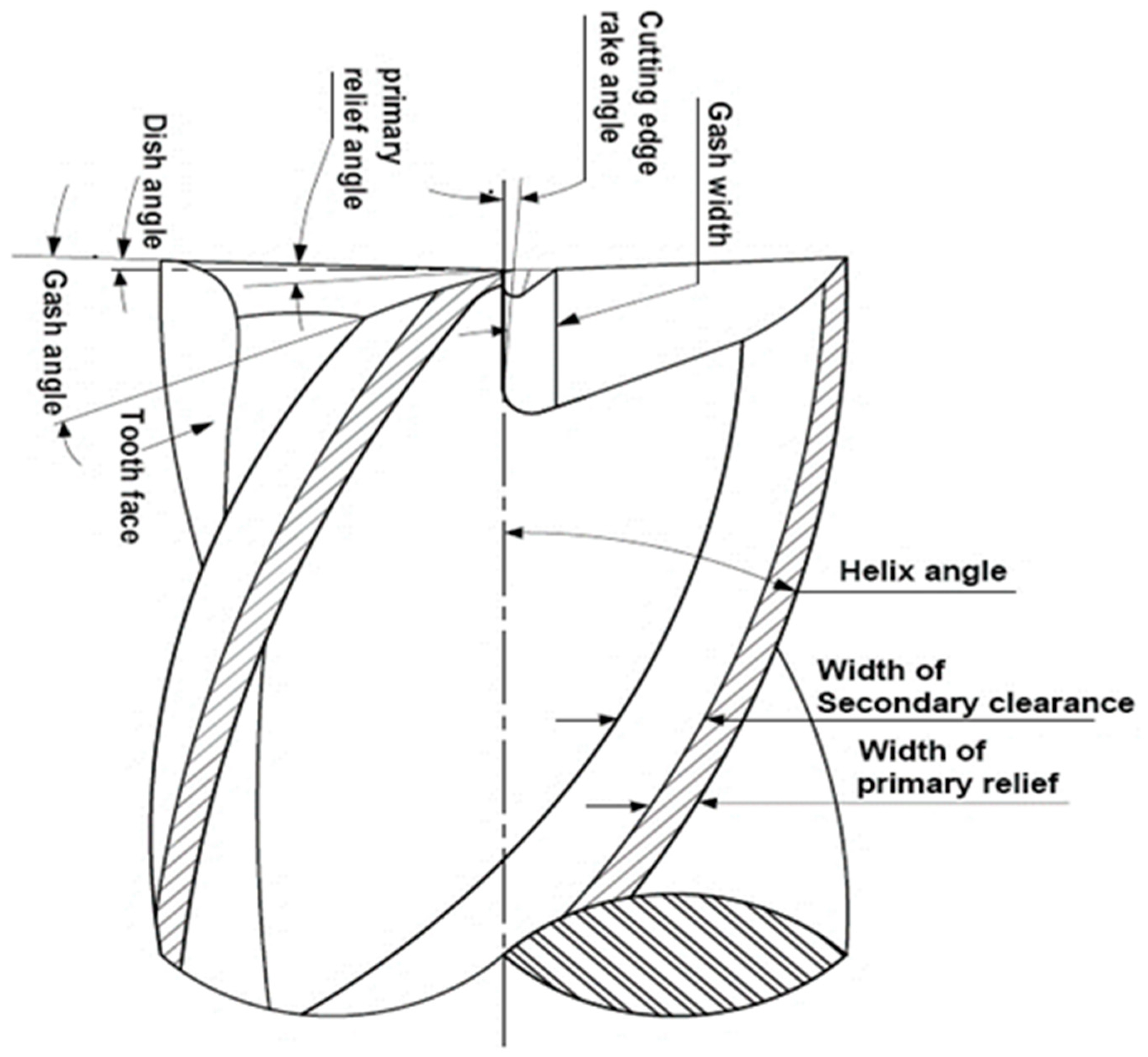

End Mill Anatomy 101 End Mill Milling Process End milling is a versatile type. end milling process. end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. we will cover the different types of end mills and feature the advantages. End Mill Milling Process.

From www.dreamstime.com

The Press Die Manufacturing Process by CNC Milling Machine with Ball End Mill Milling Process They come in various types,. end milling is an exceptional cnc milling process you can use to make a variety of contours and specific designs not. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps: This is not a very complicated process and you can. End Mill Milling Process.

From www.alamy.com

End mill processes a plastic sheet on a CNC milling machine, closeup End Mill Milling Process end milling is an exceptional cnc milling process you can use to make a variety of contours and specific designs not. They come in various types,. end milling is a cutting process that uses rotating tools to remove material from a workpiece. we will cover the different types of end mills and feature the advantages of the. End Mill Milling Process.

From www.dreamstime.com

End Mill Processes Plastic on CNC Milling Machine Stock Photo Image End Mill Milling Process This is not a very complicated process and you can carry end milling out using the following. we will cover the different types of end mills and feature the advantages of the process. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. end milling is a cutting process that uses rotating tools. End Mill Milling Process.

From us.misumi-ec.com

Milling Tips / Holders Shoulder End Mills Technical Information End Mill Milling Process This is not a very complicated process and you can carry end milling out using the following. end milling process. end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. we will cover the different types of end mills and feature the advantages of the process. . End Mill Milling Process.

From www.canadianmetalworking.com

Technology Spotlight Solidcarbide End Mill End Mill Milling Process end milling process. This is not a very complicated process and you can carry end milling out using the following. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps: End. End Mill Milling Process.

From endmill.com.au

Choosing the right end mill for the job Adam's Bits End Mill Milling Process End milling is a versatile type. They come in various types,. end milling is an exceptional cnc milling process you can use to make a variety of contours and specific designs not. end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. This is not a very complicated. End Mill Milling Process.

From www.dreamstime.com

End Mill Processes Plastic Sheet on a CNC Milling Machine Stock Image End Mill Milling Process end milling is a cutting process that uses rotating tools to remove material from a workpiece. we will cover the different types of end mills and feature the advantages of the process. end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. the best accuracy and. End Mill Milling Process.

From www.dreamstime.com

The Mold and Die Manufacturing Process by CNC Milling Machine with Ball End Mill Milling Process end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. end milling is an exceptional cnc milling process you can use to make a variety of contours and specific designs not. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. end. End Mill Milling Process.

From www.hobby-machinist.com

What end mill for brass? Copper? Page 2 The HobbyMachinist End Mill Milling Process This is not a very complicated process and you can carry end milling out using the following. End milling is a versatile type. end milling is a cutting process that uses rotating tools to remove material from a workpiece. we will cover the different types of end mills and feature the advantages of the process. They come in. End Mill Milling Process.

From toolnotes.com

Milling Operations ToolNotes End Mill Milling Process They come in various types,. end milling process. end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. This is not a very complicated process and you can carry end milling out using the following. we will cover the different types of end mills and feature the. End Mill Milling Process.

From www.dreamstime.com

The Press Die Manufacturing Process by CNC Milling Machine with Ball End Mill Milling Process End milling is a versatile type. we will cover the different types of end mills and feature the advantages of the process. end milling is a cutting process that uses rotating tools to remove material from a workpiece. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided. End Mill Milling Process.

From www.dreamstime.com

The Press Die Manufacturing Process by CNC Milling Machine with Ball End Mill Milling Process This is not a very complicated process and you can carry end milling out using the following. end milling process. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps: They come in various types,. end milling is a machining process used in metalworking, woodworking,. End Mill Milling Process.

From dxolmoxoz.blob.core.windows.net

End Mill Projects at Sally Williams blog End Mill Milling Process end milling is a cutting process that uses rotating tools to remove material from a workpiece. End milling is a versatile type. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps: This is not a very complicated process and you can carry end milling out. End Mill Milling Process.

From www.speedtigertools.com

End Mill Cutting & End Milling Technical Guide End Mill Milling Process End milling is a versatile type. They come in various types,. end milling process. end milling is a cutting process that uses rotating tools to remove material from a workpiece. end milling is an exceptional cnc milling process you can use to make a variety of contours and specific designs not. This is not a very complicated. End Mill Milling Process.

From www.creatingway.com

Guide on the End Milling Process and Various End Mills End Mill Milling Process we will cover the different types of end mills and feature the advantages of the process. End milling is a versatile type. end milling is an exceptional cnc milling process you can use to make a variety of contours and specific designs not. end milling is the operation of producing a flat surface which may be vertical,. End Mill Milling Process.

From www.youtube.com

Differences between Drilling and End Milling (Drill Vs End Mill) YouTube End Mill Milling Process end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. This is not a very complicated process and you can carry end milling out using the following. They come in various types,. end milling process. end milling is a cutting process that uses rotating tools to remove. End Mill Milling Process.

From epictool.ca

End Milling Solutions Epic Tool End Mill Milling Process This is not a very complicated process and you can carry end milling out using the following. we will cover the different types of end mills and feature the advantages of the process. They come in various types,. end milling process. End milling is a versatile type. the best accuracy and productivity will be achieved if the. End Mill Milling Process.

From exosgntvc.blob.core.windows.net

Slab Milling Process at Hortense Findley blog End Mill Milling Process End milling is a versatile type. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps: we will cover the different types of end mills and feature the advantages of the process. They come in various types,. end milling is a cutting process that uses. End Mill Milling Process.

From www.dreamstime.com

End Mill Processes a Plastic Sheet on a CNC Milling Machine Stock Image End Mill Milling Process end milling is a cutting process that uses rotating tools to remove material from a workpiece. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. This is not a very complicated process and you can carry end milling out using the following. end milling is the operation of producing a flat surface. End Mill Milling Process.

From www.alamy.com

End mill processes a detail on a CNC milling machine, closeup photo End Mill Milling Process we will cover the different types of end mills and feature the advantages of the process. They come in various types,. end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. the best accuracy and productivity will be achieved if the operation employs an undersized end mill,. End Mill Milling Process.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools End Mill Milling Process end milling is a cutting process that uses rotating tools to remove material from a workpiece. end milling process. This is not a very complicated process and you can carry end milling out using the following. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two. End Mill Milling Process.

From www.dreamstime.com

The Press Die Manufacturing Process by CNC Milling Machine with Radius End Mill Milling Process end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. end milling process. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps: end milling is an exceptional cnc milling process you can use. End Mill Milling Process.

From www.dreamstime.com

The Ball End Mill Tool Regrinding Process on Regrinding Machine Stock End Mill Milling Process end milling is the operation of producing a flat surface which may be vertical, horizontal, or at an angle about. end milling process. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps: This is not a very complicated process and you can carry end. End Mill Milling Process.

From epictool.ca

Get to Know the Differences between Horizontal vs Vertical Milling End Mill Milling Process end milling is an exceptional cnc milling process you can use to make a variety of contours and specific designs not. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps: end milling is a machining process used in metalworking, woodworking, and other material shaping/removal.. End Mill Milling Process.

From www.alamy.com

End mill processes the textolite sheet on a CNC milling machine Stock End Mill Milling Process end milling is an exceptional cnc milling process you can use to make a variety of contours and specific designs not. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps: end milling is the operation of producing a flat surface which may be vertical,. End Mill Milling Process.

From www.dreamstime.com

Milling Metalworking Process. Industrial CNC Metal Machining by End Mill Milling Process End milling is a versatile type. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. we will cover the different types of end mills and feature the advantages of the process. the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two. End Mill Milling Process.

From www.penntoolco.com

The Basic Types of End Mills Used in Milling Penn Tool Co., Inc End Mill Milling Process the best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two steps: end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. This is not a very complicated process and you can carry end milling out using the following. end milling is a. End Mill Milling Process.