Sand Blaster Gun Not Working . If your sandblaster is not feeding sand, there could be several reasons for this. If your blast gun is not drawing any abrasive, turn off the compressed air supply. Often particles removed from the part being processed get into the abrasive and sieve down to the. Remove the nozzle from the. The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. If the size is not right, it will affect the. 1) air pressure issues : One of the most common reasons for flow problems in a sandblaster is an inadequate air compressor. If the sandblaster is blowing air but not picking up any sand, check the nozzle size. Firstly, check for clogs in the nozzle and ensure. Sand blasters produce high noise levels and dust that can be dangerous if not operated properly; 5 common causes of abrasive flow problems and how to fix them.

from www.sandblasters.co.uk

1) air pressure issues : One of the most common reasons for flow problems in a sandblaster is an inadequate air compressor. Sand blasters produce high noise levels and dust that can be dangerous if not operated properly; If your sandblaster is not feeding sand, there could be several reasons for this. If the sandblaster is blowing air but not picking up any sand, check the nozzle size. The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. Often particles removed from the part being processed get into the abrasive and sieve down to the. If the size is not right, it will affect the. If your blast gun is not drawing any abrasive, turn off the compressed air supply. Remove the nozzle from the.

A Guide to Sand Blast

Sand Blaster Gun Not Working Firstly, check for clogs in the nozzle and ensure. The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. 5 common causes of abrasive flow problems and how to fix them. Sand blasters produce high noise levels and dust that can be dangerous if not operated properly; If your blast gun is not drawing any abrasive, turn off the compressed air supply. 1) air pressure issues : Often particles removed from the part being processed get into the abrasive and sieve down to the. Firstly, check for clogs in the nozzle and ensure. If your sandblaster is not feeding sand, there could be several reasons for this. Remove the nozzle from the. One of the most common reasons for flow problems in a sandblaster is an inadequate air compressor. If the size is not right, it will affect the. If the sandblaster is blowing air but not picking up any sand, check the nozzle size.

From badboyblasters.com

ABRASIVE MEDIA SAND BLASTER BB2260LEDBVRPRHVFL Sand Blaster Gun Not Working Remove the nozzle from the. Sand blasters produce high noise levels and dust that can be dangerous if not operated properly; If your blast gun is not drawing any abrasive, turn off the compressed air supply. If your sandblaster is not feeding sand, there could be several reasons for this. The first reason that your sandblaster flow is not proper. Sand Blaster Gun Not Working.

From www.ebay.co.uk

Switzer Portable Sand Blaster 38L 10 Gallon Mobile Sand Bead Blasting Gun Incl 5055418300124 Sand Blaster Gun Not Working 1) air pressure issues : One of the most common reasons for flow problems in a sandblaster is an inadequate air compressor. If the sandblaster is blowing air but not picking up any sand, check the nozzle size. 5 common causes of abrasive flow problems and how to fix them. If your blast gun is not drawing any abrasive, turn. Sand Blaster Gun Not Working.

From www.amazon.com

Sand Blaster Gun Kit, Portable Sandblaster, Adjustable Pneumatic Sandblasting Gun Set, 90psi Sand Blaster Gun Not Working Often particles removed from the part being processed get into the abrasive and sieve down to the. 5 common causes of abrasive flow problems and how to fix them. 1) air pressure issues : Firstly, check for clogs in the nozzle and ensure. If the size is not right, it will affect the. If the sandblaster is blowing air but. Sand Blaster Gun Not Working.

From device.report

WILTEC 61303 Air Sand Blaster Gun User Manual Sand Blaster Gun Not Working Remove the nozzle from the. 5 common causes of abrasive flow problems and how to fix them. If the sandblaster is blowing air but not picking up any sand, check the nozzle size. 1) air pressure issues : Sand blasters produce high noise levels and dust that can be dangerous if not operated properly; If your blast gun is not. Sand Blaster Gun Not Working.

From www.mydreamality.com

What Is a Sand Blast Booth and Why We Need It My Dreamality Sand Blaster Gun Not Working If your blast gun is not drawing any abrasive, turn off the compressed air supply. Remove the nozzle from the. If the sandblaster is blowing air but not picking up any sand, check the nozzle size. 1) air pressure issues : 5 common causes of abrasive flow problems and how to fix them. Often particles removed from the part being. Sand Blaster Gun Not Working.

From www.alamy.com

Sandblasting machine hires stock photography and images Alamy Sand Blaster Gun Not Working The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. If your blast gun is not drawing any abrasive, turn off the compressed air supply. 1) air pressure issues : If the size is not right, it will affect the. Remove the nozzle from the. 5. Sand Blaster Gun Not Working.

From shuntool.com

Sand Blast Gun No Vacuum, Big Mess ShunTool Sand Blaster Gun Not Working If the size is not right, it will affect the. If your blast gun is not drawing any abrasive, turn off the compressed air supply. 5 common causes of abrasive flow problems and how to fix them. Firstly, check for clogs in the nozzle and ensure. One of the most common reasons for flow problems in a sandblaster is an. Sand Blaster Gun Not Working.

From www.amazon.co.uk

Improved Sandblaster Sand Blaster Gun Kit, Soda Blaster, Professional Sand Blasters, Media Sand Blaster Gun Not Working 1) air pressure issues : If the size is not right, it will affect the. The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. Often particles removed from the part being processed get into the abrasive and sieve down to the. If your blast gun. Sand Blaster Gun Not Working.

From www.desertcart.ph

LE LEMATEC Sand Blaster Gun Kit, Rust Remover and Paint Stripper, Continuous Blasting Sand Blaster Gun Not Working If your blast gun is not drawing any abrasive, turn off the compressed air supply. The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. Often particles removed from the part being processed get into the abrasive and sieve down to the. 1) air pressure issues. Sand Blaster Gun Not Working.

From flavored.ph

Automotive Tools & Supplies DHL Ship LEMATEC Sand Blasting Nozzle Gun Sandblaster Portable Speed Sand Blaster Gun Not Working One of the most common reasons for flow problems in a sandblaster is an inadequate air compressor. 5 common causes of abrasive flow problems and how to fix them. If the size is not right, it will affect the. If your sandblaster is not feeding sand, there could be several reasons for this. The first reason that your sandblaster flow. Sand Blaster Gun Not Working.

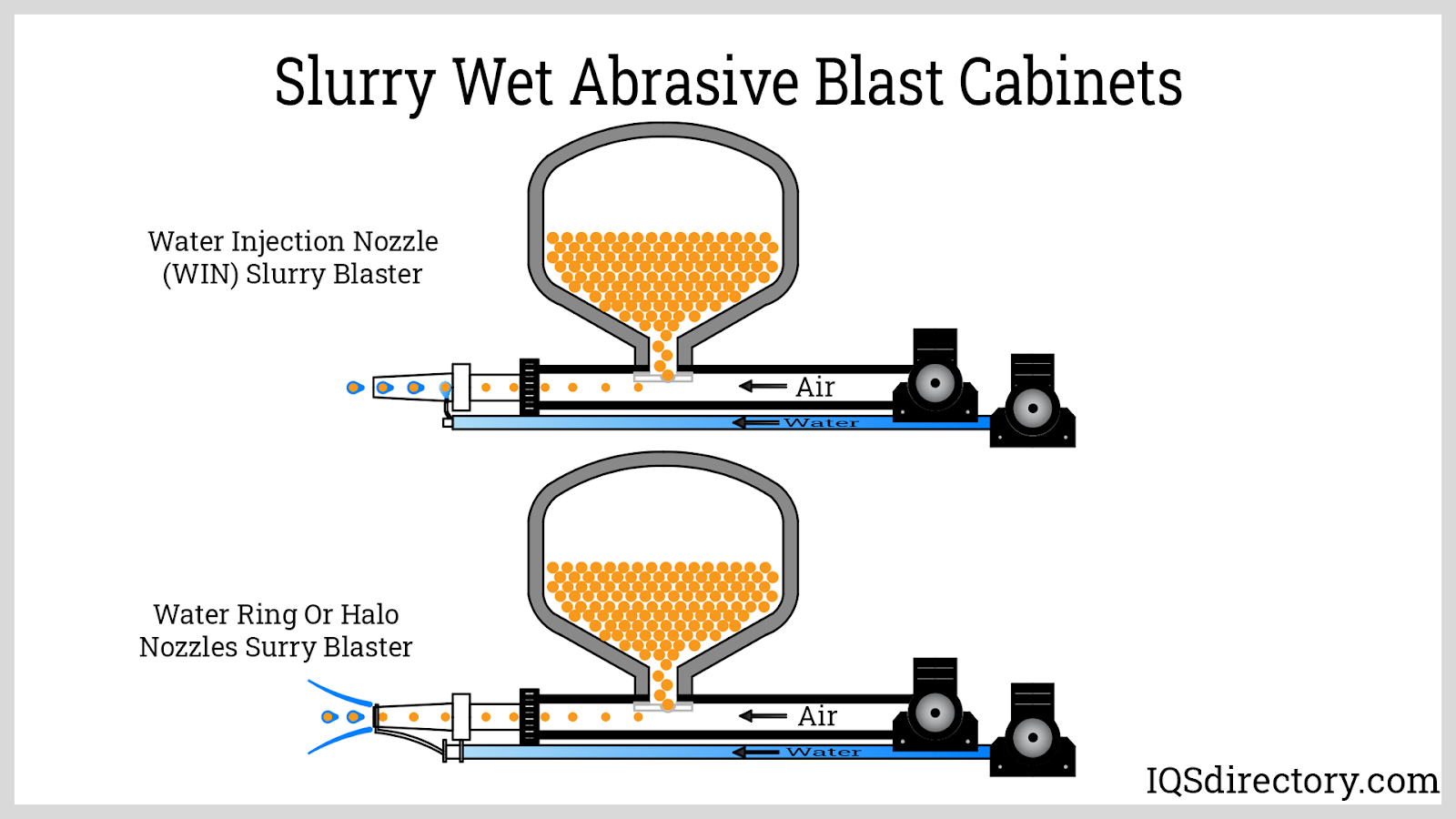

From www.iqsdirectory.com

Abrasive Blast Equipment What Is It? How Does It Work? Uses Sand Blaster Gun Not Working If the sandblaster is blowing air but not picking up any sand, check the nozzle size. 1) air pressure issues : The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. If your blast gun is not drawing any abrasive, turn off the compressed air supply.. Sand Blaster Gun Not Working.

From www.amazon.com

Sandblaster Air Sand Blasting Gun Kit, Spray Gun Air Sand Blaster Grit Blasting, Air Siphon Feed Sand Blaster Gun Not Working If the sandblaster is blowing air but not picking up any sand, check the nozzle size. If your blast gun is not drawing any abrasive, turn off the compressed air supply. Firstly, check for clogs in the nozzle and ensure. Remove the nozzle from the. One of the most common reasons for flow problems in a sandblaster is an inadequate. Sand Blaster Gun Not Working.

From applianceselloff.com

Best Air Compressor For Sandblasting Home Appliances Sand Blaster Gun Not Working The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. If the sandblaster is blowing air but not picking up any sand, check the nozzle size. Often particles removed from the part being processed get into the abrasive and sieve down to the. 1) air pressure. Sand Blaster Gun Not Working.

From www.amazon.co.uk

Pneumatic Sandblaster Abrasive Air Sand Blaster Gun Professional Sandblaster Blasting Machine Sand Blaster Gun Not Working If your blast gun is not drawing any abrasive, turn off the compressed air supply. One of the most common reasons for flow problems in a sandblaster is an inadequate air compressor. Often particles removed from the part being processed get into the abrasive and sieve down to the. 5 common causes of abrasive flow problems and how to fix. Sand Blaster Gun Not Working.

From www.sandblasters.co.uk

A Guide to Sand Blast Sand Blaster Gun Not Working If your blast gun is not drawing any abrasive, turn off the compressed air supply. If the sandblaster is blowing air but not picking up any sand, check the nozzle size. Firstly, check for clogs in the nozzle and ensure. If your sandblaster is not feeding sand, there could be several reasons for this. Remove the nozzle from the. 5. Sand Blaster Gun Not Working.

From www.cycloneblasters.com

Sandblaster Gun What is it? How it is used? Cyclone Manufacturing Sand Blaster Gun Not Working 1) air pressure issues : One of the most common reasons for flow problems in a sandblaster is an inadequate air compressor. The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. Firstly, check for clogs in the nozzle and ensure. If your sandblaster is not. Sand Blaster Gun Not Working.

From www.thewarehouse.co.nz

Hand Held Sandblaster Sand Blaster Gun Kit The Warehouse Sand Blaster Gun Not Working 1) air pressure issues : Sand blasters produce high noise levels and dust that can be dangerous if not operated properly; If the sandblaster is blowing air but not picking up any sand, check the nozzle size. If the size is not right, it will affect the. Often particles removed from the part being processed get into the abrasive and. Sand Blaster Gun Not Working.

From www.ebay.com

New Grit Shot Air Sandblaster Gun Air Sand Blaster Sandblasting Kit eBay Sand Blaster Gun Not Working If the sandblaster is blowing air but not picking up any sand, check the nozzle size. Often particles removed from the part being processed get into the abrasive and sieve down to the. If your sandblaster is not feeding sand, there could be several reasons for this. If the size is not right, it will affect the. One of the. Sand Blaster Gun Not Working.

From hupshenghardware.com

Gison GP970 Pneumatic Air Spot Sand Blaster Tool Sand Blaster Gun Not Working One of the most common reasons for flow problems in a sandblaster is an inadequate air compressor. The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. If the size is not right, it will affect the. Sand blasters produce high noise levels and dust that. Sand Blaster Gun Not Working.

From www.reddit.com

Sand blaster not working r/harborfreight Sand Blaster Gun Not Working If the size is not right, it will affect the. Often particles removed from the part being processed get into the abrasive and sieve down to the. Remove the nozzle from the. The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. If your blast gun. Sand Blaster Gun Not Working.

From www.amazon.co.uk

Professional Sand Blaster Gun Hand Held Pneumatic Sandblaster Air Sandblasting Gun for Remove Sand Blaster Gun Not Working Remove the nozzle from the. The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. If your sandblaster is not feeding sand, there could be several reasons for this. If your blast gun is not drawing any abrasive, turn off the compressed air supply. 5 common. Sand Blaster Gun Not Working.

From www.youtube.com

2 STAGE DUST CYCLONE for Separating Sand Blaster Media & Extracting Dust How well does it work Sand Blaster Gun Not Working One of the most common reasons for flow problems in a sandblaster is an inadequate air compressor. 5 common causes of abrasive flow problems and how to fix them. If the size is not right, it will affect the. Firstly, check for clogs in the nozzle and ensure. If your blast gun is not drawing any abrasive, turn off the. Sand Blaster Gun Not Working.

From www.youtube.com

How To Fix Repair A Gel Gun Blaster Not Working Or Can not shooting Like M4 YouTube Sand Blaster Gun Not Working If the sandblaster is blowing air but not picking up any sand, check the nozzle size. Firstly, check for clogs in the nozzle and ensure. The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. Sand blasters produce high noise levels and dust that can be. Sand Blaster Gun Not Working.

From www.sandblasters.co.uk

A Guide to Sand Blast Sand Blaster Gun Not Working The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. If your sandblaster is not feeding sand, there could be several reasons for this. Firstly, check for clogs in the nozzle and ensure. 1) air pressure issues : 5 common causes of abrasive flow problems and. Sand Blaster Gun Not Working.

From www.kedri.info

Harbor Freight Sandblaster Gun Get All You Need Sand Blaster Gun Not Working Firstly, check for clogs in the nozzle and ensure. If your blast gun is not drawing any abrasive, turn off the compressed air supply. If your sandblaster is not feeding sand, there could be several reasons for this. Sand blasters produce high noise levels and dust that can be dangerous if not operated properly; Remove the nozzle from the. 5. Sand Blaster Gun Not Working.

From flavored.ph

Automotive Tools & Supplies DHL Ship LEMATEC Sand Blasting Nozzle Gun Sandblaster Portable Speed Sand Blaster Gun Not Working Remove the nozzle from the. Often particles removed from the part being processed get into the abrasive and sieve down to the. 1) air pressure issues : Sand blasters produce high noise levels and dust that can be dangerous if not operated properly; If your blast gun is not drawing any abrasive, turn off the compressed air supply. One of. Sand Blaster Gun Not Working.

From www.youtube.com

Sand Blasting Pressurised Sandblaster YouTube Sand Blaster Gun Not Working Often particles removed from the part being processed get into the abrasive and sieve down to the. Firstly, check for clogs in the nozzle and ensure. If your sandblaster is not feeding sand, there could be several reasons for this. Remove the nozzle from the. The first reason that your sandblaster flow is not proper can be due to air. Sand Blaster Gun Not Working.

From www.youtube.com

Portable Air Blasting Gun Handheld Sandblaster Kit with Vacuum Function YouTube Sand Blaster Gun Not Working The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. Sand blasters produce high noise levels and dust that can be dangerous if not operated properly; If your sandblaster is not feeding sand, there could be several reasons for this. If the size is not right,. Sand Blaster Gun Not Working.

From www.amazon.ca

Pneumatic Sandblaster, Hand Held Portable Sand Blaster Sandblasting Gun Sand Blaster Gun Kit Sand Blaster Gun Not Working Firstly, check for clogs in the nozzle and ensure. The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. Remove the nozzle from the. One of the most common reasons for flow problems in a sandblaster is an inadequate air compressor. 5 common causes of abrasive. Sand Blaster Gun Not Working.

From www.youtube.com

Amazing! How does LEMATEC Sandblasting Gun work to remove rust or paint easily? YouTube Sand Blaster Gun Not Working If the sandblaster is blowing air but not picking up any sand, check the nozzle size. If your blast gun is not drawing any abrasive, turn off the compressed air supply. The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. 5 common causes of abrasive. Sand Blaster Gun Not Working.

From www.icollector.com

DAMAGED APW WZ0 SAND BLASTER NOT WORKING Sand Blaster Gun Not Working If your sandblaster is not feeding sand, there could be several reasons for this. If the size is not right, it will affect the. Sand blasters produce high noise levels and dust that can be dangerous if not operated properly; The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be. Sand Blaster Gun Not Working.

From www.directindustry.com

Sandblasting gun 9175 ProTek gravity Sand Blaster Gun Not Working If the sandblaster is blowing air but not picking up any sand, check the nozzle size. If your sandblaster is not feeding sand, there could be several reasons for this. 5 common causes of abrasive flow problems and how to fix them. Firstly, check for clogs in the nozzle and ensure. 1) air pressure issues : Sand blasters produce high. Sand Blaster Gun Not Working.

From shopee.ph

HUS Handhold Air Sand Blaster Gun With Gravity Feed Hopper Heavy Duty Sand Blaster For Home Sand Blaster Gun Not Working One of the most common reasons for flow problems in a sandblaster is an inadequate air compressor. The first reason that your sandblaster flow is not proper can be due to air pressure, you may not be getting the proper air. Sand blasters produce high noise levels and dust that can be dangerous if not operated properly; 1) air pressure. Sand Blaster Gun Not Working.

From www.amazon.com

AS118 Black Sand Blaster Gun Kit with 1/4Inch NPT AR07 Air Pressure Regulator Bundle Sand Blaster Gun Not Working One of the most common reasons for flow problems in a sandblaster is an inadequate air compressor. Remove the nozzle from the. 5 common causes of abrasive flow problems and how to fix them. If your blast gun is not drawing any abrasive, turn off the compressed air supply. Sand blasters produce high noise levels and dust that can be. Sand Blaster Gun Not Working.

From teletalkbd.com

Everything You Need To Know About A Sand Blaster Gun Kit A Comprehensive Guide Sand Blaster Gun Not Working Remove the nozzle from the. 5 common causes of abrasive flow problems and how to fix them. One of the most common reasons for flow problems in a sandblaster is an inadequate air compressor. Sand blasters produce high noise levels and dust that can be dangerous if not operated properly; If your blast gun is not drawing any abrasive, turn. Sand Blaster Gun Not Working.