Centrifuge Gone Wrong . To prevent and minimize centrifuge problems, it is crucial to perform routine maintenance and regular inspections. Below are three of the most common errors that fresh scientists make when they’re learning the ropes of centrifugation. Remove the rotor and inspect for any debris or imbalance. The machine is not level. Use a bubble level to ensure proper alignment. If there are any visible obstructions, remove them by cleaning the machine’s exterior with a dry cloth and use compressed air to blow out the ventilation. Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your laboratory experiments. Ensure the motor and bearings are lubricated to avoid frictional heat. Learn the causes and solutions of an imbalanced centrifuge, a common fault that stops the rotor from spinning. If your centrifuge is producing excessive noise or vibrations, it can be a sign of underlying issues: Turn off the centrifuge immediately before checking the ventilation system for blocks. This includes cleaning the centrifuge. The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. Check if the centrifuge is placed on a flat, stable surface. Find out how to load the rotor properly, grease the trunnions, check the motor shaft and contact a repair specialist.

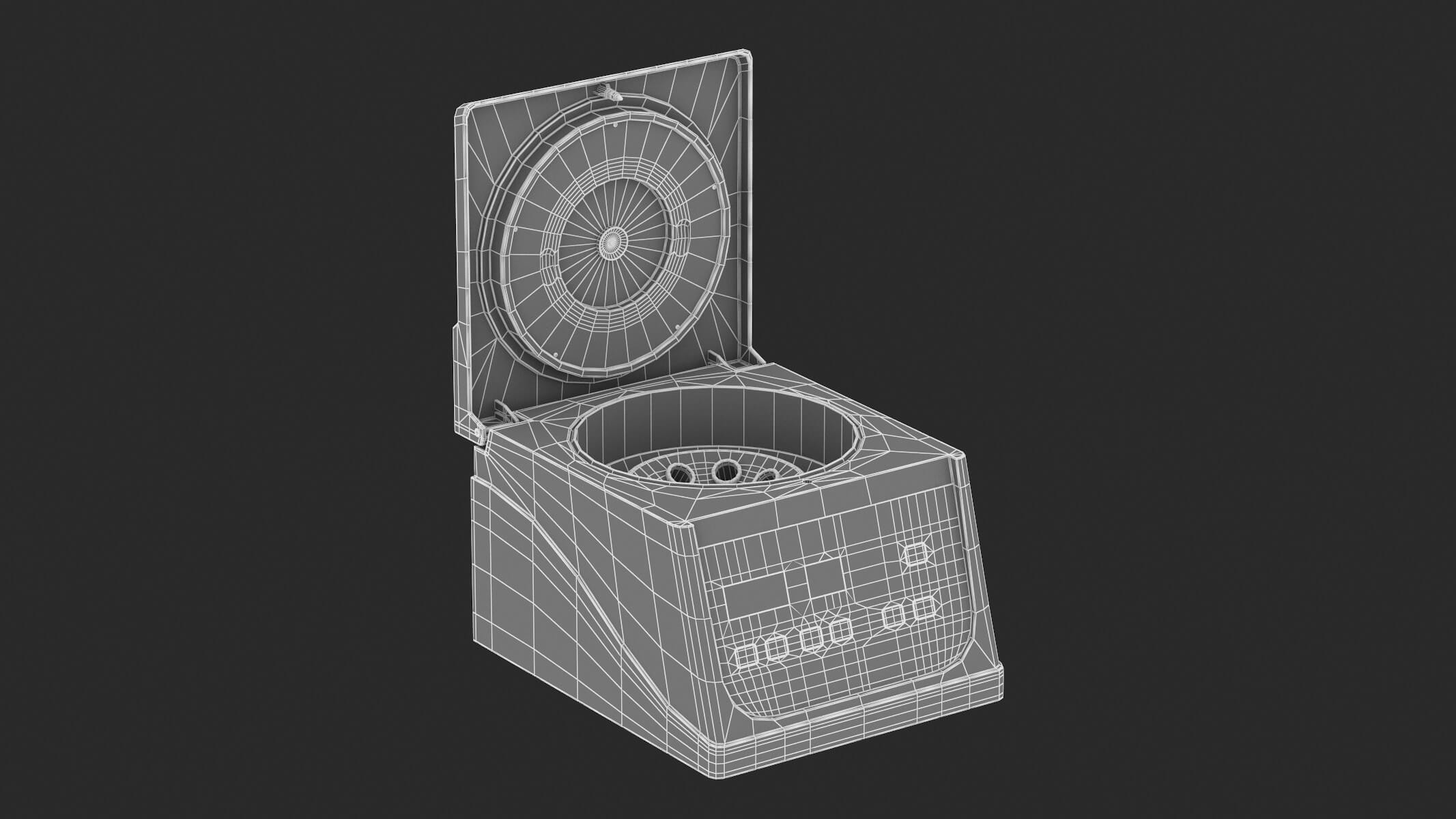

from www.renderhub.com

Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your laboratory experiments. Check if the centrifuge is placed on a flat, stable surface. Ensure the motor and bearings are lubricated to avoid frictional heat. Below are three of the most common errors that fresh scientists make when they’re learning the ropes of centrifugation. Remove the rotor and inspect for any debris or imbalance. If there are any visible obstructions, remove them by cleaning the machine’s exterior with a dry cloth and use compressed air to blow out the ventilation. The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. Turn off the centrifuge immediately before checking the ventilation system for blocks. This includes cleaning the centrifuge. To prevent and minimize centrifuge problems, it is crucial to perform routine maintenance and regular inspections.

Medical Centrifuge 3D Model by frezzy

Centrifuge Gone Wrong Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your laboratory experiments. Use a bubble level to ensure proper alignment. Ensure the motor and bearings are lubricated to avoid frictional heat. The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. Learn the causes and solutions of an imbalanced centrifuge, a common fault that stops the rotor from spinning. Turn off the centrifuge immediately before checking the ventilation system for blocks. If your centrifuge is producing excessive noise or vibrations, it can be a sign of underlying issues: Below are three of the most common errors that fresh scientists make when they’re learning the ropes of centrifugation. This includes cleaning the centrifuge. If there are any visible obstructions, remove them by cleaning the machine’s exterior with a dry cloth and use compressed air to blow out the ventilation. The machine is not level. Remove the rotor and inspect for any debris or imbalance. Find out how to load the rotor properly, grease the trunnions, check the motor shaft and contact a repair specialist. To prevent and minimize centrifuge problems, it is crucial to perform routine maintenance and regular inspections. Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your laboratory experiments. Check if the centrifuge is placed on a flat, stable surface.

From biotechsci.co.th

เครื่องปั่นเหวี่ยง Centrifuge biotechscilabfurniture Centrifuge Gone Wrong Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your laboratory experiments. Ensure the motor and bearings are lubricated to avoid frictional heat. Use a bubble level to ensure proper alignment. Check if the centrifuge is placed on a flat, stable surface. To prevent and minimize centrifuge problems, it is crucial to perform routine. Centrifuge Gone Wrong.

From southwestscience.com

FullFeatured 12place Clinical Centrifuge Southwest Science Centrifuge Gone Wrong Ensure the motor and bearings are lubricated to avoid frictional heat. Below are three of the most common errors that fresh scientists make when they’re learning the ropes of centrifugation. To prevent and minimize centrifuge problems, it is crucial to perform routine maintenance and regular inspections. Check if the centrifuge is placed on a flat, stable surface. This includes cleaning. Centrifuge Gone Wrong.

From www.youtube.com

First centrifuge failure YouTube Centrifuge Gone Wrong This includes cleaning the centrifuge. The machine is not level. Remove the rotor and inspect for any debris or imbalance. Ensure the motor and bearings are lubricated to avoid frictional heat. Turn off the centrifuge immediately before checking the ventilation system for blocks. If there are any visible obstructions, remove them by cleaning the machine’s exterior with a dry cloth. Centrifuge Gone Wrong.

From labstac.com

Rising Demand for Centrifuge in Medical Aesthetics Centrifuge Gone Wrong Ensure the motor and bearings are lubricated to avoid frictional heat. Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your laboratory experiments. The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. Use a bubble level to ensure proper alignment. Find out how to. Centrifuge Gone Wrong.

From www.renderhub.com

Medical Centrifuge 3D Model by frezzy Centrifuge Gone Wrong The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your laboratory experiments. Below are three of the most common errors that fresh scientists make when they’re learning the ropes of centrifugation. Find out how to. Centrifuge Gone Wrong.

From www.thoughtco.com

Centrifuge Definition, Types, and Uses Centrifuge Gone Wrong Ensure the motor and bearings are lubricated to avoid frictional heat. Check if the centrifuge is placed on a flat, stable surface. This includes cleaning the centrifuge. Turn off the centrifuge immediately before checking the ventilation system for blocks. Remove the rotor and inspect for any debris or imbalance. Below are three of the most common errors that fresh scientists. Centrifuge Gone Wrong.

From www.biobase.com

China Centrifuge Manufacturers page 2 Centrifuge Gone Wrong This includes cleaning the centrifuge. To prevent and minimize centrifuge problems, it is crucial to perform routine maintenance and regular inspections. Ensure the motor and bearings are lubricated to avoid frictional heat. The machine is not level. Find out how to load the rotor properly, grease the trunnions, check the motor shaft and contact a repair specialist. Learn the causes. Centrifuge Gone Wrong.

From www.lssfrance.com

Universal Centrifuge France, Manufacturers, Suppliers & Exporters in France Centrifuge Gone Wrong Turn off the centrifuge immediately before checking the ventilation system for blocks. Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your laboratory experiments. To prevent and minimize centrifuge problems, it is crucial to perform routine maintenance and regular inspections. Check if the centrifuge is placed on a flat, stable surface. Remove the rotor. Centrifuge Gone Wrong.

From www.antteknik.com

Centrifuge 5425 / 5425 R Micro Centrifuge Centrifuge Gone Wrong Find out how to load the rotor properly, grease the trunnions, check the motor shaft and contact a repair specialist. The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. Remove the rotor and inspect for any debris or imbalance. Regular cleaning and maintenance of your centrifuge are crucial for the. Centrifuge Gone Wrong.

From en.wikipedia.org

Centrifuge Wikipedia Centrifuge Gone Wrong If there are any visible obstructions, remove them by cleaning the machine’s exterior with a dry cloth and use compressed air to blow out the ventilation. Ensure the motor and bearings are lubricated to avoid frictional heat. Remove the rotor and inspect for any debris or imbalance. This includes cleaning the centrifuge. Regular cleaning and maintenance of your centrifuge are. Centrifuge Gone Wrong.

From www.renderhub.com

Medical Centrifuge 3D Model by frezzy Centrifuge Gone Wrong Turn off the centrifuge immediately before checking the ventilation system for blocks. If there are any visible obstructions, remove them by cleaning the machine’s exterior with a dry cloth and use compressed air to blow out the ventilation. Check if the centrifuge is placed on a flat, stable surface. Find out how to load the rotor properly, grease the trunnions,. Centrifuge Gone Wrong.

From www.wikihow.com

How to Use a Centrifuge 14 Steps (with Pictures) wikiHow Centrifuge Gone Wrong Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your laboratory experiments. Below are three of the most common errors that fresh scientists make when they’re learning the ropes of centrifugation. Find out how to load the rotor properly, grease the trunnions, check the motor shaft and contact a repair specialist. If there are. Centrifuge Gone Wrong.

From microbenotes.com

Centrifuge Principle, Parts, Types, Uses, Examples Centrifuge Gone Wrong Ensure the motor and bearings are lubricated to avoid frictional heat. Below are three of the most common errors that fresh scientists make when they’re learning the ropes of centrifugation. If there are any visible obstructions, remove them by cleaning the machine’s exterior with a dry cloth and use compressed air to blow out the ventilation. Turn off the centrifuge. Centrifuge Gone Wrong.

From www.redbubble.com

"Balanced Centrifuge" Sticker for Sale by TrailMixArt Redbubble Centrifuge Gone Wrong Find out how to load the rotor properly, grease the trunnions, check the motor shaft and contact a repair specialist. If there are any visible obstructions, remove them by cleaning the machine’s exterior with a dry cloth and use compressed air to blow out the ventilation. The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected. Centrifuge Gone Wrong.

From roadie-music.com

CENTRIFUGE abala as estruturas com o poderoso single “It’s All Gone Centrifuge Gone Wrong Find out how to load the rotor properly, grease the trunnions, check the motor shaft and contact a repair specialist. Turn off the centrifuge immediately before checking the ventilation system for blocks. The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. Below are three of the most common errors that. Centrifuge Gone Wrong.

From ehrs.upenn.edu

Ultracentrifuge Explosion Damages Laboratory PennEHRS Centrifuge Gone Wrong Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your laboratory experiments. Check if the centrifuge is placed on a flat, stable surface. To prevent and minimize centrifuge problems, it is crucial to perform routine maintenance and regular inspections. Below are three of the most common errors that fresh scientists make when they’re learning. Centrifuge Gone Wrong.

From www.diychatroom.com

Broken centrifuge help needed DIY Home Improvement Forum Centrifuge Gone Wrong The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. Find out how to load the rotor properly, grease the trunnions, check the motor shaft and contact a repair specialist. To prevent and minimize centrifuge problems, it is crucial to perform routine maintenance and regular inspections. This includes cleaning the centrifuge.. Centrifuge Gone Wrong.

From www.core77.com

A NoFuel, CentrifugeBased Rocket Launching System That's Like an Centrifuge Gone Wrong The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. Use a bubble level to ensure proper alignment. Remove the rotor and inspect for any debris or imbalance. Learn the causes and solutions of an imbalanced centrifuge, a common fault that stops the rotor from spinning. If your centrifuge is producing. Centrifuge Gone Wrong.

From microbeonline.com

Centrifuge Parts, Types, and Handling Microbe Online Centrifuge Gone Wrong If your centrifuge is producing excessive noise or vibrations, it can be a sign of underlying issues: To prevent and minimize centrifuge problems, it is crucial to perform routine maintenance and regular inspections. Find out how to load the rotor properly, grease the trunnions, check the motor shaft and contact a repair specialist. Turn off the centrifuge immediately before checking. Centrifuge Gone Wrong.

From filmnosis.com

The Centrifuge Brain Project & analysis Filmnosis Centrifuge Gone Wrong Check if the centrifuge is placed on a flat, stable surface. Turn off the centrifuge immediately before checking the ventilation system for blocks. If your centrifuge is producing excessive noise or vibrations, it can be a sign of underlying issues: To prevent and minimize centrifuge problems, it is crucial to perform routine maintenance and regular inspections. Find out how to. Centrifuge Gone Wrong.

From surgical-hut.com

DM0506 DLAB Centrifuge Machine Low speed centrifuge Machine Price Centrifuge Gone Wrong The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. Below are three of the most common errors that fresh scientists make when they’re learning the ropes of centrifugation. Use a bubble level to ensure proper alignment. The machine is not level. Find out how to load the rotor properly, grease. Centrifuge Gone Wrong.

From philmedicalsupplies.com

Centrifuge 8 Placer, DIGISYSTEM DSC200T AR1508 Philippine Medical Centrifuge Gone Wrong Remove the rotor and inspect for any debris or imbalance. If your centrifuge is producing excessive noise or vibrations, it can be a sign of underlying issues: Find out how to load the rotor properly, grease the trunnions, check the motor shaft and contact a repair specialist. The machine is not level. Below are three of the most common errors. Centrifuge Gone Wrong.

From www.labohouse.com

Laboratory Centrifuge Centrifuge Gone Wrong Below are three of the most common errors that fresh scientists make when they’re learning the ropes of centrifugation. If your centrifuge is producing excessive noise or vibrations, it can be a sign of underlying issues: The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. The machine is not level.. Centrifuge Gone Wrong.

From www.kucari.com

Jual Centrifuge Tube 10ml Harga Murah 2024 Centrifuge Gone Wrong Find out how to load the rotor properly, grease the trunnions, check the motor shaft and contact a repair specialist. Turn off the centrifuge immediately before checking the ventilation system for blocks. If your centrifuge is producing excessive noise or vibrations, it can be a sign of underlying issues: To prevent and minimize centrifuge problems, it is crucial to perform. Centrifuge Gone Wrong.

From www.dreamstime.com

Centrifuge stock image. Image of biochemistry, furniture 261622429 Centrifuge Gone Wrong To prevent and minimize centrifuge problems, it is crucial to perform routine maintenance and regular inspections. Check if the centrifuge is placed on a flat, stable surface. Below are three of the most common errors that fresh scientists make when they’re learning the ropes of centrifugation. If there are any visible obstructions, remove them by cleaning the machine’s exterior with. Centrifuge Gone Wrong.

From labstac.com

Rising Demand for Centrifuge in Medical Aesthetics Centrifuge Gone Wrong Turn off the centrifuge immediately before checking the ventilation system for blocks. The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. If there are any visible obstructions, remove them by cleaning the machine’s exterior with a dry cloth and use compressed air to blow out the ventilation. Check if the. Centrifuge Gone Wrong.

From www.desertcart.no

Buy Centrifugal machine Benchtop Lowspeed Centrifuge Electric Centrifuge Gone Wrong To prevent and minimize centrifuge problems, it is crucial to perform routine maintenance and regular inspections. The machine is not level. Use a bubble level to ensure proper alignment. Below are three of the most common errors that fresh scientists make when they’re learning the ropes of centrifugation. Check if the centrifuge is placed on a flat, stable surface. Learn. Centrifuge Gone Wrong.

From www.etsy.com

Centrifuge Unbalanced Etsy Centrifuge Gone Wrong The machine is not level. Learn the causes and solutions of an imbalanced centrifuge, a common fault that stops the rotor from spinning. The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. Remove the rotor and inspect for any debris or imbalance. Below are three of the most common errors. Centrifuge Gone Wrong.

From bahamas.desertcart.com

Buy WFWJSKJ Laboratory Centrifuges Electric Centrifuge Conventional Centrifuge Gone Wrong If your centrifuge is producing excessive noise or vibrations, it can be a sign of underlying issues: Check if the centrifuge is placed on a flat, stable surface. To prevent and minimize centrifuge problems, it is crucial to perform routine maintenance and regular inspections. Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your. Centrifuge Gone Wrong.

From www.studocu.com

Teklab Centrifuge CENTRIFUGE Centrifuge adalah instrumen Centrifuge Gone Wrong Remove the rotor and inspect for any debris or imbalance. Use a bubble level to ensure proper alignment. Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your laboratory experiments. This includes cleaning the centrifuge. Learn the causes and solutions of an imbalanced centrifuge, a common fault that stops the rotor from spinning. Find. Centrifuge Gone Wrong.

From in.eteachers.edu.vn

Details 58+ centrifuge sketch diagram best in.eteachers Centrifuge Gone Wrong Use a bubble level to ensure proper alignment. Turn off the centrifuge immediately before checking the ventilation system for blocks. Remove the rotor and inspect for any debris or imbalance. The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. Learn the causes and solutions of an imbalanced centrifuge, a common. Centrifuge Gone Wrong.

From kgrowth.blogspot.com

KGrowth What can we know about centrifuge? Centrifuge Gone Wrong If there are any visible obstructions, remove them by cleaning the machine’s exterior with a dry cloth and use compressed air to blow out the ventilation. Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your laboratory experiments. Below are three of the most common errors that fresh scientists make when they’re learning the. Centrifuge Gone Wrong.

From pharmasiksha.com

Super centrifuge principle, construction, working and uses. Pharmasiksha Centrifuge Gone Wrong Ensure the motor and bearings are lubricated to avoid frictional heat. The machine is not level. Remove the rotor and inspect for any debris or imbalance. Learn the causes and solutions of an imbalanced centrifuge, a common fault that stops the rotor from spinning. Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your. Centrifuge Gone Wrong.

From microbenotes.com

Centrifuge Principle, Parts, Types, Uses, Examples Centrifuge Gone Wrong To prevent and minimize centrifuge problems, it is crucial to perform routine maintenance and regular inspections. The power supply, centrifuge assembly, motor, speed control, and centrifuge must all be inspected and tested to identify any. Regular cleaning and maintenance of your centrifuge are crucial for the accuracy and reliability of your laboratory experiments. Learn the causes and solutions of an. Centrifuge Gone Wrong.

From www.reddit.com

Centrifuge failure r/labrats Centrifuge Gone Wrong Remove the rotor and inspect for any debris or imbalance. Check if the centrifuge is placed on a flat, stable surface. Turn off the centrifuge immediately before checking the ventilation system for blocks. This includes cleaning the centrifuge. The machine is not level. Find out how to load the rotor properly, grease the trunnions, check the motor shaft and contact. Centrifuge Gone Wrong.