Laser Etching Foam . So, how to laser cut foam? Laser cutting foam involves harnessing the potent energy of a laser beam, accurately vaporizing the foam while cutting. The laser engraving process can be used to. Foam laser cutting, also known as laser cutting foam, is a refined method for precisely shaping foam material into various. Clean process with no residue on the tool or on the work surface. Use dot mode, low power and low speed in order to reduce the amount of heat going into the job. Laser cutting foam is the secret sauce that elevates eva foam to a whole new level of creativity and precision. Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene foam, or eva. Lower the laser nozzle down to 3mm from the surface to.

from www.coherent.com

Laser cutting foam is the secret sauce that elevates eva foam to a whole new level of creativity and precision. A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. The laser engraving process can be used to. Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene foam, or eva. Lower the laser nozzle down to 3mm from the surface to. Foam laser cutting, also known as laser cutting foam, is a refined method for precisely shaping foam material into various. Laser cutting foam involves harnessing the potent energy of a laser beam, accurately vaporizing the foam while cutting. Clean process with no residue on the tool or on the work surface. So, how to laser cut foam?

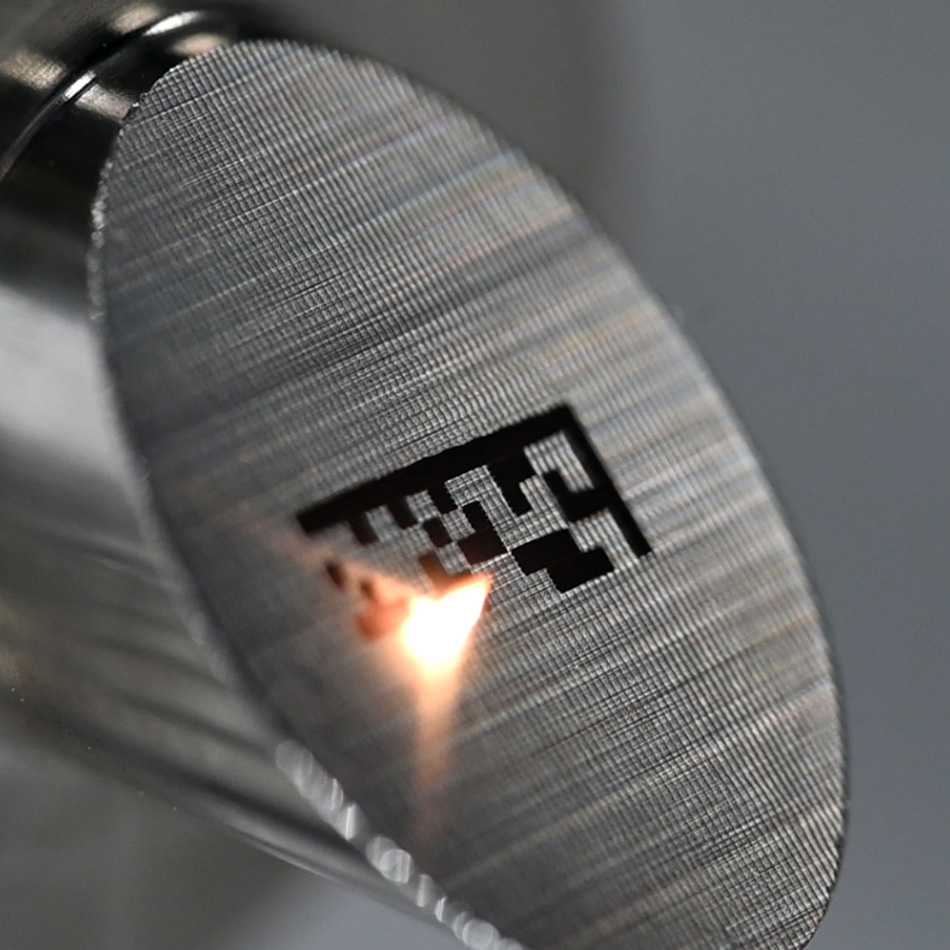

Laser Marking and Engraving Machines Coherent

Laser Etching Foam Lower the laser nozzle down to 3mm from the surface to. A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Foam laser cutting, also known as laser cutting foam, is a refined method for precisely shaping foam material into various. The laser engraving process can be used to. Clean process with no residue on the tool or on the work surface. So, how to laser cut foam? Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene foam, or eva. Use dot mode, low power and low speed in order to reduce the amount of heat going into the job. Lower the laser nozzle down to 3mm from the surface to. Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. Laser cutting foam is the secret sauce that elevates eva foam to a whole new level of creativity and precision. Laser cutting foam involves harnessing the potent energy of a laser beam, accurately vaporizing the foam while cutting.

From www.diytrade.com

laser foam cutting machine SK1280 Suke (China Trading Company Laser Etching Foam A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. So, how to laser cut foam? Lower the laser nozzle down to 3mm from the surface to.. Laser Etching Foam.

From jtechphotonics.com

Cutting Open Cell Foam J Tech Photonics, Inc. Laser Etching Foam Lower the laser nozzle down to 3mm from the surface to. So, how to laser cut foam? A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. The laser engraving process can be used to. Laser cutting foam involves harnessing the potent energy of a laser beam, accurately vaporizing the. Laser Etching Foam.

From www.laser-master.com

Laser Cutting Foam and Rubber Laser Master Laser Etching Foam Clean process with no residue on the tool or on the work surface. Laser cutting foam involves harnessing the potent energy of a laser beam, accurately vaporizing the foam while cutting. Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. Use dot mode, low power and. Laser Etching Foam.

From www.haitechlasers.com

The Laser Etching Process Hai Tech Lasers Laser Etching Foam Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. Clean process with no residue on the tool or on the work surface. A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Laser cutting foam involves. Laser Etching Foam.

From www.youtube.com

Foam laser cutting machine for EVA YouTube Laser Etching Foam So, how to laser cut foam? Foam laser cutting, also known as laser cutting foam, is a refined method for precisely shaping foam material into various. Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. Laser cutting foam involves harnessing the potent energy of a laser. Laser Etching Foam.

From www.youtube.com

Silicon rubber laser cutting YouTube Laser Etching Foam Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene foam, or eva. The laser engraving process can be used to. Laser cutting foam involves harnessing the potent energy of a laser beam, accurately vaporizing the foam while cutting. Laser cutting foam is the secret sauce that elevates eva foam to a whole new level of. Laser Etching Foam.

From www.richa1.com

EVA Foam Armor cut on a laser Richard's site Laser Etching Foam Laser cutting foam involves harnessing the potent energy of a laser beam, accurately vaporizing the foam while cutting. So, how to laser cut foam? The laser engraving process can be used to. Laser cutting foam is the secret sauce that elevates eva foam to a whole new level of creativity and precision. Lower the laser nozzle down to 3mm from. Laser Etching Foam.

From www.protectore.com.au

Custom hard case and foam inserts for world class asset protection Laser Etching Foam A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Clean process with no residue on the tool or on the work surface. Foam laser cutting, also known as laser cutting foam, is a refined method for precisely shaping foam material into various. Lower the laser nozzle down to 3mm. Laser Etching Foam.

From www.technitoolinc.com

Foam Cutting / Laser Etching TechniTool, Inc. Laser Etching Foam Lower the laser nozzle down to 3mm from the surface to. Clean process with no residue on the tool or on the work surface. Laser cutting foam involves harnessing the potent energy of a laser beam, accurately vaporizing the foam while cutting. Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene foam, or eva. Foam. Laser Etching Foam.

From www.cnc-laser.cn

Laser Cutting Foam for Tool Shadowing Wrench Metal Engraving Laser Etching Foam A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. Use dot mode, low power and low speed in order to reduce the amount of heat going. Laser Etching Foam.

From uk.pinterest.com

Small Dragon Scale Pattern EVA Foam Sheets for Cosplay Armor , Props Laser Etching Foam Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene foam, or eva. Laser cutting foam involves harnessing the potent energy of a laser beam, accurately vaporizing the foam while cutting. Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. Laser cutting. Laser Etching Foam.

From www.coherent.com

Laser Marking and Engraving Machines Coherent Laser Etching Foam Lower the laser nozzle down to 3mm from the surface to. Laser cutting foam involves harnessing the potent energy of a laser beam, accurately vaporizing the foam while cutting. Use dot mode, low power and low speed in order to reduce the amount of heat going into the job. Laser cutting foam is the secret sauce that elevates eva foam. Laser Etching Foam.

From www.redboxtools.com

Tool Foam Red Box Tools Laser Etching Foam Lower the laser nozzle down to 3mm from the surface to. Use dot mode, low power and low speed in order to reduce the amount of heat going into the job. Laser cutting foam is the secret sauce that elevates eva foam to a whole new level of creativity and precision. Laser cut foam will always deliver better quality control. Laser Etching Foam.

From chinacncmachines.en.made-in-china.com

CNC Metal Nonmetal Small CO2 Laser Cutting/ Etching Machine Laser Laser Etching Foam Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. Lower the laser nozzle down to 3mm from the surface to. A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Use dot mode, low power and. Laser Etching Foam.

From mellowpine.com

Laser Cutting FoamInserts,Tool Shadowing [2023] MellowPine Laser Etching Foam Lower the laser nozzle down to 3mm from the surface to. Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. Clean process with no residue on the tool or on the work surface. Laser cutting foam involves harnessing the potent energy of a laser beam, accurately. Laser Etching Foam.

From camfivelaser.com

Information Foam and Polyurethane Laser Cutters for Packing and other Laser Etching Foam So, how to laser cut foam? Lower the laser nozzle down to 3mm from the surface to. Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene foam, or eva. Laser cutting foam is the secret sauce that elevates eva foam to a whole new level of creativity and precision. Laser cut foam will always deliver. Laser Etching Foam.

From www.mactron-tech.com

Can A Laser Machine Engrave Or Cut On Foam Or Silicone Rubber Laser Etching Foam A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Laser cutting foam is the secret sauce that elevates eva foam to a whole new level of creativity and precision. Clean process with no residue on the tool or on the work surface. Choose the type of foam suitable for. Laser Etching Foam.

From www.youtube.com

Laser Engrave Aluminum with a diode laser with acid etching or zincit Laser Etching Foam Clean process with no residue on the tool or on the work surface. Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene foam, or eva. So, how to laser cut foam? Laser. Laser Etching Foam.

From www.gwp.co.uk

Laser Cut Foam & Engraving Custom Foam Logos / Branding GWP Protective Laser Etching Foam A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Laser cutting foam is the secret sauce that elevates eva foam to a whole new level of creativity and precision. The laser engraving process can be used to. Laser cut foam will always deliver better quality control than tools like. Laser Etching Foam.

From mellowpine.com

Color Laser Engraving with Fiber Lasers [2023] MellowPine Laser Etching Foam The laser engraving process can be used to. Laser cutting foam is the secret sauce that elevates eva foam to a whole new level of creativity and precision. Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. Use dot mode, low power and low speed in. Laser Etching Foam.

From www.goldenlaser.cc

Cutting Foam with a Laser Cutter Goldenlaser Laser Etching Foam Lower the laser nozzle down to 3mm from the surface to. Clean process with no residue on the tool or on the work surface. Foam laser cutting, also known as laser cutting foam, is a refined method for precisely shaping foam material into various. Laser cutting foam involves harnessing the potent energy of a laser beam, accurately vaporizing the foam. Laser Etching Foam.

From identificationtags.com

What is Laser Engraving or Etching? Laser Etching Foam A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene foam, or eva. The laser engraving process can be used to. Laser cutting foam is the secret sauce that elevates eva foam to a whole new. Laser Etching Foam.

From www.sunrise-metal.com

Laser Etching & Engraving Top 5 Things About Them Sunrise Metal Laser Etching Foam Laser cutting foam is the secret sauce that elevates eva foam to a whole new level of creativity and precision. Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene foam, or eva. Foam laser cutting, also known as laser cutting foam, is a refined method for precisely shaping foam material into various. Clean process with. Laser Etching Foam.

From kernlasers.com

Large Format Laser Cutting Systems and Laser Engravers Laser Etching Foam Clean process with no residue on the tool or on the work surface. A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Use dot mode, low power and low speed in order to reduce the amount of heat going into the job. So, how to laser cut foam? Foam. Laser Etching Foam.

From www.youtube.com

EVA foam laser engraving test YouTube Laser Etching Foam Lower the laser nozzle down to 3mm from the surface to. Laser cutting foam is the secret sauce that elevates eva foam to a whole new level of creativity and precision. Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. Foam laser cutting, also known as. Laser Etching Foam.

From jtechphotonics.com

Cutting 1/8" and 3/16" Foam Board with the 1.7W laser upgrade kit J Laser Etching Foam Foam laser cutting, also known as laser cutting foam, is a refined method for precisely shaping foam material into various. Laser cutting foam involves harnessing the potent energy of a laser beam, accurately vaporizing the foam while cutting. So, how to laser cut foam? Use dot mode, low power and low speed in order to reduce the amount of heat. Laser Etching Foam.

From www.samcases.co.uk

Custom Foam Inserts Design & Manufacture From SAM Cases Laser Etching Foam A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. The laser engraving process can be used to. Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. Lower the laser nozzle down to 3mm from the. Laser Etching Foam.

From precisionboard.com

Laser Cutting Foam Precision Board OSHA Approved, Highly Effective Laser Etching Foam A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Laser cutting foam involves harnessing the potent energy of a laser beam, accurately vaporizing the foam while cutting. Use dot mode, low power and low speed in order to reduce the amount of heat going into the job. Laser cutting. Laser Etching Foam.

From laser-atelier.ch

Materials Laser cutting and engraving Laser Atelier Laser Etching Foam So, how to laser cut foam? Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene foam, or eva. Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. Laser cutting foam is the secret sauce that elevates eva foam to a whole. Laser Etching Foam.

From www.youtube.com

Geneva Engraving Laser Foam Etching YouTube Laser Etching Foam The laser engraving process can be used to. Foam laser cutting, also known as laser cutting foam, is a refined method for precisely shaping foam material into various. Laser cutting foam is the secret sauce that elevates eva foam to a whole new level of creativity and precision. Choose the type of foam suitable for laser cutting, such as polyurethane. Laser Etching Foam.

From www.youtube.com

Laser engraving on foam YouTube Laser Etching Foam Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. So, how to laser cut foam? A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Use dot mode, low power and low speed in order to. Laser Etching Foam.

From hispeedlaser.com

Laser Etching Machine The Laser Etching Process You Need to Know Laser Etching Foam Laser cutting foam involves harnessing the potent energy of a laser beam, accurately vaporizing the foam while cutting. A co 2 laser is best for laser engraving polymer foams, while a fiber laser is best for metal foams. Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene foam, or eva. Laser cutting foam is the. Laser Etching Foam.

From wattsan.com

Foam Laser Cutting Machine Wattsan Laser Etching Foam Laser cut foam will always deliver better quality control than tools like jigsaws, but the benefits go far beyond visual and physical quality. Clean process with no residue on the tool or on the work surface. Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene foam, or eva. Laser cutting foam is the secret sauce. Laser Etching Foam.

From www.youtube.com

Laser etching on Stainless steel YouTube Laser Etching Foam Use dot mode, low power and low speed in order to reduce the amount of heat going into the job. Foam laser cutting, also known as laser cutting foam, is a refined method for precisely shaping foam material into various. So, how to laser cut foam? Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene. Laser Etching Foam.

From www.laser-master.com

laser cut polyethylene foam Archives Laser Master Laser Etching Foam So, how to laser cut foam? Use dot mode, low power and low speed in order to reduce the amount of heat going into the job. Clean process with no residue on the tool or on the work surface. Foam laser cutting, also known as laser cutting foam, is a refined method for precisely shaping foam material into various. Choose. Laser Etching Foam.