Mixing Nozzle For Injection Molding . Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks. The existing nozzle is replaced by. What are mixing nozzles in injection molding? Tmn16/20/30/40 series of mixing nozzles for injection molding machines. Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the. This distinctive device eliminates uneven coloration in injection. The nozzle is attached to the cylinder of the. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. The resulting high viscous plastics melt flow is. The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize the polymer. Benefits of using mixing nozzles for injection molding are.

from pazard.com

The nozzle is attached to the cylinder of the. This distinctive device eliminates uneven coloration in injection. Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the. Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. Benefits of using mixing nozzles for injection molding are. Tmn16/20/30/40 series of mixing nozzles for injection molding machines. What are mixing nozzles in injection molding? The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize the polymer. The resulting high viscous plastics melt flow is.

5 kinds of Injection molding nozzle tip types you must know Pazard

Mixing Nozzle For Injection Molding Benefits of using mixing nozzles for injection molding are. This distinctive device eliminates uneven coloration in injection. The nozzle is attached to the cylinder of the. The resulting high viscous plastics melt flow is. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. Tmn16/20/30/40 series of mixing nozzles for injection molding machines. The existing nozzle is replaced by. Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the. What are mixing nozzles in injection molding? Benefits of using mixing nozzles for injection molding are. The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize the polymer. Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks.

From www.invotecsolutions.co.uk

Invotec Standard Size Removable Tip Moulding Nozzles Invotec Solutions Mixing Nozzle For Injection Molding Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the. The existing nozzle is replaced by. This distinctive device eliminates uneven coloration in injection. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize. Mixing Nozzle For Injection Molding.

From pazard.com

5 kinds of Injection molding nozzle tip types you must know Pazard Mixing Nozzle For Injection Molding This distinctive device eliminates uneven coloration in injection. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. The nozzle is attached to the cylinder of the. Tmn16/20/30/40 series of mixing nozzles for injection molding machines. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. Mixing nozzles. Mixing Nozzle For Injection Molding.

From www.indiamart.com

Injection Molding Nozzle at Rs 3500/piece Hot Tip Nozzles in Chennai Mixing Nozzle For Injection Molding Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. The existing nozzle is replaced by. Tmn16/20/30/40 series of mixing nozzles for injection molding machines. Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks. The stamixco smn injection moulding mixing. Mixing Nozzle For Injection Molding.

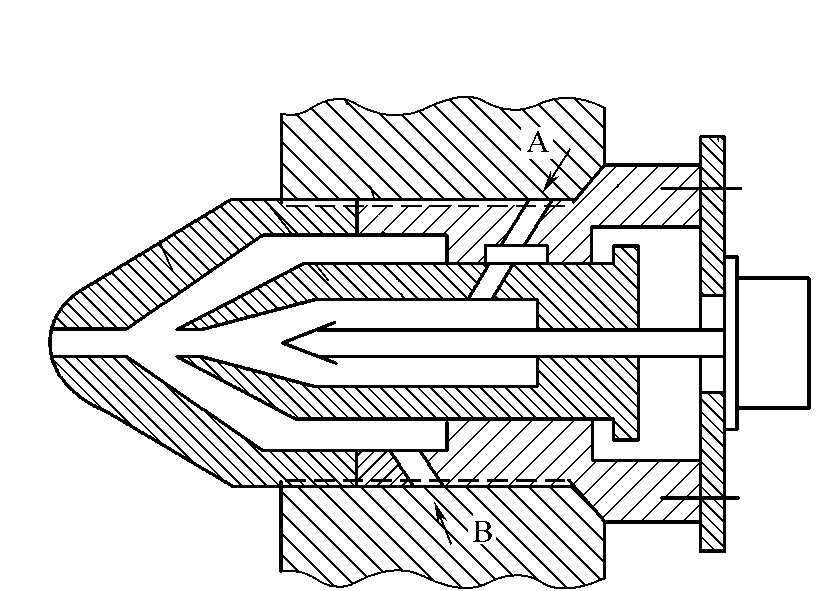

From www.stamixco-usa.com

Injection Molding Static Mixing Nozzle (Type SMN) StaMixCo Static Mixing Nozzle For Injection Molding Tmn16/20/30/40 series of mixing nozzles for injection molding machines. Benefits of using mixing nozzles for injection molding are. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks. Mixing nozzles ensure. Mixing Nozzle For Injection Molding.

From www.ajsolutions.be

Static mixers for noses AJ Solutions Mixing Nozzle For Injection Molding The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks. This distinctive device eliminates uneven coloration in injection. The resulting high viscous plastics melt flow is. The nozzle is attached to. Mixing Nozzle For Injection Molding.

From www.voestalpine.com

Nozzle filters flow filter Mixing Nozzle For Injection Molding The resulting high viscous plastics melt flow is. Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks. The existing nozzle is replaced by. What are mixing nozzles in injection molding? Tmn16/20/30/40 series of mixing nozzles for injection molding machines. Benefits of using mixing nozzles for injection. Mixing Nozzle For Injection Molding.

From pazard.com

5 kinds of Injection molding nozzle tip types you must know Pazard Mixing Nozzle For Injection Molding Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. The stamixco smn injection moulding. Mixing Nozzle For Injection Molding.

From aic-plastico.com

Injection Molding Nozzle Tips AIC Equipment & PlastiCo® Mixing Nozzle For Injection Molding The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. Benefits of using mixing nozzles for injection molding are. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within. Mixing Nozzle For Injection Molding.

From guanxin-machinery.com

Liquid Silicone Injection Molding Process Plastic Injection Molding Mixing Nozzle For Injection Molding Benefits of using mixing nozzles for injection molding are. What are mixing nozzles in injection molding? The existing nozzle is replaced by. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. The resulting high viscous plastics melt flow is. Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the. Our. Mixing Nozzle For Injection Molding.

From www.plasticportal.eu

Plastic Injection Molding Improved Part Quality and Considerable Cost Mixing Nozzle For Injection Molding The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. The resulting high viscous plastics melt flow is. The existing nozzle is replaced by. Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the. What are mixing nozzles in injection molding? Benefits of using mixing nozzles for injection molding are. The. Mixing Nozzle For Injection Molding.

From rootier.en.made-in-china.com

Injection Molding Color Mixing Dispersion Static Mixer Nozzle Mixing Nozzle For Injection Molding The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize the polymer. Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks. The nozzle is attached to the cylinder of the. The resulting high viscous plastics melt flow is. Mixing. Mixing Nozzle For Injection Molding.

From studylib.net

SMN Injection Moulding Mixing Nozzle Mixing Nozzle For Injection Molding The resulting high viscous plastics melt flow is. What are mixing nozzles in injection molding? Tmn16/20/30/40 series of mixing nozzles for injection molding machines. Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. The existing nozzle is replaced by. The. Mixing Nozzle For Injection Molding.

From www.plastics-technology.com

Mixing Nozzles For Injection Molding Primary Plastics Processing Mixing Nozzle For Injection Molding Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. Tmn16/20/30/40 series of mixing nozzles for injection molding machines. The resulting high viscous plastics melt flow is. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. The existing nozzle is replaced by. Mixing nozzles ensure that additives,. Mixing Nozzle For Injection Molding.

From www.emicorp.com

Standard Nozzle Tips for End of Barrel in Plastic Injection Molding Mixing Nozzle For Injection Molding Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. Benefits of using mixing nozzles for injection molding are. The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize the polymer.. Mixing Nozzle For Injection Molding.

From juguanghengsmt.en.made-in-china.com

Stainless Steel Custom Color Mixing Screw Special Lengthening Nozzle Mixing Nozzle For Injection Molding This distinctive device eliminates uneven coloration in injection. Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks. Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the. The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that. Mixing Nozzle For Injection Molding.

From www.promix-solutions.com

Eliminate color streaks and flow lines Mixing Nozzle For Injection Molding Benefits of using mixing nozzles for injection molding are. What are mixing nozzles in injection molding? Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. This distinctive device eliminates uneven coloration in injection. Tmn16/20/30/40 series of mixing. Mixing Nozzle For Injection Molding.

From www.vrogue.co

Mixing Nozzle For Injection Molding Machines Fluid Pr vrogue.co Mixing Nozzle For Injection Molding Benefits of using mixing nozzles for injection molding are. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. The existing nozzle is replaced by. Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks. The resulting high viscous plastics melt. Mixing Nozzle For Injection Molding.

From www.alibaba.com

Injection Molding Ratio Mixing Nozzle Applicator Adhesives Epoxy Resin Mixing Nozzle For Injection Molding What are mixing nozzles in injection molding? Benefits of using mixing nozzles for injection molding are. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. The existing nozzle is replaced by. The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize the polymer. The nozzle is. Mixing Nozzle For Injection Molding.

From www.vrogue.co

Mixing Nozzle For Injection Molding Machines Fluid Pr vrogue.co Mixing Nozzle For Injection Molding The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. The nozzle is attached to the cylinder of the. This distinctive device eliminates uneven coloration in injection. The existing nozzle is replaced by. What are mixing nozzles in injection molding? Tmn16/20/30/40 series of mixing nozzles for injection molding machines. Mixing nozzles for the most. Mixing Nozzle For Injection Molding.

From www.rootierind.com

Injection Filter Nozzle Rootier Plastic Machinery Parts Mixing Nozzle For Injection Molding Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. The resulting high viscous plastics. Mixing Nozzle For Injection Molding.

From rootier.en.made-in-china.com

Injection Molding Color Mixing Dispersion Static Mixer Nozzle China Mixing Nozzle For Injection Molding What are mixing nozzles in injection molding? The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. Benefits of using mixing nozzles for injection molding are. This distinctive device eliminates uneven coloration in injection. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. The existing nozzle is. Mixing Nozzle For Injection Molding.

From www.tradeindia.com

Nozzel Polished Round Stainless Steel Nozzle For Injection Molding Mixing Nozzle For Injection Molding The nozzle is attached to the cylinder of the. Benefits of using mixing nozzles for injection molding are. The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize the polymer. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. Tmn16/20/30/40 series of mixing nozzles for injection. Mixing Nozzle For Injection Molding.

From www.rootier.cn

ROOTIER INDUSTRY,Injection NozzlesSupplier, Injection NozzlesFactory Mixing Nozzle For Injection Molding Benefits of using mixing nozzles for injection molding are. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. This distinctive device eliminates uneven coloration in injection. The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize the polymer. What are mixing nozzles in injection molding? The. Mixing Nozzle For Injection Molding.

From www.alibaba.com

Injection Molding Ratio Mixing Nozzle Applicator Adhesives Epoxy Resin Mixing Nozzle For Injection Molding Benefits of using mixing nozzles for injection molding are. Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the. The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize the polymer. The resulting high viscous plastics melt flow is. Tmn16/20/30/40 series of mixing nozzles for injection molding machines. What are. Mixing Nozzle For Injection Molding.

From www.alibaba.com

Static Mixer Nozzle For Injection Molding Colour Mixing Buy Plastic Mixing Nozzle For Injection Molding The existing nozzle is replaced by. Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the. Tmn16/20/30/40 series. Mixing Nozzle For Injection Molding.

From prototool.com

Injection Molding Nozzle How to Troubleshoot Nozzle Leaks Mixing Nozzle For Injection Molding Benefits of using mixing nozzles for injection molding are. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. This distinctive device eliminates uneven coloration in injection. The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize the polymer. The existing nozzle is replaced by. Tmn16/20/30/40 series. Mixing Nozzle For Injection Molding.

From ritmindustry.com

Injection nozzle / for liquids / internal mixing RITM Industry Mixing Nozzle For Injection Molding Benefits of using mixing nozzles for injection molding are. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. What are mixing nozzles in injection molding? The nozzle is attached to the cylinder of the. The existing nozzle is replaced by. Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the.. Mixing Nozzle For Injection Molding.

From exoiisphe.blob.core.windows.net

How Many Types Of Nozzle In Injection Moulding Machine at Larry Wicker blog Mixing Nozzle For Injection Molding This distinctive device eliminates uneven coloration in injection. The existing nozzle is replaced by. The resulting high viscous plastics melt flow is. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. The nozzle is attached to the cylinder of the. Mixing nozzles for the most common injection molding machines are in stock with. Mixing Nozzle For Injection Molding.

From www.vrogue.co

Mixing Nozzle For Injection Molding Machines Fluid Pr vrogue.co Mixing Nozzle For Injection Molding The existing nozzle is replaced by. The resulting high viscous plastics melt flow is. Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks. Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the. The nozzle is attached to the cylinder of the. Our. Mixing Nozzle For Injection Molding.

From www.alibaba.com

Injection Molding Ratio Mixing Nozzle Applicator Adhesives Epoxy Resin Mixing Nozzle For Injection Molding This distinctive device eliminates uneven coloration in injection. The nozzle is attached to the cylinder of the. What are mixing nozzles in injection molding? The existing nozzle is replaced by. The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize the polymer. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing. Mixing Nozzle For Injection Molding.

From www.ajsolutions.be

Static mixers for noses AJ Solutions Mixing Nozzle For Injection Molding Benefits of using mixing nozzles for injection molding are. The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize the polymer. Mixing nozzles for the most common injection molding machines are in stock with us and can be delivered within 1 to 2 weeks. This distinctive device eliminates uneven coloration in injection. Mixing. Mixing Nozzle For Injection Molding.

From www.katosansho.com

TORAY MIXING NOZZLE For Injection Molding 樹脂関連 Product Information Mixing Nozzle For Injection Molding Benefits of using mixing nozzles for injection molding are. Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the. Tmn16/20/30/40 series of mixing nozzles for injection molding machines. The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize the polymer. The stamixco smn injection molding static mixing nozzle creates homogeneous. Mixing Nozzle For Injection Molding.

From www.indiamart.com

Silver Stainless Steel 60mm Injection Molding Nozzle Filters, Rs 7500 Mixing Nozzle For Injection Molding The existing nozzle is replaced by. The stamixco smn injection moulding mixing nozzle contains eight (8) very efficient static mixing elements that homogenize the polymer. This distinctive device eliminates uneven coloration in injection. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. Tmn16/20/30/40 series of mixing nozzles for injection molding machines. Benefits of. Mixing Nozzle For Injection Molding.

From pazard.com

5 kinds of Injection molding nozzle tip types you must know Pazard Mixing Nozzle For Injection Molding Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the. What are mixing nozzles in injection molding? Tmn16/20/30/40 series of mixing nozzles for injection molding machines. The nozzle is attached to the cylinder of the. Our mixing nozzles for injection molding assure you consistently homogeneous melt, guaranteed by their patented geometry. The stamixco smn injection moulding mixing. Mixing Nozzle For Injection Molding.

From www.indiamart.com

Injection Molding Mixing Nozzle, इंजेक्शन नोजल, इंजेक्शन नलिका in Mixing Nozzle For Injection Molding The resulting high viscous plastics melt flow is. Mixing nozzles ensure that additives, such as colorants, are evenly distributed throughout the. This distinctive device eliminates uneven coloration in injection. The stamixco smn injection molding static mixing nozzle creates homogeneous mixing of polymer melt during injection. Tmn16/20/30/40 series of mixing nozzles for injection molding machines. What are mixing nozzles in injection. Mixing Nozzle For Injection Molding.