Best Gasket Material For Seawater . Often used to protect electrical systems from bad weather. our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications. some of the common gasket materials suitable for seawater applications include: kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. Neoprene will not degrade easily when exposed to either salt or freshwater. Nitrile rubber (nbr) and epdm (ethylene. choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and.

from www.directindustry.com

choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). Nitrile rubber (nbr) and epdm (ethylene. our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications. some of the common gasket materials suitable for seawater applications include: kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. Neoprene will not degrade easily when exposed to either salt or freshwater. Often used to protect electrical systems from bad weather. nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and.

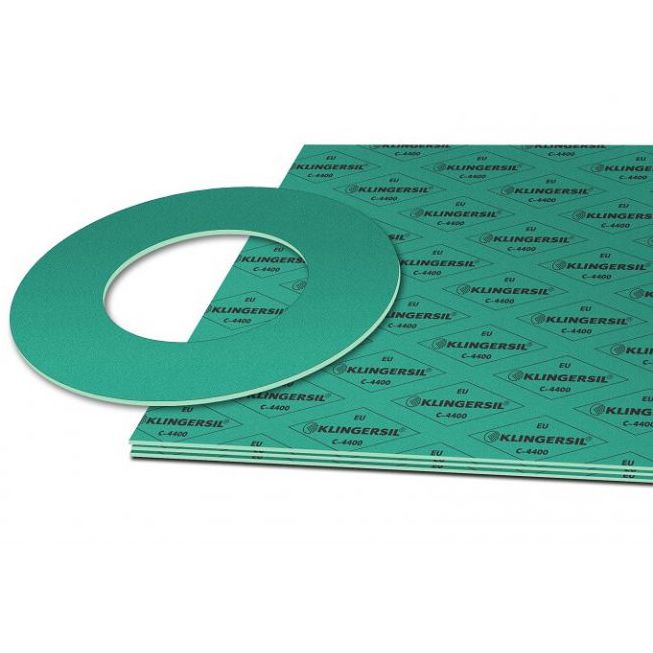

NBR gasket sheet KLINGERSIL® C4400 KLINGER aramid / water / high

Best Gasket Material For Seawater nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and. our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications. some of the common gasket materials suitable for seawater applications include: Often used to protect electrical systems from bad weather. choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). Neoprene will not degrade easily when exposed to either salt or freshwater. Nitrile rubber (nbr) and epdm (ethylene. kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and.

From srm-industries.com

What are the best gasket materials? SRM Industries Best Gasket Material For Seawater Neoprene will not degrade easily when exposed to either salt or freshwater. choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications. kain4 tested a variety. Best Gasket Material For Seawater.

From www.youtube.com

6 Tips for Choosing the Best Gasket Materials, Types, Uses YouTube Best Gasket Material For Seawater our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications. nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and. Neoprene will not degrade easily when exposed to either salt or freshwater. Nitrile rubber (nbr) and. Best Gasket Material For Seawater.

From www.heat-exchangergasket.com

Seawater Sondex S100 Plate Heat Exchanger Gaskets For Marine Oil Cooler Best Gasket Material For Seawater our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications. some of the common gasket materials suitable for seawater applications include: kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. . Best Gasket Material For Seawater.

From www.iqsdirectory.com

Gasket Material Types, Uses, Features and Benefits Best Gasket Material For Seawater choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). some of the common gasket materials suitable for seawater applications include: Often used to protect electrical systems from bad weather. our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide. Best Gasket Material For Seawater.

From www.pheaccessories.com

Seawater plate cooling m6mfg m10mfg m15mfg sealing Best Gasket Material For Seawater Neoprene will not degrade easily when exposed to either salt or freshwater. nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and. choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). Nitrile rubber (nbr) and epdm (ethylene. . Best Gasket Material For Seawater.

From www.marineenergy.com.au

Gasket LP 3008400 Seawater Pump mount Cummins, John Deere Pumps Best Gasket Material For Seawater our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications. kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. Often used to protect electrical systems from bad weather. Neoprene will not degrade. Best Gasket Material For Seawater.

From www.dgxtphe.com

DGXT Brand SeaWater high efficiency NBR gasket Titanium plate heat Best Gasket Material For Seawater Nitrile rubber (nbr) and epdm (ethylene. kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. Neoprene will not degrade easily when exposed to either salt or freshwater. nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to. Best Gasket Material For Seawater.

From www.dgxtphe.com

China Brand SeaWater Steam water heat transfer gasket plate and frame Best Gasket Material For Seawater Neoprene will not degrade easily when exposed to either salt or freshwater. nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and. kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. Nitrile rubber (nbr). Best Gasket Material For Seawater.

From bdteletalk.com

How to Choose the Best Gasket Material for Your Project A Best Gasket Material For Seawater nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and. kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. choose a material such as a neoprene rubber, neoprene foam, or epdm (which is. Best Gasket Material For Seawater.

From www.curee.org

20 Best Gasket Sealer For Water Pump [2023] Curee Best Gasket Material For Seawater Nitrile rubber (nbr) and epdm (ethylene. some of the common gasket materials suitable for seawater applications include: choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). Often used to protect electrical systems from bad weather. kain4 tested a variety of gasket materials with 316l flanges in natural. Best Gasket Material For Seawater.

From tym.co.uk

Best Gasket Material for Your Needs? TYM Seals and Gaskets Best Gasket Material For Seawater nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and. Neoprene will not degrade easily when exposed to either salt or freshwater. kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. choose a. Best Gasket Material For Seawater.

From www.iqsdirectory.com

Gasket Material Types, Uses, Features and Benefits Best Gasket Material For Seawater choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). Often used to protect electrical systems from bad weather. kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. some of the common gasket materials. Best Gasket Material For Seawater.

From bdteletalk.com

How to Choose the Best Gasket Material for Your Project A Best Gasket Material For Seawater some of the common gasket materials suitable for seawater applications include: nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and. our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications. Neoprene will not degrade. Best Gasket Material For Seawater.

From www.dgxtphe.com

China Brand SeaWater Steam water heat transfer gasket plate heat exchanger Best Gasket Material For Seawater our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications. Neoprene will not degrade easily when exposed to either salt or freshwater. choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). Often used to protect electrical. Best Gasket Material For Seawater.

From storables.com

What Is The Best Gasket Sealer For A Water Pump Storables Best Gasket Material For Seawater Neoprene will not degrade easily when exposed to either salt or freshwater. some of the common gasket materials suitable for seawater applications include: kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are. Best Gasket Material For Seawater.

From exoquhxqu.blob.core.windows.net

Gasket Material For High Pressure Water at Thad Herdon blog Best Gasket Material For Seawater kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. Nitrile rubber (nbr) and epdm (ethylene. Neoprene will not degrade easily when exposed to either salt or freshwater. Often used to protect electrical systems from bad weather. nitrile rubber, silicone rubber, and epdm (ethylene propylene. Best Gasket Material For Seawater.

From www.iqsdirectory.com

Gasket Material Types, Uses, Features and Benefits Best Gasket Material For Seawater Neoprene will not degrade easily when exposed to either salt or freshwater. Often used to protect electrical systems from bad weather. choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). Nitrile rubber (nbr) and epdm (ethylene. nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular. Best Gasket Material For Seawater.

From wonderfulengineering.com

10 Best Gasket Materials For A Perfect Seal Best Gasket Material For Seawater Nitrile rubber (nbr) and epdm (ethylene. nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and. some of the common gasket materials suitable for seawater applications include: choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). . Best Gasket Material For Seawater.

From www.youtube.com

Best Gasket Sealer For Water Pumps 2024 Top 4 Picks YouTube Best Gasket Material For Seawater Often used to protect electrical systems from bad weather. choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. Nitrile rubber (nbr) and epdm (ethylene. Neoprene. Best Gasket Material For Seawater.

From sinoprettech.en.made-in-china.com

Stainless Steel Gasket Plate Heat Exchanger for Seawater Cooling System Best Gasket Material For Seawater kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. Often used to protect electrical systems from bad weather. Nitrile rubber (nbr) and epdm (ethylene. Neoprene will not degrade easily when exposed to either salt or freshwater. some of the common gasket materials suitable for. Best Gasket Material For Seawater.

From bdteletalk.com

Choosing The Best Water Pump Gasket Sealer For LongLasting Performance Best Gasket Material For Seawater some of the common gasket materials suitable for seawater applications include: nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and. Often used to protect electrical systems from bad weather. kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range. Best Gasket Material For Seawater.

From www.globecomposite.com

Using the Best Gasket Material for the U.S. Navy Best Gasket Material For Seawater Neoprene will not degrade easily when exposed to either salt or freshwater. choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). Often used to protect electrical systems from bad weather. some of the common gasket materials suitable for seawater applications include: Nitrile rubber (nbr) and epdm (ethylene. . Best Gasket Material For Seawater.

From defender.com

Bomar SelfAdhesive Hatch Gasket Material Defender Marine Best Gasket Material For Seawater nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and. some of the common gasket materials suitable for seawater applications include: our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications. Often used to protect. Best Gasket Material For Seawater.

From www.eng-tips.com

Spiral Wound Gasket filler selection for seawater applications Best Gasket Material For Seawater our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications. Neoprene will not degrade easily when exposed to either salt or freshwater. choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). kain4 tested a variety. Best Gasket Material For Seawater.

From www.sbmar.com

SMX 1730 Seawater Pump Gasket ORing Kit Seaboard Marine Best Gasket Material For Seawater Nitrile rubber (nbr) and epdm (ethylene. our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications. Often used to protect electrical systems from bad weather. Neoprene will not degrade easily when exposed to either salt or freshwater. nitrile rubber, silicone rubber, and epdm (ethylene propylene diene. Best Gasket Material For Seawater.

From www.directindustry.com

NBR gasket sheet KLINGERSIL® C4400 KLINGER aramid / water / high Best Gasket Material For Seawater nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and. Neoprene will not degrade easily when exposed to either salt or freshwater. Often used to protect electrical systems from bad weather. kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range. Best Gasket Material For Seawater.

From carcaretotal.com

7 Best Gasket Sealers of 2022 Reviews, Buying Guide and FAQs Best Gasket Material For Seawater nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and. some of the common gasket materials suitable for seawater applications include: kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. our highly. Best Gasket Material For Seawater.

From www.dmsseals.com

pi best gasket material for water seals for air compressor DMS Seals Best Gasket Material For Seawater Nitrile rubber (nbr) and epdm (ethylene. nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and. our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications. Neoprene will not degrade easily when exposed to either salt. Best Gasket Material For Seawater.

From usseal.com

How to choose the best Gasket Material for your application! Best Gasket Material For Seawater our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide range of gasket applications. Nitrile rubber (nbr) and epdm (ethylene. kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. choose a material such as a. Best Gasket Material For Seawater.

From www.indiamart.com

Nitrile Natural Rubber Gaskets For Pipeline Flanges, Packaging Type Best Gasket Material For Seawater kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. some of the common gasket materials suitable for seawater applications include: choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). Often used to protect. Best Gasket Material For Seawater.

From www.dmsseals.com

nbr best gasket material for water seals for preventing the seal from Best Gasket Material For Seawater Nitrile rubber (nbr) and epdm (ethylene. some of the common gasket materials suitable for seawater applications include: Neoprene will not degrade easily when exposed to either salt or freshwater. nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular choices for their resilience to water, weathering, and. our highly experienced technicians can advise you on. Best Gasket Material For Seawater.

From www.coowor.com

Supply Heat Exchanger equivalent Plate Gasket For seawater Plate heat Best Gasket Material For Seawater Nitrile rubber (nbr) and epdm (ethylene. choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). some of the common gasket materials suitable for seawater applications include: Often used to protect electrical systems from bad weather. nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are popular. Best Gasket Material For Seawater.

From lcmeide.en.made-in-china.com

Welded Plate Heat Exchanger with Gasket for Seawater Titanium Plate Best Gasket Material For Seawater Neoprene will not degrade easily when exposed to either salt or freshwater. choose a material such as a neoprene rubber, neoprene foam, or epdm (which is common in the water industry). Often used to protect electrical systems from bad weather. our highly experienced technicians can advise you on the best sheet materials and manufacturing processes for a wide. Best Gasket Material For Seawater.

From www.slideserve.com

PPT Buy the Best Gasket Material PowerPoint Presentation, free Best Gasket Material For Seawater some of the common gasket materials suitable for seawater applications include: Neoprene will not degrade easily when exposed to either salt or freshwater. kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. nitrile rubber, silicone rubber, and epdm (ethylene propylene diene monomer) are. Best Gasket Material For Seawater.

From wonderfulengineering.com

10 Best Gasket Materials For A Perfect Seal Best Gasket Material For Seawater Neoprene will not degrade easily when exposed to either salt or freshwater. some of the common gasket materials suitable for seawater applications include: kain4 tested a variety of gasket materials with 316l flanges in natural seawater in the temperature range 25° to 32°c for 28 days. choose a material such as a neoprene rubber, neoprene foam, or. Best Gasket Material For Seawater.