Welding Tip Size Chart . selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality of welds in. the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. use the correct tip size. the goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. When a contact tip begins. To get the best results, it is important to. The tip size is determined by the orifice. Using an oversized tip results in poor current transfer; welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding.

from materialwelding.com

the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. When a contact tip begins. Using an oversized tip results in poor current transfer; The tip size is determined by the orifice. selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality of welds in. use the correct tip size. To get the best results, it is important to. the goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding.

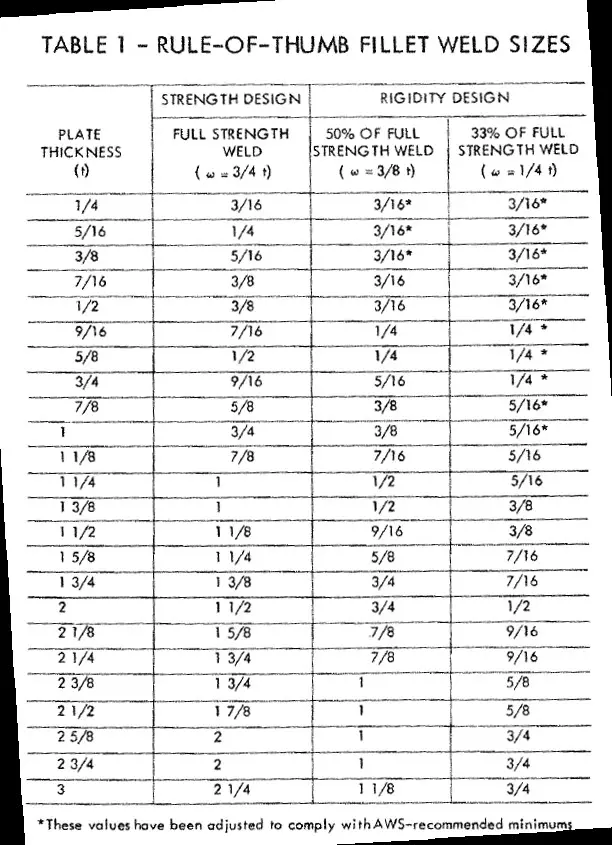

Rule Of Thumb For determining the Fillet Weld Size

Welding Tip Size Chart the goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. Using an oversized tip results in poor current transfer; The tip size is determined by the orifice. When a contact tip begins. selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality of welds in. contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. the goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. To get the best results, it is important to. welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. use the correct tip size.

From www.aliexpress.com

5pcslotH0112oxypropaneweldingnozzleweldingtipsizesof1234.jpg Welding Tip Size Chart contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality of welds in. use the correct tip size. To get the best results,. Welding Tip Size Chart.

From michaelfarmer.z21.web.core.windows.net

Oxy Acetylene Victor Welding Tip Chart Welding Tip Size Chart To get the best results, it is important to. the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. When a contact tip begins. welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. selecting the right size for the. Welding Tip Size Chart.

From studycampuslemann.z19.web.core.windows.net

Victor Welding Tip Size Chart Welding Tip Size Chart use the correct tip size. To get the best results, it is important to. the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. The tip size is determined by the orifice. Using an oversized tip results in poor current transfer; When a contact tip begins. contact tip size. Welding Tip Size Chart.

From dxorkmqso.blob.core.windows.net

Welding Rods Guide at Demetrius Carlson blog Welding Tip Size Chart selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality of welds in. To get the best results, it is important to. welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. contact tip size determines. Welding Tip Size Chart.

From bakersgas.com

Cutting Torch Tip Flow Charts Baker's Gas & Welding Supplies, Inc. Welding Tip Size Chart contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. To get the best results, it is important to. the goal is to have the wire feed. Welding Tip Size Chart.

From studycampuslemann.z19.web.core.windows.net

Victor Welding Cutting Tip Size Chart Welding Tip Size Chart The tip size is determined by the orifice. welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. contact tip size determines what wire size you can use and the. Welding Tip Size Chart.

From dat.perueduca.edu.pe

Victor Tip Size Chart Printable Templates Free Welding Tip Size Chart When a contact tip begins. use the correct tip size. The tip size is determined by the orifice. welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. To get the best results, it is important to. Using an oversized tip results in poor current transfer; the goal. Welding Tip Size Chart.

From materialwelding.com

Rule Of Thumb For determining the Fillet Weld Size Welding Tip Size Chart When a contact tip begins. use the correct tip size. the goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. To get the best results, it is important to. contact. Welding Tip Size Chart.

From weldguru.com

Welding Rod Sizes How To Choose the Right Electrode Weld Guru Welding Tip Size Chart selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality of welds in. the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]). Welding Tip Size Chart.

From legaleagleflyingadventures.com

Gas Welding tip size Legal Eagle Flying Adventures Welding Tip Size Chart Using an oversized tip results in poor current transfer; the goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. selecting the right size for the mig welding torch contact tip is. Welding Tip Size Chart.

From bakersgas.com

Cutting Torch Tip Flow Charts Baker's Gas & Welding Supplies, Inc. Welding Tip Size Chart contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. The tip size is determined by the orifice. To get the best results, it is important to. use the correct tip size. the tip sizes range from 000 to 8, coinciding with a metal thickness. Welding Tip Size Chart.

From www.arc-zone.com

Welding, Brazing Tip w/ Gas Mixer Style W1 ArcZone Welding Tip Size Chart the goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. use the correct tip size. When a contact tip begins. The tip size is determined by the orifice. selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality. Welding Tip Size Chart.

From weaversteelweld.com

Pipe Size Chart Weaver Steel Welding Welding Tip Size Chart welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. the goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. Using an oversized. Welding Tip Size Chart.

From exoavpvly.blob.core.windows.net

Welding Machine Setting Chart at Mark Knepp blog Welding Tip Size Chart Using an oversized tip results in poor current transfer; When a contact tip begins. To get the best results, it is important to. contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. use the correct tip size. selecting the right size for the mig. Welding Tip Size Chart.

From weldguru.com

MIG Welder Settings Explained (with Chart) Weld Guru Welding Tip Size Chart selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality of welds in. Using an oversized tip results in poor current transfer; The tip size is determined by the orifice. contact tip size determines what wire size you can use and the amount of filler material. Welding Tip Size Chart.

From weldingtroop.com

MIG Welding Contact Tip Thread Size Chart And Users Guide Welding Tip Size Chart the goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. Using an oversized tip results in poor current transfer; welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. use the correct tip size. contact tip size determines what wire. Welding Tip Size Chart.

From www.scribd.com

Harris Welding Tip Chart Gases Mechanical Engineering Welding Tip Size Chart selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality of welds in. the goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. To get the best results, it is important to. the tip sizes range from 000. Welding Tip Size Chart.

From www.hotrod.com

MIG Welding Tricks, Tips, and Proper Techniques Custom Classic Trucks Welding Tip Size Chart use the correct tip size. contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. The tip size is determined by the orifice. Using an oversized tip results in poor current transfer; welding tips usually produce positive pressure (higher than 1 pound per square inch. Welding Tip Size Chart.

From maisieweston.z13.web.core.windows.net

Victor Torch Tip Chart Welding Tip Size Chart contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. use the correct tip size. When a contact tip begins. To get the best results, it is important to. Using an oversized tip results in poor current transfer; the tip sizes range from 000 to. Welding Tip Size Chart.

From bakersgas.com

Cutting Torch Tip Flow Charts Baker's Gas & Welding Supplies, Inc. Welding Tip Size Chart contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. When a contact tip begins. To get the best results, it is important to. selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality. Welding Tip Size Chart.

From www.pinterest.co.uk

Type 17 Size Chart Brazing, Metal working, Welding Welding Tip Size Chart contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. When a contact tip begins. use the correct tip size. Using an oversized tip results in poor current transfer; the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to. Welding Tip Size Chart.

From weldingtroop.com

MIG Welding Contact Tip Thread Size Chart And Users Guide Welding Tip Size Chart selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality of welds in. contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. the goal is to have the wire feed through the. Welding Tip Size Chart.

From louislyons.z19.web.core.windows.net

Victor Welding Tip Chart Welding Tip Size Chart the goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. use the correct tip size. The tip size is determined by the orifice. the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. When a contact tip begins. To get the best. Welding Tip Size Chart.

From joeblowweldingsupply.com

About Joe Blow Welding Supply Welding Tip Size Chart the goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. The tip size is determined by the orifice. contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. welding tips usually produce positive pressure (higher than 1 pound. Welding Tip Size Chart.

From niamhhenderson.z13.web.core.windows.net

Oxy Acetylene Victor Welding Tip Chart Welding Tip Size Chart To get the best results, it is important to. contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. When a contact tip begins. use the correct tip size. selecting the right size for the mig welding torch contact tip is a critical point in. Welding Tip Size Chart.

From dxofrsbjd.blob.core.windows.net

Oxy Acetylene Welding Torch Tip Sizes at Weldon Guzman blog Welding Tip Size Chart To get the best results, it is important to. use the correct tip size. When a contact tip begins. contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. The tip size is determined by the orifice. the tip sizes range from 000 to 8,. Welding Tip Size Chart.

From weldguru.com

Welding Cable Size Guide Charts & Tips for the Right Choice Welding Tip Size Chart welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. use the correct tip size. To get the best results, it is important to. Using an oversized tip results in poor current transfer; When a contact tip begins. contact tip size determines what wire size you can use. Welding Tip Size Chart.

From cz.pinterest.com

Welding Tip Size Comparison Chart Welding tips, Welding, Tips Welding Tip Size Chart To get the best results, it is important to. selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality of welds in. the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. use the correct tip size.. Welding Tip Size Chart.

From nicholasgeorge.z13.web.core.windows.net

Tig Weld Amperage Chart Welding Tip Size Chart The tip size is determined by the orifice. Using an oversized tip results in poor current transfer; welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding.. Welding Tip Size Chart.

From mungfali.com

Smith Cutting Torch Tip Size Chart Welding Tip Size Chart contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. use the correct tip size. selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality of welds in. Using an oversized tip results. Welding Tip Size Chart.

From weldingoutfitter.com

MillerSmith SC503 HD Propane Cutting Tip Welding Tip Size Chart Using an oversized tip results in poor current transfer; contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. the tip sizes range from 000 to. Welding Tip Size Chart.

From www.ebay.com.au

OxyAcetylene Welding Tips Model W1 Compatible with 100 Series Victor Welding Tip Size Chart the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality of welds in. To get the best results, it is important to. When a contact tip begins. . Welding Tip Size Chart.

From weldguru.com

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru Welding Tip Size Chart Using an oversized tip results in poor current transfer; contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal. the goal is to have the wire. Welding Tip Size Chart.

From jonathanhenry.z13.web.core.windows.net

Tig Weld Amp Chart Welding Tip Size Chart use the correct tip size. selecting the right size for the mig welding torch contact tip is a critical point in mig welding that may affect quality of welds in. When a contact tip begins. the goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. welding tips usually produce. Welding Tip Size Chart.

From bakersgas.com

Cutting Torch Tip Flow Charts Baker's Gas & Welding Supplies, Inc. Welding Tip Size Chart use the correct tip size. the goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. When a contact tip begins. contact tip size determines what wire size you can use and the amount of filler material that will be distributed during welding. selecting the right size for the mig. Welding Tip Size Chart.