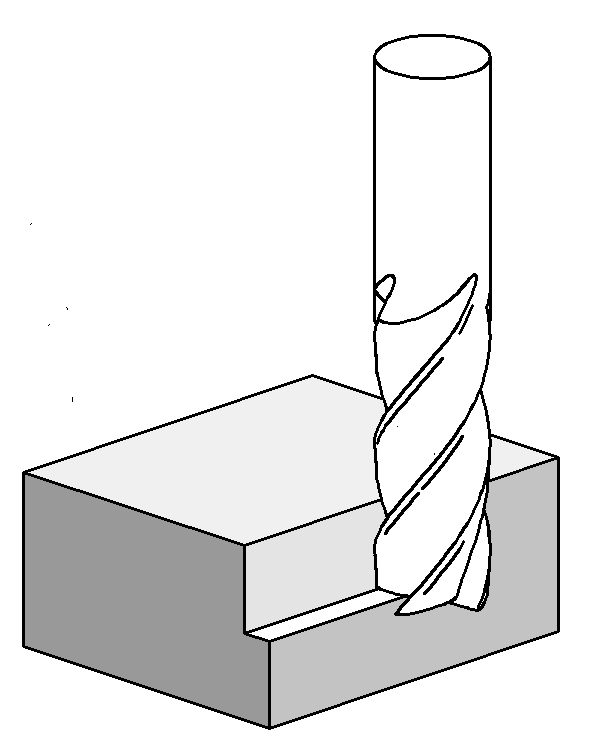

Slab Milling Is . It is also known as surface milling or slab milling. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. Plain milling is performed to produce a plain, flat, horizontal. Plain or surface milling, as the name implies, applies to flat surfaces. Moreover, it is a process of. Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing portions of material from a. The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Plain milling is the most common type of milling machine operation. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Also known as slab milling or.

from exosgntvc.blob.core.windows.net

It is also known as surface milling or slab milling. Also known as slab milling or. Moreover, it is a process of. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Plain milling is performed to produce a plain, flat, horizontal. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing portions of material from a. Plain or surface milling, as the name implies, applies to flat surfaces.

Slab Milling Process at Hortense Findley blog

Slab Milling Is It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. Plain milling is performed to produce a plain, flat, horizontal. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing portions of material from a. The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Plain or surface milling, as the name implies, applies to flat surfaces. It is also known as surface milling or slab milling. Plain milling is the most common type of milling machine operation. Moreover, it is a process of. Also known as slab milling or.

From www.slideserve.com

PPT Milling Machine PowerPoint Presentation, free download ID9172901 Slab Milling Is Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Moreover, it is a process of. The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Plain milling is performed to produce a plain, flat, horizontal. Plain milling is the process of removing material from. Slab Milling Is.

From qhunt.blogspot.com

What are the operations carried out in Milling Machine? Q Hunt Slab Milling Is It is also known as surface milling or slab milling. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling is performed to produce a plain, flat, horizontal. Plain milling is the most common type of milling machine operation. Plain milling is the process of removing material from a. Slab Milling Is.

From www.youtube.com

Heavy Duty Slab Milling Machine YouTube Slab Milling Is Plain milling is performed to produce a plain, flat, horizontal. It is also known as surface milling or slab milling. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. Also known as slab milling or. Plain milling (also known as slab milling) is a. Slab Milling Is.

From exosgntvc.blob.core.windows.net

Slab Milling Process at Hortense Findley blog Slab Milling Is Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling is performed to produce a plain, flat, horizontal. Moreover, it is a process of. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish.. Slab Milling Is.

From www.slideserve.com

PPT ME 350 Lecture 5 Chapter 22 & 23 PowerPoint Presentation ID Slab Milling Is It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Plain milling is the most common type of milling machine operation. Plain milling is performed to produce a plain, flat, horizontal. Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing portions of material from. Slab Milling Is.

From www.kccustomhardwoods.com

What is the Process for Live Edge Slab Milling? KC Custom Hardwoods Slab Milling Is Plain or surface milling, as the name implies, applies to flat surfaces. Moreover, it is a process of. Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing portions of material from a. Also known as slab milling or. Plain milling is the most common type of milling machine operation. Plain milling is. Slab Milling Is.

From gertnergroup.com

Slab milling machines (MFL) Gertnergroup Slab Milling Is Also known as slab milling or. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Plain milling is the most common type of milling machine operation.. Slab Milling Is.

From www.slideserve.com

PPT Chapter4 MILLING PROCESS PowerPoint Presentation ID518382 Slab Milling Is It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Moreover, it is a process of. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing. Slab Milling Is.

From www.chegg.com

Solved I. A slab milling operation will take place on a part Slab Milling Is Moreover, it is a process of. Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing portions of material from a. It is also known as surface milling or slab milling. Plain milling is performed to produce a plain, flat, horizontal. The movement of the cutter removes unwanted material from the workpiece creating. Slab Milling Is.

From www.chegg.com

Solved A slabmilling operation is being carried out on a Slab Milling Is It is also known as surface milling or slab milling. Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing portions of material from a. Plain milling is the most common type of milling machine operation. Moreover, it is a process of. Plain milling, also known as slab or surface milling, is a. Slab Milling Is.

From www.chegg.com

Solved Question 4 (20 marks) A slab milling operation is Slab Milling Is Plain milling is performed to produce a plain, flat, horizontal. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling is the most common type of milling machine operation. Moreover, it is a process of. Plain milling (also known as slab milling) is a subtractive manufacturing process which means. Slab Milling Is.

From www.slideshare.net

MIlling 1 Slab Milling Is The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Plain milling is the most common type of milling machine operation. Moreover, it is a process of. Plain milling is performed to produce a plain, flat, horizontal. Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing. Slab Milling Is.

From www.youtube.com

Slab milling or plain milling YouTube Slab Milling Is Plain milling is the most common type of milling machine operation. Plain milling is performed to produce a plain, flat, horizontal. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. Plain or surface milling, as the name implies, applies to flat surfaces. Also known. Slab Milling Is.

From arianmetal.ir

Arian Slab Milling Is The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain or surface milling, as the name implies, applies to flat surfaces. It involves using a milling cutter which rotates on an axis that is. Slab Milling Is.

From www.highlandwoodworking.com

Woodpeckers Slab Flattening Mill Slab Milling Is Plain milling is performed to produce a plain, flat, horizontal. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Plain or surface milling, as the name implies, applies to flat surfaces. Plain milling is the most common type of milling machine operation. Moreover, it is a process of. Also known as. Slab Milling Is.

From www.coursehero.com

A slabmilling operation is being carried out on a out on a... Course Slab Milling Is Plain milling is the most common type of milling machine operation. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. Plain milling is performed to produce a plain, flat, horizontal. The movement of the cutter removes unwanted material from the workpiece creating the desired. Slab Milling Is.

From caddesignr.com

Milling machine operations photos Cad Designer Slab Milling Is Moreover, it is a process of. Also known as slab milling or. The movement of the cutter removes unwanted material from the workpiece creating the desired end product. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. It is also known as surface milling or slab milling. Plain milling is the. Slab Milling Is.

From www.coastmachinery.com

Used Slab Milling Machine Coast Machinery Group Slab Milling Is Plain or surface milling, as the name implies, applies to flat surfaces. Moreover, it is a process of. Also known as slab milling or. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling is performed to produce a plain, flat, horizontal. Plain milling (also known as slab milling). Slab Milling Is.

From kreasimudaindonesia.com

Pahami Metode Pemotongan Pada Mesin Milling CNC, yuk! Kreasi Muda Slab Milling Is Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing portions of material from a. Plain or surface milling, as the name implies, applies to flat surfaces. It is also known as surface milling or slab milling. Plain milling, also known as slab or surface milling, is a process used when machining a. Slab Milling Is.

From proleantech.com

Understanding Milling Cutters in CNC Machining Slab Milling Is Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling is the most common type of milling machine operation. Also known as slab milling or. The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Plain milling (also known as slab milling) is. Slab Milling Is.

From www.coastmachinery.com

Used Slab Milling Machine Coast Machinery Group Slab Milling Is Also known as slab milling or. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Moreover, it is a process of. Plain or surface milling, as the name implies, applies to flat surfaces. The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Plain milling. Slab Milling Is.

From www.indiamart.com

Slab Milling Cutters, CNC Milling Cutter, Computer Numerical Control Slab Milling Is Moreover, it is a process of. Plain or surface milling, as the name implies, applies to flat surfaces. It is also known as surface milling or slab milling. The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Also known as slab milling or. Plain milling is the most common type of milling machine. Slab Milling Is.

From exosgntvc.blob.core.windows.net

Slab Milling Process at Hortense Findley blog Slab Milling Is Plain or surface milling, as the name implies, applies to flat surfaces. The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. It is also known as surface milling. Slab Milling Is.

From fractory.com

Milling Cutters & Tools Types and Their Purposes (with Images) Slab Milling Is The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling is the most common type of milling machine operation. It involves using a milling cutter which rotates on an axis that is parallel. Slab Milling Is.

From fractory.com

Milling Cutters & Tools Types and Their Purposes (with Images) Slab Milling Is Plain milling is the most common type of milling machine operation. Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing portions of material from a. Moreover, it is a process of. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Also known as. Slab Milling Is.

From www.woodworkersjournal.com

Woodpeckers Slab Flattening Mill Router Woodworker's Journal Slab Milling Is Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing portions of material from a. Plain milling is performed to produce a plain, flat, horizontal. It is also known as surface milling or slab milling. Also known as slab milling or. Plain milling is the process of removing material from a flat surface. Slab Milling Is.

From www.youtube.com

Slab milling on a Brown & Sharpe 3A universal milling machine. YouTube Slab Milling Is It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling is the most common type of milling machine operation. It is also known as surface milling or slab milling. Moreover, it. Slab Milling Is.

From toolnotes.com

Milling Operations ToolNotes Slab Milling Is Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing portions of material from a. Plain or surface milling, as the name implies, applies to flat surfaces. Plain milling is performed to produce a plain, flat, horizontal. Plain milling is the process of removing material from a flat surface using a rotating cutter. Slab Milling Is.

From kreasimudaindonesia.com

Pahami Metode Pemotongan Pada Mesin Milling CNC, yuk! Kreasi Muda Slab Milling Is The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Plain milling is the process of removing material from a flat surface using a rotating cutter that has multiple teeth to give a smooth finish. Moreover, it is a process of. It involves using a milling cutter which rotates on an axis that is. Slab Milling Is.

From www.chegg.com

Solved You are slab milling a 300 mm wide slab of metal that Slab Milling Is It is also known as surface milling or slab milling. Plain milling is performed to produce a plain, flat, horizontal. Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing portions of material from a. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal. Slab Milling Is.

From woodmizer.com

MB100 SlabMizer Slab Flattening Mill Portable Sawmills & Wood Slab Milling Is It is also known as surface milling or slab milling. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Plain or surface milling, as the name implies, applies to flat surfaces. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Also. Slab Milling Is.

From www.slideserve.com

PPT CHAPTER 23 PowerPoint Presentation, free download ID1275516 Slab Milling Is Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing portions of material from a. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Also known as slab milling or. Plain or surface milling, as the name implies, applies to flat surfaces. Plain. Slab Milling Is.

From www.slideserve.com

PPT Milling Machine PowerPoint Presentation, free download ID9172901 Slab Milling Is Plain milling is performed to produce a plain, flat, horizontal. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling is the most common type of milling machine operation. The movement of the cutter removes unwanted material from the workpiece creating the desired end product. Plain milling is the. Slab Milling Is.

From www.china-machining.com

Plain Milling Understanding this Fascinating Production Process Slab Milling Is It is also known as surface milling or slab milling. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. It involves using a milling cutter which rotates on an axis that is parallel to the milled surface. Also known as slab milling or. Plain or surface milling, as the name. Slab Milling Is.

From www.chegg.com

Solved A slabmilling operation is carried out on a Slab Milling Is Plain milling (also known as slab milling) is a subtractive manufacturing process which means it involves removing portions of material from a. It is also known as surface milling or slab milling. Plain milling is the most common type of milling machine operation. Plain milling, also known as slab or surface milling, is a process used when machining a flat,. Slab Milling Is.