End Mill Regrinding . Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Garr tool offers regrinding services for its own tools, such as end mills, drills, and reamers. Geometry design and parameter verification. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. Find out the three levels of end mill. For optimal performance, regrinding or reconditioning is imperative. In this issue, we look at the factors which will impact the overall performance of an endmill and “weird” endmills that have higher geometrical levels of complexity. About the bottom blade shape. Learn how to request a quote, specify. Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,.

from cuttermasters.com

Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. Find out the three levels of end mill. Garr tool offers regrinding services for its own tools, such as end mills, drills, and reamers. About the bottom blade shape. For optimal performance, regrinding or reconditioning is imperative. Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Learn how to request a quote, specify. In this issue, we look at the factors which will impact the overall performance of an endmill and “weird” endmills that have higher geometrical levels of complexity. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. Geometry design and parameter verification.

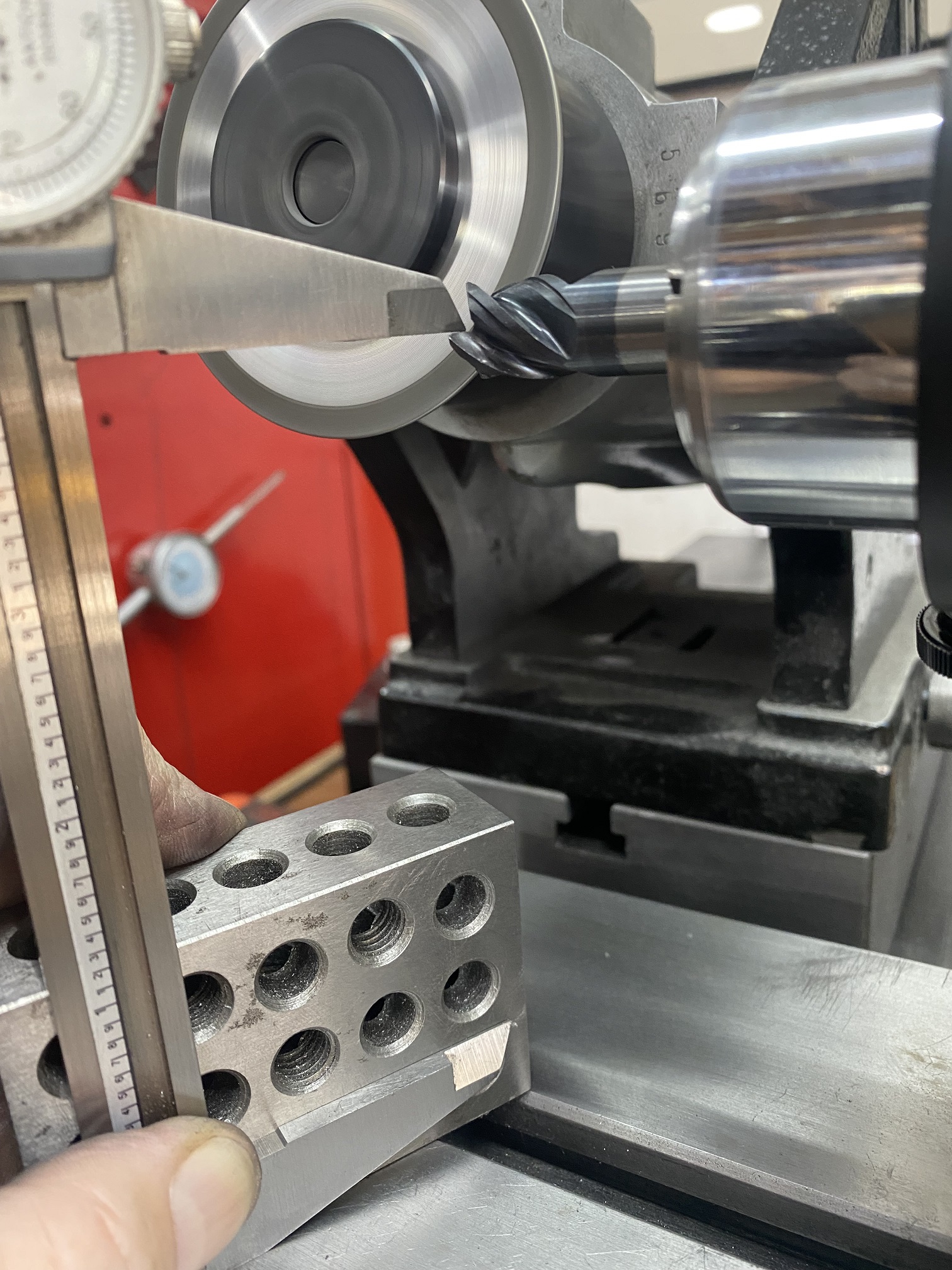

Regrinding Variable Flute End MIlls Cuttermasters

End Mill Regrinding Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. In this issue, we look at the factors which will impact the overall performance of an endmill and “weird” endmills that have higher geometrical levels of complexity. Find out the three levels of end mill. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. About the bottom blade shape. Learn how to request a quote, specify. Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. For optimal performance, regrinding or reconditioning is imperative. Garr tool offers regrinding services for its own tools, such as end mills, drills, and reamers. Geometry design and parameter verification.

From huanatools.com

what is an end mill and how to make an end mill Huana Tools End Mill Regrinding Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. About the bottom blade shape. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. For optimal performance, regrinding or reconditioning is imperative. Learn. End Mill Regrinding.

From www.dreamstime.com

The Ball End Mill Tool Type Regrinding Process Control by CNC Program End Mill Regrinding In this issue, we look at the factors which will impact the overall performance of an endmill and “weird” endmills that have higher geometrical levels of complexity. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. Find out the three levels of end mill. Geometry design. End Mill Regrinding.

From shopee.com.my

Li You End Mill Regrinding Machine ERM12 (Original) Shopee Malaysia End Mill Regrinding Geometry design and parameter verification. For optimal performance, regrinding or reconditioning is imperative. Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Find out the three levels of end mill. About the bottom blade shape. Learn how to request a quote, specify. In this issue, we look at the factors. End Mill Regrinding.

From www.youtube.com

End mill regrind YouTube End Mill Regrinding About the bottom blade shape. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Low helix (15 degrees) to high helix (60 degrees) in high helix tools. End Mill Regrinding.

From www.cyber-rc.com

Regrinding endmills on GriStar Series No.3 (Ball End Endmill)|CyberRC End Mill Regrinding Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Learn how to request a quote, specify. In this issue, we look at the factors which will impact the overall performance of an endmill and “weird” endmills that have higher geometrical levels of complexity. Find out the three levels of end. End Mill Regrinding.

From www.dreamstime.com

The Ball End Mill Tool Regrinding Process on Regrinding Machine Stock End Mill Regrinding Geometry design and parameter verification. Find out the three levels of end mill. Garr tool offers regrinding services for its own tools, such as end mills, drills, and reamers. Learn how to request a quote, specify. Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Low helix (15 degrees) to. End Mill Regrinding.

From www.dreamstime.com

The Ball End Mill Tool Type Regrinding Process Control by CNC Program End Mill Regrinding About the bottom blade shape. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Learn how to request a quote, specify. Geometry design and parameter verification. Find. End Mill Regrinding.

From www.scmtstool.com

Something about carbide end mill regrinding End Mill Regrinding Find out the three levels of end mill. Learn how to request a quote, specify. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. In this issue, we look at the factors which will impact the overall performance of an endmill and “weird” endmills that have. End Mill Regrinding.

From www.mmc-carbide.com

End Mill Terminology Technical Info / Cutting Formula MITSUBISHI End Mill Regrinding About the bottom blade shape. In this issue, we look at the factors which will impact the overall performance of an endmill and “weird” endmills that have higher geometrical levels of complexity. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. Geometry design and parameter verification.. End Mill Regrinding.

From www.dreamstime.com

141 Regrinding Machine Stock Photos Free & RoyaltyFree Stock Photos End Mill Regrinding About the bottom blade shape. Learn how to request a quote, specify. Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. Geometry design and parameter verification. Garr. End Mill Regrinding.

From www.dreamstime.com

204 Tool Regrinding Stock Photos Free & RoyaltyFree Stock Photos End Mill Regrinding Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Geometry design and parameter verification. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. Learn how to request a quote, specify. For optimal performance, regrinding or reconditioning. End Mill Regrinding.

From huanatools.com

what is an end mill and how to make an end mill Huana Tools End Mill Regrinding Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. In this issue, we look at the factors which will impact the overall performance of an endmill and “weird” endmills that have higher geometrical levels of complexity. Low helix (15 degrees) to high helix (60 degrees) in. End Mill Regrinding.

From connect2india.com

Regrinding Cutting Tool, Solid Carbide Taper Drill, Solid Carbide NC End Mill Regrinding Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. In this issue, we look at the factors which will impact the overall performance. End Mill Regrinding.

From cuttermasters.com

Regrinding Variable Flute End MIlls Cuttermasters End Mill Regrinding For optimal performance, regrinding or reconditioning is imperative. Learn how to request a quote, specify. Garr tool offers regrinding services for its own tools, such as end mills, drills, and reamers. Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. In this issue, we look at. End Mill Regrinding.

From www.dreamstime.com

Type Regrinding Stock Photos Free & RoyaltyFree Stock Photos from End Mill Regrinding In this issue, we look at the factors which will impact the overall performance of an endmill and “weird” endmills that have higher geometrical levels of complexity. About the bottom blade shape. Geometry design and parameter verification. Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Low helix (15 degrees). End Mill Regrinding.

From www.shutterstock.com

Close Scene Ball Nose End Mill Stock Photo 2376189487 Shutterstock End Mill Regrinding Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. In this issue, we look at the factors which will impact the overall performance of an endmill and. End Mill Regrinding.

From www.dreamstime.com

The Ball End Mill Tool Type Regrinding Process Control by CNC Program End Mill Regrinding Garr tool offers regrinding services for its own tools, such as end mills, drills, and reamers. Geometry design and parameter verification. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. About the bottom blade shape. For optimal performance, regrinding or reconditioning is imperative. Low helix (15. End Mill Regrinding.

From www.dreamstime.com

The Flat End Mill Tool Regrinding Process on Regrinding Machine Stock End Mill Regrinding Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Find out the three levels of end mill. For optimal performance, regrinding or reconditioning is imperative. Garr tool offers regrinding services for its own tools, such as end mills, drills, and reamers. About the bottom blade shape. Geometry design and parameter. End Mill Regrinding.

From www.istockphoto.com

Close Up Scene The Ball Nose End Mill Tool Regrinding Process On End Mill Regrinding Find out the three levels of end mill. For optimal performance, regrinding or reconditioning is imperative. Learn how to request a quote, specify. Geometry design and parameter verification. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. In this issue, we look at the factors which. End Mill Regrinding.

From www.mskcnctools.com

Bottom price End Mill Regrinding HRC55 Wholesale Free Sample 3 Flute End Mill Regrinding About the bottom blade shape. Find out the three levels of end mill. Learn how to request a quote, specify. In this issue, we look at the factors which will impact the overall performance of an endmill and “weird” endmills that have higher geometrical levels of complexity. Garr tool offers regrinding services for its own tools, such as end mills,. End Mill Regrinding.

From www.youtube.com

CNC Grinding an End Mill at AB Tools! YouTube End Mill Regrinding Geometry design and parameter verification. Find out the three levels of end mill. About the bottom blade shape. Learn how to request a quote, specify. In this issue, we look at the factors which will impact the overall performance of an endmill and “weird” endmills that have higher geometrical levels of complexity. Learn how tool regrinding can save money, when. End Mill Regrinding.

From jpcutters.com

More Tool Life, More Productivity The Profitable Economy of Retipping End Mill Regrinding Learn how to request a quote, specify. Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. For optimal performance, regrinding or reconditioning is imperative. Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Garr tool offers. End Mill Regrinding.

From www.dreamstime.com

The Tool Regrinding Process by Machine Operator Stock Image Image of End Mill Regrinding Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. About the bottom blade shape. For optimal performance, regrinding or reconditioning is imperative. Geometry design and parameter verification. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded.. End Mill Regrinding.

From www.youtube.com

CNC Grinding A Endmill YouTube End Mill Regrinding About the bottom blade shape. Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Learn how to request a quote, specify. Garr tool offers regrinding services for. End Mill Regrinding.

From www.dreamstime.com

Close Up Scene the Flat End Mill Tool Regrinding Process on Regrinding End Mill Regrinding Learn how to request a quote, specify. Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Find out the three levels of end mill. About the bottom blade shape. Geometry design and parameter verification. Learn how tool regrinding can save money, when it is an option and how to find. End Mill Regrinding.

From cuttermasters.com

Regrinding Variable Flute End MIlls Cuttermasters End Mill Regrinding Garr tool offers regrinding services for its own tools, such as end mills, drills, and reamers. For optimal performance, regrinding or reconditioning is imperative. Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. In this issue, we look at the factors which will impact the overall. End Mill Regrinding.

From www.dreamstime.com

Close Up Scene the Flat End Mill Tool Regrinding Process on Regrinding End Mill Regrinding Learn how to request a quote, specify. About the bottom blade shape. Geometry design and parameter verification. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. Garr tool offers regrinding services for its own tools, such as end mills, drills, and reamers. Low helix (15 degrees). End Mill Regrinding.

From www.penntoolco.com

Cuttermaster Professional Journeyman JX Advanced End Mill / Tool End Mill Regrinding Learn how to request a quote, specify. Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. Geometry design and parameter verification. Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Garr tool offers regrinding services for. End Mill Regrinding.

From www.dreamstime.com

The Solid End Mill Tool Manual Regrinding Process with Abrasive Wheel End Mill Regrinding Find out the three levels of end mill. Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. For optimal performance, regrinding or reconditioning. End Mill Regrinding.

From cuttermasters.com

Regrinding Variable Flute End MIlls Cuttermasters End Mill Regrinding Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. Learn how to request a quote, specify. Find out the three levels of end mill. For optimal performance, regrinding or reconditioning is imperative. Garr tool offers regrinding services for its own tools, such as end mills, drills,. End Mill Regrinding.

From www.scmtstool.com

Something about carbide end mill regrinding End Mill Regrinding Learn how to request a quote, specify. Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. Garr tool offers regrinding services for its own tools, such as end mills, drills, and reamers. About the bottom blade shape. Geometry design and parameter verification. For optimal performance, regrinding. End Mill Regrinding.

From www.dreamstime.com

The Solid End Mill Tool Manual Regrinding Process with Abrasive Wheel End Mill Regrinding Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. Learn how tool regrinding can save money, when it is an option and how to find out if your tool can be regrinded. Geometry design and parameter verification. Find out the three levels of end mill. In this issue, we look. End Mill Regrinding.

From www.dreamstime.com

The Ball End Mill Tool Type Regrinding Process Control by CNC Program End Mill Regrinding For optimal performance, regrinding or reconditioning is imperative. In this issue, we look at the factors which will impact the overall performance of an endmill and “weird” endmills that have higher geometrical levels of complexity. About the bottom blade shape. Find out the three levels of end mill. Learn how to request a quote, specify. Learn how to tell when. End Mill Regrinding.

From www.istockphoto.com

Close Up Scene The Flat End Mill Tool Regrinding Process On Regrinding End Mill Regrinding In this issue, we look at the factors which will impact the overall performance of an endmill and “weird” endmills that have higher geometrical levels of complexity. For optimal performance, regrinding or reconditioning is imperative. Learn how to request a quote, specify. Learn how tool regrinding can save money, when it is an option and how to find out if. End Mill Regrinding.

From gorillamill.com

Regrids Gorilla Mill Gorilla Mill End Mill Regrinding Low helix (15 degrees) to high helix (60 degrees) in high helix tools the cutting forces are directed more vertically and less horizontally,. Learn how to request a quote, specify. Geometry design and parameter verification. Learn how to tell when your end mill needs to be resharpened and why it's better than replacing it. For optimal performance, regrinding or reconditioning. End Mill Regrinding.