Plastic Extrusion Screw . The taming of the screw. The extruder contains a screw within a heated cylindrical barrel. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. The screw of the extruder. This screw, when rotated by a motor, melts the resin within the barrel and serves to transport it to the die at the end, which is responsible for forming various product shapes. Familiarity with the characteristics, benefits, and uses of each. The barrels must heat the. The right selection can make the difference in the yield and efficiency of the process. The screw is at the core of the extrusion process. Max impact™ screws provide improved melt.

from www.pvcfilmblowingmachine.com

The extruder contains a screw within a heated cylindrical barrel. Max impact™ screws provide improved melt. The screw is at the core of the extrusion process. The right selection can make the difference in the yield and efficiency of the process. The taming of the screw. The screw of the extruder. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. This screw, when rotated by a motor, melts the resin within the barrel and serves to transport it to the die at the end, which is responsible for forming various product shapes. Familiarity with the characteristics, benefits, and uses of each. The barrels must heat the.

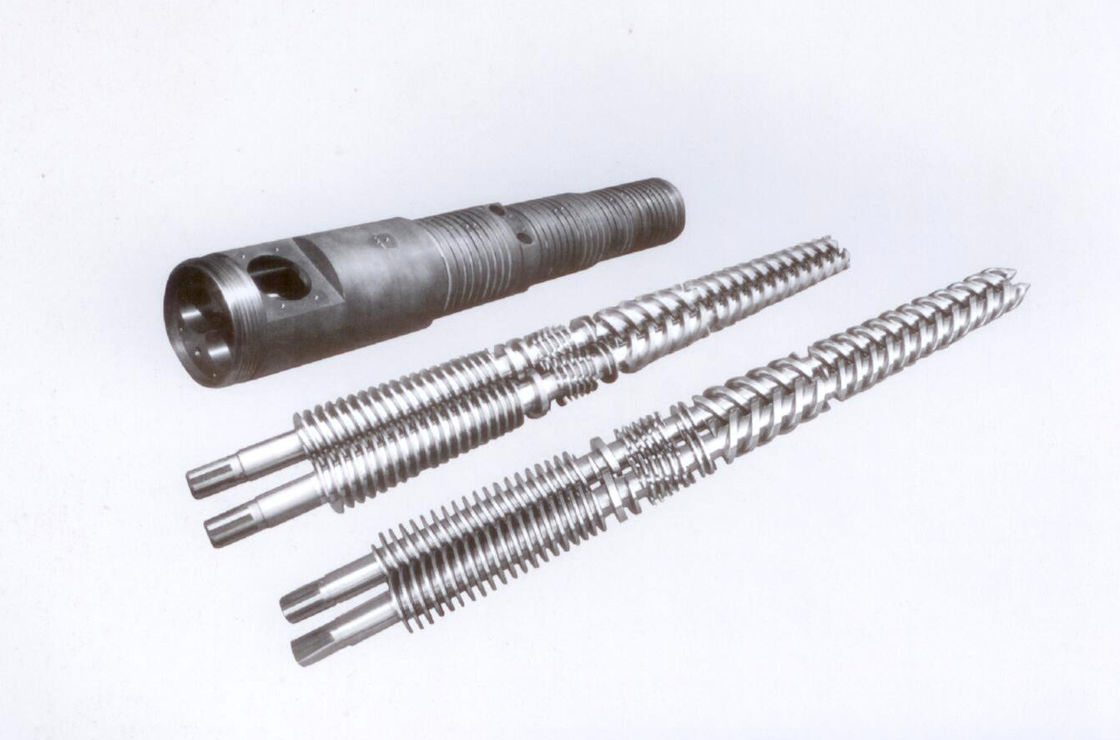

Custom Types Plastic Extrusion Screw Extruder Machine Parts 0.60.8mm

Plastic Extrusion Screw The taming of the screw. The screw is at the core of the extrusion process. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. Familiarity with the characteristics, benefits, and uses of each. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. The barrels must heat the. Max impact™ screws provide improved melt. This screw, when rotated by a motor, melts the resin within the barrel and serves to transport it to the die at the end, which is responsible for forming various product shapes. The taming of the screw. The extruder contains a screw within a heated cylindrical barrel. The screw of the extruder. The right selection can make the difference in the yield and efficiency of the process.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Plastic Extrusion Screw Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. The right selection can make the difference in the yield and efficiency of the process. The barrels must heat the. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. The extruder contains. Plastic Extrusion Screw.

From www.indiamart.com

Plastic Extrusion Screw at Rs 50000/piece Polymer Extrusion Auger in Plastic Extrusion Screw Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. The screw of the extruder. The screw is at the core of the extrusion process. This screw, when rotated by a motor, melts the resin within the barrel and serves to transport it to the die at the end, which is responsible for forming various. Plastic Extrusion Screw.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Plastic Extrusion Screw The barrels must heat the. The right selection can make the difference in the yield and efficiency of the process. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. The screw of. Plastic Extrusion Screw.

From www.indiamart.com

Concept Engineering Plastic Extrusion Single Screw at Rs 115000/unit in Plastic Extrusion Screw The screw of the extruder. The extruder contains a screw within a heated cylindrical barrel. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. Familiarity with the characteristics, benefits, and uses of each. The screw is at the core of the extrusion process. This screw, when rotated. Plastic Extrusion Screw.

From www.rbplasticsmachinery.com

Plastic Extrusion Screws R&B Plastics Machinery Plastic Extrusion Screw The screw of the extruder. The taming of the screw. The barrels must heat the. The screw is at the core of the extrusion process. Familiarity with the characteristics, benefits, and uses of each. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. This screw, when rotated by a motor, melts the resin within. Plastic Extrusion Screw.

From www.rbplasticsmachinery.com

SingleScrew Plastics Extruder R&B Plastics Machinery Plastic Extrusion Screw The taming of the screw. Familiarity with the characteristics, benefits, and uses of each. The screw of the extruder. This screw, when rotated by a motor, melts the resin within the barrel and serves to transport it to the die at the end, which is responsible for forming various product shapes. Provide the melted polymer to the forming process at. Plastic Extrusion Screw.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Plastic Extrusion Screw The screw of the extruder. The screw is at the core of the extrusion process. Max impact™ screws provide improved melt. Familiarity with the characteristics, benefits, and uses of each. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. Plastic extrusion relies heavily on barrel technology to. Plastic Extrusion Screw.

From www.indiamart.com

PVC Extrusion Screws, Size 120 Mm at Rs 75000 in New Delhi ID Plastic Extrusion Screw The taming of the screw. The screw of the extruder. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. Familiarity with the characteristics, benefits, and uses of each. The right selection can make the difference in the yield and efficiency of the process. The barrels must heat the. This screw, when rotated by a. Plastic Extrusion Screw.

From www.machineto.com

Plastic Extrusion Screw and Barrel Plastic Extrusion Screw The right selection can make the difference in the yield and efficiency of the process. Familiarity with the characteristics, benefits, and uses of each. The screw of the extruder. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. This screw, when rotated by a motor, melts the. Plastic Extrusion Screw.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Plastic Extrusion Screw The screw of the extruder. The right selection can make the difference in the yield and efficiency of the process. Max impact™ screws provide improved melt. The screw is at the core of the extrusion process. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. The taming of the screw. This screw, when rotated. Plastic Extrusion Screw.

From www.indiamart.com

Plastic Extrusion Screw And Barrrel at best price in Ahmedabad Plastic Extrusion Screw The screw of the extruder. The taming of the screw. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. This screw, when rotated by a motor, melts the resin within the barrel. Plastic Extrusion Screw.

From www.exportersindia.com

Stainless Steel Plastic Extrusion Screw, Grade 304, Length 6000mm Plastic Extrusion Screw Max impact™ screws provide improved melt. The screw of the extruder. The taming of the screw. Familiarity with the characteristics, benefits, and uses of each. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. The right selection can make the difference in the yield and efficiency of. Plastic Extrusion Screw.

From www.materialalloy.com

Extrusion Screw Elements And Barrel For Plastic Extruder Machine Parts Plastic Extrusion Screw The extruder contains a screw within a heated cylindrical barrel. Familiarity with the characteristics, benefits, and uses of each. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. The right selection can make the difference in the yield and efficiency of the process. The barrels must heat. Plastic Extrusion Screw.

From www.rbplasticsmachinery.com

Plastic Extrusion Screws R&B Plastics Machinery Plastic Extrusion Screw The screw is at the core of the extrusion process. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. This screw, when rotated by a motor, melts the resin within the barrel and serves to transport it to the die at the end, which is responsible for forming various product shapes. Max impact™ screws. Plastic Extrusion Screw.

From www.indiamart.com

Plastic Extrusion Screw, Size 90 Mm, Rs 10000 /piece Khodiyar Plastic Extrusion Screw The screw of the extruder. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. The barrels must heat the. The right selection can make the difference in the yield and efficiency of the process. The screw is at the core of the extrusion process. Provide the melted polymer to the forming process at the. Plastic Extrusion Screw.

From www.rbplasticsmachinery.com

Plastic Extrusion Screws R&B Plastics Machinery Plastic Extrusion Screw The screw of the extruder. The right selection can make the difference in the yield and efficiency of the process. The barrels must heat the. Max impact™ screws provide improved melt. Familiarity with the characteristics, benefits, and uses of each. This screw, when rotated by a motor, melts the resin within the barrel and serves to transport it to the. Plastic Extrusion Screw.

From bazar.preciousplastic.com

Precious Plastic Extrusion Screw Plastic Extrusion Screw Familiarity with the characteristics, benefits, and uses of each. The right selection can make the difference in the yield and efficiency of the process. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. The extruder contains a screw within a heated cylindrical barrel. The taming of the. Plastic Extrusion Screw.

From citytron.com.my

PLASTIC EXTRUSION SCREW & BARREL Citytron Plastic Extrusion Screw The taming of the screw. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. This screw, when rotated by a motor, melts the resin within the barrel and serves to transport it to the die at the end, which is responsible for forming various product shapes. Familiarity. Plastic Extrusion Screw.

From www.pvcfilmblowingmachine.com

Type Plastic Extrusion Screws For Pvc Plastic Extrusion Screw The screw is at the core of the extrusion process. The barrels must heat the. The taming of the screw. The extruder contains a screw within a heated cylindrical barrel. Familiarity with the characteristics, benefits, and uses of each. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. The screw of the extruder. The. Plastic Extrusion Screw.

From www.rbplasticsmachinery.com

Plastic Extrusion Screws R&B Plastics Machinery Plastic Extrusion Screw The taming of the screw. This screw, when rotated by a motor, melts the resin within the barrel and serves to transport it to the die at the end, which is responsible for forming various product shapes. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. The. Plastic Extrusion Screw.

From www.rbplasticsmachinery.com

Plastic Extrusion Screws R&B Plastics Machinery Plastic Extrusion Screw Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. The right selection can make the difference in the yield and efficiency of the process. Familiarity with the characteristics, benefits, and uses of each. The screw is at the core of the extrusion process. Max impact™ screws provide improved melt. This screw, when rotated by. Plastic Extrusion Screw.

From www.elastron.com

What is Extrusion? Plastic Extrusion Process Elastron TPE Plastic Extrusion Screw The right selection can make the difference in the yield and efficiency of the process. The taming of the screw. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. The screw is at the core of the extrusion process. Familiarity with the characteristics, benefits, and uses of each. This screw, when rotated by a. Plastic Extrusion Screw.

From beslakmal.blogspot.com

BioElectrionix Hub Plastic Extruder Plastic Extrusion Screw The extruder contains a screw within a heated cylindrical barrel. The screw of the extruder. The barrels must heat the. The right selection can make the difference in the yield and efficiency of the process. The taming of the screw. Max impact™ screws provide improved melt. Provide the melted polymer to the forming process at the desired rate, uniformity, and. Plastic Extrusion Screw.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Plastic Extrusion Screw Familiarity with the characteristics, benefits, and uses of each. The extruder contains a screw within a heated cylindrical barrel. The screw of the extruder. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. The taming of the screw. The screw is at the core of the extrusion process. Max impact™ screws provide improved melt.. Plastic Extrusion Screw.

From www.indiamart.com

Plastic Extrusion Screw at Rs 50000/piece Polymer Extrusion Auger in Plastic Extrusion Screw The barrels must heat the. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. Max impact™ screws provide improved melt. The taming of the screw. Familiarity with the characteristics, benefits, and uses of each. The screw is at the core of the extrusion process. The screw of the extruder. Provide the melted polymer to. Plastic Extrusion Screw.

From www.pvcfilmblowingmachine.com

Custom Types Plastic Extrusion Screw Extruder Machine Parts 0.60.8mm Plastic Extrusion Screw The right selection can make the difference in the yield and efficiency of the process. The taming of the screw. The barrels must heat the. The screw is at the core of the extrusion process. The screw of the extruder. The extruder contains a screw within a heated cylindrical barrel. This screw, when rotated by a motor, melts the resin. Plastic Extrusion Screw.

From www.rbplasticsmachinery.com

Plastic Extrusion Screws R&B Plastics Machinery Plastic Extrusion Screw The screw of the extruder. The screw is at the core of the extrusion process. The barrels must heat the. The extruder contains a screw within a heated cylindrical barrel. Max impact™ screws provide improved melt. This screw, when rotated by a motor, melts the resin within the barrel and serves to transport it to the die at the end,. Plastic Extrusion Screw.

From www.rbplasticsmachinery.com

Plastic Extrusion Screws R&B Plastics Machinery Plastic Extrusion Screw Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. The extruder contains a screw within a heated cylindrical barrel. The right selection can make the difference in the yield and efficiency of the process. Familiarity with the characteristics, benefits, and uses of each. The screw is at the core of the extrusion process. The. Plastic Extrusion Screw.

From www.indiamart.com

Plastic Extrusion Screw at Rs 30000/piece Plastic Extrusion Screw in Plastic Extrusion Screw The right selection can make the difference in the yield and efficiency of the process. The barrels must heat the. The extruder contains a screw within a heated cylindrical barrel. Familiarity with the characteristics, benefits, and uses of each. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within. Plastic Extrusion Screw.

From www.tradeindia.com

45mm Plastic Extrusion Screw at 13800.00 INR in Ahmedabad Khodiyar Plastic Extrusion Screw The extruder contains a screw within a heated cylindrical barrel. This screw, when rotated by a motor, melts the resin within the barrel and serves to transport it to the die at the end, which is responsible for forming various product shapes. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the. Plastic Extrusion Screw.

From www.indiamart.com

Plastic Extrusion Screw at Rs 50000 Polymer Extrusion Auger in Plastic Extrusion Screw Max impact™ screws provide improved melt. Familiarity with the characteristics, benefits, and uses of each. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. The taming of the screw. The extruder contains a screw within a heated cylindrical barrel. The screw is at the core of the. Plastic Extrusion Screw.

From www.indiamart.com

Plastic Extrusion Screw at best price in Ahmedabad by Adroit Engineers Plastic Extrusion Screw The extruder contains a screw within a heated cylindrical barrel. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. The taming of the screw. The screw of the extruder. Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. The screw is. Plastic Extrusion Screw.

From www.indiamart.com

Plastic Extrusion Screw at Rs 50000/piece Mhalasakant Colony Saswad Plastic Extrusion Screw The right selection can make the difference in the yield and efficiency of the process. The barrels must heat the. Familiarity with the characteristics, benefits, and uses of each. The screw is at the core of the extrusion process. The extruder contains a screw within a heated cylindrical barrel. This screw, when rotated by a motor, melts the resin within. Plastic Extrusion Screw.

From www.rbplasticsmachinery.com

Plastic Extrusion Screws R&B Plastics Machinery Plastic Extrusion Screw This screw, when rotated by a motor, melts the resin within the barrel and serves to transport it to the die at the end, which is responsible for forming various product shapes. The barrels must heat the. The extruder contains a screw within a heated cylindrical barrel. Familiarity with the characteristics, benefits, and uses of each. Provide the melted polymer. Plastic Extrusion Screw.

From www.indiamart.com

Single Plastic Extrusion Screw, For Industrial, PP at best price in Plastic Extrusion Screw Provide the melted polymer to the forming process at the desired rate, uniformity, and quality to produce the finished product within specifications. Max impact™ screws provide improved melt. Plastic extrusion relies heavily on barrel technology to maintain process stability and ensure product quality. The barrels must heat the. The screw of the extruder. This screw, when rotated by a motor,. Plastic Extrusion Screw.