Cylinder Hone Finish . The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit diamond. Achieve optimal performance with precision. It consists of an abrasive stone or brush attached to a power drill,. To the naked eye, a freshly honed. Learn the importance of proper bore geometry and surface finish for engine cylinders. A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. A 320 grit, and even sometimes as fine as 400 grit. Honing is a stock removal process intended to perfect bore geometry and size by removing a minimal metal layer while. A cylinder honing tool is a specialized tool designed to improve the surface finish of an internal cylindrical surface. A good machinist will use a profilometer to measure the surface texture of his cylinder wall and adjust the roughness of the honing stones, the speed of his machine, and the load applied to the stones to achieve the desired surface finish. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed.

from www.grainger.com

A good machinist will use a profilometer to measure the surface texture of his cylinder wall and adjust the roughness of the honing stones, the speed of his machine, and the load applied to the stones to achieve the desired surface finish. A cylinder honing tool is a specialized tool designed to improve the surface finish of an internal cylindrical surface. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. It consists of an abrasive stone or brush attached to a power drill,. Achieve optimal performance with precision. A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. Honing is a stock removal process intended to perfect bore geometry and size by removing a minimal metal layer while. The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit diamond. Learn the importance of proper bore geometry and surface finish for engine cylinders. A 320 grit, and even sometimes as fine as 400 grit.

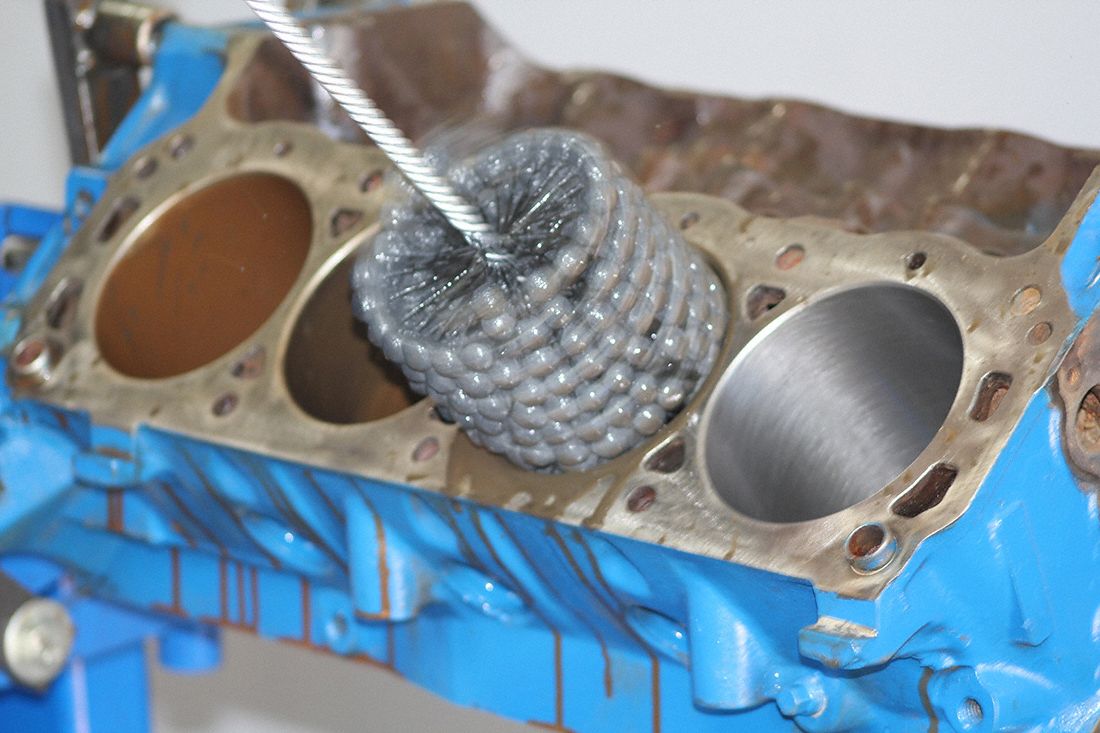

FLEXHONE TOOL Silicon Carbide Flexible Cylinder Hone, Medium Grade

Cylinder Hone Finish To the naked eye, a freshly honed. A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. To the naked eye, a freshly honed. Learn the importance of proper bore geometry and surface finish for engine cylinders. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. A good machinist will use a profilometer to measure the surface texture of his cylinder wall and adjust the roughness of the honing stones, the speed of his machine, and the load applied to the stones to achieve the desired surface finish. The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit diamond. A cylinder honing tool is a specialized tool designed to improve the surface finish of an internal cylindrical surface. Achieve optimal performance with precision. Honing is a stock removal process intended to perfect bore geometry and size by removing a minimal metal layer while. It consists of an abrasive stone or brush attached to a power drill,. A 320 grit, and even sometimes as fine as 400 grit.

From www.youtube.com

External honing for precision surface finishing on rods and shafts Cylinder Hone Finish The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit diamond. Achieve optimal performance with precision. To the naked eye, a freshly honed. It consists of an abrasive stone or brush attached to a power drill,. A 320 grit, and even sometimes as fine as 400. Cylinder Hone Finish.

From www.rlengines.com

Cylinder Honing Engine Block Cylinder FinishingMA,CT,RI,NH,VT,ME,NY,NJ Cylinder Hone Finish Achieve optimal performance with precision. A good machinist will use a profilometer to measure the surface texture of his cylinder wall and adjust the roughness of the honing stones, the speed of his machine, and the load applied to the stones to achieve the desired surface finish. A cylinder honing tool is a specialized tool designed to improve the surface. Cylinder Hone Finish.

From www.amazon.ca

Brush Research FLEXHONE Cylinder Hone, GB Series, Silicon Carbide Cylinder Hone Finish The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit diamond. Learn the importance of proper bore geometry and surface finish for engine cylinders. A cylinder honing tool is a specialized tool designed to improve the surface finish of an internal cylindrical surface. Honing is a. Cylinder Hone Finish.

From hfoplant.blogspot.com

CYLINDER LINER HONING (PURPOSE, HONING TEXTURE, ANGLE & PROCEDURE Cylinder Hone Finish Honing is a stock removal process intended to perfect bore geometry and size by removing a minimal metal layer while. The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit diamond. Achieve optimal performance with precision. A bore finish honed with #280 grit stones will seat. Cylinder Hone Finish.

From www.performanceracingengine.com

Rottler H85 AX Diamond Cylinder Honing IL,MO,IA,KY,IN Cylinder Hone Finish To the naked eye, a freshly honed. The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit diamond. A cylinder honing tool is a specialized tool designed to improve the surface finish of an internal cylindrical surface. Learn the importance of proper bore geometry and surface. Cylinder Hone Finish.

From www.rideapart.com

How To Hone Your Cylinders At Home With A FlexHone Cylinder Hone Finish Achieve optimal performance with precision. To the naked eye, a freshly honed. A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. A 320 grit, and even sometimes as fine. Cylinder Hone Finish.

From www.rlengines.com

Cylinder Honing Engine Block Cylinder FinishingMA,CT,RI,NH,VT,ME,NY,NJ Cylinder Hone Finish A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. It consists of an abrasive stone or brush attached to a power drill,. Honing is a stock removal process intended to perfect bore geometry and size by removing a minimal metal layer while. Achieve optimal performance with precision. Hones with 180 to 240. Cylinder Hone Finish.

From www.jalopyjournal.com

Block honing cylinder on the left has been finish honed, cylinder on Cylinder Hone Finish A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. Honing is a stock removal process intended to perfect bore geometry and size by removing a minimal metal layer while. Learn the importance of proper bore geometry and surface finish for engine cylinders. Achieve optimal performance with precision. It consists of an abrasive. Cylinder Hone Finish.

From diahoning.com

Cylinder Honing Tools, Hone Head Zhengzhou Boson Abrasives Co.,Ltd. Cylinder Hone Finish Achieve optimal performance with precision. A good machinist will use a profilometer to measure the surface texture of his cylinder wall and adjust the roughness of the honing stones, the speed of his machine, and the load applied to the stones to achieve the desired surface finish. Learn the importance of proper bore geometry and surface finish for engine cylinders.. Cylinder Hone Finish.

From www.youtube.com

2 Stroke Cylinder Honing Facts and How I do it YouTube Cylinder Hone Finish A 320 grit, and even sometimes as fine as 400 grit. Achieve optimal performance with precision. To the naked eye, a freshly honed. It consists of an abrasive stone or brush attached to a power drill,. The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit. Cylinder Hone Finish.

From hfoplant.blogspot.com

CYLINDER LINER HONING (PURPOSE, HONING TEXTURE, ANGLE & PROCEDURE Cylinder Hone Finish The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit diamond. A cylinder honing tool is a specialized tool designed to improve the surface finish of an internal cylindrical surface. Achieve optimal performance with precision. A 320 grit, and even sometimes as fine as 400 grit.. Cylinder Hone Finish.

From diahoning.com

Cylinder Diamond Honing Stones Zhengzhou Boson Abrasives Co.,Ltd. Cylinder Hone Finish Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. Achieve optimal performance with precision. Learn the importance of proper bore geometry and surface finish for engine cylinders. A cylinder. Cylinder Hone Finish.

From caraid.co.nz

Cylinder Honing Car Aid Christchurch Engine Rebuilding Service Cylinder Hone Finish It consists of an abrasive stone or brush attached to a power drill,. A cylinder honing tool is a specialized tool designed to improve the surface finish of an internal cylindrical surface. A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. Achieve optimal performance with precision. Honing is a stock removal process. Cylinder Hone Finish.

From www.grainger.com

FLEXHONE TOOL Silicon Carbide Flexible Cylinder Hone, Extra Fine Grade Cylinder Hone Finish Achieve optimal performance with precision. A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. A cylinder honing tool is a specialized tool designed to improve the surface finish of an internal cylindrical surface. Honing is a stock removal process intended to perfect bore geometry and size by removing a minimal metal layer. Cylinder Hone Finish.

From www.walmart.com

AMMCO Rigid Cylinder Hone Stones Standard/Fine 220 Grit 3952 Walmart Cylinder Hone Finish To the naked eye, a freshly honed. It consists of an abrasive stone or brush attached to a power drill,. Learn the importance of proper bore geometry and surface finish for engine cylinders. Achieve optimal performance with precision. A 320 grit, and even sometimes as fine as 400 grit. Hones with 180 to 240 grits are good choices for general. Cylinder Hone Finish.

From maxtorqueperformance.com

The Art And Science Of Cylinder Honing MaxTorquePerformance Cylinder Hone Finish A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. Honing is a stock removal process intended to perfect bore geometry and size by removing a minimal metal layer while. Learn the importance of proper bore geometry and surface finish for engine cylinders. A cylinder honing tool is a specialized tool designed to. Cylinder Hone Finish.

From maxtorqueperformance.com

The Art And Science Of Cylinder Honing MaxTorquePerformance Cylinder Hone Finish Achieve optimal performance with precision. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. A good machinist will use a profilometer to measure the surface texture of his cylinder wall and adjust the roughness of the honing stones, the speed of his machine, and the load. Cylinder Hone Finish.

From rhkhydraulics.com

Honing RHK Hydraulic Cylinder Services Inc Cylinder Hone Finish Learn the importance of proper bore geometry and surface finish for engine cylinders. To the naked eye, a freshly honed. A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. A good machinist will use a profilometer to measure the surface texture of his cylinder wall and adjust the roughness of the honing. Cylinder Hone Finish.

From modelenginenews.org

How To Make and Use Cylinder Hones Cylinder Hone Finish The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit diamond. A cylinder honing tool is a specialized tool designed to improve the surface finish of an internal cylindrical surface. A good machinist will use a profilometer to measure the surface texture of his cylinder wall. Cylinder Hone Finish.

From learnmechanical.com

Honing Process Definition, Parts or Construction, Working Principle Cylinder Hone Finish A 320 grit, and even sometimes as fine as 400 grit. Achieve optimal performance with precision. Learn the importance of proper bore geometry and surface finish for engine cylinders. A cylinder honing tool is a specialized tool designed to improve the surface finish of an internal cylindrical surface. The second way to produce a plateau finish is to hone the. Cylinder Hone Finish.

From www.performanceracingengine.com

Engine_Block_Cylinder_Honing Cylinder Hone Finish The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit diamond. A good machinist will use a profilometer to measure the surface texture of his cylinder wall and adjust the roughness of the honing stones, the speed of his machine, and the load applied to the. Cylinder Hone Finish.

From www.mech4study.com

What is Honing, its Process Parameter, Types and its Advantages Cylinder Hone Finish Achieve optimal performance with precision. A 320 grit, and even sometimes as fine as 400 grit. A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. It consists of an abrasive stone or brush attached to a power drill,. A good machinist will use a profilometer to measure the surface texture of his. Cylinder Hone Finish.

From www.directindustry.com

Cylinder hone FlexHone BC Series Brush Research Manufacturing Cylinder Hone Finish A 320 grit, and even sometimes as fine as 400 grit. A cylinder honing tool is a specialized tool designed to improve the surface finish of an internal cylindrical surface. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. It consists of an abrasive stone or. Cylinder Hone Finish.

From diahoning.com

Cylinder Honing Tools, Hone Head Zhengzhou Boson Abrasives Co.,Ltd. Cylinder Hone Finish A good machinist will use a profilometer to measure the surface texture of his cylinder wall and adjust the roughness of the honing stones, the speed of his machine, and the load applied to the stones to achieve the desired surface finish. A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. The. Cylinder Hone Finish.

From aldermanmachine.com

Rottler HP7A Precision Cylinder Hone — Alderman Automotive Machine Cylinder Hone Finish Learn the importance of proper bore geometry and surface finish for engine cylinders. A 320 grit, and even sometimes as fine as 400 grit. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. Honing is a stock removal process intended to perfect bore geometry and size. Cylinder Hone Finish.

From www.made-in-china.com

Hone Head, Cylinder Roughing and Finishing China Honing Tool and Cylinder Hone Finish It consists of an abrasive stone or brush attached to a power drill,. Learn the importance of proper bore geometry and surface finish for engine cylinders. The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit diamond. A 320 grit, and even sometimes as fine as. Cylinder Hone Finish.

From hfoplant.blogspot.com

CYLINDER LINER HONING (PURPOSE, HONING TEXTURE, ANGLE & PROCEDURE Cylinder Hone Finish Achieve optimal performance with precision. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. A good machinist will use a profilometer to measure the surface texture of his cylinder wall and adjust the roughness of the honing stones, the speed of his machine, and the load. Cylinder Hone Finish.

From www.kitplanes.com

Cylinder Hones and Honing KITPLANES Cylinder Hone Finish To the naked eye, a freshly honed. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. A 320 grit, and even sometimes as fine as 400 grit. Learn the importance of proper bore geometry and surface finish for engine cylinders. Achieve optimal performance with precision. Honing. Cylinder Hone Finish.

From www.hotrod.com

Cylinder Honing Honed For Speed Hot Rod Network Cylinder Hone Finish The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit diamond. A cylinder honing tool is a specialized tool designed to improve the surface finish of an internal cylindrical surface. Learn the importance of proper bore geometry and surface finish for engine cylinders. A 320 grit,. Cylinder Hone Finish.

From www.grainger.com

FLEXHONE TOOL Silicon Carbide Flexible Cylinder Hone, Medium Grade Cylinder Hone Finish The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit diamond. A good machinist will use a profilometer to measure the surface texture of his cylinder wall and adjust the roughness of the honing stones, the speed of his machine, and the load applied to the. Cylinder Hone Finish.

From www.flexhoneblog.com

FlexHone® Blog Brush Research Manufacturing's Company Blog Flexible Cylinder Hone Finish Honing is a stock removal process intended to perfect bore geometry and size by removing a minimal metal layer while. To the naked eye, a freshly honed. A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is. Cylinder Hone Finish.

From thaispringfish.co.th

Top 9 Best engine cylinder honing oil Cylinder Hone Finish The second way to produce a plateau finish is to hone the cylinders with #220 or #280 grit abrasive (or #400 or #500 grit diamond. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. It consists of an abrasive stone or brush attached to a power. Cylinder Hone Finish.

From www.performanceracingengine.com

Engine_Block_Cylinder_Honing Cylinder Hone Finish A good machinist will use a profilometer to measure the surface texture of his cylinder wall and adjust the roughness of the honing stones, the speed of his machine, and the load applied to the stones to achieve the desired surface finish. A 320 grit, and even sometimes as fine as 400 grit. To the naked eye, a freshly honed.. Cylinder Hone Finish.

From www.buellxb.com

Cylinder Bore Surface Finish Cylinder Hone Finish Learn the importance of proper bore geometry and surface finish for engine cylinders. Achieve optimal performance with precision. It consists of an abrasive stone or brush attached to a power drill,. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going to be bored or honed. A 320 grit, and even sometimes. Cylinder Hone Finish.

From diahoning.com

Cylinder Diamond Honing Stones Zhengzhou Boson Abrasives Co.,Ltd. Cylinder Hone Finish A bore finish honed with #280 grit stones will seat faster than one finished with #220 stones. Achieve optimal performance with precision. It consists of an abrasive stone or brush attached to a power drill,. To the naked eye, a freshly honed. Hones with 180 to 240 grits are good choices for general deglazing where the cylinder is not going. Cylinder Hone Finish.