Gear Manufacturing Process Step By Step . Ever wondered how gears are made? The process involves multiple intricate steps to achieve precision and efficiency. Here is the detailed process. This can be done using. Gear generating involves gear cutting through the relative motion of a rotating cutting tool and the generating, or rotational, motion of the. The process involves three key steps: Engineers develop gears based on application needs by using special. The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different types of gears, materials, and techniques used. There is no single process to gear manufacturing as they require different processes depending on the type and application. Developing the optimal combination that aligns with specifications for durability, precision, and.

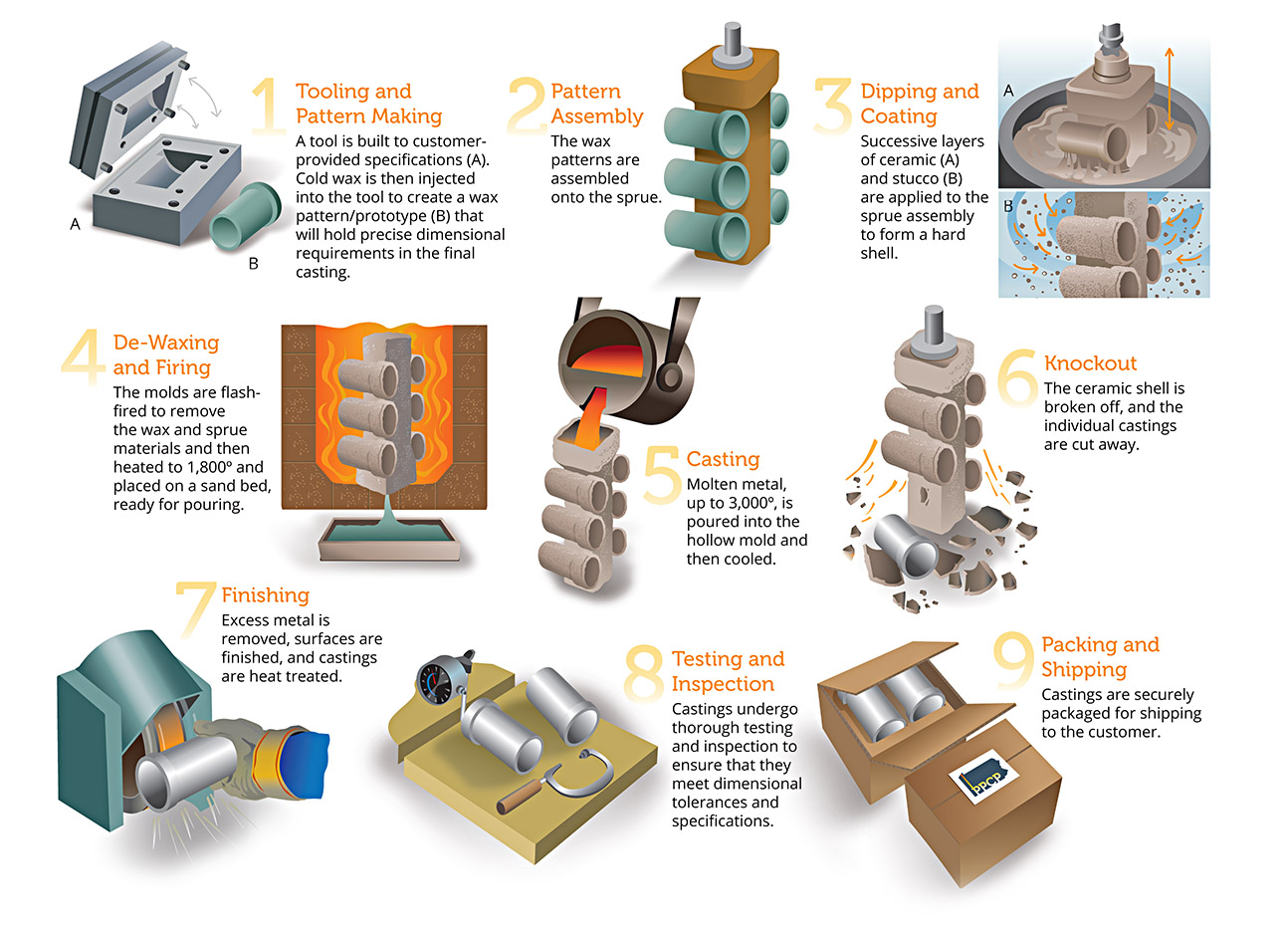

from ppcpinc.com

The process involves three key steps: The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. This can be done using. The process involves multiple intricate steps to achieve precision and efficiency. Developing the optimal combination that aligns with specifications for durability, precision, and. Here is the detailed process. Ever wondered how gears are made? In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different types of gears, materials, and techniques used. Engineers develop gears based on application needs by using special. Gear generating involves gear cutting through the relative motion of a rotating cutting tool and the generating, or rotational, motion of the.

» PPCP Process

Gear Manufacturing Process Step By Step Developing the optimal combination that aligns with specifications for durability, precision, and. Here is the detailed process. Developing the optimal combination that aligns with specifications for durability, precision, and. There is no single process to gear manufacturing as they require different processes depending on the type and application. The process involves three key steps: Gear generating involves gear cutting through the relative motion of a rotating cutting tool and the generating, or rotational, motion of the. Ever wondered how gears are made? This can be done using. Engineers develop gears based on application needs by using special. The process involves multiple intricate steps to achieve precision and efficiency. In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different types of gears, materials, and techniques used. The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material.

From www.youtube.com

Gear Cutting on Milling Machine YouTube Gear Manufacturing Process Step By Step Ever wondered how gears are made? Gear generating involves gear cutting through the relative motion of a rotating cutting tool and the generating, or rotational, motion of the. Engineers develop gears based on application needs by using special. This can be done using. The first step in the gear manufacturing process is to cut the gear blank from a larger. Gear Manufacturing Process Step By Step.

From blog.thepipingmart.com

Gear Cutting The Process of Machining Gears ThePipingMart Blog Gear Manufacturing Process Step By Step Here is the detailed process. The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. Developing the optimal combination that aligns with specifications for durability, precision, and. Engineers develop gears based on application needs by using special. The process involves multiple intricate steps to achieve precision and efficiency. Ever. Gear Manufacturing Process Step By Step.

From www.researchgate.net

6 Classification of the most common gear manufacturing methods [1 Gear Manufacturing Process Step By Step The process involves multiple intricate steps to achieve precision and efficiency. This can be done using. The process involves three key steps: Ever wondered how gears are made? The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. There is no single process to gear manufacturing as they require. Gear Manufacturing Process Step By Step.

From ppcpinc.com

» PPCP Process Gear Manufacturing Process Step By Step Developing the optimal combination that aligns with specifications for durability, precision, and. There is no single process to gear manufacturing as they require different processes depending on the type and application. In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different types of gears, materials, and techniques used. Gear generating involves. Gear Manufacturing Process Step By Step.

From www.researchgate.net

Progress and machining time summary of the whole gear manufacturing Gear Manufacturing Process Step By Step There is no single process to gear manufacturing as they require different processes depending on the type and application. This can be done using. The process involves three key steps: Ever wondered how gears are made? Gear generating involves gear cutting through the relative motion of a rotating cutting tool and the generating, or rotational, motion of the. In this. Gear Manufacturing Process Step By Step.

From editorialge.com

What is the Gear Manufacturing Process? Editorialge Gear Manufacturing Process Step By Step Developing the optimal combination that aligns with specifications for durability, precision, and. The process involves multiple intricate steps to achieve precision and efficiency. Ever wondered how gears are made? Engineers develop gears based on application needs by using special. The process involves three key steps: In this article, we will explore the process of gear manufacturing, from design to production,. Gear Manufacturing Process Step By Step.

From slidemodel.com

Process Gear Diagrams for PowerPoint SlideModel Gear Manufacturing Process Step By Step The process involves multiple intricate steps to achieve precision and efficiency. There is no single process to gear manufacturing as they require different processes depending on the type and application. Engineers develop gears based on application needs by using special. Ever wondered how gears are made? This can be done using. Here is the detailed process. Gear generating involves gear. Gear Manufacturing Process Step By Step.

From www.youtube.com

Gear Manufacturing Process Gear Box Explained PPT ENGINEERING Gear Manufacturing Process Step By Step The process involves multiple intricate steps to achieve precision and efficiency. There is no single process to gear manufacturing as they require different processes depending on the type and application. Engineers develop gears based on application needs by using special. This can be done using. Developing the optimal combination that aligns with specifications for durability, precision, and. The process involves. Gear Manufacturing Process Step By Step.

From www.youtube.com

Gear Manufacturing Methods ENGINEERING STUDY MATERIALS YouTube Gear Manufacturing Process Step By Step Here is the detailed process. Engineers develop gears based on application needs by using special. There is no single process to gear manufacturing as they require different processes depending on the type and application. This can be done using. The process involves three key steps: In this article, we will explore the process of gear manufacturing, from design to production,. Gear Manufacturing Process Step By Step.

From mechheart.com

Gear Manufacturing Process Step by Step MECHHEART Gear Manufacturing Process Step By Step This can be done using. There is no single process to gear manufacturing as they require different processes depending on the type and application. Here is the detailed process. The process involves three key steps: The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. In this article, we. Gear Manufacturing Process Step By Step.

From mechanicstips.blogspot.com

Gear Manufacturing Practice Forming and Generating MechanicsTips Gear Manufacturing Process Step By Step Engineers develop gears based on application needs by using special. The process involves three key steps: In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different types of gears, materials, and techniques used. Developing the optimal combination that aligns with specifications for durability, precision, and. Here is the detailed process. There. Gear Manufacturing Process Step By Step.

From www.researchgate.net

Basic manufacturing process of industrial gearbox and geared motor Gear Manufacturing Process Step By Step The process involves three key steps: Engineers develop gears based on application needs by using special. In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different types of gears, materials, and techniques used. The first step in the gear manufacturing process is to cut the gear blank from a larger piece. Gear Manufacturing Process Step By Step.

From mechheart.com

Gear Manufacturing Process Step by Step MECHHEART Gear Manufacturing Process Step By Step There is no single process to gear manufacturing as they require different processes depending on the type and application. In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different types of gears, materials, and techniques used. Gear generating involves gear cutting through the relative motion of a rotating cutting tool and. Gear Manufacturing Process Step By Step.

From khkgears.net

Gear Manufacturing KHK Gears Gear Manufacturing Process Step By Step Developing the optimal combination that aligns with specifications for durability, precision, and. The process involves three key steps: Ever wondered how gears are made? The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. This can be done using. Here is the detailed process. Engineers develop gears based on. Gear Manufacturing Process Step By Step.

From mechheart.com

Gear Manufacturing Process Step by Step MECHHEART Gear Manufacturing Process Step By Step Here is the detailed process. In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different types of gears, materials, and techniques used. The process involves three key steps: Ever wondered how gears are made? Developing the optimal combination that aligns with specifications for durability, precision, and. The first step in the. Gear Manufacturing Process Step By Step.

From mechheart.com

Gear Manufacturing Process Step by Step MECHHEART Gear Manufacturing Process Step By Step Gear generating involves gear cutting through the relative motion of a rotating cutting tool and the generating, or rotational, motion of the. The process involves multiple intricate steps to achieve precision and efficiency. The process involves three key steps: Engineers develop gears based on application needs by using special. The first step in the gear manufacturing process is to cut. Gear Manufacturing Process Step By Step.

From www.slideserve.com

PPT GEARS MACHINING PowerPoint Presentation, free download ID1414221 Gear Manufacturing Process Step By Step Here is the detailed process. In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different types of gears, materials, and techniques used. Gear generating involves gear cutting through the relative motion of a rotating cutting tool and the generating, or rotational, motion of the. There is no single process to gear. Gear Manufacturing Process Step By Step.

From www.pinterest.com

gear manufacturing process Manufacturing process, Word find Gear Manufacturing Process Step By Step This can be done using. In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different types of gears, materials, and techniques used. The process involves multiple intricate steps to achieve precision and efficiency. The first step in the gear manufacturing process is to cut the gear blank from a larger piece. Gear Manufacturing Process Step By Step.

From www.youtube.com

Powerful Gear Processing Method Machines Amazing Big Gear Production Gear Manufacturing Process Step By Step There is no single process to gear manufacturing as they require different processes depending on the type and application. Gear generating involves gear cutting through the relative motion of a rotating cutting tool and the generating, or rotational, motion of the. In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different. Gear Manufacturing Process Step By Step.

From true-gear.com

A Basic Understanding of Gear Manufacturing Processes Gear Manufacturing Process Step By Step The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. Ever wondered how gears are made? Engineers develop gears based on application needs by using special. There is no single process to gear manufacturing as they require different processes depending on the type and application. This can be done. Gear Manufacturing Process Step By Step.

From learnmech.com

19 Methods Of Manufacturing Of all types of Gears Gear Manufacturing Process Step By Step The process involves multiple intricate steps to achieve precision and efficiency. Developing the optimal combination that aligns with specifications for durability, precision, and. This can be done using. The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. There is no single process to gear manufacturing as they require. Gear Manufacturing Process Step By Step.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Gear Manufacturing Process Step By Step The process involves multiple intricate steps to achieve precision and efficiency. The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. The process involves three key steps: In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different types of gears,. Gear Manufacturing Process Step By Step.

From www.youtube.com

Gear manufacturing process YouTube Gear Manufacturing Process Step By Step Ever wondered how gears are made? Engineers develop gears based on application needs by using special. There is no single process to gear manufacturing as they require different processes depending on the type and application. Here is the detailed process. In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different types. Gear Manufacturing Process Step By Step.

From khatabook.com

Gear Manufacturing Understand the Basic Process of the Gear Industry Gear Manufacturing Process Step By Step Developing the optimal combination that aligns with specifications for durability, precision, and. Here is the detailed process. Engineers develop gears based on application needs by using special. The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. This can be done using. There is no single process to gear. Gear Manufacturing Process Step By Step.

From www.scribd.com

Gear Manufacturing Process Gear Simulation Gear Manufacturing Process Step By Step The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. Here is the detailed process. Engineers develop gears based on application needs by using special. This can be done using. In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different. Gear Manufacturing Process Step By Step.

From www.scribd.com

Gear Manufacturing Gear Machining Gear Manufacturing Process Step By Step Ever wondered how gears are made? Gear generating involves gear cutting through the relative motion of a rotating cutting tool and the generating, or rotational, motion of the. Engineers develop gears based on application needs by using special. Here is the detailed process. There is no single process to gear manufacturing as they require different processes depending on the type. Gear Manufacturing Process Step By Step.

From www.researchgate.net

(PDF) PROCESS FOR BEVEL GEAR MANUFACTURING Gear Manufacturing Process Step By Step This can be done using. The process involves three key steps: Gear generating involves gear cutting through the relative motion of a rotating cutting tool and the generating, or rotational, motion of the. Developing the optimal combination that aligns with specifications for durability, precision, and. The process involves multiple intricate steps to achieve precision and efficiency. The first step in. Gear Manufacturing Process Step By Step.

From www.youtube.com

Complete worm gear manufacturing process step by step YouTube Gear Manufacturing Process Step By Step There is no single process to gear manufacturing as they require different processes depending on the type and application. Here is the detailed process. This can be done using. Ever wondered how gears are made? The process involves multiple intricate steps to achieve precision and efficiency. The process involves three key steps: Engineers develop gears based on application needs by. Gear Manufacturing Process Step By Step.

From www.youtube.com

Guide to Gear Manufacturing Processes YouTube Gear Manufacturing Process Step By Step The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. There is no single process to gear manufacturing as they require different processes depending on the type and application. The process involves three key steps: Gear generating involves gear cutting through the relative motion of a rotating cutting tool. Gear Manufacturing Process Step By Step.

From www.machinemfg.com

11 Steps of Gear Processing You Must Know MachineMFG Gear Manufacturing Process Step By Step Ever wondered how gears are made? There is no single process to gear manufacturing as they require different processes depending on the type and application. Here is the detailed process. In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different types of gears, materials, and techniques used. The first step in. Gear Manufacturing Process Step By Step.

From slidemodel.com

Process Gear Diagrams for PowerPoint SlideModel Gear Manufacturing Process Step By Step Engineers develop gears based on application needs by using special. There is no single process to gear manufacturing as they require different processes depending on the type and application. The process involves three key steps: Gear generating involves gear cutting through the relative motion of a rotating cutting tool and the generating, or rotational, motion of the. The first step. Gear Manufacturing Process Step By Step.

From xkldase.edu.vn

Top 157+ ring gear manufacturing process best xkldase.edu.vn Gear Manufacturing Process Step By Step In this article, we will explore the process of gear manufacturing, from design to production, and highlight the different types of gears, materials, and techniques used. The process involves multiple intricate steps to achieve precision and efficiency. There is no single process to gear manufacturing as they require different processes depending on the type and application. This can be done. Gear Manufacturing Process Step By Step.

From mechheart.com

Gear Manufacturing Process Step by Step MECHHEART Gear Manufacturing Process Step By Step Here is the detailed process. The process involves three key steps: Engineers develop gears based on application needs by using special. Developing the optimal combination that aligns with specifications for durability, precision, and. The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. This can be done using. The. Gear Manufacturing Process Step By Step.

From slidemodel.com

6 Step Gear Process Diagram Slide SlideModel Gear Manufacturing Process Step By Step Developing the optimal combination that aligns with specifications for durability, precision, and. There is no single process to gear manufacturing as they require different processes depending on the type and application. The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. Engineers develop gears based on application needs by. Gear Manufacturing Process Step By Step.

From khkgears.net

Gear Manufacturing KHK Gears Gear Manufacturing Process Step By Step Engineers develop gears based on application needs by using special. Gear generating involves gear cutting through the relative motion of a rotating cutting tool and the generating, or rotational, motion of the. The first step in the gear manufacturing process is to cut the gear blank from a larger piece of stock material. There is no single process to gear. Gear Manufacturing Process Step By Step.