Cartridge Case Manufacturing Process . Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. It begins with brass being formed into coils and cut into cups through a. Ammo cartridge cases are typically made through a manufacturing process known as brass casings. The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. Cartridge brass manufacturing process — how cases are made. The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and their cupping.

from www.gaudi.ch

The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and their cupping. Ammo cartridge cases are typically made through a manufacturing process known as brass casings. Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. Cartridge brass manufacturing process — how cases are made. It begins with brass being formed into coils and cut into cups through a.

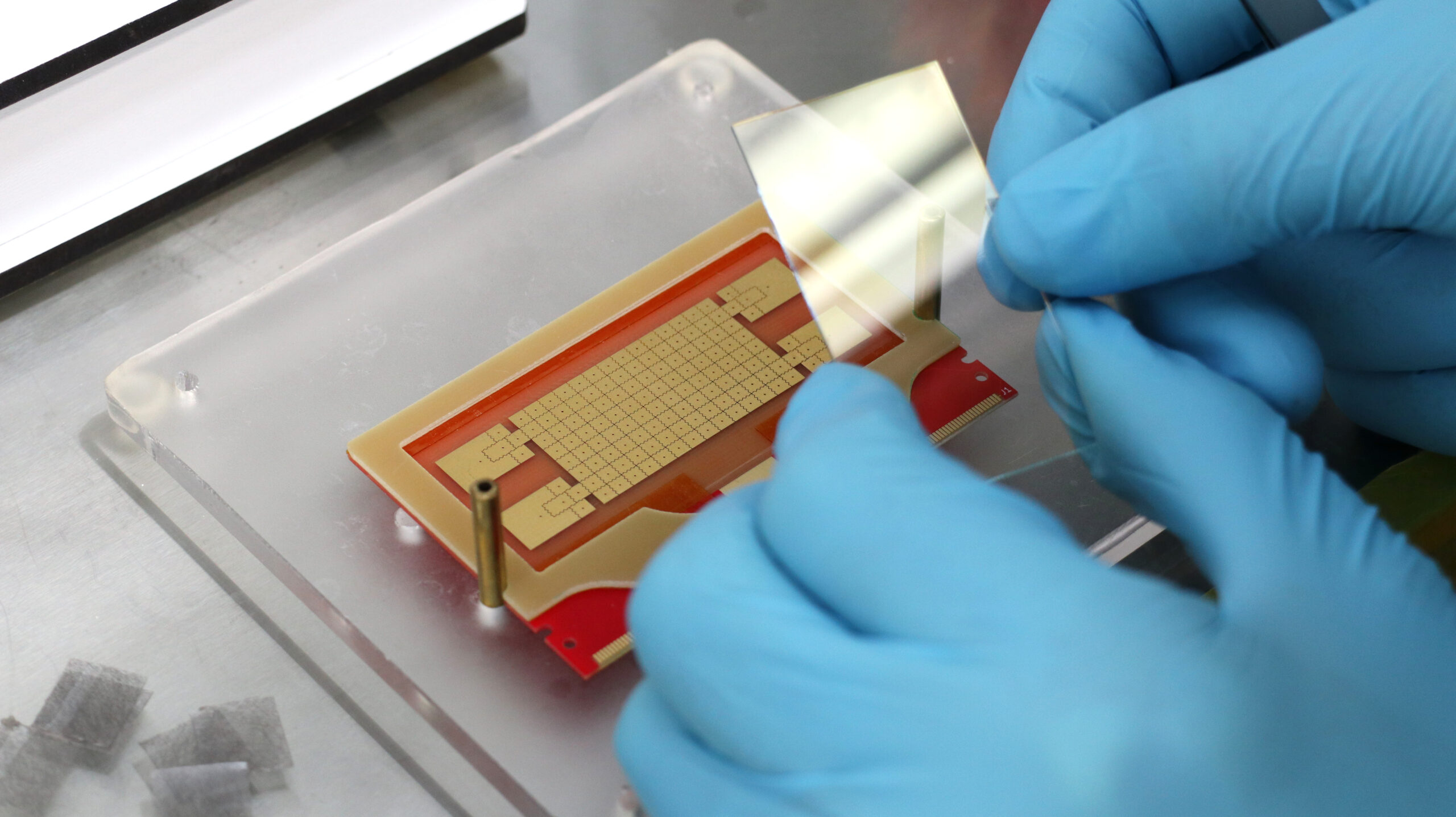

Cartridge Production Process Cartridge Assembly OpenDrop

Cartridge Case Manufacturing Process Ammo cartridge cases are typically made through a manufacturing process known as brass casings. Cartridge brass manufacturing process — how cases are made. The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and their cupping. Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. It begins with brass being formed into coils and cut into cups through a. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. Ammo cartridge cases are typically made through a manufacturing process known as brass casings.

From www.scribd.com

Drawing Brass Our Brass Cartridge Case Manufacturing Process PDF Cartridge Case Manufacturing Process It begins with brass being formed into coils and cut into cups through a. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. Ammo cartridge cases are typically made through a manufacturing process known as brass casings. Cartridge brass manufacturing process — how cases are made. Brass sheets or. Cartridge Case Manufacturing Process.

From gunsinthenews.com

Back To Basics Cartridge Cases Guns in the News Cartridge Case Manufacturing Process Ammo cartridge cases are typically made through a manufacturing process known as brass casings. Cartridge brass manufacturing process — how cases are made. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. The process of making a cartridge case begins at an automatic punch press where dies are used. Cartridge Case Manufacturing Process.

From www.army.mil

Joint Service Partnership Maintains DeepDrawn Cartridge Case Readiness Cartridge Case Manufacturing Process Ammo cartridge cases are typically made through a manufacturing process known as brass casings. It begins with brass being formed into coils and cut into cups through a. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. Cartridge brass manufacturing process — how cases are made. The steps below. Cartridge Case Manufacturing Process.

From www.youtube.com

Cartridge Filling at Berkshire Sterile Manufacturing YouTube Cartridge Case Manufacturing Process Cartridge brass manufacturing process — how cases are made. Ammo cartridge cases are typically made through a manufacturing process known as brass casings. The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and their cupping. The process of making a cartridge case begins at an automatic punch press where dies are used to. Cartridge Case Manufacturing Process.

From www.casedesigncorp.com

The Custom Case Manufacturing Process Case Design Corp Cartridge Case Manufacturing Process The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and their cupping. It begins with brass being formed into coils and cut into cups through a.. Cartridge Case Manufacturing Process.

From www.hornady.com

Cartridge Cases Hornady Manufacturing, Inc Cartridge Case Manufacturing Process The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. Cartridge brass manufacturing process — how cases are made. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. Brass sheets or coils. Cartridge Case Manufacturing Process.

From www.youtube.com

Cartridge Case Draw Press 240 Parts/Min Ammunition Machinery YouTube Cartridge Case Manufacturing Process Ammo cartridge cases are typically made through a manufacturing process known as brass casings. Cartridge brass manufacturing process — how cases are made. Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. The process of making a cartridge case begins at an automatic punch press where dies are used to. Cartridge Case Manufacturing Process.

From schematicpartduo.z4.web.core.windows.net

The Diagram Below Shows The Manufacturing Cartridge Case Manufacturing Process The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and their cupping. Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups. Cartridge Case Manufacturing Process.

From www.handloadermagazine.com

Learn To Reload (Handloading Basics) Handloader Magazine Cartridge Case Manufacturing Process The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. It begins with brass being formed into coils and cut into cups through a. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually. Cartridge Case Manufacturing Process.

From blog.cheaperthandirt.com

Reloading 101 The Cartridge Case Cartridge Case Manufacturing Process Cartridge brass manufacturing process — how cases are made. Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and their cupping. Ammo cartridge cases are typically made through a manufacturing process known as brass. Cartridge Case Manufacturing Process.

From www.gunsandoptics.com

How Brass Case Are Made? All You Need To Know About Process Of Forming Cartridge Case Manufacturing Process Cartridge brass manufacturing process — how cases are made. Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. Ammo cartridge cases are typically made through a manufacturing process known as brass casings. It begins with brass being formed into coils and cut into cups through a. The steps below show. Cartridge Case Manufacturing Process.

From ammo.com

Steel Case Ammo at Steel Casings Explained Cartridge Case Manufacturing Process It begins with brass being formed into coils and cut into cups through a. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. Cartridge brass manufacturing process — how cases are made. The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and. Cartridge Case Manufacturing Process.

From www.youtube.com

AMAZING !!! Ammunition Manufacturing Process in Factory YouTube Cartridge Case Manufacturing Process Ammo cartridge cases are typically made through a manufacturing process known as brass casings. Cartridge brass manufacturing process — how cases are made. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and. Cartridge Case Manufacturing Process.

From www.thefirearmblog.com

Modern Cartridge Case Manufacturing Methods Cartridge Case Manufacturing Process Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. It begins with brass being formed into coils and cut into cups through a. Ammo cartridge cases are typically made through a manufacturing process known as brass casings. Cartridge brass manufacturing process — how cases are made. The steps below show. Cartridge Case Manufacturing Process.

From exoexfduz.blob.core.windows.net

Cartridge Case Making Machine at Wayne Lapan blog Cartridge Case Manufacturing Process The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and their cupping. The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. It begins with brass being formed into coils and cut into cups through a.. Cartridge Case Manufacturing Process.

From www.slideserve.com

PPT Firearms, Toolmarks, and Impressions PowerPoint Presentation Cartridge Case Manufacturing Process The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and their cupping. The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. It begins with brass being formed into coils and cut into cups through a.. Cartridge Case Manufacturing Process.

From www.psicorp.com

Combustible Cartridge Cases Physical Sciences Inc. Cartridge Case Manufacturing Process Cartridge brass manufacturing process — how cases are made. The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. The steps below show peterson. Cartridge Case Manufacturing Process.

From www.google.com

Patent US3408718 Method of manufacturing cartridge cases and article Cartridge Case Manufacturing Process The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. Cartridge brass manufacturing process — how cases are made. Shooters understand the importance of. Cartridge Case Manufacturing Process.

From www.slideserve.com

PPT Firearms PowerPoint Presentation, free download ID3574888 Cartridge Case Manufacturing Process The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. It begins with brass being formed into coils and cut into cups through a. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually. Cartridge Case Manufacturing Process.

From www.gaudi.ch

Cartridge Production Process Cartridge Assembly OpenDrop Cartridge Case Manufacturing Process Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. It begins with brass being formed into coils and cut into cups through a. The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass. Cartridge Case Manufacturing Process.

From www.army.mil

Joint Service Partnership Maintains DeepDrawn Cartridge Case Readiness Cartridge Case Manufacturing Process The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and their cupping. It begins with brass being formed into coils and cut into cups through a.. Cartridge Case Manufacturing Process.

From www.researchgate.net

Cartridge model & its detail parts. Download Scientific Diagram Cartridge Case Manufacturing Process Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. Ammo cartridge cases are typically made through a manufacturing process known as brass casings. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. The process of making a cartridge case. Cartridge Case Manufacturing Process.

From www.gaudi.ch

Cartridge Production Process Cartridge Assembly OpenDrop Cartridge Case Manufacturing Process The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. It begins with brass being formed into coils and cut into cups through a. Cartridge brass manufacturing process — how cases are made. Ammo cartridge cases are typically made through a manufacturing process. Cartridge Case Manufacturing Process.

From www.google.com

Patent US3408718 Method of manufacturing cartridge cases and article Cartridge Case Manufacturing Process The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and their cupping. Ammo cartridge cases are typically made through a manufacturing process known as brass casings.. Cartridge Case Manufacturing Process.

From www.casedesigncorp.com

The Custom Case Manufacturing Process Case Design Corp Cartridge Case Manufacturing Process Ammo cartridge cases are typically made through a manufacturing process known as brass casings. Cartridge brass manufacturing process — how cases are made. Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are. Cartridge Case Manufacturing Process.

From www.reddit.com

setup to making cartridge cases r/GunnitRust Cartridge Case Manufacturing Process It begins with brass being formed into coils and cut into cups through a. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. Ammo cartridge cases are typically made through a manufacturing process known as brass casings. The process of making a cartridge case begins at an automatic punch. Cartridge Case Manufacturing Process.

From m-asystems.com

Ammunition Manufacturing Solutions MA Systems Cartridge Case Manufacturing Process The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. It begins with brass being formed into coils and cut into cups through a. The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and their cupping.. Cartridge Case Manufacturing Process.

From www.groninger-group.com

Syringe Filling Machines Vials & Cartridges groninger Cartridge Case Manufacturing Process Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. It begins with brass being formed into coils and cut into cups through a. The process of making a cartridge case. Cartridge Case Manufacturing Process.

From www.americanrifleman.org

Back To Basics Cartridge Cases An Official Journal Of The NRA Cartridge Case Manufacturing Process Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. It begins with brass being formed into coils and cut into cups through a. The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy.. Cartridge Case Manufacturing Process.

From www.youtube.com

ammunition transfer press (CASE) 240 pieces/min deep drawing YouTube Cartridge Case Manufacturing Process Ammo cartridge cases are typically made through a manufacturing process known as brass casings. Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. It begins with brass being formed into. Cartridge Case Manufacturing Process.

From m-asystems.com

Ammunition Manufacturing Solutions MA Systems Cartridge Case Manufacturing Process Cartridge brass manufacturing process — how cases are made. It begins with brass being formed into coils and cut into cups through a. The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and their cupping. Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge. Cartridge Case Manufacturing Process.

From www.scribd.com

Cartridge Case Manufacture Cartridge (Firearms) Sheet Metal Cartridge Case Manufacturing Process The process of making a cartridge case begins at an automatic punch press where dies are used to punch small brass cups from sheets of brass alloy. Cartridge brass manufacturing process — how cases are made. It begins with brass being formed into coils and cut into cups through a. The steps below show peterson cartridge's brass cartridge casing manufacturing. Cartridge Case Manufacturing Process.

From www.reddit.com

self manufacturing cartridge cases using hydroforming grease and a Cartridge Case Manufacturing Process Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. Brass sheets or coils are cut into small discs, then stamped and drawn into the shape of cartridge cases. It begins with brass being formed into coils and cut into cups through a. The steps below show peterson cartridge's brass. Cartridge Case Manufacturing Process.

From zerohertz.github.io

Manufacturing Process Zerohertz Cartridge Case Manufacturing Process Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. Cartridge brass manufacturing process — how cases are made. It begins with brass being formed into coils and cut into cups through a. Ammo cartridge cases are typically made through a manufacturing process known as brass casings. The process of. Cartridge Case Manufacturing Process.

From www.youtube.com

How Shotgun Cartridges Is Made ! Production Process YouTube Cartridge Case Manufacturing Process The steps below show peterson cartridge's brass cartridge casing manufacturing process from the original brass manufacturer and their cupping. Shooters understand the importance of good brass, but many of us have no idea how cartridge cases are actually made. Ammo cartridge cases are typically made through a manufacturing process known as brass casings. It begins with brass being formed into. Cartridge Case Manufacturing Process.