Frequency Settings For Fiber Lasers . In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time. Speed, power, hatch, frequency settings. Typically, frequencies between 20 khz to 80 khz are used depending on the material and the depth of engraving required. The best way to think about frequency is to think of it like sandpaper. If you have 20 grit sandpaper, it’s got big rough sand. Learn how the hatches and. Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. Individual materials and preference will determine the final combination of settings for each application. Here's a layman's explanation of the frequency setting in ezcad2 that might be helpful for.

from www.theengineer.co.uk

Here's a layman's explanation of the frequency setting in ezcad2 that might be helpful for. Typically, frequencies between 20 khz to 80 khz are used depending on the material and the depth of engraving required. Individual materials and preference will determine the final combination of settings for each application. Speed, power, hatch, frequency settings. In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time. The best way to think about frequency is to think of it like sandpaper. Learn how the hatches and. Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. If you have 20 grit sandpaper, it’s got big rough sand.

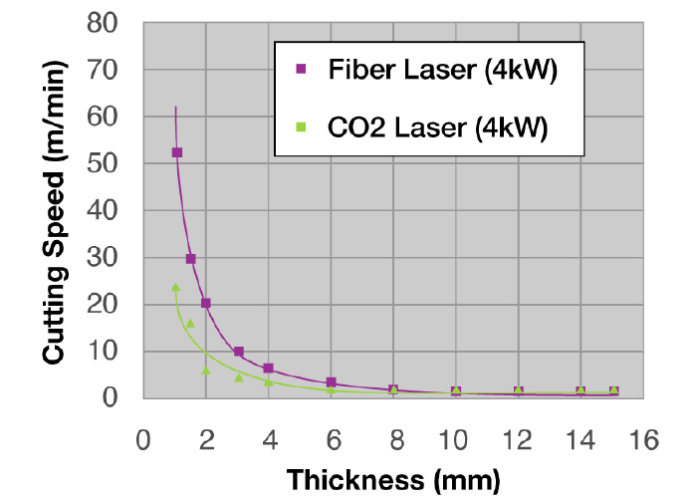

Fiber Laser vs CO2 Laser

Frequency Settings For Fiber Lasers In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time. Typically, frequencies between 20 khz to 80 khz are used depending on the material and the depth of engraving required. Here's a layman's explanation of the frequency setting in ezcad2 that might be helpful for. If you have 20 grit sandpaper, it’s got big rough sand. Speed, power, hatch, frequency settings. Learn how the hatches and. Individual materials and preference will determine the final combination of settings for each application. In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. The best way to think about frequency is to think of it like sandpaper.

From www.oceanproperty.co.th

Frequency Settings For Fiber Lasers EZCAD2, 50 OFF Frequency Settings For Fiber Lasers Speed, power, hatch, frequency settings. Individual materials and preference will determine the final combination of settings for each application. Typically, frequencies between 20 khz to 80 khz are used depending on the material and the depth of engraving required. The best way to think about frequency is to think of it like sandpaper. Processing jobs at 400 dpi vs 600. Frequency Settings For Fiber Lasers.

From www.researchgate.net

(a) Experimental setup for the singlefrequency fiber laser Frequency Settings For Fiber Lasers Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time. The best way to think about frequency is to think of it like sandpaper. Learn how the hatches and. In summary, selecting the right fiber laser settings for your cutting application can significantly. Frequency Settings For Fiber Lasers.

From www.nakazawa.riec.tohoku.ac.jp

Reserch Activities Frequency Settings For Fiber Lasers Speed, power, hatch, frequency settings. Here's a layman's explanation of the frequency setting in ezcad2 that might be helpful for. If you have 20 grit sandpaper, it’s got big rough sand. Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. Typically, frequencies between 20 khz to 80 khz are used depending on the material and the. Frequency Settings For Fiber Lasers.

From www.semanticscholar.org

Figure 1 from Using difference frequency generation to lock a CW Frequency Settings For Fiber Lasers Individual materials and preference will determine the final combination of settings for each application. Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. Learn how the hatches and. The best way to think about frequency is to think of it like sandpaper. In summary, selecting the right fiber laser settings for your cutting application can significantly. Frequency Settings For Fiber Lasers.

From www.mdpi.com

Photonics Free FullText Ultrafast Fiber Laser Emitting at 2.8 µm Frequency Settings For Fiber Lasers The best way to think about frequency is to think of it like sandpaper. Here's a layman's explanation of the frequency setting in ezcad2 that might be helpful for. If you have 20 grit sandpaper, it’s got big rough sand. In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Speed, power,. Frequency Settings For Fiber Lasers.

From mellowpine.com

Fiber Laser vs Diode Laser Expert Guide [2022] MellowPine Frequency Settings For Fiber Lasers Learn how the hatches and. Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time. Here's a layman's explanation of the frequency setting in ezcad2 that might be helpful for. Individual materials and preference will determine the final combination of settings for each. Frequency Settings For Fiber Lasers.

From en.jptoe.com

Simple Guidance In JPT MOPA Fiber Laser JPT Blog Frequency Settings For Fiber Lasers Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time. Learn how the hatches and. Individual materials and preference will determine the final combination of settings for each application. The best way to think about frequency is to think of it like sandpaper.. Frequency Settings For Fiber Lasers.

From www.youtube.com

1.04 EZCAD2 Frequency Settings for Fiber Lasers Marking Machine YouTube Frequency Settings For Fiber Lasers Learn how the hatches and. Individual materials and preference will determine the final combination of settings for each application. The best way to think about frequency is to think of it like sandpaper. Typically, frequencies between 20 khz to 80 khz are used depending on the material and the depth of engraving required. Here's a layman's explanation of the frequency. Frequency Settings For Fiber Lasers.

From www.beamq.com

Single Frequency Tunable Fiber Lasers 6,850.00 BeamQ Laser, DFB Frequency Settings For Fiber Lasers Typically, frequencies between 20 khz to 80 khz are used depending on the material and the depth of engraving required. Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time.. Frequency Settings For Fiber Lasers.

From informacionpublica.svet.gob.gt

Frequency Settings For Fiber Lasers EZCAD2 Frequency Settings For Fiber Lasers If you have 20 grit sandpaper, it’s got big rough sand. In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time. Typically, frequencies between 20. Frequency Settings For Fiber Lasers.

From mpbcommunications.com

SingleFrequency Fiber Laser Systems Frequency Settings For Fiber Lasers In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. Individual materials and preference will determine the final combination of settings for each application. The best way to think about frequency is to think of it like sandpaper. Learn. Frequency Settings For Fiber Lasers.

From www.mdpi.com

Applied Sciences Free FullText ModeLocking Dynamics in an AllPM Frequency Settings For Fiber Lasers Typically, frequencies between 20 khz to 80 khz are used depending on the material and the depth of engraving required. Learn how the hatches and. The best way to think about frequency is to think of it like sandpaper. Individual materials and preference will determine the final combination of settings for each application. Processing jobs at 400 dpi vs 600. Frequency Settings For Fiber Lasers.

From www.oceanproperty.co.th

Frequency Settings For Fiber Lasers EZCAD2, 50 OFF Frequency Settings For Fiber Lasers Learn how the hatches and. Typically, frequencies between 20 khz to 80 khz are used depending on the material and the depth of engraving required. Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. If you have 20 grit sandpaper, it’s got big rough sand. The best way to think about frequency is to think of. Frequency Settings For Fiber Lasers.

From www.researchgate.net

Qswitched Ybdoped fiber laser (a) cavity configuration; (b) output Frequency Settings For Fiber Lasers If you have 20 grit sandpaper, it’s got big rough sand. Typically, frequencies between 20 khz to 80 khz are used depending on the material and the depth of engraving required. Individual materials and preference will determine the final combination of settings for each application. Here's a layman's explanation of the frequency setting in ezcad2 that might be helpful for.. Frequency Settings For Fiber Lasers.

From www.oceanproperty.co.th

Frequency Settings For Fiber Lasers EZCAD2, 50 OFF Frequency Settings For Fiber Lasers Individual materials and preference will determine the final combination of settings for each application. Speed, power, hatch, frequency settings. Here's a layman's explanation of the frequency setting in ezcad2 that might be helpful for. If you have 20 grit sandpaper, it’s got big rough sand. Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to. Frequency Settings For Fiber Lasers.

From www.oceanproperty.co.th

Frequency Settings For Fiber Lasers EZCAD2, 50 OFF Frequency Settings For Fiber Lasers Here's a layman's explanation of the frequency setting in ezcad2 that might be helpful for. If you have 20 grit sandpaper, it’s got big rough sand. Learn how the hatches and. The best way to think about frequency is to think of it like sandpaper. Individual materials and preference will determine the final combination of settings for each application. Processing. Frequency Settings For Fiber Lasers.

From informacionpublica.svet.gob.gt

Frequency Settings For Fiber Lasers EZCAD2 Frequency Settings For Fiber Lasers Learn how the hatches and. If you have 20 grit sandpaper, it’s got big rough sand. In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Individual materials and preference will determine the final combination of settings for each application. Speed, power, hatch, frequency settings. Fiber laser engraving settings for metals, plastics,. Frequency Settings For Fiber Lasers.

From www.researchgate.net

Operation principle of the coherent Brillouin random fiber laser Frequency Settings For Fiber Lasers Learn how the hatches and. Individual materials and preference will determine the final combination of settings for each application. Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time. Typically, frequencies between 20 khz to 80 khz are used depending on the material. Frequency Settings For Fiber Lasers.

From www.laserlabsource.com

Fiber Laser Basics and Design Principles (with VIDEOS) Frequency Settings For Fiber Lasers Typically, frequencies between 20 khz to 80 khz are used depending on the material and the depth of engraving required. Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. Here's a layman's explanation of the frequency setting in ezcad2 that might be helpful for. Speed, power, hatch, frequency settings. In summary, selecting the right fiber laser. Frequency Settings For Fiber Lasers.

From www.robotdigg.com

QSwitched Pulse Fiber Laser Source for Laser Marking RobotDigg Frequency Settings For Fiber Lasers In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. The best way to think about frequency is to think of it like sandpaper. If you have 20 grit sandpaper, it’s got big rough sand. Typically, frequencies between 20 khz to 80 khz are used depending on the material and the depth. Frequency Settings For Fiber Lasers.

From www.cnioptics.com

266 nm ps fiber laser with pulse width 100 ps & rep. rate variable, and Frequency Settings For Fiber Lasers The best way to think about frequency is to think of it like sandpaper. In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Typically, frequencies between 20 khz to 80 khz are used depending on the material and the depth of engraving required. Here's a layman's explanation of the frequency setting. Frequency Settings For Fiber Lasers.

From www.researchgate.net

Singlefrequency laser properties of the GC fiber. (a) Spectrum of the Frequency Settings For Fiber Lasers Speed, power, hatch, frequency settings. In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Individual materials and preference will determine the final combination of settings for each application. Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. Here's a layman's explanation of the frequency setting in ezcad2. Frequency Settings For Fiber Lasers.

From www.researchgate.net

Power and efficiency of frequency doubled 589 nm laser generation as a Frequency Settings For Fiber Lasers If you have 20 grit sandpaper, it’s got big rough sand. The best way to think about frequency is to think of it like sandpaper. Here's a layman's explanation of the frequency setting in ezcad2 that might be helpful for. Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300. Frequency Settings For Fiber Lasers.

From www.pannier.com

Laser Wavelengths for Specific Materials Pannier Marking Systems Frequency Settings For Fiber Lasers If you have 20 grit sandpaper, it’s got big rough sand. Individual materials and preference will determine the final combination of settings for each application. The best way to think about frequency is to think of it like sandpaper. In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Typically, frequencies between. Frequency Settings For Fiber Lasers.

From www.laserax.com

Fiber Lasers Everything You Need to Know Laserax Frequency Settings For Fiber Lasers In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. If you have 20 grit sandpaper, it’s got big rough sand. Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time. Typically, frequencies between 20. Frequency Settings For Fiber Lasers.

From www.spilasers.com

Marking with a Pulsed Fiber Laser SPI Lasers Frequency Settings For Fiber Lasers Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. The best way to think about frequency is to think of it like sandpaper. Individual materials and preference will determine the final combination of settings for each application. Learn how the hatches and. Typically, frequencies between 20 khz to 80 khz are used depending on the material. Frequency Settings For Fiber Lasers.

From www.oceanproperty.co.th

Frequency Settings For Fiber Lasers EZCAD2, 50 OFF Frequency Settings For Fiber Lasers Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time. Individual materials and preference will determine the final combination of settings for each application. Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. Typically, frequencies between 20 khz to. Frequency Settings For Fiber Lasers.

From www.theengineer.co.uk

Fiber Laser vs CO2 Laser Frequency Settings For Fiber Lasers Typically, frequencies between 20 khz to 80 khz are used depending on the material and the depth of engraving required. Learn how the hatches and. Individual materials and preference will determine the final combination of settings for each application. In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. If you have. Frequency Settings For Fiber Lasers.

From www.researchgate.net

Typical types of lasers and corresponding wavelengths [69]. Download Frequency Settings For Fiber Lasers In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time. Learn how the hatches and. Individual materials and preference will determine the final combination of. Frequency Settings For Fiber Lasers.

From www.youtube.com

ALL of my Fiber Laser Parameters and CO2 Laser Settings YouTube Frequency Settings For Fiber Lasers Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time. In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Speed, power, hatch, frequency settings. Fiber laser engraving settings for metals, plastics, wood, glass, leather,. Frequency Settings For Fiber Lasers.

From www.youtube.com

Frequency Settings for Fiber Lasers EZCAD2 YouTube Frequency Settings For Fiber Lasers In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. The best way to think about frequency is to think of it like sandpaper. Speed, power, hatch, frequency settings. Learn how the hatches and. Processing jobs at 400 dpi. Frequency Settings For Fiber Lasers.

From www.intechopen.com

Tunable Single, Dual and Multiwavelength Fibre Lasers by Using Twin Frequency Settings For Fiber Lasers Learn how the hatches and. Typically, frequencies between 20 khz to 80 khz are used depending on the material and the depth of engraving required. Here's a layman's explanation of the frequency setting in ezcad2 that might be helpful for. In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Fiber laser. Frequency Settings For Fiber Lasers.

From lasertips.org

Fiber Laser Settings Frequency Settings For Fiber Lasers Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. Speed, power, hatch, frequency settings. Individual materials and preference will determine the final combination of settings for each application. If you have 20 grit sandpaper, it’s got big rough sand. Learn how the hatches and. The best way to think about frequency is to think of it. Frequency Settings For Fiber Lasers.

From www.researchgate.net

Experimental setup for efficient frequency doubling in a fiber laser Frequency Settings For Fiber Lasers Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time. Fiber laser engraving settings for metals, plastics, wood, glass, leather, paperboard, pcb cards. Speed, power, hatch, frequency settings. Typically, frequencies between 20 khz to 80 khz are used depending on the material and. Frequency Settings For Fiber Lasers.

From www.intechopen.com

Tunable Single, Dual and Multiwavelength Fibre Lasers by Using Twin Frequency Settings For Fiber Lasers If you have 20 grit sandpaper, it’s got big rough sand. In summary, selecting the right fiber laser settings for your cutting application can significantly impact cutting speed, precision,. Processing jobs at 400 dpi vs 600 dpi can reduce cycle times by up to 30%, and processing at 300 dpi could mean half the cycle time. Here's a layman's explanation. Frequency Settings For Fiber Lasers.