How To Calculate Cycle Time Per Hour . An ideal cycle time should be less than 48 hours. Cycle time= 10 tasks / 35 hours =3.5 hours per task. For this example, we will assume a standard shift of 8 hours = 480 min. For this example, we will say that 1000 parts were made. If dealing with batches of items, instead of one piece flow, simply take the total parts produced and divide that quantity by the production run time to determine the cycle time per part. Whether you work at a big factory or. You can calculate cycle time with this simple formula: First, determine the number of parts produced in a shift. Shorter cycle times in software. Next, determine the length of the shift. The above example, however, is the simplest method for understanding average cycle time on a basic level. Once the elements of the measurement are determined, the calculation is relatively straightforward. Finally, calculate the cycle time. Cycle time (ct) = net production time (npt) / number of units made (u) here, net. In this case, computing cycle time is the total production time divided by the units produced:

from www.allaboutlean.com

Finally, calculate the cycle time. Depending on the manufacturer, there may be a few different variations of this formula. For this example, we will assume a standard shift of 8 hours = 480 min. If dealing with batches of items, instead of one piece flow, simply take the total parts produced and divide that quantity by the production run time to determine the cycle time per part. First, determine the number of parts produced in a shift. Cycle time (ct) = net production time (npt) / number of units made (u) here, net. How to calculate cycle time? Pu = units produced during net production time In this case, computing cycle time is the total production time divided by the units produced: Cycle time = total production time/number of goods (x) produced.

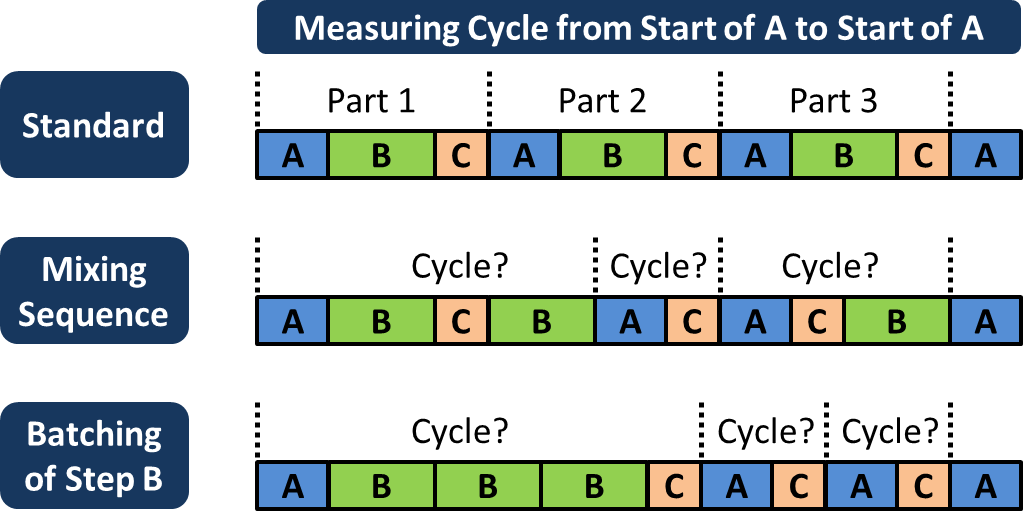

How to Measure Cycle Times Part 2

How To Calculate Cycle Time Per Hour Depending on the manufacturer, there may be a few different variations of this formula. Cycle time (ct) = net production time (npt) / number of units made (u) here, net. How to calculate cycle time? Pt = net production time; An ideal cycle time should be less than 48 hours. Shorter cycle times in software. For this example, we will say that 1000 parts were made. If dealing with batches of items, instead of one piece flow, simply take the total parts produced and divide that quantity by the production run time to determine the cycle time per part. The cycle time calculator tells you how fast, on average, it takes someone to produce one item. Finally, calculate the cycle time. Whether you work at a big factory or. Once the elements of the measurement are determined, the calculation is relatively straightforward. You can calculate cycle time with this simple formula: Next, determine the length of the shift. For this example, we will assume a standard shift of 8 hours = 480 min. First, determine the number of parts produced in a shift.

From www.keypup.io

Calculating Cycle Time Templates and Tutorials Keypup How To Calculate Cycle Time Per Hour Depending on the manufacturer, there may be a few different variations of this formula. Once the elements of the measurement are determined, the calculation is relatively straightforward. Pu = units produced during net production time For this example, we will assume a standard shift of 8 hours = 480 min. Cycle time = total production time/number of goods (x) produced.. How To Calculate Cycle Time Per Hour.

From www.onlineclothingstudy.com

How to Calculate Pieces per Hour from Cycle Time? How To Calculate Cycle Time Per Hour How to calculate cycle time? The cycle time calculator tells you how fast, on average, it takes someone to produce one item. An ideal cycle time should be less than 48 hours. Cycle time= 10 tasks / 35 hours =3.5 hours per task. Depending on the manufacturer, there may be a few different variations of this formula. Once the elements. How To Calculate Cycle Time Per Hour.

From www.vrogue.co

How To Calculate Cycle Time Of A Process vrogue.co How To Calculate Cycle Time Per Hour Pu = units produced during net production time Finally, calculate the cycle time. If dealing with batches of items, instead of one piece flow, simply take the total parts produced and divide that quantity by the production run time to determine the cycle time per part. The cycle time calculator tells you how fast, on average, it takes someone to. How To Calculate Cycle Time Per Hour.

From www.exceldemy.com

How to Calculate Cycle Time in Excel (7 Examples) ExcelDemy How To Calculate Cycle Time Per Hour For this example, we will say that 1000 parts were made. Next, determine the length of the shift. Cycle time (ct) = net production time (npt) / number of units made (u) here, net. Shorter cycle times in software. Finally, calculate the cycle time. Whether you work at a big factory or. Cycle time= 10 tasks / 35 hours =3.5. How To Calculate Cycle Time Per Hour.

From www.thetechedvocate.org

How to calculate cycle time The Tech Edvocate How To Calculate Cycle Time Per Hour How to calculate cycle time? The cycle time calculator tells you how fast, on average, it takes someone to produce one item. First, determine the number of parts produced in a shift. Depending on the manufacturer, there may be a few different variations of this formula. In this case, computing cycle time is the total production time divided by the. How To Calculate Cycle Time Per Hour.

From www.youtube.com

Throughput Time, Manufacturing Cycle Efficiency (Accounting) YouTube How To Calculate Cycle Time Per Hour How to calculate cycle time? If dealing with batches of items, instead of one piece flow, simply take the total parts produced and divide that quantity by the production run time to determine the cycle time per part. Cycle time = total production time/number of goods (x) produced. Cycle time (ct) = net production time (npt) / number of units. How To Calculate Cycle Time Per Hour.

From hubstaff.com

Measuring Cycle Time A Comprehensive Guide Hubstaff Blog How To Calculate Cycle Time Per Hour An ideal cycle time should be less than 48 hours. Finally, calculate the cycle time. How to calculate cycle time? Cycle time = total production time/number of goods (x) produced. The above example, however, is the simplest method for understanding average cycle time on a basic level. Pu = units produced during net production time First, determine the number of. How To Calculate Cycle Time Per Hour.

From www.youtube.com

How to Calculate Cycle Time in Jira YouTube How To Calculate Cycle Time Per Hour In this case, computing cycle time is the total production time divided by the units produced: Cycle time (ct) = net production time (npt) / number of units made (u) here, net. Whether you work at a big factory or. If dealing with batches of items, instead of one piece flow, simply take the total parts produced and divide that. How To Calculate Cycle Time Per Hour.

From www.exceldemy.com

How to Calculate Cycle Time in Excel (7 Examples) ExcelDemy How To Calculate Cycle Time Per Hour Pt = net production time; For this example, we will assume a standard shift of 8 hours = 480 min. Shorter cycle times in software. Next, determine the length of the shift. Cycle time (ct) = net production time (npt) / number of units made (u) here, net. For this example, we will say that 1000 parts were made. If. How To Calculate Cycle Time Per Hour.

From unitymanufacture.com

How To Calculate CNC Turning Cycle Time? Unity Manufacture How To Calculate Cycle Time Per Hour Cycle time = total production time/number of goods (x) produced. Shorter cycle times in software. Finally, calculate the cycle time. Pu = units produced during net production time If dealing with batches of items, instead of one piece flow, simply take the total parts produced and divide that quantity by the production run time to determine the cycle time per. How To Calculate Cycle Time Per Hour.

From prostech.vn

Cycle Time How to Calculate & Improve PROSTECH How To Calculate Cycle Time Per Hour Pu = units produced during net production time The cycle time calculator tells you how fast, on average, it takes someone to produce one item. The above example, however, is the simplest method for understanding average cycle time on a basic level. Next, determine the length of the shift. How to calculate cycle time? If dealing with batches of items,. How To Calculate Cycle Time Per Hour.

From linearb.io

Cycle Time Formulas for Your Software Group LinearB How To Calculate Cycle Time Per Hour An ideal cycle time should be less than 48 hours. Finally, calculate the cycle time. The cycle time calculator tells you how fast, on average, it takes someone to produce one item. Next, determine the length of the shift. You can calculate cycle time with this simple formula: The above example, however, is the simplest method for understanding average cycle. How To Calculate Cycle Time Per Hour.

From ihsanpedia.com

How To Calculate Hours Worked The Ultimate Guide IHSANPEDIA How To Calculate Cycle Time Per Hour First, determine the number of parts produced in a shift. Once the elements of the measurement are determined, the calculation is relatively straightforward. If dealing with batches of items, instead of one piece flow, simply take the total parts produced and divide that quantity by the production run time to determine the cycle time per part. Next, determine the length. How To Calculate Cycle Time Per Hour.

From www.vrogue.co

How To Calculate Cycle Time Of A Process vrogue.co How To Calculate Cycle Time Per Hour Whether you work at a big factory or. Cycle time (ct) = net production time (npt) / number of units made (u) here, net. Next, determine the length of the shift. If dealing with batches of items, instead of one piece flow, simply take the total parts produced and divide that quantity by the production run time to determine the. How To Calculate Cycle Time Per Hour.

From www.presentationeze.com

How to calculate cycle time.PresentationEZE How To Calculate Cycle Time Per Hour Depending on the manufacturer, there may be a few different variations of this formula. Once the elements of the measurement are determined, the calculation is relatively straightforward. The cycle time calculator tells you how fast, on average, it takes someone to produce one item. Pt = net production time; If dealing with batches of items, instead of one piece flow,. How To Calculate Cycle Time Per Hour.

From www.youtube.com

What is Cycle Time ! Cycle Time kya Hota h ! How to Calculate Cycle How To Calculate Cycle Time Per Hour Whether you work at a big factory or. Cycle time = total production time/number of goods (x) produced. If dealing with batches of items, instead of one piece flow, simply take the total parts produced and divide that quantity by the production run time to determine the cycle time per part. First, determine the number of parts produced in a. How To Calculate Cycle Time Per Hour.

From prostech.vn

Cycle Time (C/T) How to Calculate & Improve PROSTECH How To Calculate Cycle Time Per Hour Whether you work at a big factory or. You can calculate cycle time with this simple formula: In this case, computing cycle time is the total production time divided by the units produced: Cycle time= 10 tasks / 35 hours =3.5 hours per task. If dealing with batches of items, instead of one piece flow, simply take the total parts. How To Calculate Cycle Time Per Hour.

From prostech.vn

Cycle Time How to Calculate & Improve PROSTECH How To Calculate Cycle Time Per Hour An ideal cycle time should be less than 48 hours. You can calculate cycle time with this simple formula: Depending on the manufacturer, there may be a few different variations of this formula. First, determine the number of parts produced in a shift. Shorter cycle times in software. How do you calculate cycle time? The above example, however, is the. How To Calculate Cycle Time Per Hour.

From www.allaboutlean.com

How to Measure Cycle Times Part 2 How To Calculate Cycle Time Per Hour Finally, calculate the cycle time. For this example, we will assume a standard shift of 8 hours = 480 min. Cycle time (ct) = net production time (npt) / number of units made (u) here, net. If dealing with batches of items, instead of one piece flow, simply take the total parts produced and divide that quantity by the production. How To Calculate Cycle Time Per Hour.

From prostech.vn

Cycle Time (C/T) How to Calculate & Improve PROSTECH How To Calculate Cycle Time Per Hour How do you calculate cycle time? If dealing with batches of items, instead of one piece flow, simply take the total parts produced and divide that quantity by the production run time to determine the cycle time per part. You can calculate cycle time with this simple formula: Pt = net production time; The above example, however, is the simplest. How To Calculate Cycle Time Per Hour.

From gomingo.io

How Do You Calculate Cycle Time in Manufacturing? Mingo Smart Factory How To Calculate Cycle Time Per Hour Next, determine the length of the shift. Finally, calculate the cycle time. The above example, however, is the simplest method for understanding average cycle time on a basic level. How to calculate cycle time? Shorter cycle times in software. For this example, we will say that 1000 parts were made. Cycle time= 10 tasks / 35 hours =3.5 hours per. How To Calculate Cycle Time Per Hour.

From www.presentationeze.com

How to calculate cycle time.PresentationEZE How To Calculate Cycle Time Per Hour An ideal cycle time should be less than 48 hours. In this case, computing cycle time is the total production time divided by the units produced: Whether you work at a big factory or. Cycle time= 10 tasks / 35 hours =3.5 hours per task. Once the elements of the measurement are determined, the calculation is relatively straightforward. How to. How To Calculate Cycle Time Per Hour.

From www.keypup.io

Calculating Cycle Time Templates and Tutorials Keypup How To Calculate Cycle Time Per Hour How to calculate cycle time? How do you calculate cycle time? You can calculate cycle time with this simple formula: Depending on the manufacturer, there may be a few different variations of this formula. Whether you work at a big factory or. Cycle time= 10 tasks / 35 hours =3.5 hours per task. In this case, computing cycle time is. How To Calculate Cycle Time Per Hour.

From www.keypup.io

Calculating Cycle Time Templates and Tutorials Keypup How To Calculate Cycle Time Per Hour Finally, calculate the cycle time. How to calculate cycle time? First, determine the number of parts produced in a shift. Cycle time = total production time/number of goods (x) produced. Next, determine the length of the shift. Depending on the manufacturer, there may be a few different variations of this formula. Whether you work at a big factory or. Cycle. How To Calculate Cycle Time Per Hour.

From www.nesta.com.hk

Calculating Cycle Time Understanding and Applying the Formula How To Calculate Cycle Time Per Hour Shorter cycle times in software. Whether you work at a big factory or. How to calculate cycle time? Cycle time = total production time/number of goods (x) produced. Pu = units produced during net production time Once the elements of the measurement are determined, the calculation is relatively straightforward. First, determine the number of parts produced in a shift. Finally,. How To Calculate Cycle Time Per Hour.

From www.projectmanager.com

How to Calculate Manufacturing Cycle Time ProjectManager How To Calculate Cycle Time Per Hour Cycle time (ct) = net production time (npt) / number of units made (u) here, net. Once the elements of the measurement are determined, the calculation is relatively straightforward. Pt = net production time; Depending on the manufacturer, there may be a few different variations of this formula. An ideal cycle time should be less than 48 hours. Pu =. How To Calculate Cycle Time Per Hour.

From www.exceldemy.com

How to Calculate Cycle Time in Excel (7 Examples) ExcelDemy How To Calculate Cycle Time Per Hour Cycle time (ct) = net production time (npt) / number of units made (u) here, net. Pt = net production time; How do you calculate cycle time? The above example, however, is the simplest method for understanding average cycle time on a basic level. How to calculate cycle time? First, determine the number of parts produced in a shift. Pu. How To Calculate Cycle Time Per Hour.

From www.youtube.com

How to calculate cycle time in Excel YouTube How To Calculate Cycle Time Per Hour Pu = units produced during net production time The above example, however, is the simplest method for understanding average cycle time on a basic level. First, determine the number of parts produced in a shift. Finally, calculate the cycle time. The cycle time calculator tells you how fast, on average, it takes someone to produce one item. In this case,. How To Calculate Cycle Time Per Hour.

From www.youtube.com

How to Calculate Takt time,Cycle time,Throughput time, Lead time ? Tips How To Calculate Cycle Time Per Hour First, determine the number of parts produced in a shift. Pu = units produced during net production time Finally, calculate the cycle time. Cycle time (ct) = net production time (npt) / number of units made (u) here, net. Depending on the manufacturer, there may be a few different variations of this formula. For this example, we will assume a. How To Calculate Cycle Time Per Hour.

From linearb.io

How to Calculate Cycle Time Precisely LinearB Blog How To Calculate Cycle Time Per Hour The cycle time calculator tells you how fast, on average, it takes someone to produce one item. How to calculate cycle time? Once the elements of the measurement are determined, the calculation is relatively straightforward. Pu = units produced during net production time Finally, calculate the cycle time. Cycle time = total production time/number of goods (x) produced. You can. How To Calculate Cycle Time Per Hour.

From www.usemotion.com

Everything You Need to Know About Agile Cycle Time Motion Motion How To Calculate Cycle Time Per Hour How to calculate cycle time? Cycle time= 10 tasks / 35 hours =3.5 hours per task. Pt = net production time; Depending on the manufacturer, there may be a few different variations of this formula. Shorter cycle times in software. The cycle time calculator tells you how fast, on average, it takes someone to produce one item. The above example,. How To Calculate Cycle Time Per Hour.

From www.youtube.com

Calculating cycle time on parallel paths and rework loops YouTube How To Calculate Cycle Time Per Hour If dealing with batches of items, instead of one piece flow, simply take the total parts produced and divide that quantity by the production run time to determine the cycle time per part. Finally, calculate the cycle time. Cycle time (ct) = net production time (npt) / number of units made (u) here, net. For this example, we will say. How To Calculate Cycle Time Per Hour.

From www.vrogue.co

How To Calculate Cycle Time In Excel 7 Examples Excel vrogue.co How To Calculate Cycle Time Per Hour The cycle time calculator tells you how fast, on average, it takes someone to produce one item. Cycle time= 10 tasks / 35 hours =3.5 hours per task. Cycle time (ct) = net production time (npt) / number of units made (u) here, net. How do you calculate cycle time? How to calculate cycle time? You can calculate cycle time. How To Calculate Cycle Time Per Hour.

From www.youtube.com

How To Count Or Calculate Hours Worked In Excel YouTube How To Calculate Cycle Time Per Hour How do you calculate cycle time? Shorter cycle times in software. An ideal cycle time should be less than 48 hours. Cycle time = total production time/number of goods (x) produced. If dealing with batches of items, instead of one piece flow, simply take the total parts produced and divide that quantity by the production run time to determine the. How To Calculate Cycle Time Per Hour.

From slideplayer.com

Cycle Time at IC Electrical Test Operation Simulation by Jitrayut How To Calculate Cycle Time Per Hour First, determine the number of parts produced in a shift. Pu = units produced during net production time For this example, we will assume a standard shift of 8 hours = 480 min. How to calculate cycle time? Cycle time (ct) = net production time (npt) / number of units made (u) here, net. In this case, computing cycle time. How To Calculate Cycle Time Per Hour.