How To Arc Weld Upside Down . learn the basics of stick welding, from tips and techniques to supplies and safety measures. Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool. After starting the arc, move the rod to the. the key to mig welding upside down is keeping your feed regular and your arc short. Way too many of you guys are asking. Hot metal fragments and sparks can fall down on the fabricator, in this guide we cover how to weld in an upside down position. wleding upside down can take some major pratice. While you are in a less than. practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make sure you get fusion. this is another long one fellas. When welding inverted you must think safety first.

from eziil.com

this is another long one fellas. When welding inverted you must think safety first. practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make sure you get fusion. the key to mig welding upside down is keeping your feed regular and your arc short. While you are in a less than. wleding upside down can take some major pratice. Hot metal fragments and sparks can fall down on the fabricator, in this guide we cover how to weld in an upside down position. Way too many of you guys are asking. After starting the arc, move the rod to the. Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool.

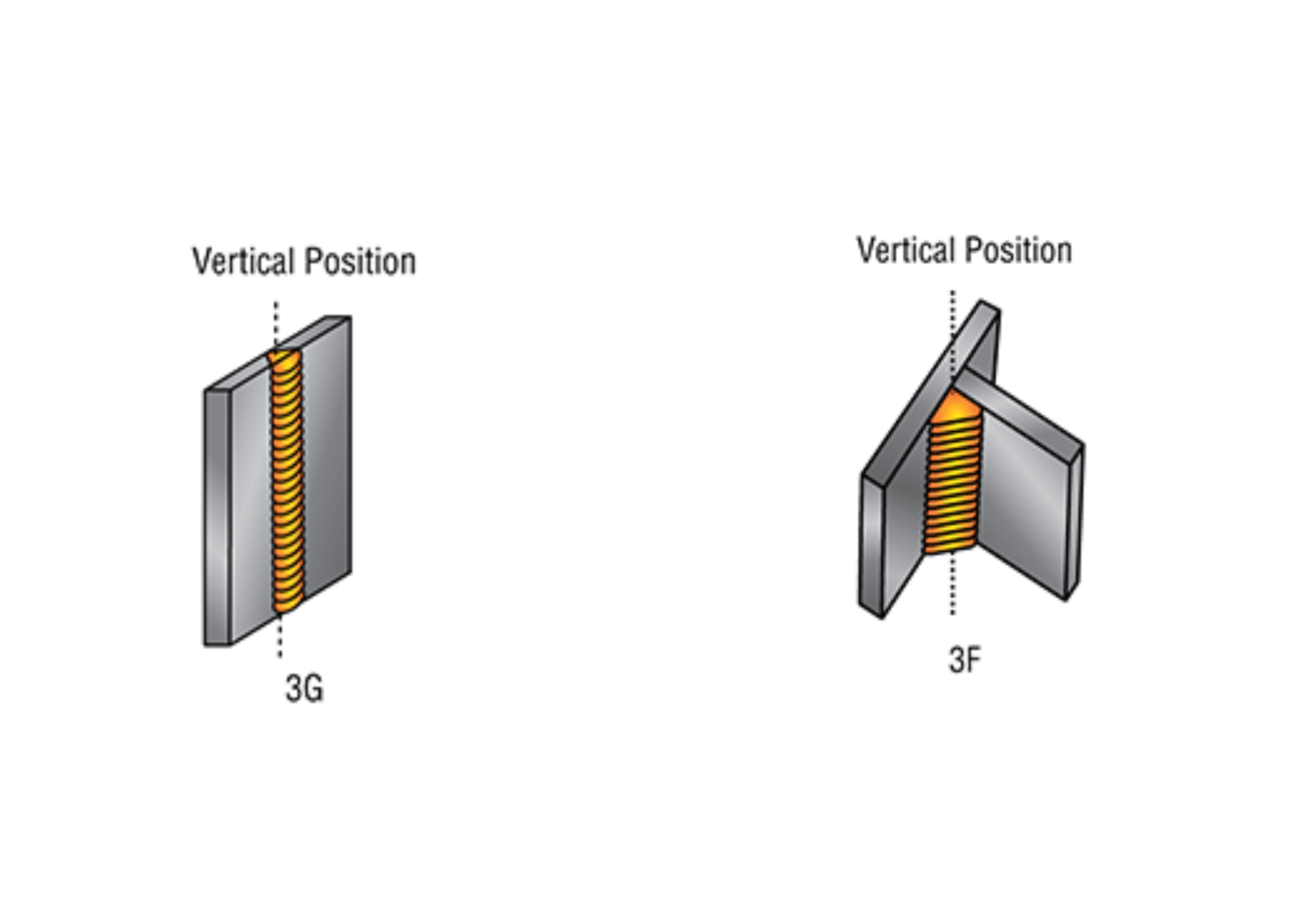

5 Types of Welding Positions 1g, 2f, 3g, 4g...

How To Arc Weld Upside Down this is another long one fellas. learn the basics of stick welding, from tips and techniques to supplies and safety measures. practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make sure you get fusion. While you are in a less than. After starting the arc, move the rod to the. Hot metal fragments and sparks can fall down on the fabricator, in this guide we cover how to weld in an upside down position. this is another long one fellas. Way too many of you guys are asking. the key to mig welding upside down is keeping your feed regular and your arc short. When welding inverted you must think safety first. Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool. wleding upside down can take some major pratice.

From prolife.org.uk

How To MIG Weld Upside Down In 2022? [Inverted Welding] How To Arc Weld Upside Down learn the basics of stick welding, from tips and techniques to supplies and safety measures. When welding inverted you must think safety first. Way too many of you guys are asking. While you are in a less than. practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make. How To Arc Weld Upside Down.

From learninglibenlicing6t.z14.web.core.windows.net

Printable Weld Symbol Chart How To Arc Weld Upside Down After starting the arc, move the rod to the. Way too many of you guys are asking. When welding inverted you must think safety first. Hot metal fragments and sparks can fall down on the fabricator, in this guide we cover how to weld in an upside down position. While you are in a less than. wleding upside down. How To Arc Weld Upside Down.

From schematicsekci7r.z21.web.core.windows.net

Welding Schematic Diagram How To Arc Weld Upside Down Hot metal fragments and sparks can fall down on the fabricator, in this guide we cover how to weld in an upside down position. Way too many of you guys are asking. After starting the arc, move the rod to the. Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool.. How To Arc Weld Upside Down.

From www.youtube.com

Upside down welding YouTube How To Arc Weld Upside Down Way too many of you guys are asking. While you are in a less than. Hot metal fragments and sparks can fall down on the fabricator, in this guide we cover how to weld in an upside down position. practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make. How To Arc Weld Upside Down.

From www.youtube.com

Welding up and turning down a shaft. YouTube How To Arc Weld Upside Down practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make sure you get fusion. this is another long one fellas. Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool. After starting the arc, move the rod to the.. How To Arc Weld Upside Down.

From www.reddit.com

Less than two hours teaching myself, pesky E8018G’s to weld with, and How To Arc Weld Upside Down the key to mig welding upside down is keeping your feed regular and your arc short. Way too many of you guys are asking. When welding inverted you must think safety first. While you are in a less than. After starting the arc, move the rod to the. this is another long one fellas. practise on a. How To Arc Weld Upside Down.

From enginelibaberrant.z21.web.core.windows.net

Introduction Of Arc Welding How To Arc Weld Upside Down After starting the arc, move the rod to the. the key to mig welding upside down is keeping your feed regular and your arc short. Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool. wleding upside down can take some major pratice. Way too many of you guys. How To Arc Weld Upside Down.

From weldingmastermind.com

10 Tips and Tricks For Welding Upside Down! Welding Mastermind How To Arc Weld Upside Down practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make sure you get fusion. After starting the arc, move the rod to the. learn the basics of stick welding, from tips and techniques to supplies and safety measures. this is another long one fellas. Way too many. How To Arc Weld Upside Down.

From www.youtube.com

How to Arc Weld Welding YouTube How To Arc Weld Upside Down After starting the arc, move the rod to the. the key to mig welding upside down is keeping your feed regular and your arc short. Hot metal fragments and sparks can fall down on the fabricator, in this guide we cover how to weld in an upside down position. Way too many of you guys are asking. learn. How To Arc Weld Upside Down.

From eziil.com

5 Types of Welding Positions 1g, 2f, 3g, 4g... How To Arc Weld Upside Down wleding upside down can take some major pratice. When welding inverted you must think safety first. the key to mig welding upside down is keeping your feed regular and your arc short. practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make sure you get fusion. . How To Arc Weld Upside Down.

From guidebarbolasblogv4.z13.web.core.windows.net

Electric Arc Welding Diagram How To Arc Weld Upside Down the key to mig welding upside down is keeping your feed regular and your arc short. this is another long one fellas. learn the basics of stick welding, from tips and techniques to supplies and safety measures. After starting the arc, move the rod to the. wleding upside down can take some major pratice. Maintain a. How To Arc Weld Upside Down.

From schematicpajellahy.z13.web.core.windows.net

Arc Welding Setup Diagram How To Arc Weld Upside Down Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool. Way too many of you guys are asking. this is another long one fellas. After starting the arc, move the rod to the. Hot metal fragments and sparks can fall down on the fabricator, in this guide we cover how. How To Arc Weld Upside Down.

From www.mig-welding.co.uk

Welding upside down! MIG Welding Forum How To Arc Weld Upside Down this is another long one fellas. When welding inverted you must think safety first. Way too many of you guys are asking. After starting the arc, move the rod to the. wleding upside down can take some major pratice. While you are in a less than. Hot metal fragments and sparks can fall down on the fabricator, in. How To Arc Weld Upside Down.

From welderslab.com

What is the Best Way to Weld Upside Down Tips, Techniques, and How To Arc Weld Upside Down learn the basics of stick welding, from tips and techniques to supplies and safety measures. wleding upside down can take some major pratice. practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make sure you get fusion. When welding inverted you must think safety first. the. How To Arc Weld Upside Down.

From www.youtube.com

Tig welding upside down by Sporadic Fabrication YouTube How To Arc Weld Upside Down Way too many of you guys are asking. When welding inverted you must think safety first. While you are in a less than. wleding upside down can take some major pratice. the key to mig welding upside down is keeping your feed regular and your arc short. learn the basics of stick welding, from tips and techniques. How To Arc Weld Upside Down.

From sensibledigs.com

How To Arc Weld (Simple StepbyStep Guide) Sensible Digs How To Arc Weld Upside Down Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool. the key to mig welding upside down is keeping your feed regular and your arc short. Way too many of you guys are asking. While you are in a less than. practise on a few pieces of scrap and. How To Arc Weld Upside Down.

From mungfali.com

Fillet Weld Positions How To Arc Weld Upside Down Hot metal fragments and sparks can fall down on the fabricator, in this guide we cover how to weld in an upside down position. Way too many of you guys are asking. this is another long one fellas. Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool. When welding. How To Arc Weld Upside Down.

From weldingmastermind.com

Can You TIG Weld Aluminum Upside Down? Welding Mastermind How To Arc Weld Upside Down the key to mig welding upside down is keeping your feed regular and your arc short. learn the basics of stick welding, from tips and techniques to supplies and safety measures. this is another long one fellas. practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to. How To Arc Weld Upside Down.

From blog.thepipingmart.com

How to Stick Weld Upside Down A Complete Guide How To Arc Weld Upside Down this is another long one fellas. learn the basics of stick welding, from tips and techniques to supplies and safety measures. After starting the arc, move the rod to the. Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool. practise on a few pieces of scrap and. How To Arc Weld Upside Down.

From ar.inspiredpencil.com

Fcaw Welding Process How To Arc Weld Upside Down wleding upside down can take some major pratice. While you are in a less than. learn the basics of stick welding, from tips and techniques to supplies and safety measures. Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool. When welding inverted you must think safety first. . How To Arc Weld Upside Down.

From mavink.com

What Is Arc Welding How To Arc Weld Upside Down Way too many of you guys are asking. practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make sure you get fusion. Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool. Hot metal fragments and sparks can fall down. How To Arc Weld Upside Down.

From weldinginsider.com

How to MIG Weld Upside Down [Inverted Welding] Welding Insider How To Arc Weld Upside Down wleding upside down can take some major pratice. practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make sure you get fusion. this is another long one fellas. the key to mig welding upside down is keeping your feed regular and your arc short. Way too. How To Arc Weld Upside Down.

From weldingmastermind.com

How to MIG Weld Upside Down Welding Mastermind How To Arc Weld Upside Down this is another long one fellas. practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make sure you get fusion. learn the basics of stick welding, from tips and techniques to supplies and safety measures. After starting the arc, move the rod to the. the key. How To Arc Weld Upside Down.

From aptidco.in

Beginner's Guide To Shielded Metal Arc Welding , 56 OFF How To Arc Weld Upside Down practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make sure you get fusion. Way too many of you guys are asking. the key to mig welding upside down is keeping your feed regular and your arc short. learn the basics of stick welding, from tips and. How To Arc Weld Upside Down.

From userlibrarybernard.z13.web.core.windows.net

Arc Welding Basics Pdf How To Arc Weld Upside Down this is another long one fellas. Way too many of you guys are asking. Hot metal fragments and sparks can fall down on the fabricator, in this guide we cover how to weld in an upside down position. wleding upside down can take some major pratice. practise on a few pieces of scrap and you should get. How To Arc Weld Upside Down.

From weldguru.com

Arc Welding Explained What Is It & How Does It Work? Weld Guru How To Arc Weld Upside Down wleding upside down can take some major pratice. When welding inverted you must think safety first. this is another long one fellas. Way too many of you guys are asking. Hot metal fragments and sparks can fall down on the fabricator, in this guide we cover how to weld in an upside down position. Maintain a short arc. How To Arc Weld Upside Down.

From www.youtube.com

Shielded Metal Arc Welding Part 1 YouTube How To Arc Weld Upside Down Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool. learn the basics of stick welding, from tips and techniques to supplies and safety measures. Way too many of you guys are asking. When welding inverted you must think safety first. After starting the arc, move the rod to the.. How To Arc Weld Upside Down.

From ljfabricators.com

Welding Upside Down ? LJ Fabricators How To Arc Weld Upside Down Way too many of you guys are asking. While you are in a less than. Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool. Hot metal fragments and sparks can fall down on the fabricator, in this guide we cover how to weld in an upside down position. After starting. How To Arc Weld Upside Down.

From weldingmastermind.com

10 Tips and Tricks For Welding Upside Down! Welding Mastermind How To Arc Weld Upside Down learn the basics of stick welding, from tips and techniques to supplies and safety measures. After starting the arc, move the rod to the. wleding upside down can take some major pratice. the key to mig welding upside down is keeping your feed regular and your arc short. this is another long one fellas. Maintain a. How To Arc Weld Upside Down.

From www.youtube.com

Lead welding upside down. YouTube How To Arc Weld Upside Down Maintain a short arc length, typically around 1/8 to 1/4 inch, to ensure a stable and controlled weld pool. this is another long one fellas. After starting the arc, move the rod to the. When welding inverted you must think safety first. Hot metal fragments and sparks can fall down on the fabricator, in this guide we cover how. How To Arc Weld Upside Down.

From www.weldingtipsandtricks.com

Mig Welding Uphill Tips How To Arc Weld Upside Down the key to mig welding upside down is keeping your feed regular and your arc short. Way too many of you guys are asking. learn the basics of stick welding, from tips and techniques to supplies and safety measures. Hot metal fragments and sparks can fall down on the fabricator, in this guide we cover how to weld. How To Arc Weld Upside Down.

From exoyenypj.blob.core.windows.net

How To Weld A Weld Nut at Adam Baxter blog How To Arc Weld Upside Down Way too many of you guys are asking. wleding upside down can take some major pratice. After starting the arc, move the rod to the. practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make sure you get fusion. While you are in a less than. Maintain a. How To Arc Weld Upside Down.

From weldinginsider.com

How to MIG Weld Upside Down [Inverted Welding] Welding Insider How To Arc Weld Upside Down practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make sure you get fusion. the key to mig welding upside down is keeping your feed regular and your arc short. When welding inverted you must think safety first. this is another long one fellas. wleding upside. How To Arc Weld Upside Down.

From www.youtube.com

How Arc Welding Works YouTube How To Arc Weld Upside Down When welding inverted you must think safety first. After starting the arc, move the rod to the. the key to mig welding upside down is keeping your feed regular and your arc short. practise on a few pieces of scrap and you should get the hang of it quite quickly, also, to make sure you get fusion. Maintain. How To Arc Weld Upside Down.

From weldguru.com

4 Main Types of Welding Processes (with diagrams) How To Arc Weld Upside Down Way too many of you guys are asking. the key to mig welding upside down is keeping your feed regular and your arc short. learn the basics of stick welding, from tips and techniques to supplies and safety measures. While you are in a less than. wleding upside down can take some major pratice. this is. How To Arc Weld Upside Down.