How To Check Bottom End Bearings . The procedure for taking clearance is. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Only then can you measure bearing tolerances. Video on how to check your bottom end bearings, at home, by yourselfinstagram :. Its the traditional method, but requires that bearing are tightened just to obtain clearance. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. In order to do this job properly, you will need some accurate measuring tools. 2) for measurement of crankpin bearing clearance or bottom end bearing. Move the unit to bdc and then using feeler gauge, measure the clearance.

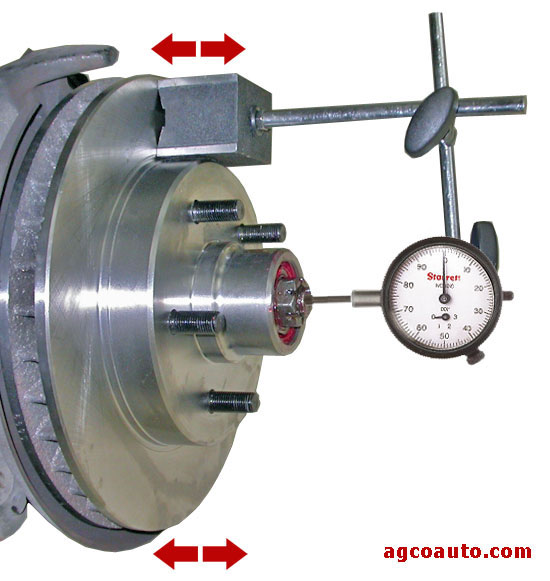

from www.agcoauto.com

The procedure for taking clearance is. Its the traditional method, but requires that bearing are tightened just to obtain clearance. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. 2) for measurement of crankpin bearing clearance or bottom end bearing. Only then can you measure bearing tolerances. Move the unit to bdc and then using feeler gauge, measure the clearance. Video on how to check your bottom end bearings, at home, by yourselfinstagram :. In order to do this job properly, you will need some accurate measuring tools.

AGCO Automotive Repair Service Baton Rouge, LA Detailed Auto Topics

How To Check Bottom End Bearings Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. The procedure for taking clearance is. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. Its the traditional method, but requires that bearing are tightened just to obtain clearance. Only then can you measure bearing tolerances. 2) for measurement of crankpin bearing clearance or bottom end bearing. In order to do this job properly, you will need some accurate measuring tools. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Video on how to check your bottom end bearings, at home, by yourselfinstagram :. Move the unit to bdc and then using feeler gauge, measure the clearance.

From www.youtube.com

How to use Plastiguage to Determine Main Bearing Clearance YouTube How To Check Bottom End Bearings Its the traditional method, but requires that bearing are tightened just to obtain clearance. Move the unit to bdc and then using feeler gauge, measure the clearance. Only then can you measure bearing tolerances. The procedure for taking clearance is. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear.. How To Check Bottom End Bearings.

From bossbearing.com

Honda Bottom End Bearing Replacement and Seal Kit How To Check Bottom End Bearings Only then can you measure bearing tolerances. 2) for measurement of crankpin bearing clearance or bottom end bearing. Move the unit to bdc and then using feeler gauge, measure the clearance. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Its the traditional method, but requires that bearing are. How To Check Bottom End Bearings.

From www.ford-trucks.com

Bottom end bearings Ford Truck Enthusiasts Forums How To Check Bottom End Bearings In order to do this job properly, you will need some accurate measuring tools. 2) for measurement of crankpin bearing clearance or bottom end bearing. The procedure for taking clearance is. Move the unit to bdc and then using feeler gauge, measure the clearance. Its the traditional method, but requires that bearing are tightened just to obtain clearance. Practical tips. How To Check Bottom End Bearings.

From www.youtube.com

How To Rebuild A Diesel Engine. Part 3. Main Bearings, Thrust Bearings How To Check Bottom End Bearings The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Its the traditional method, but requires that bearing are tightened just to obtain clearance. Move the unit to bdc and then using feeler gauge, measure the clearance. Only then can you measure bearing tolerances. Practical tips to measure me bearing. How To Check Bottom End Bearings.

From www.homebuilthelp.com

Tip of the Week 60 Using Rod End Bearings How To Check Bottom End Bearings The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Move the unit to bdc and then using feeler gauge, measure the clearance. Only then can you measure bearing tolerances. In order to do this job properly, you will need some accurate measuring tools. The procedure for taking clearance is.. How To Check Bottom End Bearings.

From baartgroup.com

How to Determine Approximate Bearing Life Baart Industrial Group How To Check Bottom End Bearings Only then can you measure bearing tolerances. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. 2) for measurement of crankpin bearing clearance or bottom end bearing. Move the unit to bdc and then using feeler gauge, measure the clearance. Video on how to check your bottom end bearings,. How To Check Bottom End Bearings.

From eriks.com

Bearing grease select the right lubrication method How To Check Bottom End Bearings The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. The procedure for taking clearance is. 2) for measurement of crankpin bearing clearance or bottom end bearing. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. Move the unit to bdc. How To Check Bottom End Bearings.

From www.youtube.com

VQ35DE bottom end bearing replacement How To. How to measure How To Check Bottom End Bearings Only then can you measure bearing tolerances. Move the unit to bdc and then using feeler gauge, measure the clearance. The procedure for taking clearance is. Video on how to check your bottom end bearings, at home, by yourselfinstagram :. 2) for measurement of crankpin bearing clearance or bottom end bearing. The first step in checking your engine's bottom end. How To Check Bottom End Bearings.

From www.agcoauto.com

AGCO Automotive Repair Service Baton Rouge, LA Detailed Auto Topics How To Check Bottom End Bearings The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Video on how to check your bottom end bearings, at home, by yourselfinstagram :. The procedure for taking clearance is. In order to do this job properly, you will need some accurate measuring tools. Its the traditional method, but requires. How To Check Bottom End Bearings.

From www.chevyhardcore.com

Clearing the Air on Bearing Clearances How To Check Bottom End Bearings In order to do this job properly, you will need some accurate measuring tools. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Its the traditional method, but requires that bearing are tightened just to obtain clearance. Video on how to check your bottom end bearings, at home, by. How To Check Bottom End Bearings.

From www.youtube.com

BEARING CLEARANCE How to MEASURE and PREVENT engine damage YouTube How To Check Bottom End Bearings The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Video on how to check your bottom end bearings, at home, by yourselfinstagram :. The procedure for taking clearance is. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. Move the. How To Check Bottom End Bearings.

From www.hotrod.com

How to Measure Bottom End Clearance Hot Rod Network How To Check Bottom End Bearings The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. 2) for measurement of crankpin bearing clearance or bottom end bearing. In order to do this job properly, you will need some accurate measuring tools. Only then can you measure bearing tolerances. Its the traditional method, but requires that bearing. How To Check Bottom End Bearings.

From www.ford-trucks.com

Bottom end bearings Ford Truck Enthusiasts Forums How To Check Bottom End Bearings 2) for measurement of crankpin bearing clearance or bottom end bearing. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. In order to do this job properly, you will need some. How To Check Bottom End Bearings.

From www.eng-tips.com

Eccentric big end bearing Engine & fuel engineering EngTips How To Check Bottom End Bearings Move the unit to bdc and then using feeler gauge, measure the clearance. The procedure for taking clearance is. 2) for measurement of crankpin bearing clearance or bottom end bearing. Only then can you measure bearing tolerances. Its the traditional method, but requires that bearing are tightened just to obtain clearance. The first step in checking your engine's bottom end. How To Check Bottom End Bearings.

From www.visordown.com

How to… fit new big end and main bearings Visordown How To Check Bottom End Bearings Move the unit to bdc and then using feeler gauge, measure the clearance. Video on how to check your bottom end bearings, at home, by yourselfinstagram :. Only then can you measure bearing tolerances. Its the traditional method, but requires that bearing are tightened just to obtain clearance. Practical tips to measure me bearing clearances for main bearing, crankpin bearing,. How To Check Bottom End Bearings.

From themetricnut.co.nz

Big End Bearings +1.00mm (+0.40 How To Check Bottom End Bearings Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. The procedure for taking clearance is. Video on how to check your bottom end bearings, at home, by yourselfinstagram :. In order to do this job properly, you will need some accurate measuring tools. Its the traditional method, but requires that bearing. How To Check Bottom End Bearings.

From honda-tech.com

Bottom end bearing scratched HondaTech Honda Forum Discussion How To Check Bottom End Bearings Move the unit to bdc and then using feeler gauge, measure the clearance. Video on how to check your bottom end bearings, at home, by yourselfinstagram :. In order to do this job properly, you will need some accurate measuring tools. The procedure for taking clearance is. Its the traditional method, but requires that bearing are tightened just to obtain. How To Check Bottom End Bearings.

From www.britishcarforum.com

MGB Talk to me about bottom end bearings How To Check Bottom End Bearings The procedure for taking clearance is. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. Video on how to check your bottom end bearings, at home, by yourselfinstagram :. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Only then. How To Check Bottom End Bearings.

From www.rev6sports.com

Polaris 0810 RGR/RZR 800 Complete Bottom End Bearing Kit How To Check Bottom End Bearings In order to do this job properly, you will need some accurate measuring tools. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Its the traditional method, but requires that bearing are tightened just to obtain clearance. Video on how to check your bottom end bearings, at home, by. How To Check Bottom End Bearings.

From knowhow.napaonline.com

KnowHow Notes How to Measure Engine Bearing Clearance » NAPA Blog How To Check Bottom End Bearings Video on how to check your bottom end bearings, at home, by yourselfinstagram :. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. The procedure for taking clearance is. Its the traditional method, but requires that bearing are tightened just to obtain clearance. Move the unit to bdc and. How To Check Bottom End Bearings.

From www.engine-dynamics.com

Engine Components Crankshaft "Big End" Bearings How To Check Bottom End Bearings The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. In order to do this job properly, you will need some accurate measuring tools. Video on how to check your bottom end bearings, at home, by yourselfinstagram :. The procedure for taking clearance is. Its the traditional method, but requires. How To Check Bottom End Bearings.

From honda-tech.com

Bottom end bearing scratched HondaTech Honda Forum Discussion How To Check Bottom End Bearings The procedure for taking clearance is. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. Move the unit to bdc and then using feeler gauge, measure the clearance. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. In order to. How To Check Bottom End Bearings.

From passionford.com

Spun a big end bearing! PassionFord Ford Focus, Escort & RS Forum How To Check Bottom End Bearings Video on how to check your bottom end bearings, at home, by yourselfinstagram :. 2) for measurement of crankpin bearing clearance or bottom end bearing. The procedure for taking clearance is. Move the unit to bdc and then using feeler gauge, measure the clearance. The first step in checking your engine's bottom end is to carefully inspect all bearings for. How To Check Bottom End Bearings.

From carfromjapan.com

What Is the Rod Bearing Replacement Cost? How To Check Bottom End Bearings Its the traditional method, but requires that bearing are tightened just to obtain clearance. 2) for measurement of crankpin bearing clearance or bottom end bearing. Only then can you measure bearing tolerances. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. Move the unit to bdc and then using feeler gauge,. How To Check Bottom End Bearings.

From www.hotrod.com

How to Measure Bottom End Clearance Hot Rod Network How To Check Bottom End Bearings Its the traditional method, but requires that bearing are tightened just to obtain clearance. The procedure for taking clearance is. In order to do this job properly, you will need some accurate measuring tools. 2) for measurement of crankpin bearing clearance or bottom end bearing. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing. How To Check Bottom End Bearings.

From www.3pracing.com

Bottom end Bearings Engine Jet Ski 3P Racing How To Check Bottom End Bearings Move the unit to bdc and then using feeler gauge, measure the clearance. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. Video on how to check your bottom end bearings, at home, by yourselfinstagram :. The procedure for taking clearance is. The first step in checking your engine's bottom end. How To Check Bottom End Bearings.

From www.chevyhardcore.com

Tech Choosing The Proper Bearings For Your Engine How To Check Bottom End Bearings Only then can you measure bearing tolerances. Move the unit to bdc and then using feeler gauge, measure the clearance. 2) for measurement of crankpin bearing clearance or bottom end bearing. The procedure for taking clearance is. Its the traditional method, but requires that bearing are tightened just to obtain clearance. Practical tips to measure me bearing clearances for main. How To Check Bottom End Bearings.

From www.disco3.co.uk

DISCO3.CO.UK View topic Big end bearing torque 2.7 tdv6 How To Check Bottom End Bearings Only then can you measure bearing tolerances. The procedure for taking clearance is. 2) for measurement of crankpin bearing clearance or bottom end bearing. Video on how to check your bottom end bearings, at home, by yourselfinstagram :. Move the unit to bdc and then using feeler gauge, measure the clearance. Its the traditional method, but requires that bearing are. How To Check Bottom End Bearings.

From www.3pracing.com

Bottom end Bearings Engine Jet Ski 3P Racing How To Check Bottom End Bearings Video on how to check your bottom end bearings, at home, by yourselfinstagram :. Move the unit to bdc and then using feeler gauge, measure the clearance. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. Its the traditional method, but requires that bearing are tightened just to obtain clearance. The. How To Check Bottom End Bearings.

From circuitwiringsilk.z21.web.core.windows.net

Carrier Bearing Diagram How To Check Bottom End Bearings 2) for measurement of crankpin bearing clearance or bottom end bearing. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. The procedure for taking clearance is. Its the traditional method, but requires that bearing are tightened just to obtain clearance. The first step in checking your engine's bottom end is to. How To Check Bottom End Bearings.

From www.hotrod.com

How to Select and Install HighPerformance Engine Bearings Hot Rod How To Check Bottom End Bearings In order to do this job properly, you will need some accurate measuring tools. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. The procedure for taking clearance is. Only then. How To Check Bottom End Bearings.

From www.youtube.com

Sonvia Rebuild Bottom end Bearings inspection YouTube How To Check Bottom End Bearings In order to do this job properly, you will need some accurate measuring tools. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Move the unit to bdc and then using feeler gauge, measure the clearance. Its the traditional method, but requires that bearing are tightened just to obtain. How To Check Bottom End Bearings.

From meoexamsmmd.blogspot.com

Bottom End Bearing Inspection Procedure How To Check Bottom End Bearings 2) for measurement of crankpin bearing clearance or bottom end bearing. Video on how to check your bottom end bearings, at home, by yourselfinstagram :. Move the unit to bdc and then using feeler gauge, measure the clearance. Only then can you measure bearing tolerances. Its the traditional method, but requires that bearing are tightened just to obtain clearance. The. How To Check Bottom End Bearings.

From partdiagramsucraretzzt.z21.web.core.windows.net

302 Engine Diagram 20 Piston How To Check Bottom End Bearings Video on how to check your bottom end bearings, at home, by yourselfinstagram :. In order to do this job properly, you will need some accurate measuring tools. Only then can you measure bearing tolerances. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Move the unit to bdc. How To Check Bottom End Bearings.

From exozuexjn.blob.core.windows.net

How To Lubricate An Air Tool at Arthur Bryant blog How To Check Bottom End Bearings Its the traditional method, but requires that bearing are tightened just to obtain clearance. The first step in checking your engine's bottom end is to carefully inspect all bearings for damage or uneven wear. Practical tips to measure me bearing clearances for main bearing, crankpin bearing, and crosshead bearing and how to. Only then can you measure bearing tolerances. Video. How To Check Bottom End Bearings.