Laser Welding Optics . It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds rapidly and reliably. Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. In our video we offer some basic answers and. What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? Here’s how it works step by. Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. Laser welding or laser beam welding (lbw) is a process that uses a concentrated heat source in the form of a laser to melt the materials, which fuse together as they cool down.

from www.precitec.com

Here’s how it works step by. It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. In our video we offer some basic answers and. Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. Laser welding or laser beam welding (lbw) is a process that uses a concentrated heat source in the form of a laser to melt the materials, which fuse together as they cool down. What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds rapidly and reliably.

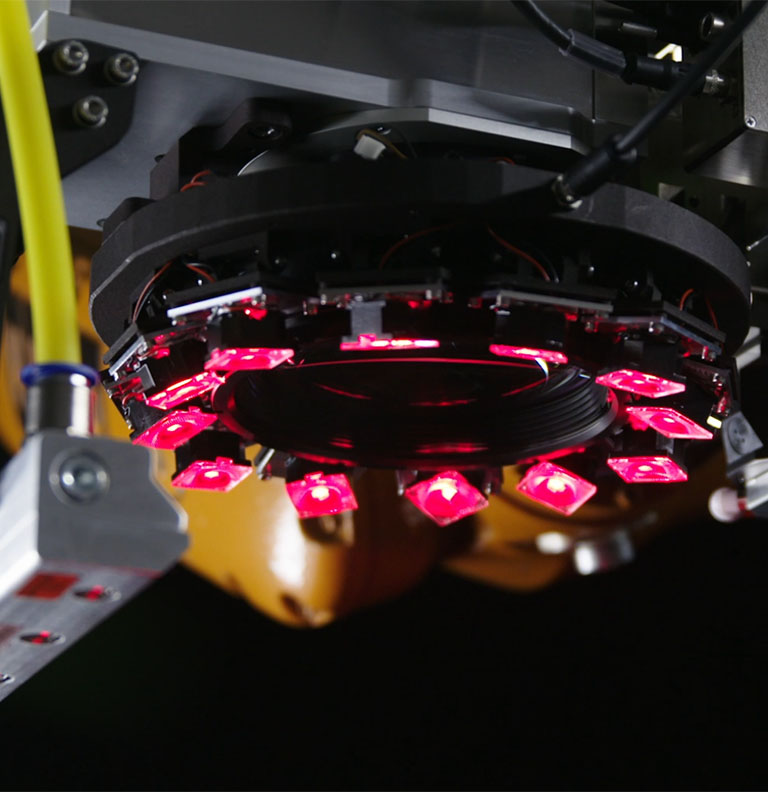

Laser remote welding for series production PRECITEC

Laser Welding Optics Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds rapidly and reliably. Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. Laser welding or laser beam welding (lbw) is a process that uses a concentrated heat source in the form of a laser to melt the materials, which fuse together as they cool down. What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds rapidly and reliably. In our video we offer some basic answers and. Here’s how it works step by.

From www.precitec.com

Focusing optics YW30/YW52 Laser welding PRECITEC Laser Welding Optics Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. In our video we offer some basic answers and. Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent. Laser Welding Optics.

From www.laser2000.de

Cailabs Canunda HP Laser welding optics with highly stable beam Laser Welding Optics Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. Here’s how it works step by. What actually is the difference between laser welding and laser brazing, and. Laser Welding Optics.

From www.precitec.com

Focusing optics YW30/YW52 Laser welding PRECITEC Laser Welding Optics Here’s how it works step by. Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. In our video we offer some basic answers and. Laser welding or laser beam welding (lbw) is a process. Laser Welding Optics.

From www.thefabricator.com

Welding nozzle protects weld zone and laser beam delivery optics Laser Welding Optics Here’s how it works step by. Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds rapidly and reliably. What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? In our video we offer some basic answers and. It. Laser Welding Optics.

From www.holoor.co.il

Laser beam shaping optics for laser welding applications Holo Or Laser Welding Optics What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep. Laser Welding Optics.

From www.carmanhaaslaser.com

Trending Products Fiber Optic Laser Welding Welding Ftheta Lenses Laser Welding Optics What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? In our video we offer some basic answers and. It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. Laser welding or laser. Laser Welding Optics.

From tinifiber.com

The Crucial Role of Fiber Optics in Laser Welding TiniFiber Laser Welding Optics Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. Laser welding or laser beam welding (lbw) is a process that uses a concentrated heat source in the form of a laser to melt the. Laser Welding Optics.

From www.laserax.com

Fiber Laser Welding Advantages, Systems and Applications Laserax Laser Welding Optics Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. In our video we offer some basic answers and. Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds rapidly and reliably. Laser welding or laser beam welding (lbw) is a process that uses a. Laser Welding Optics.

From www.mmindia.co.in

TRUMPF to Launch New Solution to Improve Laser Welding Quality Laser Welding Optics Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds rapidly and reliably. What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? It is a versatile process since it can weld thin materials at rapid welding speeds while. Laser Welding Optics.

From www.youtube.com

[LXSHOW Laser]Fiber laser welding machine operation process and welding Laser Welding Optics Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. In our video we offer some basic answers and. Whether for precision or structural welding, laser welding is. Laser Welding Optics.

From www.precitec.com

Focusing optics YW30/YW52 Laser welding PRECITEC Laser Welding Optics Here’s how it works step by. In our video we offer some basic answers and. Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? Laser welding or laser beam. Laser Welding Optics.

From www.scansonic.de

Laser Welding EMobilitiy Scansonic Optics for Laser Welding Laser Welding Optics In our video we offer some basic answers and. Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. It is a versatile process since it can weld thin materials at rapid welding speeds while. Laser Welding Optics.

From www.opticlaser.net

Handheld Laser Welding Machine Raycus IPG fiber handheld laser Laser Welding Optics In our video we offer some basic answers and. What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds rapidly and reliably. It is a versatile process since it. Laser Welding Optics.

From www.youtube.com

Optical Fiber Laser Welding Machinery 1000W Handheld Laser Welding Laser Welding Optics Here’s how it works step by. Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds rapidly and reliably. In our video we offer some basic answers and. What actually is the difference between. Laser Welding Optics.

From www.trumpf.com

Programmable focusing optics TRUMPF Laser Welding Optics Laser welding or laser beam welding (lbw) is a process that uses a concentrated heat source in the form of a laser to melt the materials, which fuse together as they cool down. Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. It is a versatile process since it can weld thin. Laser Welding Optics.

From www.sintec.sg

3 in 1 Laser Cutting, Welding & CleaningVideosSintec Optronics Pte Laser Welding Optics In our video we offer some basic answers and. What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds rapidly and reliably. Laser welding or laser beam welding (lbw). Laser Welding Optics.

From www.medicaldevice-network.com

Laser welding for medical wire How one company is solving supply chain Laser Welding Optics It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? Here’s how it works step by. Laserline’s welding optics can be configured flexibly. Laser Welding Optics.

From www.precitec.com

Focusing optics YW30/YW52 Laser welding PRECITEC Laser Welding Optics Laser welding or laser beam welding (lbw) is a process that uses a concentrated heat source in the form of a laser to melt the materials, which fuse together as they cool down. It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. In our video. Laser Welding Optics.

From www.mdpi.com

Materials Free FullText Laser Welding of 316L Austenitic Stainless Laser Welding Optics In our video we offer some basic answers and. Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. Here’s how it works step by. It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. Whether for precision or. Laser Welding Optics.

From www.opticlaser.net

Handheld Laser welding machine wobble laser head OPTIC OPTIC Laser Welding Optics In our video we offer some basic answers and. Laser welding or laser beam welding (lbw) is a process that uses a concentrated heat source in the form of a laser to melt the materials, which fuse together as they cool down. What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer. Laser Welding Optics.

From www.precitec.com

Modularity for your laser welding machine PRECITEC Laser Welding Optics It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. Laser welding or laser beam welding (lbw) is a process that uses a concentrated heat source in the form of a laser to melt the materials, which fuse together as they cool down. Here’s how it. Laser Welding Optics.

From www.opticlaser.net

Laser Welding Machine Technology Laser Welder Supplier OPTIC LASER Laser Welding Optics What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. Laser welding or laser beam welding (lbw) is a process that uses a. Laser Welding Optics.

From www.nidec.com

Fiber laser welding head Laser Welding Optics In our video we offer some basic answers and. Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds rapidly and reliably. Here’s how it works step by. What actually is the difference between. Laser Welding Optics.

From www.precitec.com

Tracking with beam guidance laser welding PRECITEC Laser Welding Optics Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds rapidly and reliably. Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. In our video we offer some basic answers and. Laser welding or laser beam welding (lbw) is a process that uses. Laser Welding Optics.

From chutian-laser.com

3 In 1 Handheld Laser Welding Machine » Chutianlaser Laser Welding Optics Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. Here’s how it works step by. In our video we offer some basic answers and. Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. Laser welding or laser beam welding (lbw) is a process. Laser Welding Optics.

From www.youtube.com

The Best Micro Laser Welding Systems MotionFX MultiAxis CNC Laser Welding Optics In our video we offer some basic answers and. Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. It is a versatile process since it can weld thin materials at rapid welding speeds while. Laser Welding Optics.

From www.researchgate.net

(PDF) Ultrafast Laser Welding Taming Ultrafast Laser Filaments for Laser Welding Optics Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds. Laser Welding Optics.

From efcmotion.com

Modular laser welding optics YW30 / YW52 EFC MOTION Laser Welding Optics In our video we offer some basic answers and. Here’s how it works step by. Laser welding or laser beam welding (lbw) is a process that uses a concentrated heat source in the form of a laser to melt the materials, which fuse together as they cool down. It is a versatile process since it can weld thin materials at. Laser Welding Optics.

From www.canadianmetalworking.com

LightWELD from IPG Photonics provides fiber laser welding in handheld Laser Welding Optics It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? In our video we offer some basic answers and. Here’s how it works. Laser Welding Optics.

From kinemetrix.com

Laser Welding Solutions Kinemetrix Laser Welding Optics In our video we offer some basic answers and. Laser welding or laser beam welding (lbw) is a process that uses a concentrated heat source in the form of a laser to melt the materials, which fuse together as they cool down. Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds. Laser Welding Optics.

From www.carmanhaaslaser.com

New Delivery for Hermetic Laser Welding Optical Collimation Module Laser Welding Optics Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. Laser welding or laser beam welding (lbw) is a process that uses a concentrated heat source in the. Laser Welding Optics.

From www.amadaweldtech.eu

Advanced Laser Welding System CNC Laser Welding Workstation Laser Welding Optics Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary. Laser welding or laser beam welding (lbw) is a process that uses a concentrated heat source in the form of a laser to melt the materials, which fuse together as they cool down. Laser welding uses the energy contained in a focused. Laser Welding Optics.

From www.thefabricator.com

Tough optics for extreme laser welding Laser Welding Optics Laser welding uses the energy contained in a focused beam of light to melt and fuse surfaces. It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. In our video we offer some basic answers and. Here’s how it works step by. Laser welding or laser. Laser Welding Optics.

From www.precitec.com

Focusing optics NexoWelder Laser welding PRECITEC Laser Welding Optics It is a versatile process since it can weld thin materials at rapid welding speeds while running narrow and deep welds for thicker materials. What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? Whether for precision or structural welding, laser welding is an easily automated solution. Laser Welding Optics.

From www.precitec.com

Laser remote welding for series production PRECITEC Laser Welding Optics What actually is the difference between laser welding and laser brazing, and what advantages do diode lasers offer in terms of metal welding? Whether for precision or structural welding, laser welding is an easily automated solution for creating excellent quality welds rapidly and reliably. Laser welding uses the energy contained in a focused beam of light to melt and fuse. Laser Welding Optics.