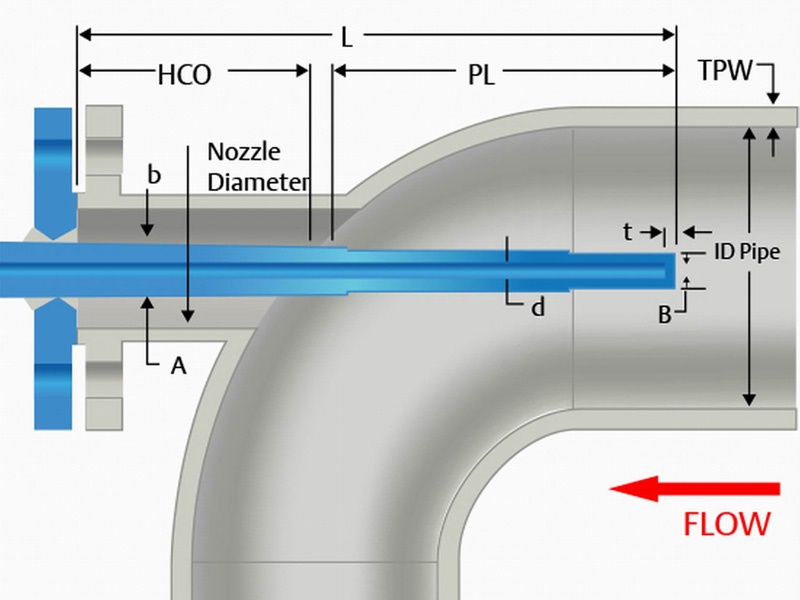

Thermowell Placement In Pipe . However, it is allowed to install on 45 o from pipe axis or on pipe elbow. How dimensions are established for the thermowells and the immersion probes that fit into them are not readily apparent. When thermowell is installed near to dp type flow transmitter (orifice element, venturi or pitot tube) or vortex type flowmeter, sufficient distance should be maintained to avoid flow measurement error. Support ring thermowells are designed to provide maximum support for thermowell in severe vibration and bending. Thermowell installation is a calculated and meticulous procedure. The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor mixing or two phase flow. It requires an appropriate selection of thermowells, calculation of insertion depth/ immersion. Thermowell is preferred to install at 90 o from pipe axis. In general, the tip of the thermowell should be placed in the middle third of the pipe, though the position may differ in special cases.

from whatsnewinprocessing.co.za

When thermowell is installed near to dp type flow transmitter (orifice element, venturi or pitot tube) or vortex type flowmeter, sufficient distance should be maintained to avoid flow measurement error. Thermowell is preferred to install at 90 o from pipe axis. Thermowell installation is a calculated and meticulous procedure. However, it is allowed to install on 45 o from pipe axis or on pipe elbow. The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor mixing or two phase flow. In general, the tip of the thermowell should be placed in the middle third of the pipe, though the position may differ in special cases. How dimensions are established for the thermowells and the immersion probes that fit into them are not readily apparent. Support ring thermowells are designed to provide maximum support for thermowell in severe vibration and bending. It requires an appropriate selection of thermowells, calculation of insertion depth/ immersion.

Thermowell design What's New in Processing

Thermowell Placement In Pipe However, it is allowed to install on 45 o from pipe axis or on pipe elbow. Support ring thermowells are designed to provide maximum support for thermowell in severe vibration and bending. Thermowell is preferred to install at 90 o from pipe axis. However, it is allowed to install on 45 o from pipe axis or on pipe elbow. How dimensions are established for the thermowells and the immersion probes that fit into them are not readily apparent. Thermowell installation is a calculated and meticulous procedure. It requires an appropriate selection of thermowells, calculation of insertion depth/ immersion. In general, the tip of the thermowell should be placed in the middle third of the pipe, though the position may differ in special cases. The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor mixing or two phase flow. When thermowell is installed near to dp type flow transmitter (orifice element, venturi or pitot tube) or vortex type flowmeter, sufficient distance should be maintained to avoid flow measurement error.

From whatispiping.com

What is a Thermowell? Types of Thermowell What Is Piping All about Thermowell Placement In Pipe However, it is allowed to install on 45 o from pipe axis or on pipe elbow. When thermowell is installed near to dp type flow transmitter (orifice element, venturi or pitot tube) or vortex type flowmeter, sufficient distance should be maintained to avoid flow measurement error. How dimensions are established for the thermowells and the immersion probes that fit into. Thermowell Placement In Pipe.

From whatispiping.com

What is a Thermowell? Types of Thermowell What Is Piping All about Thermowell Placement In Pipe However, it is allowed to install on 45 o from pipe axis or on pipe elbow. How dimensions are established for the thermowells and the immersion probes that fit into them are not readily apparent. Support ring thermowells are designed to provide maximum support for thermowell in severe vibration and bending. Thermowell is preferred to install at 90 o from. Thermowell Placement In Pipe.

From www.linquip.com

What is Thermowell? Types & Working Principle Linquip Thermowell Placement In Pipe However, it is allowed to install on 45 o from pipe axis or on pipe elbow. The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor mixing or two phase flow. Thermowell installation is a calculated and meticulous procedure. Thermowell. Thermowell Placement In Pipe.

From www.intempco.com

What is a Thermowell? Intempco Thermowell Placement In Pipe In general, the tip of the thermowell should be placed in the middle third of the pipe, though the position may differ in special cases. However, it is allowed to install on 45 o from pipe axis or on pipe elbow. When thermowell is installed near to dp type flow transmitter (orifice element, venturi or pitot tube) or vortex type. Thermowell Placement In Pipe.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Thermowell Placement In Pipe In general, the tip of the thermowell should be placed in the middle third of the pipe, though the position may differ in special cases. Support ring thermowells are designed to provide maximum support for thermowell in severe vibration and bending. The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be. Thermowell Placement In Pipe.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Thermowell Placement In Pipe How dimensions are established for the thermowells and the immersion probes that fit into them are not readily apparent. However, it is allowed to install on 45 o from pipe axis or on pipe elbow. It requires an appropriate selection of thermowells, calculation of insertion depth/ immersion. Support ring thermowells are designed to provide maximum support for thermowell in severe. Thermowell Placement In Pipe.

From www.linquip.com

4 Types of Thermowell Comprehensive Overview Linquip Thermowell Placement In Pipe The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor mixing or two phase flow. However, it is allowed to install on 45 o from pipe axis or on pipe elbow. When thermowell is installed near to dp type flow. Thermowell Placement In Pipe.

From pipestd.com

Thermowell Pipe Dimension And Piping Information Thermowell Placement In Pipe However, it is allowed to install on 45 o from pipe axis or on pipe elbow. When thermowell is installed near to dp type flow transmitter (orifice element, venturi or pitot tube) or vortex type flowmeter, sufficient distance should be maintained to avoid flow measurement error. It requires an appropriate selection of thermowells, calculation of insertion depth/ immersion. Support ring. Thermowell Placement In Pipe.

From www.youtube.com

What is Thermowell? How does it Work? Why and Where Use Thermowell Thermowell Placement In Pipe In general, the tip of the thermowell should be placed in the middle third of the pipe, though the position may differ in special cases. When thermowell is installed near to dp type flow transmitter (orifice element, venturi or pitot tube) or vortex type flowmeter, sufficient distance should be maintained to avoid flow measurement error. Support ring thermowells are designed. Thermowell Placement In Pipe.

From www.emerson.com

Rosemount™ Thermowells Emerson US Thermowell Placement In Pipe Support ring thermowells are designed to provide maximum support for thermowell in severe vibration and bending. Thermowell installation is a calculated and meticulous procedure. The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor mixing or two phase flow. How. Thermowell Placement In Pipe.

From pipelinebundle.com

OnLine Thermowell Installation PipelineBundleServices Thermowell Placement In Pipe When thermowell is installed near to dp type flow transmitter (orifice element, venturi or pitot tube) or vortex type flowmeter, sufficient distance should be maintained to avoid flow measurement error. However, it is allowed to install on 45 o from pipe axis or on pipe elbow. How dimensions are established for the thermowells and the immersion probes that fit into. Thermowell Placement In Pipe.

From www.tili.eu.org

Thermowell Insertion and Immersion Length Thermowell Placement In Pipe The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor mixing or two phase flow. Support ring thermowells are designed to provide maximum support for thermowell in severe vibration and bending. However, it is allowed to install on 45 o. Thermowell Placement In Pipe.

From paktechpoint.com

WHAT IS THERMOWELL? EXPLAIN THERMOWELL PAKTECHPOINT Thermowell Placement In Pipe Thermowell is preferred to install at 90 o from pipe axis. It requires an appropriate selection of thermowells, calculation of insertion depth/ immersion. However, it is allowed to install on 45 o from pipe axis or on pipe elbow. When thermowell is installed near to dp type flow transmitter (orifice element, venturi or pitot tube) or vortex type flowmeter, sufficient. Thermowell Placement In Pipe.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Thermowell Placement In Pipe The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor mixing or two phase flow. However, it is allowed to install on 45 o from pipe axis or on pipe elbow. Support ring thermowells are designed to provide maximum support. Thermowell Placement In Pipe.

From instrumentationtools.com

Thermowell Design Guidelines Inst Tools Thermowell Placement In Pipe In general, the tip of the thermowell should be placed in the middle third of the pipe, though the position may differ in special cases. When thermowell is installed near to dp type flow transmitter (orifice element, venturi or pitot tube) or vortex type flowmeter, sufficient distance should be maintained to avoid flow measurement error. How dimensions are established for. Thermowell Placement In Pipe.

From whatsnewinprocessing.co.za

Thermowell design What's New in Processing Thermowell Placement In Pipe However, it is allowed to install on 45 o from pipe axis or on pipe elbow. When thermowell is installed near to dp type flow transmitter (orifice element, venturi or pitot tube) or vortex type flowmeter, sufficient distance should be maintained to avoid flow measurement error. The distance of the thermowell in a pipeline from a heat exchanger, static mixer,. Thermowell Placement In Pipe.

From www.process-worldwide.com

What Has Changed with the 2016 Revision of the ASME PTC 19.3 TW Standard? Thermowell Placement In Pipe However, it is allowed to install on 45 o from pipe axis or on pipe elbow. How dimensions are established for the thermowells and the immersion probes that fit into them are not readily apparent. Thermowell installation is a calculated and meticulous procedure. The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet. Thermowell Placement In Pipe.

From www.ramsensors.com

Proper Thermowell Installation Temperature Sensor RAM Sensors, Inc. Thermowell Placement In Pipe The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor mixing or two phase flow. However, it is allowed to install on 45 o from pipe axis or on pipe elbow. Thermowell installation is a calculated and meticulous procedure. When. Thermowell Placement In Pipe.

From www.tili.eu.org

Thermowell Insertion and Immersion Length Thermowell Placement In Pipe Thermowell is preferred to install at 90 o from pipe axis. How dimensions are established for the thermowells and the immersion probes that fit into them are not readily apparent. The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor. Thermowell Placement In Pipe.

From www.scribd.com

Thermowell and Immersion Probe Installation Overview Pipe (Fluid Thermowell Placement In Pipe However, it is allowed to install on 45 o from pipe axis or on pipe elbow. The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor mixing or two phase flow. It requires an appropriate selection of thermowells, calculation of. Thermowell Placement In Pipe.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Thermowell Placement In Pipe Thermowell installation is a calculated and meticulous procedure. The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor mixing or two phase flow. It requires an appropriate selection of thermowells, calculation of insertion depth/ immersion. Support ring thermowells are designed. Thermowell Placement In Pipe.

From instrumentationtools.com

Thermowell Design Guidelines Inst Tools Thermowell Placement In Pipe It requires an appropriate selection of thermowells, calculation of insertion depth/ immersion. In general, the tip of the thermowell should be placed in the middle third of the pipe, though the position may differ in special cases. Thermowell is preferred to install at 90 o from pipe axis. However, it is allowed to install on 45 o from pipe axis. Thermowell Placement In Pipe.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Thermowell Placement In Pipe Support ring thermowells are designed to provide maximum support for thermowell in severe vibration and bending. How dimensions are established for the thermowells and the immersion probes that fit into them are not readily apparent. Thermowell is preferred to install at 90 o from pipe axis. When thermowell is installed near to dp type flow transmitter (orifice element, venturi or. Thermowell Placement In Pipe.

From www.wermac.org

Temperature Measurement Thermowells Thermowell Placement In Pipe Thermowell installation is a calculated and meticulous procedure. The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor mixing or two phase flow. In general, the tip of the thermowell should be placed in the middle third of the pipe,. Thermowell Placement In Pipe.

From vosprofils.com

Reasons To Use Thermowell In Industrial Process Operation System Thermowell Placement In Pipe Thermowell is preferred to install at 90 o from pipe axis. The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor mixing or two phase flow. Support ring thermowells are designed to provide maximum support for thermowell in severe vibration. Thermowell Placement In Pipe.

From www.youtube.com

What is a thermowell? Installation in a pipe, thermowell types Thermowell Placement In Pipe Thermowell is preferred to install at 90 o from pipe axis. Support ring thermowells are designed to provide maximum support for thermowell in severe vibration and bending. Thermowell installation is a calculated and meticulous procedure. In general, the tip of the thermowell should be placed in the middle third of the pipe, though the position may differ in special cases.. Thermowell Placement In Pipe.

From instrumentationtools.com

How to install Thermowell on an Elbow? InstrumentationTools Thermowell Placement In Pipe Thermowell is preferred to install at 90 o from pipe axis. Thermowell installation is a calculated and meticulous procedure. Support ring thermowells are designed to provide maximum support for thermowell in severe vibration and bending. How dimensions are established for the thermowells and the immersion probes that fit into them are not readily apparent. In general, the tip of the. Thermowell Placement In Pipe.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Thermowell Placement In Pipe Support ring thermowells are designed to provide maximum support for thermowell in severe vibration and bending. However, it is allowed to install on 45 o from pipe axis or on pipe elbow. How dimensions are established for the thermowells and the immersion probes that fit into them are not readily apparent. Thermowell is preferred to install at 90 o from. Thermowell Placement In Pipe.

From forumautomation.com

Thermowell Placement Perfection Best Practices Guide Temperature Thermowell Placement In Pipe It requires an appropriate selection of thermowells, calculation of insertion depth/ immersion. When thermowell is installed near to dp type flow transmitter (orifice element, venturi or pitot tube) or vortex type flowmeter, sufficient distance should be maintained to avoid flow measurement error. The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should. Thermowell Placement In Pipe.

From forumautomation.com

Thermowell Placement Perfection Best Practices Guide Temperature Thermowell Placement In Pipe The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be optimized to reduce the transportation delay but minimize noise from poor mixing or two phase flow. When thermowell is installed near to dp type flow transmitter (orifice element, venturi or pitot tube) or vortex type flowmeter, sufficient distance should be maintained. Thermowell Placement In Pipe.

From instrumentationtools.com

Thermowell Installation near Critical Equipment Design Rules Thermowell Placement In Pipe Support ring thermowells are designed to provide maximum support for thermowell in severe vibration and bending. In general, the tip of the thermowell should be placed in the middle third of the pipe, though the position may differ in special cases. The distance of the thermowell in a pipeline from a heat exchanger, static mixer, or desuperheater outlet should be. Thermowell Placement In Pipe.

From instrumentationtools.blogspot.com

Thermowell Insertion and Immersion Length Instrumentation Tools Thermowell Placement In Pipe When thermowell is installed near to dp type flow transmitter (orifice element, venturi or pitot tube) or vortex type flowmeter, sufficient distance should be maintained to avoid flow measurement error. However, it is allowed to install on 45 o from pipe axis or on pipe elbow. Thermowell is preferred to install at 90 o from pipe axis. The distance of. Thermowell Placement In Pipe.

From www.youtube.com

Thermowell Types, Purpose, Construction, Specifications and Selection Thermowell Placement In Pipe However, it is allowed to install on 45 o from pipe axis or on pipe elbow. Thermowell installation is a calculated and meticulous procedure. In general, the tip of the thermowell should be placed in the middle third of the pipe, though the position may differ in special cases. Thermowell is preferred to install at 90 o from pipe axis.. Thermowell Placement In Pipe.

From www.linquip.com

What is Thermowell? Types & Working Principle Linquip Thermowell Placement In Pipe Support ring thermowells are designed to provide maximum support for thermowell in severe vibration and bending. Thermowell installation is a calculated and meticulous procedure. It requires an appropriate selection of thermowells, calculation of insertion depth/ immersion. However, it is allowed to install on 45 o from pipe axis or on pipe elbow. In general, the tip of the thermowell should. Thermowell Placement In Pipe.

From westcoastbrewer.com

How to install a thermowell Brewers Blog Thermowell Placement In Pipe Thermowell installation is a calculated and meticulous procedure. Thermowell is preferred to install at 90 o from pipe axis. Support ring thermowells are designed to provide maximum support for thermowell in severe vibration and bending. It requires an appropriate selection of thermowells, calculation of insertion depth/ immersion. How dimensions are established for the thermowells and the immersion probes that fit. Thermowell Placement In Pipe.