Thermal Imaging Flaw Detection . As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their.

from www.shimadzu.com

Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in.

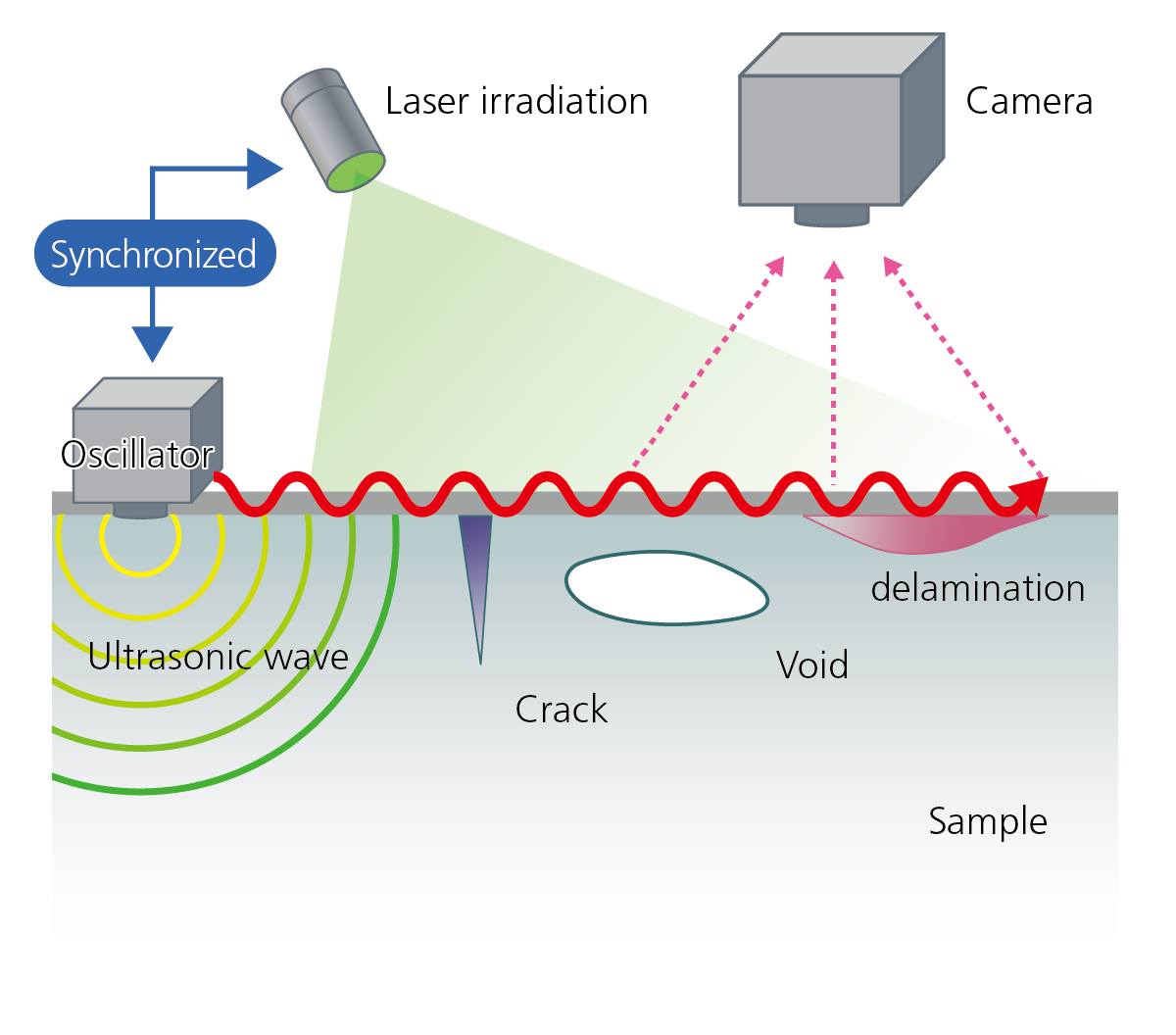

SHIMADZU CORPORATION Detecting Flaws within Objects Quickly and Easily Using Ultrasonic and

Thermal Imaging Flaw Detection Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active.

From usndt.com

GE Krautkramer USL 42 Ultrasonic Flaw Detector USNDT, Inc. Thermal Imaging Flaw Detection Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance. Thermal Imaging Flaw Detection.

From usndt.com

NDT Systems Raptor Ultrasonic Flaw Detector USNDT, Inc. Thermal Imaging Flaw Detection Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of. Thermal Imaging Flaw Detection.

From phys.org

Flaw detector for testing composite aircrafts Thermal Imaging Flaw Detection Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance. Thermal Imaging Flaw Detection.

From blues.io

Thermal Image Anomaly Detection with TinyML Blues Wireless Thermal Imaging Flaw Detection Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of. Thermal Imaging Flaw Detection.

From www.jwjndt.com

Prisma Ultrasonic Flaw Detector JWJ NDT Thermal Imaging Flaw Detection Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance. Thermal Imaging Flaw Detection.

From irss.ca

Sonatest Prisma UT Flaw Detector IR Supplies and Services Thermal Imaging Flaw Detection Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance. Thermal Imaging Flaw Detection.

From ndtsupply.com

Ultrasonic Flaw Detection Phased Array Systems ACS ACS A1525 SOLO TFM Phased Array Flaw Thermal Imaging Flaw Detection Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of. Thermal Imaging Flaw Detection.

From www.onestopndt.com

Introducing the Compact OmniScan™ X3 64Channel Flaw Detector Thermal Imaging Flaw Detection Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance. Thermal Imaging Flaw Detection.

From visionify.ai

The Power of Infrared Thermal Imaging for People Detection Thermal Imaging Flaw Detection Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of. Thermal Imaging Flaw Detection.

From www.foodmag.com.au

Accurately identify flaws with the right thermal imaging with FLIR Thermal Imaging Flaw Detection Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but. Thermal Imaging Flaw Detection.

From uk.trotec.com

Thermal imaging camera XC300 highresolution thermography system TROTEC Thermal Imaging Flaw Detection As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but. Thermal Imaging Flaw Detection.

From www.scribd.com

Phase Coherence Imaging For Flaw Detection PDF Nondestructive Testing Ultrasound Thermal Imaging Flaw Detection Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance. Thermal Imaging Flaw Detection.

From usndt.com

Olympus Omniscan X3 32128 PR Ultrasonic Flaw Detector USNDT, Inc. Thermal Imaging Flaw Detection Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of. Thermal Imaging Flaw Detection.

From uk.trotec.com

Thermal imaging camera XC300 highresolution thermography system TROTEC Thermal Imaging Flaw Detection As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of. Thermal Imaging Flaw Detection.

From uk.trotec.com

Thermal imaging camera XC300 highresolution thermography system TROTEC Thermal Imaging Flaw Detection Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but. Thermal Imaging Flaw Detection.

From usndt.com

GE Krautkramer USL 42 Ultrasonic Flaw Detector USNDT, Inc. Thermal Imaging Flaw Detection Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance. Thermal Imaging Flaw Detection.

From usndt.com

Olympus Epoch LTC Ultrasonic Flaw Detector USNDT, Inc. Thermal Imaging Flaw Detection Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of. Thermal Imaging Flaw Detection.

From www.foodmag.com.au

Accurately identify flaws with the right thermal imaging with FLIR Thermal Imaging Flaw Detection Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of. Thermal Imaging Flaw Detection.

From modsonic.com

Ultrasonic Flaw Detection A Complete Guide Thermal Imaging Flaw Detection Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of. Thermal Imaging Flaw Detection.

From www.wabteccorp.com

FLEX Ultrasonic Rail Flaw Detection System Wabtec Corporation Thermal Imaging Flaw Detection Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance. Thermal Imaging Flaw Detection.

From www.multianalyzersurveying.com

NDT Systems Raptor Advanced Imaging Flaw Detector MULTI ANALYZER SURVEYING Thermal Imaging Flaw Detection As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of. Thermal Imaging Flaw Detection.

From www.shimadzu.com

SHIMADZU CORPORATION Detecting Flaws within Objects Quickly and Easily Using Ultrasonic and Thermal Imaging Flaw Detection Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance. Thermal Imaging Flaw Detection.

From www.jwjndt.com

Sonatest WAVE Flaw Detector JWJ NDT Thermal Imaging Flaw Detection Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of. Thermal Imaging Flaw Detection.

From irss.ca

Sonatest Prisma UT Flaw Detector IR Supplies and Services Thermal Imaging Flaw Detection As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of. Thermal Imaging Flaw Detection.

From www.jwjndt.com

Sonatest WAVE Flaw Detector JWJ NDT Thermal Imaging Flaw Detection As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of. Thermal Imaging Flaw Detection.

From uk.trotec.com

Thermal imaging camera XC300 highresolution thermography system TROTEC Thermal Imaging Flaw Detection Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance. Thermal Imaging Flaw Detection.

From plus.fluke.com

3 Types of Thermographic Inspection Fluke Thermal Imaging Flaw Detection Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of. Thermal Imaging Flaw Detection.

From www.jwjndt.com

Prisma Ultrasonic Flaw Detector JWJ NDT Thermal Imaging Flaw Detection Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but. Thermal Imaging Flaw Detection.

From www.findlight.net

Flaw Detection in Laser Powder Bed Fusion Thermal Imaging Flaw Detection Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but. Thermal Imaging Flaw Detection.

From www.globalfastertech.com

Olympus OmniScan X3 Phased Array Flaw Detector Global Faster Tech Thermal Imaging Flaw Detection Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of. Thermal Imaging Flaw Detection.

From www.jwjndt.com

Proceq UT8000 Portable Ultrasonic Flaw Detector JWJ NDT Thermal Imaging Flaw Detection As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but. Thermal Imaging Flaw Detection.

From usndt.com

NDT Systems Raptor Ultrasonic Flaw Detector USNDT, Inc. Thermal Imaging Flaw Detection Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of. Thermal Imaging Flaw Detection.

From irss.ca

Sonatest Prisma PA Ultrasonic Flaw Detector IR Supplies and Services Thermal Imaging Flaw Detection Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of. Thermal Imaging Flaw Detection.

From www.jwjndt.com

Sonatest WAVE Interactive Ultrasonic Flaw Detector JWJ NDT Thermal Imaging Flaw Detection Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but their. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance. Thermal Imaging Flaw Detection.

From usndt.com

Olympus Panametrics Epoch 3 Ultrasonic Flaw Detector USNDT, Inc. Thermal Imaging Flaw Detection Quality control of additively manufactured (am) metallic structures is essential prior to deployment of these. As a popular nondestructive testing (ndt) technique, thermal imaging test demonstrates competitive performance in. Recent advancements in dimensionality reduction techniques have significantly contributed to the field of active. Thermal imaging techniques have proven to be successful for the nondestructive evaluation (nde) of composite materials, but. Thermal Imaging Flaw Detection.