Disadvantages Of Composite Propeller . · minimized production costs since composites production is done through a broad. The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.), which weakens the bond between layers. · part count gets reduced. There are advantages and disadvantages of using composite materials in aircraft. A side benefit of some mt composite propellers is that in the event of a prop strike, the blade may simply break off and not damage the engine (although a teardown is usually required). Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted to different applications. Because composite materials don’t break easily, that makes it hard to tell if the interior structure has been damaged at all and this, of course, is the single most concerning. It’s a lot more complicated than. Pros · for a given weight, composites give higher performance and increase fuel savings. Basically, composites used in modern airplanes are impervious to just about everything except sunlight and condensation. Composite materials are broadly used in. Many factors determine how effective a types of propeller system will be, including the blade pitch, the number of propeller blades, engine torque, and a propeller’s revolutions’ speed.

from www.slideshare.net

· minimized production costs since composites production is done through a broad. The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.), which weakens the bond between layers. Basically, composites used in modern airplanes are impervious to just about everything except sunlight and condensation. Composite materials are broadly used in. A side benefit of some mt composite propellers is that in the event of a prop strike, the blade may simply break off and not damage the engine (although a teardown is usually required). There are advantages and disadvantages of using composite materials in aircraft. Pros · for a given weight, composites give higher performance and increase fuel savings. It’s a lot more complicated than. Many factors determine how effective a types of propeller system will be, including the blade pitch, the number of propeller blades, engine torque, and a propeller’s revolutions’ speed. Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted to different applications.

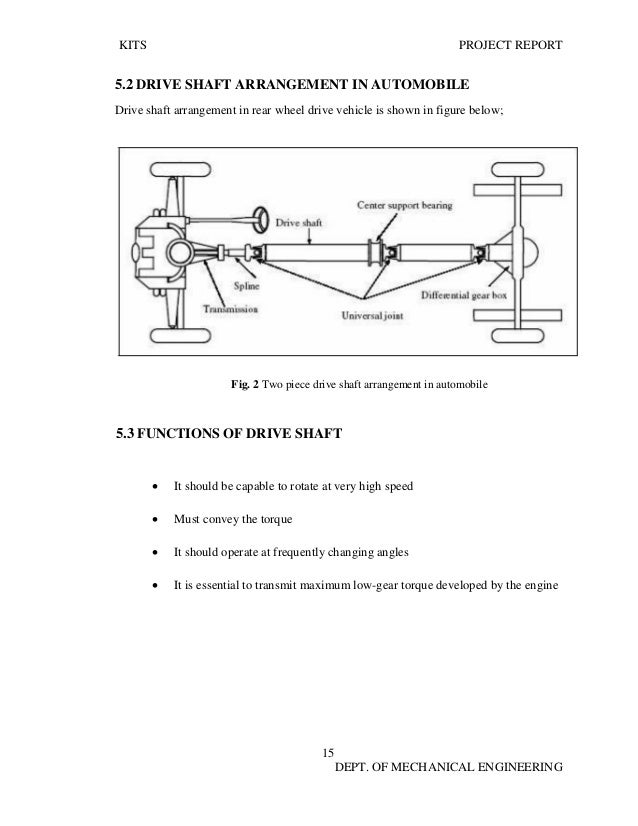

DESIGN AND ANALYSIS OF COMPOSITE PROPELLER/DRIVEN SHAFT USING FEA

Disadvantages Of Composite Propeller Because composite materials don’t break easily, that makes it hard to tell if the interior structure has been damaged at all and this, of course, is the single most concerning. Because composite materials don’t break easily, that makes it hard to tell if the interior structure has been damaged at all and this, of course, is the single most concerning. A side benefit of some mt composite propellers is that in the event of a prop strike, the blade may simply break off and not damage the engine (although a teardown is usually required). Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted to different applications. It’s a lot more complicated than. · minimized production costs since composites production is done through a broad. Many factors determine how effective a types of propeller system will be, including the blade pitch, the number of propeller blades, engine torque, and a propeller’s revolutions’ speed. Composite materials are broadly used in. Pros · for a given weight, composites give higher performance and increase fuel savings. There are advantages and disadvantages of using composite materials in aircraft. The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.), which weakens the bond between layers. Basically, composites used in modern airplanes are impervious to just about everything except sunlight and condensation. · part count gets reduced.

From eaaforums.org

Selling composite propellers Disadvantages Of Composite Propeller Pros · for a given weight, composites give higher performance and increase fuel savings. Composite materials are broadly used in. Because composite materials don’t break easily, that makes it hard to tell if the interior structure has been damaged at all and this, of course, is the single most concerning. Basically, composites used in modern airplanes are impervious to just. Disadvantages Of Composite Propeller.

From www.youtube.com

Material Science 2 C3L15 Advantage and Disadvantages of Disadvantages Of Composite Propeller · minimized production costs since composites production is done through a broad. Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted to different applications. Composite materials are broadly used in. The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.), which weakens the. Disadvantages Of Composite Propeller.

From www.slideserve.com

PPT Composite Materials in the aerospace industry PowerPoint Disadvantages Of Composite Propeller The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.), which weakens the bond between layers. Because composite materials don’t break easily, that makes it hard to tell if the interior structure has been damaged at all and this, of course, is the single most concerning. Pros · for. Disadvantages Of Composite Propeller.

From hartzellprop.com

Composite Propellers Why Make the Switch? Hartzell Propeller Disadvantages Of Composite Propeller Basically, composites used in modern airplanes are impervious to just about everything except sunlight and condensation. Pros · for a given weight, composites give higher performance and increase fuel savings. Composite materials are broadly used in. A side benefit of some mt composite propellers is that in the event of a prop strike, the blade may simply break off and. Disadvantages Of Composite Propeller.

From www.slideserve.com

PPT Composites PowerPoint Presentation, free download ID38357 Disadvantages Of Composite Propeller Basically, composites used in modern airplanes are impervious to just about everything except sunlight and condensation. A side benefit of some mt composite propellers is that in the event of a prop strike, the blade may simply break off and not damage the engine (although a teardown is usually required). There are advantages and disadvantages of using composite materials in. Disadvantages Of Composite Propeller.

From www.materialsciencejournal.org

A Review on Hybrid Composites used for Marine Propellers Material Disadvantages Of Composite Propeller Composite materials are broadly used in. It’s a lot more complicated than. Because composite materials don’t break easily, that makes it hard to tell if the interior structure has been damaged at all and this, of course, is the single most concerning. Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted to different applications.. Disadvantages Of Composite Propeller.

From hartzellprop.com

Composite Propellers Piston Engine Aircraft Hartzell Propeller Inc. Disadvantages Of Composite Propeller Many factors determine how effective a types of propeller system will be, including the blade pitch, the number of propeller blades, engine torque, and a propeller’s revolutions’ speed. · part count gets reduced. The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.), which weakens the bond between layers.. Disadvantages Of Composite Propeller.

From engineerforspace.com

The Importance of Composites in the Aerospace and Astronautical Disadvantages Of Composite Propeller The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.), which weakens the bond between layers. It’s a lot more complicated than. · minimized production costs since composites production is done through a broad. There are advantages and disadvantages of using composite materials in aircraft. Basically, composites used in. Disadvantages Of Composite Propeller.

From www.slideshare.net

DESIGN AND ANALYSIS OF COMPOSITE PROPELLER/DRIVEN SHAFT USING FEA Disadvantages Of Composite Propeller Basically, composites used in modern airplanes are impervious to just about everything except sunlight and condensation. Many factors determine how effective a types of propeller system will be, including the blade pitch, the number of propeller blades, engine torque, and a propeller’s revolutions’ speed. · minimized production costs since composites production is done through a broad. A side benefit of. Disadvantages Of Composite Propeller.

From www.slideserve.com

PPT Composites Full Lecture PowerPoint Presentation, free download Disadvantages Of Composite Propeller · minimized production costs since composites production is done through a broad. Because composite materials don’t break easily, that makes it hard to tell if the interior structure has been damaged at all and this, of course, is the single most concerning. · part count gets reduced. Composite materials are broadly used in. A side benefit of some mt composite. Disadvantages Of Composite Propeller.

From hartzellprop.com

How to Maintain a Composite Propeller Hartzell Propeller Disadvantages Of Composite Propeller · minimized production costs since composites production is done through a broad. There are advantages and disadvantages of using composite materials in aircraft. A side benefit of some mt composite propellers is that in the event of a prop strike, the blade may simply break off and not damage the engine (although a teardown is usually required). The fabric (glass. Disadvantages Of Composite Propeller.

From www.researchgate.net

schematic of morphing composite propeller (mCp) (a) conventional Disadvantages Of Composite Propeller Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted to different applications. Basically, composites used in modern airplanes are impervious to just about everything except sunlight and condensation. Pros · for a given weight, composites give higher performance and increase fuel savings. · part count gets reduced. There are advantages and disadvantages of using. Disadvantages Of Composite Propeller.

From hartzellprop.com

How a Composite Propeller Blade is Made Hartzell Propeller Disadvantages Of Composite Propeller Because composite materials don’t break easily, that makes it hard to tell if the interior structure has been damaged at all and this, of course, is the single most concerning. The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.), which weakens the bond between layers. Many factors determine. Disadvantages Of Composite Propeller.

From www.phase-trans.msm.cam.ac.uk

Disadvantages of Composites Disadvantages Of Composite Propeller A side benefit of some mt composite propellers is that in the event of a prop strike, the blade may simply break off and not damage the engine (although a teardown is usually required). Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted to different applications. There are advantages and disadvantages of using composite. Disadvantages Of Composite Propeller.

From www.jeccomposites.com

DigiProp Developing the next generation of composite propeller blades Disadvantages Of Composite Propeller Composite materials are broadly used in. · minimized production costs since composites production is done through a broad. The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.), which weakens the bond between layers. Many factors determine how effective a types of propeller system will be, including the blade. Disadvantages Of Composite Propeller.

From simpleflying.com

From Wood To Composites How Aircraft Materials Have Changed Over The Years Disadvantages Of Composite Propeller It’s a lot more complicated than. There are advantages and disadvantages of using composite materials in aircraft. Pros · for a given weight, composites give higher performance and increase fuel savings. Basically, composites used in modern airplanes are impervious to just about everything except sunlight and condensation. · part count gets reduced. Many factors determine how effective a types of. Disadvantages Of Composite Propeller.

From marine-offshore-ppd.bureauveritas.com

NEW Guidance Note for propellers made of composite materials Marine Disadvantages Of Composite Propeller Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted to different applications. · minimized production costs since composites production is done through a broad. The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.), which weakens the bond between layers. It’s a lot. Disadvantages Of Composite Propeller.

From www.slideserve.com

PPT COMPOSITES PowerPoint Presentation, free download ID6103716 Disadvantages Of Composite Propeller Basically, composites used in modern airplanes are impervious to just about everything except sunlight and condensation. Many factors determine how effective a types of propeller system will be, including the blade pitch, the number of propeller blades, engine torque, and a propeller’s revolutions’ speed. Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted to. Disadvantages Of Composite Propeller.

From www.mdpi.com

Applied Sciences Free FullText Ceramic Matrix Composites for Aero Disadvantages Of Composite Propeller The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.), which weakens the bond between layers. It’s a lot more complicated than. Composite materials are broadly used in. Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted to different applications. Pros · for. Disadvantages Of Composite Propeller.

From aviationweek.com

Composites May Be Key as Aircraft Propellers More Complex Disadvantages Of Composite Propeller It’s a lot more complicated than. The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.), which weakens the bond between layers. There are advantages and disadvantages of using composite materials in aircraft. · part count gets reduced. Understanding these variables (and many others) allows aeronautical engineers to design. Disadvantages Of Composite Propeller.

From medium.com

Advantages of Composite Materials in the Aerospace Industry by Daniel Disadvantages Of Composite Propeller Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted to different applications. Many factors determine how effective a types of propeller system will be, including the blade pitch, the number of propeller blades, engine torque, and a propeller’s revolutions’ speed. It’s a lot more complicated than. Because composite materials don’t break easily, that makes. Disadvantages Of Composite Propeller.

From www.slideserve.com

PPT Composites PowerPoint Presentation ID38357 Disadvantages Of Composite Propeller Composite materials are broadly used in. There are advantages and disadvantages of using composite materials in aircraft. Because composite materials don’t break easily, that makes it hard to tell if the interior structure has been damaged at all and this, of course, is the single most concerning. Pros · for a given weight, composites give higher performance and increase fuel. Disadvantages Of Composite Propeller.

From boatingnz.co.nz

Composite Saildrive propeller Boating NZ Disadvantages Of Composite Propeller Because composite materials don’t break easily, that makes it hard to tell if the interior structure has been damaged at all and this, of course, is the single most concerning. Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted to different applications. There are advantages and disadvantages of using composite materials in aircraft. ·. Disadvantages Of Composite Propeller.

From eaaforums.org

AERO composite propellers Disadvantages Of Composite Propeller Pros · for a given weight, composites give higher performance and increase fuel savings. Basically, composites used in modern airplanes are impervious to just about everything except sunlight and condensation. There are advantages and disadvantages of using composite materials in aircraft. · minimized production costs since composites production is done through a broad. Composite materials are broadly used in. A. Disadvantages Of Composite Propeller.

From www.slideserve.com

PPT Composite Material PowerPoint Presentation, free download ID Disadvantages Of Composite Propeller It’s a lot more complicated than. Many factors determine how effective a types of propeller system will be, including the blade pitch, the number of propeller blades, engine torque, and a propeller’s revolutions’ speed. The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.), which weakens the bond between. Disadvantages Of Composite Propeller.

From www.researchgate.net

Advantages and disadvantages of composite synthesis methods using 2D Disadvantages Of Composite Propeller It’s a lot more complicated than. Composite materials are broadly used in. Basically, composites used in modern airplanes are impervious to just about everything except sunlight and condensation. · part count gets reduced. Many factors determine how effective a types of propeller system will be, including the blade pitch, the number of propeller blades, engine torque, and a propeller’s revolutions’. Disadvantages Of Composite Propeller.

From studylib.net

1.3 Advantages and Disadvantages of Composites Disadvantages Of Composite Propeller · part count gets reduced. Basically, composites used in modern airplanes are impervious to just about everything except sunlight and condensation. Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted to different applications. The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.),. Disadvantages Of Composite Propeller.

From www.semanticscholar.org

Figure 1 from Structural Design and Analysis of Marine Composite Disadvantages Of Composite Propeller Basically, composites used in modern airplanes are impervious to just about everything except sunlight and condensation. Pros · for a given weight, composites give higher performance and increase fuel savings. Composite materials are broadly used in. Many factors determine how effective a types of propeller system will be, including the blade pitch, the number of propeller blades, engine torque, and. Disadvantages Of Composite Propeller.

From hartzellprop.com

Considering an Upgrade? Here’s What to Expect from a Composite Aircraft Disadvantages Of Composite Propeller A side benefit of some mt composite propellers is that in the event of a prop strike, the blade may simply break off and not damage the engine (although a teardown is usually required). It’s a lot more complicated than. Pros · for a given weight, composites give higher performance and increase fuel savings. · part count gets reduced. Composite. Disadvantages Of Composite Propeller.

From www.aircraftsystemstech.com

Aircraft Systems Propeller Inspection and Maintenance Disadvantages Of Composite Propeller Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted to different applications. Many factors determine how effective a types of propeller system will be, including the blade pitch, the number of propeller blades, engine torque, and a propeller’s revolutions’ speed. It’s a lot more complicated than. Basically, composites used in modern airplanes are impervious. Disadvantages Of Composite Propeller.

From www.ijraset.com

A Review on Recent Development in Advanced Composite Marine Propellers Disadvantages Of Composite Propeller A side benefit of some mt composite propellers is that in the event of a prop strike, the blade may simply break off and not damage the engine (although a teardown is usually required). There are advantages and disadvantages of using composite materials in aircraft. Understanding these variables (and many others) allows aeronautical engineers to design propeller systems uniquely adapted. Disadvantages Of Composite Propeller.

From gamma.app

Design and Analysis of Composite Propeller Blade for Aircraft Disadvantages Of Composite Propeller It’s a lot more complicated than. The fabric (glass or carbon fiber) is little affected, but the ultraviolet rays/water combination can attack the matrix (the resin, etc.), which weakens the bond between layers. Pros · for a given weight, composites give higher performance and increase fuel savings. There are advantages and disadvantages of using composite materials in aircraft. Because composite. Disadvantages Of Composite Propeller.

From hartzellprop.com

Composite Propellers Why Make the Switch? Hartzell Propeller Disadvantages Of Composite Propeller Because composite materials don’t break easily, that makes it hard to tell if the interior structure has been damaged at all and this, of course, is the single most concerning. · part count gets reduced. Many factors determine how effective a types of propeller system will be, including the blade pitch, the number of propeller blades, engine torque, and a. Disadvantages Of Composite Propeller.

From www.slideserve.com

PPT Introduction to Composite Materials Autar K. Kaw PowerPoint Disadvantages Of Composite Propeller A side benefit of some mt composite propellers is that in the event of a prop strike, the blade may simply break off and not damage the engine (although a teardown is usually required). Because composite materials don’t break easily, that makes it hard to tell if the interior structure has been damaged at all and this, of course, is. Disadvantages Of Composite Propeller.

From www.smicomposites.com

The Advantages of Composite Aircraft Design in Planes of All Sizes Disadvantages Of Composite Propeller · minimized production costs since composites production is done through a broad. Basically, composites used in modern airplanes are impervious to just about everything except sunlight and condensation. Because composite materials don’t break easily, that makes it hard to tell if the interior structure has been damaged at all and this, of course, is the single most concerning. · part. Disadvantages Of Composite Propeller.