Injection Molding Machine Working Principle . Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a mould. The injection molding process can be roughly divided into six stages: Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. Once the mold is clamped, the injection phase begins. The screw inside the barrel moves forward, pushing the. An injection molding machine consists of three main parts: Injection moulding is the ideal. Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. Mold closing, glue injection, pressure maintaining, cooling,.

from www.turbosquid.com

An injection molding machine consists of three main parts: The screw inside the barrel moves forward, pushing the. Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. Mold closing, glue injection, pressure maintaining, cooling,. Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. Injection moulding is the ideal. The injection molding process can be roughly divided into six stages: Once the mold is clamped, the injection phase begins. Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a mould.

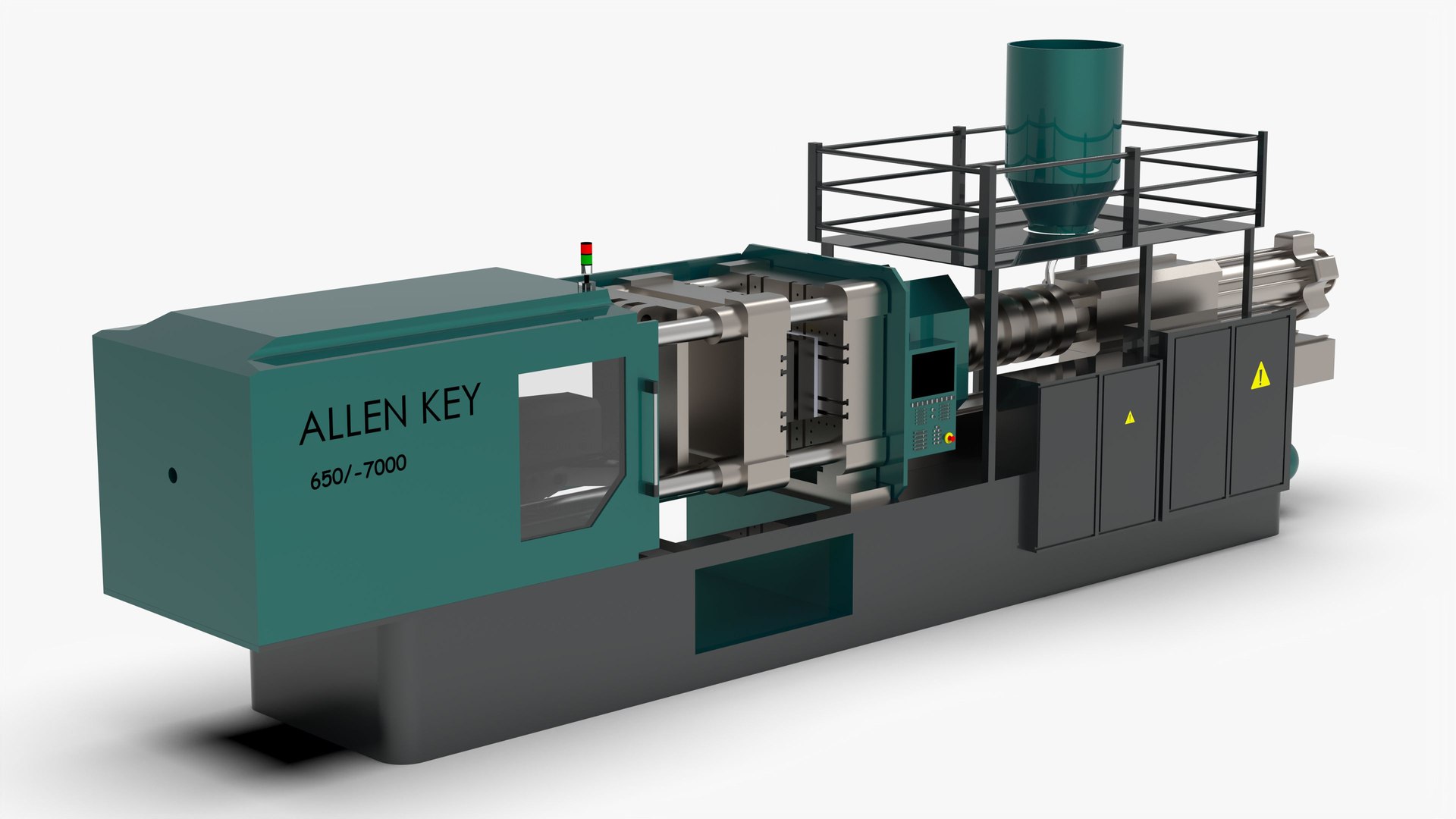

Free 3D Injection Molding Machine Equipment TurboSquid 1996728

Injection Molding Machine Working Principle Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding is the ideal. Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a mould. The screw inside the barrel moves forward, pushing the. Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. An injection molding machine consists of three main parts: Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. The injection molding process can be roughly divided into six stages: Mold closing, glue injection, pressure maintaining, cooling,. Once the mold is clamped, the injection phase begins. Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file.

From mungfali.com

Injection Molding Diagram Injection Molding Machine Working Principle Once the mold is clamped, the injection phase begins. Injection moulding is the ideal. The screw inside the barrel moves forward, pushing the. Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by. Injection Molding Machine Working Principle.

From www.moldplasticinjection.com

Injection Molding Machines Types, Costs, How To Choose The Best Injection Molding Machine Working Principle Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. The injection molding process can be roughly divided into six stages: Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. Injection moulding is the ideal. Injection moulding is a. Injection Molding Machine Working Principle.

From cn-kwmachine.en.made-in-china.com

138t High Performance Plastic Injection Molding Machine Injection Injection Molding Machine Working Principle Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. Mold closing, glue injection, pressure maintaining, cooling,. The screw inside the barrel moves forward, pushing the. Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. An. Injection Molding Machine Working Principle.

From www.youtube.com

Working principle MX series big injection molding machine's clamp unit Injection Molding Machine Working Principle The injection molding process can be roughly divided into six stages: Once the mold is clamped, the injection phase begins. Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material. Injection Molding Machine Working Principle.

From cooling-tower.my

Injection molding working principle JH Cooling Machine Injection Molding Machine Working Principle The screw inside the barrel moves forward, pushing the. Mold closing, glue injection, pressure maintaining, cooling,. An injection molding machine consists of three main parts: The injection molding process can be roughly divided into six stages: Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. Injection molding). Injection Molding Machine Working Principle.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Injection Molding Machine Working Principle Injection moulding is the ideal. Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a mould. The injection molding process can be roughly divided into six stages:. Injection Molding Machine Working Principle.

From www.plasticmoulds.net

Injection Molding Process Injection Molding Machine Working Principle Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. An injection molding machine consists of three main parts: Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Once the mold is clamped, the injection phase begins. Mold closing, glue. Injection Molding Machine Working Principle.

From www.3erp.com

What is Injection Molding and How Does it Work Definition & Working Injection Molding Machine Working Principle The injection molding process can be roughly divided into six stages: Injection moulding is the ideal. An injection molding machine consists of three main parts: Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. The screw inside the barrel moves forward, pushing the. Injection molding is a. Injection Molding Machine Working Principle.

From www.mecholic.com

injection moulding figure Injection Molding Machine Working Principle Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding is the ideal. Mold closing, glue injection, pressure maintaining, cooling,. The screw inside the barrel moves forward, pushing the. Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold.. Injection Molding Machine Working Principle.

From www.myplasticmold.com

Injection Molding Machine Components And Its Function Injection Molding Machine Working Principle Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a mould. Mold closing, glue injection, pressure maintaining, cooling,. Once the mold is clamped, the injection phase begins. An injection molding machine consists of three main parts: Injection molding) is a manufacturing process for producing parts by injecting molten material. Injection Molding Machine Working Principle.

From www.youtube.com

Working principle MX series big injection molding machine's clamp force Injection Molding Machine Working Principle The screw inside the barrel moves forward, pushing the. Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. The injection molding process can be roughly divided into six stages: Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file.. Injection Molding Machine Working Principle.

From www.myplasticmold.com

Injection Molding Machine Injection Molding Machine Working Principle An injection molding machine consists of three main parts: Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. Once the mold is clamped, the injection phase begins. The screw inside the barrel moves forward, pushing the. Injection molding is a manufacturing process in which shaping the plastic. Injection Molding Machine Working Principle.

From easchangesystems.com

Plastic injection molding process EAS Change Systems Injection Molding Machine Working Principle Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a mould. Injection moulding is the ideal. The screw inside the barrel moves forward, pushing the. An injection molding. Injection Molding Machine Working Principle.

From exoiisphe.blob.core.windows.net

How Many Types Of Nozzle In Injection Moulding Machine at Larry Wicker blog Injection Molding Machine Working Principle Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a mould. Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. The screw inside the barrel moves forward, pushing the. Injection moulding is the ideal. Mold closing, glue. Injection Molding Machine Working Principle.

From www.xcentricmold.com

Injection Molding Process Xcentric Mold & Engineering Injection Molding Machine Working Principle Mold closing, glue injection, pressure maintaining, cooling,. An injection molding machine consists of three main parts: Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a mould. Once the mold is clamped, the injection phase begins. Injection moulding is the ideal. Injection molding involves injecting molten material into a. Injection Molding Machine Working Principle.

From minhuiglobal.com

Guide to the Working Principle of vertical Injection Molding Machine Injection Molding Machine Working Principle Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. The screw inside the barrel moves forward, pushing the. An injection molding machine consists of three main parts: Injection moulding. Injection Molding Machine Working Principle.

From www.iqsdirectory.com

Thermoplastic Molding Process, Types, Materials, and Applications Injection Molding Machine Working Principle Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a mould. Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding is the ideal. The injection molding process can be roughly divided into six stages: The screw inside the. Injection Molding Machine Working Principle.

From exoiisphe.blob.core.windows.net

How Many Types Of Nozzle In Injection Moulding Machine at Larry Wicker blog Injection Molding Machine Working Principle The screw inside the barrel moves forward, pushing the. An injection molding machine consists of three main parts: The injection molding process can be roughly divided into six stages: Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a mould. Injection molding) is a manufacturing process for producing parts. Injection Molding Machine Working Principle.

From www.turbosquid.com

Free 3D Injection Molding Machine Equipment TurboSquid 1996728 Injection Molding Machine Working Principle The injection molding process can be roughly divided into six stages: Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. An injection molding machine consists of three main parts: Once. Injection Molding Machine Working Principle.

From www.cdn-inc.com

Plastic Injection Molding Process Guide 2019 Full Process Explained Injection Molding Machine Working Principle Once the mold is clamped, the injection phase begins. An injection molding machine consists of three main parts: Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. The screw inside the barrel moves forward, pushing the. Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials. Injection Molding Machine Working Principle.

From www.exelbpc.com

Injection molding machine Exel Two Shot Injection Molding Injection Molding Machine Working Principle Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. The injection molding process can be roughly divided into six stages: An injection molding machine consists of. Injection Molding Machine Working Principle.

From www.blowing-machine.com

injection molding machine working principle Yosion Machinery Injection Molding Machine Working Principle The screw inside the barrel moves forward, pushing the. Mold closing, glue injection, pressure maintaining, cooling,. Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. Once the mold is clamped, the injection phase begins. Injection molding) is a manufacturing process for producing parts by injecting molten material. Injection Molding Machine Working Principle.

From plasticjectionmoldingmachine.blogspot.com

plastic injection molding machine injection molding machine working Injection Molding Machine Working Principle Once the mold is clamped, the injection phase begins. The injection molding process can be roughly divided into six stages: Mold closing, glue injection, pressure maintaining, cooling,. Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a mould. Injection molding is a manufacturing process in which shaping the plastic. Injection Molding Machine Working Principle.

From predictabledesigns.com

Introduction to Injection Molding Injection Molding Machine Working Principle Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. Injection moulding is the ideal. An injection molding machine consists of three main parts: Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. The screw inside the barrel moves forward,. Injection Molding Machine Working Principle.

From www.weetect.com

Plastic Fabrication The Complete Guide In 2018 Wee Tect Injection Molding Machine Working Principle Mold closing, glue injection, pressure maintaining, cooling,. Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a mould. Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. Injection molding involves injecting molten material into a mold, while. Injection Molding Machine Working Principle.

From www.youtube.com

How to draw Injection Molding Machine Diagram I Plastic Injection Injection Molding Machine Working Principle An injection molding machine consists of three main parts: Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. The injection molding process can be roughly divided into six stages: The screw inside the barrel moves forward, pushing the. Injection molding) is a manufacturing process for producing parts. Injection Molding Machine Working Principle.

From themechanicalengineering.com

Injection Molding Definition, Construction, Working Process Injection Molding Machine Working Principle Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. Once the mold is clamped, the injection phase begins. The screw inside the barrel moves forward, pushing the. Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a. Injection Molding Machine Working Principle.

From www.southernfabsales.com

5 Factors to Consider When Buying Plastic Injection Molding Machinery Injection Molding Machine Working Principle An injection molding machine consists of three main parts: The injection molding process can be roughly divided into six stages: Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. Mold closing, glue injection, pressure maintaining, cooling,. Injection moulding is a manufacturing technique that involves the formation of plastic. Injection Molding Machine Working Principle.

From www.makeuseof.ir

قالب گیری تزریقی چیست و چگونه کار می کند؟ » خبر و ترفند روز Injection Molding Machine Working Principle The injection molding process can be roughly divided into six stages: Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. The screw inside the barrel moves forward, pushing the. Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material. Injection Molding Machine Working Principle.

From www.daobenmachinery.com

Precision Injection Molding Machine Superior Quality Products Injection Molding Machine Working Principle An injection molding machine consists of three main parts: Once the mold is clamped, the injection phase begins. Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. The injection molding process can be roughly divided into six stages: Injection moulding is a manufacturing technique that involves the formation. Injection Molding Machine Working Principle.

From www.rutlandplastics.co.uk

Injection Moulding Machine Diagram Rutland Plastics Injection Molding Machine Working Principle Mold closing, glue injection, pressure maintaining, cooling,. Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. The screw inside the barrel moves forward, pushing the. Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. An injection molding machine consists. Injection Molding Machine Working Principle.

From www.adtcmold.com

Injection mold principle and structure knowledge Injection Molding Machine Working Principle Injection molding involves injecting molten material into a mold, while 3d printing builds objects layer by layer from a digital design file. The screw inside the barrel moves forward, pushing the. An injection molding machine consists of three main parts: Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Once the. Injection Molding Machine Working Principle.

From www.techicy.com

5 Processes of Making Injection Molds Techicy Injection Molding Machine Working Principle The injection molding process can be roughly divided into six stages: The screw inside the barrel moves forward, pushing the. Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. Injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection. Injection Molding Machine Working Principle.

From www.automaticblowmouldingmachine.com

China Dawson Machinery & Mould Group Co.,Ltd latest company news about Injection Molding Machine Working Principle Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. The injection molding process can be roughly divided into six stages: Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a mould. Injection molding involves injecting molten material. Injection Molding Machine Working Principle.

From www.dayamachinery.com

principle of injection molding China Top Plastic Injection Molding Injection Molding Machine Working Principle Injection moulding is the ideal. Once the mold is clamped, the injection phase begins. Injection molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold. The injection molding process can be roughly divided into six stages: The screw inside the barrel moves forward, pushing the. Injection molding) is a manufacturing. Injection Molding Machine Working Principle.