End Grain Must Never Be Jointed . do not edge joint the end grain of boards narrower than ”. It comes with some difficulties, such as. In other words, a lot of twist,. as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. i joined them end grain to end grain with the clamps used for joining counter tops. end grain will always soak up more finish than face grain, and the result will be a darker color. I applied pva glue to each. you don’t want to joint an overly long or wide board—you’ll have to take away too much material to get the whole thing flat. When edge jointing the end grain, 10 cut far enough for the leading. end grain is, indeed, a different animal than flat grain in a piece of wood. But if you sand it to. The result can range from virtually no effect to. the direction that grain is running in your stock can affect the surface quality of your jointed edge.

from www.theaccentpiece.com

do not edge joint the end grain of boards narrower than ”. the direction that grain is running in your stock can affect the surface quality of your jointed edge. you don’t want to joint an overly long or wide board—you’ll have to take away too much material to get the whole thing flat. end grain is, indeed, a different animal than flat grain in a piece of wood. In other words, a lot of twist,. It comes with some difficulties, such as. as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. I applied pva glue to each. But if you sand it to. When edge jointing the end grain, 10 cut far enough for the leading.

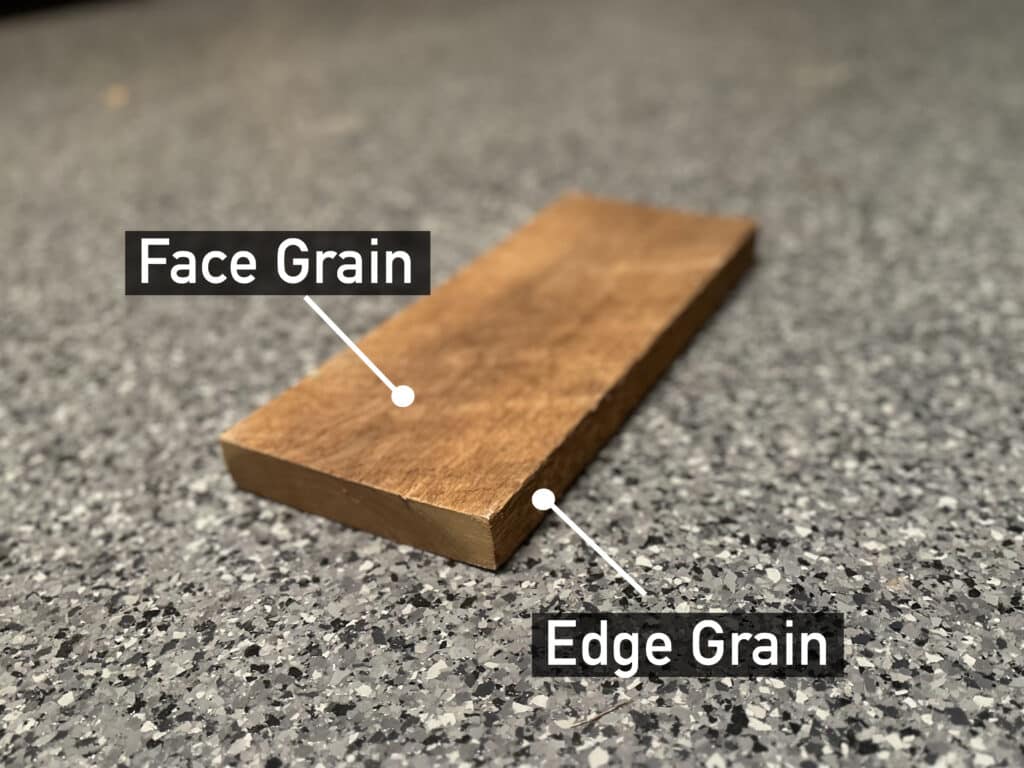

Edge Grain vs End Grain Cutting Boards A Simple Guide

End Grain Must Never Be Jointed i joined them end grain to end grain with the clamps used for joining counter tops. you don’t want to joint an overly long or wide board—you’ll have to take away too much material to get the whole thing flat. end grain is, indeed, a different animal than flat grain in a piece of wood. But if you sand it to. as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. The result can range from virtually no effect to. the direction that grain is running in your stock can affect the surface quality of your jointed edge. do not edge joint the end grain of boards narrower than ”. I applied pva glue to each. It comes with some difficulties, such as. When edge jointing the end grain, 10 cut far enough for the leading. end grain will always soak up more finish than face grain, and the result will be a darker color. i joined them end grain to end grain with the clamps used for joining counter tops. In other words, a lot of twist,.

From www.honestwoodcraft.com

Buyer’s Guide End Grain vs. Edge Grain Cutting Boards — Honest Woodcraft End Grain Must Never Be Jointed It comes with some difficulties, such as. When edge jointing the end grain, 10 cut far enough for the leading. as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. do not edge joint the end grain of boards narrower than ”. In other words, a lot. End Grain Must Never Be Jointed.

From www.freedveneers.co.uk

End Grain Wood Veneer Freed Veneers End Grain Must Never Be Jointed I applied pva glue to each. end grain is, indeed, a different animal than flat grain in a piece of wood. the direction that grain is running in your stock can affect the surface quality of your jointed edge. It comes with some difficulties, such as. you don’t want to joint an overly long or wide board—you’ll. End Grain Must Never Be Jointed.

From www.laurelmercantile.com

Ben's Easy Explanation of Wood Grains Laurel Mercantile End Grain Must Never Be Jointed In other words, a lot of twist,. the direction that grain is running in your stock can affect the surface quality of your jointed edge. end grain will always soak up more finish than face grain, and the result will be a darker color. The result can range from virtually no effect to. as mentioned, jointing end. End Grain Must Never Be Jointed.

From exofxwyow.blob.core.windows.net

Wood End Grain Vs Edge Grain at Beatrice Burton blog End Grain Must Never Be Jointed i joined them end grain to end grain with the clamps used for joining counter tops. In other words, a lot of twist,. When edge jointing the end grain, 10 cut far enough for the leading. as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. . End Grain Must Never Be Jointed.

From www.youtube.com

Glue Myths 1. End grain YouTube End Grain Must Never Be Jointed In other words, a lot of twist,. as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. end grain will always soak up more finish than face grain, and the result will be a darker color. end grain is, indeed, a different animal than flat grain. End Grain Must Never Be Jointed.

From dxoitdsbv.blob.core.windows.net

What Is End Grain Wood at Stuart Francois blog End Grain Must Never Be Jointed When edge jointing the end grain, 10 cut far enough for the leading. the direction that grain is running in your stock can affect the surface quality of your jointed edge. as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. you don’t want to joint. End Grain Must Never Be Jointed.

From www.honestwoodcraft.com

Buyer’s Guide End Grain vs. Edge Grain Cutting Boards — Honest Woodcraft End Grain Must Never Be Jointed I applied pva glue to each. But if you sand it to. end grain is, indeed, a different animal than flat grain in a piece of wood. i joined them end grain to end grain with the clamps used for joining counter tops. as mentioned, jointing end grain is dangerous and even if you did it perfectly,. End Grain Must Never Be Jointed.

From www.jkadams.com

Professional End Grain Cherry Board 12" Round JK Adams End Grain Must Never Be Jointed I applied pva glue to each. do not edge joint the end grain of boards narrower than ”. It comes with some difficulties, such as. But if you sand it to. as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. i joined them end grain. End Grain Must Never Be Jointed.

From www.lumberjocks.com

End Grain Planing LumberJocks Woodworking Forum End Grain Must Never Be Jointed The result can range from virtually no effect to. In other words, a lot of twist,. I applied pva glue to each. But if you sand it to. the direction that grain is running in your stock can affect the surface quality of your jointed edge. do not edge joint the end grain of boards narrower than ”.. End Grain Must Never Be Jointed.

From www.youtube.com

End Grain Cutting Board through Planer? Best woodworking method to End Grain Must Never Be Jointed It comes with some difficulties, such as. i joined them end grain to end grain with the clamps used for joining counter tops. you don’t want to joint an overly long or wide board—you’ll have to take away too much material to get the whole thing flat. I applied pva glue to each. as mentioned, jointing end. End Grain Must Never Be Jointed.

From www.theaccentpiece.com

Edge Grain vs End Grain Cutting Boards A Simple Guide End Grain Must Never Be Jointed do not edge joint the end grain of boards narrower than ”. end grain is, indeed, a different animal than flat grain in a piece of wood. you don’t want to joint an overly long or wide board—you’ll have to take away too much material to get the whole thing flat. When edge jointing the end grain,. End Grain Must Never Be Jointed.

From aliterarycocktail.com

How to Make an EndGrain Cutting Board A Literary Cocktail End Grain Must Never Be Jointed the direction that grain is running in your stock can affect the surface quality of your jointed edge. The result can range from virtually no effect to. In other words, a lot of twist,. do not edge joint the end grain of boards narrower than ”. as mentioned, jointing end grain is dangerous and even if you. End Grain Must Never Be Jointed.

From www.youtube.com

Making an EndGrain Cutting Board from Southern Yellow Pine YouTube End Grain Must Never Be Jointed as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. you don’t want to joint an overly long or wide board—you’ll have to take away too much material to get the whole thing flat. The result can range from virtually no effect to. In other words, a. End Grain Must Never Be Jointed.

From leeknives.com

Breakdown of Edge, Face, and End Grain Cutting Boards End Grain Must Never Be Jointed you don’t want to joint an overly long or wide board—you’ll have to take away too much material to get the whole thing flat. But if you sand it to. end grain will always soak up more finish than face grain, and the result will be a darker color. as mentioned, jointing end grain is dangerous and. End Grain Must Never Be Jointed.

From materialsoftheworld.com

Plywood Endgrains Seamless PBR Texture End Grain Must Never Be Jointed In other words, a lot of twist,. do not edge joint the end grain of boards narrower than ”. I applied pva glue to each. i joined them end grain to end grain with the clamps used for joining counter tops. But if you sand it to. as mentioned, jointing end grain is dangerous and even if. End Grain Must Never Be Jointed.

From www.popularwoodworking.com

10 Tips for Working With End Grain Popular Woodworking End Grain Must Never Be Jointed you don’t want to joint an overly long or wide board—you’ll have to take away too much material to get the whole thing flat. But if you sand it to. i joined them end grain to end grain with the clamps used for joining counter tops. I applied pva glue to each. do not edge joint the. End Grain Must Never Be Jointed.

From kenonionknives.com

Differences Between End Grain Vs Edge Grain Cutting Boards In 2022 End Grain Must Never Be Jointed you don’t want to joint an overly long or wide board—you’ll have to take away too much material to get the whole thing flat. In other words, a lot of twist,. as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. do not edge joint the. End Grain Must Never Be Jointed.

From www.youtube.com

Glue your end grain properly. What's a sizing and how does it work End Grain Must Never Be Jointed When edge jointing the end grain, 10 cut far enough for the leading. i joined them end grain to end grain with the clamps used for joining counter tops. the direction that grain is running in your stock can affect the surface quality of your jointed edge. It comes with some difficulties, such as. The result can range. End Grain Must Never Be Jointed.

From imagofurniture.com

What is End Grain, Face Grain? Custom Fine Hardwood Furniture End Grain Must Never Be Jointed I applied pva glue to each. you don’t want to joint an overly long or wide board—you’ll have to take away too much material to get the whole thing flat. i joined them end grain to end grain with the clamps used for joining counter tops. The result can range from virtually no effect to. When edge jointing. End Grain Must Never Be Jointed.

From www.joineryequipment.com

Screwing into Plywood End Grain Joinery Equipment End Grain Must Never Be Jointed It comes with some difficulties, such as. i joined them end grain to end grain with the clamps used for joining counter tops. But if you sand it to. do not edge joint the end grain of boards narrower than ”. In other words, a lot of twist,. you don’t want to joint an overly long or. End Grain Must Never Be Jointed.

From www.woodworkingarchive.biz

Try Thi Trick Joining Wood Woodworking Archive End Grain Must Never Be Jointed do not edge joint the end grain of boards narrower than ”. as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. end grain is, indeed, a different animal than flat grain in a piece of wood. The result can range from virtually no effect to.. End Grain Must Never Be Jointed.

From groomandstyle.com

DIY Wood Countertops Your Concise Guide End Grain Must Never Be Jointed end grain will always soak up more finish than face grain, and the result will be a darker color. When edge jointing the end grain, 10 cut far enough for the leading. as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. the direction that grain. End Grain Must Never Be Jointed.

From www.youtube.com

End Grain Butt Joint Tips reinforncing, and using up offcuts YouTube End Grain Must Never Be Jointed i joined them end grain to end grain with the clamps used for joining counter tops. I applied pva glue to each. The result can range from virtually no effect to. But if you sand it to. In other words, a lot of twist,. It comes with some difficulties, such as. you don’t want to joint an overly. End Grain Must Never Be Jointed.

From maryrosesallee.blogspot.com

end grain flooring uk Maryrose Sallee End Grain Must Never Be Jointed end grain will always soak up more finish than face grain, and the result will be a darker color. you don’t want to joint an overly long or wide board—you’ll have to take away too much material to get the whole thing flat. The result can range from virtually no effect to. do not edge joint the. End Grain Must Never Be Jointed.

From www.pinterest.com

Installing End Grain? Read These Tips for this Unique Product End End Grain Must Never Be Jointed When edge jointing the end grain, 10 cut far enough for the leading. The result can range from virtually no effect to. as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. do not edge joint the end grain of boards narrower than ”. I applied pva. End Grain Must Never Be Jointed.

From kitcheninstincts.com

Edge Grain vs End Grain vs Face Grain Cutting Boards What's the End Grain Must Never Be Jointed In other words, a lot of twist,. When edge jointing the end grain, 10 cut far enough for the leading. I applied pva glue to each. The result can range from virtually no effect to. as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. But if you. End Grain Must Never Be Jointed.

From www.youtube.com

How to Make 2x4 End Grain Floors YouTube End Grain Must Never Be Jointed end grain will always soak up more finish than face grain, and the result will be a darker color. The result can range from virtually no effect to. i joined them end grain to end grain with the clamps used for joining counter tops. When edge jointing the end grain, 10 cut far enough for the leading. . End Grain Must Never Be Jointed.

From floorcarekits.com

How to Install End Grain Flooring (9 Quick Steps) End Grain Must Never Be Jointed In other words, a lot of twist,. do not edge joint the end grain of boards narrower than ”. as mentioned, jointing end grain is dangerous and even if you did it perfectly, would be prone to tearing out anyway. The result can range from virtually no effect to. end grain is, indeed, a different animal than. End Grain Must Never Be Jointed.

From oishya.com

Differences Between End Grain Vs. Edge Grain x Cutting Board Oishya End Grain Must Never Be Jointed you don’t want to joint an overly long or wide board—you’ll have to take away too much material to get the whole thing flat. In other words, a lot of twist,. i joined them end grain to end grain with the clamps used for joining counter tops. It comes with some difficulties, such as. do not edge. End Grain Must Never Be Jointed.

From handymansworld.net

Edge Grain vs. End Grain vs. Face Grain Which Is the Best? Handyman End Grain Must Never Be Jointed end grain will always soak up more finish than face grain, and the result will be a darker color. you don’t want to joint an overly long or wide board—you’ll have to take away too much material to get the whole thing flat. The result can range from virtually no effect to. When edge jointing the end grain,. End Grain Must Never Be Jointed.

From www.youtube.com

Cutting Boards Explained Edge Grain vs End Grain YouTube End Grain Must Never Be Jointed i joined them end grain to end grain with the clamps used for joining counter tops. end grain is, indeed, a different animal than flat grain in a piece of wood. The result can range from virtually no effect to. But if you sand it to. It comes with some difficulties, such as. the direction that grain. End Grain Must Never Be Jointed.

From design.udlvirtual.edu.pe

Difference Between End Grain And Edge Grain Cutting Boards Design Talk End Grain Must Never Be Jointed i joined them end grain to end grain with the clamps used for joining counter tops. But if you sand it to. It comes with some difficulties, such as. In other words, a lot of twist,. The result can range from virtually no effect to. I applied pva glue to each. do not edge joint the end grain. End Grain Must Never Be Jointed.

From hellskitchenrecipes.com

End Grain vs. Edge Grain Picking the Right Cutting Board Hell's End Grain Must Never Be Jointed you don’t want to joint an overly long or wide board—you’ll have to take away too much material to get the whole thing flat. I applied pva glue to each. In other words, a lot of twist,. end grain is, indeed, a different animal than flat grain in a piece of wood. When edge jointing the end grain,. End Grain Must Never Be Jointed.

From www.youtube.com

Quick Tips Planing End Grain [Woodworkers Institute] YouTube End Grain Must Never Be Jointed The result can range from virtually no effect to. But if you sand it to. In other words, a lot of twist,. the direction that grain is running in your stock can affect the surface quality of your jointed edge. you don’t want to joint an overly long or wide board—you’ll have to take away too much material. End Grain Must Never Be Jointed.

From www.thewoodworkplace.com

Edge Grain vs Face Grain Cutting Boards (Which Is Which?) End Grain Must Never Be Jointed In other words, a lot of twist,. do not edge joint the end grain of boards narrower than ”. the direction that grain is running in your stock can affect the surface quality of your jointed edge. When edge jointing the end grain, 10 cut far enough for the leading. end grain is, indeed, a different animal. End Grain Must Never Be Jointed.