What Is Belt Deflection . Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. Select from the dropdown options below to find the appropriate belt tension for. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. To measure belt deflection, use a belt deflection tool or a ruler to. Deflection refers to the distance the belt sags or deflects when a force is applied perpendicular to it. It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. In order to ensure a long and efficient belt operation, you must properly learn how to. The number one cause of a power transmission belt failure is improper tensioning. Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system.

from www.numerade.com

Deflection refers to the distance the belt sags or deflects when a force is applied perpendicular to it. In order to ensure a long and efficient belt operation, you must properly learn how to. The number one cause of a power transmission belt failure is improper tensioning. It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. To measure belt deflection, use a belt deflection tool or a ruler to. Select from the dropdown options below to find the appropriate belt tension for. Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear.

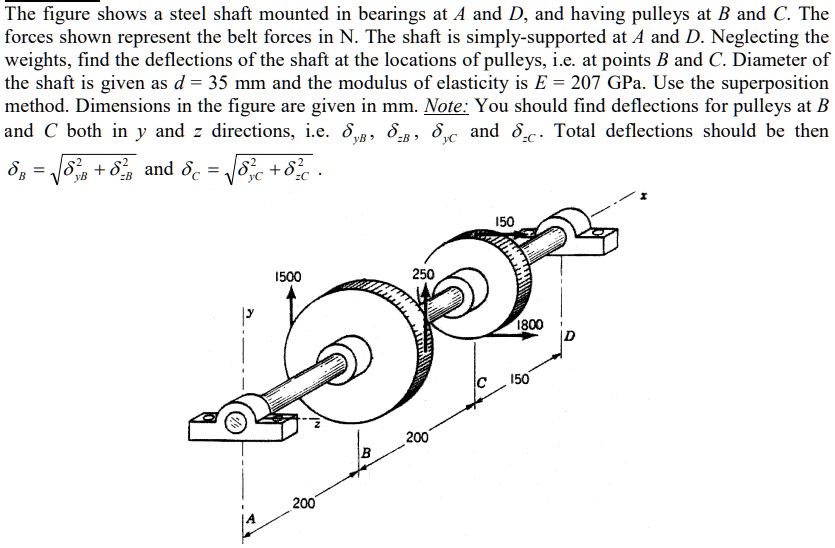

SOLVED The figure shows a steel shaft mounted in bearings at A and D

What Is Belt Deflection To measure belt deflection, use a belt deflection tool or a ruler to. Deflection refers to the distance the belt sags or deflects when a force is applied perpendicular to it. It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. In order to ensure a long and efficient belt operation, you must properly learn how to. Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. Select from the dropdown options below to find the appropriate belt tension for. To measure belt deflection, use a belt deflection tool or a ruler to. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. The number one cause of a power transmission belt failure is improper tensioning.

From www.esmagazine.com

Reliable VBelt Drive Operation 20170602 Engineered Systems Magazine What Is Belt Deflection Select from the dropdown options below to find the appropriate belt tension for. It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. To measure belt deflection, use a belt deflection tool or a ruler to. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature. What Is Belt Deflection.

From boostatv.com

Why Does Your ATV Belt Squeal? How to Fix It? What Is Belt Deflection To measure belt deflection, use a belt deflection tool or a ruler to. In order to ensure a long and efficient belt operation, you must properly learn how to. Deflection refers to the distance the belt sags or deflects when a force is applied perpendicular to it. Select from the dropdown options below to find the appropriate belt tension for.. What Is Belt Deflection.

From labbyag.es

V Belt Deflection Chart Labb by AG What Is Belt Deflection Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. To measure belt deflection, use a belt deflection tool or a. What Is Belt Deflection.

From www.researchgate.net

(PDF) Modelling of loss mechanisms in a pushing metal Vbelt What Is Belt Deflection To measure belt deflection, use a belt deflection tool or a ruler to. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. Select from the dropdown options below to find the appropriate belt. What Is Belt Deflection.

From www.researchgate.net

(PDF) Prediction of conveyor belt deflection by coupling of FEM and DEM What Is Belt Deflection Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. Deflection refers to the distance the belt sags or deflects when a force is applied perpendicular to it. Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. To measure belt deflection, use a belt deflection tool or a ruler to. It. What Is Belt Deflection.

From hurricaneperformance.ca

Belt Deflection Adjuster Hurricane Performance What Is Belt Deflection It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. In order to ensure a long and efficient belt operation, you must properly learn how to. The number one cause of a power transmission. What Is Belt Deflection.

From www.vrogue.co

Beam Strength Steel Beam Deflection Deflection Of Bea vrogue.co What Is Belt Deflection In order to ensure a long and efficient belt operation, you must properly learn how to. Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. Deflection refers to the distance the belt sags or deflects when a force is applied perpendicular. What Is Belt Deflection.

From clutchadjustments.com

Maximize Performance with Tips for Arctic Cat Belt Deflection What Is Belt Deflection Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. Select from the dropdown options below to find the appropriate belt tension for. To measure belt deflection, use a belt deflection tool or a. What Is Belt Deflection.

From www.youtube.com

Bearings & Deflection Angles (Nazeer A. Khan) YouTube What Is Belt Deflection Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. Deflection refers to the distance the belt sags or deflects when a force is applied perpendicular to it. Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. In order to ensure a long and efficient belt operation, you must properly learn. What Is Belt Deflection.

From www.vrogue.co

Belt Deflection Belt Alignment Chalking The Clutch Wi vrogue.co What Is Belt Deflection In order to ensure a long and efficient belt operation, you must properly learn how to. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. Deflection refers to the distance the belt sags or deflects when a force is. What Is Belt Deflection.

From www.researchgate.net

Equilibrium deflections of spans 1 and 3 for varying longitudinal belt What Is Belt Deflection In order to ensure a long and efficient belt operation, you must properly learn how to. To measure belt deflection, use a belt deflection tool or a ruler to. The number one cause of a power transmission belt failure is improper tensioning. Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. Select from the. What Is Belt Deflection.

From hvacrschool.com

Some Belt Tensioning Thoughts HVAC School What Is Belt Deflection In order to ensure a long and efficient belt operation, you must properly learn how to. Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. Select from the dropdown options below to find the appropriate belt tension for. The. What Is Belt Deflection.

From www.newschoolers.com

Cant adjust belt deflection Gear Talk What Is Belt Deflection In order to ensure a long and efficient belt operation, you must properly learn how to. It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. Deflection refers to the distance the belt sags or deflects when a force is applied perpendicular to it. Incorrect belt deflection can lead. What Is Belt Deflection.

From www.rzrforums.net

Rzr xp1000 belt deflection Polaris RZR Forum RZR What Is Belt Deflection Select from the dropdown options below to find the appropriate belt tension for. To measure belt deflection, use a belt deflection tool or a ruler to. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. The number one cause of a power transmission belt failure is improper tensioning. Proper belt tension ensures optimum performance. What Is Belt Deflection.

From www.winparts.eu

Deflection/Guide Pulley, vribbed belt Winparts.eu Belt tensioner What Is Belt Deflection It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. In order to ensure a long and efficient belt operation, you must properly learn how to. The number one cause of a power transmission belt failure is improper tensioning. Deflection refers to the distance the belt sags or deflects. What Is Belt Deflection.

From www.youtube.com

BELT DEFLECTION EXPLANATION AND HOW TO ADJUST! ALSO WHAT DOES WHAT What Is Belt Deflection Select from the dropdown options below to find the appropriate belt tension for. The number one cause of a power transmission belt failure is improper tensioning. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. To measure belt deflection, use a belt deflection tool or a ruler to. Measure the belt span length and. What Is Belt Deflection.

From www.researchgate.net

(PDF) Investigation of the dynamic deflection of conveyor belts via What Is Belt Deflection Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. To measure belt deflection, use a belt deflection tool or a ruler to. Deflection refers to the distance the belt sags or deflects when a force is applied perpendicular to it. Select from the dropdown options below to find the appropriate belt tension for. It. What Is Belt Deflection.

From www.youtube.com

Belt deflection, belt alignment, chalking the clutch. With and without What Is Belt Deflection It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. In order to ensure a long and efficient belt operation, you. What Is Belt Deflection.

From www.esmagazine.com

Reliable VBelt Drive Operation 20170602 Engineered Systems Magazine What Is Belt Deflection Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. Select from the dropdown options below to find the appropriate belt tension for. To measure belt deflection, use a belt deflection tool or a ruler to. The number one cause of a power transmission belt failure is improper tensioning. Deflection refers to the distance the. What Is Belt Deflection.

From www.kmotorshop.com

Deflection/Guide Pulley, Vribbed belt RNKVW004 NTY 028145278A What Is Belt Deflection Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. The number one cause of a power transmission belt failure is improper tensioning. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. It is normally used to tension drives using banded belts that require a deflection force beyond the. What Is Belt Deflection.

From ubicaciondepersonas.cdmx.gob.mx

Belt Deflection Belt Tension Chart ubicaciondepersonas.cdmx.gob.mx What Is Belt Deflection Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. To measure belt deflection, use a belt deflection tool or a ruler to. In order to ensure a long and efficient belt operation, you must properly learn how to. It is normally used to tension drives using banded belts that require a deflection force beyond. What Is Belt Deflection.

From www.tec-science.com

Maximum belt stress in belt drives tecscience What Is Belt Deflection In order to ensure a long and efficient belt operation, you must properly learn how to. To measure belt deflection, use a belt deflection tool or a ruler to. Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. Deflection refers to the distance the belt sags or deflects when a force is applied perpendicular to it.. What Is Belt Deflection.

From 2003gizmo.blogspot.com

Gizmo Broken Belt and Proper Tension What Is Belt Deflection To measure belt deflection, use a belt deflection tool or a ruler to. It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. Deflection refers to the distance the belt sags or deflects when. What Is Belt Deflection.

From labbyag.es

V Belt Deflection Chart Labb by AG What Is Belt Deflection Deflection refers to the distance the belt sags or deflects when a force is applied perpendicular to it. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. Select from the dropdown options below to find the appropriate belt tension for. Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. The. What Is Belt Deflection.

From www.numerade.com

SOLVED The figure shows a steel shaft mounted in bearings at A and D What Is Belt Deflection Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. Deflection refers to the distance the belt sags or deflects when a force is applied perpendicular to it. Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. Measure the belt span length and calculate the desired deflection distance (1/64” per inch. What Is Belt Deflection.

From ubicaciondepersonas.cdmx.gob.mx

Belt Deflection Belt Tension Chart ubicaciondepersonas.cdmx.gob.mx What Is Belt Deflection To measure belt deflection, use a belt deflection tool or a ruler to. Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. Select from the dropdown options below to find the appropriate belt tension for. Deflection refers to the distance the. What Is Belt Deflection.

From www.scribd.com

Belt Tension Deflection Table Belt (Mechanical) Manufactured Goods What Is Belt Deflection Deflection refers to the distance the belt sags or deflects when a force is applied perpendicular to it. In order to ensure a long and efficient belt operation, you must properly learn how to. Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. It is normally used to tension drives using banded belts that. What Is Belt Deflection.

From blog.amsoil.com

How to Adjust Snowmobile Belt Deflection AMSOIL Blog What Is Belt Deflection Select from the dropdown options below to find the appropriate belt tension for. In order to ensure a long and efficient belt operation, you must properly learn how to. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. To measure belt deflection, use a belt deflection tool or a ruler to. Proper belt tension. What Is Belt Deflection.

From www.youtube.com

Elastic Axial Deformation Finding Forces & Deflections in Multi What Is Belt Deflection In order to ensure a long and efficient belt operation, you must properly learn how to. It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. Deflection refers to the distance the belt sags. What Is Belt Deflection.

From www.youtube.com

Recap of Deflection & Slope YouTube What Is Belt Deflection It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. To measure belt deflection, use a belt deflection tool or a ruler to. Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. The number one cause of a power transmission belt failure is. What Is Belt Deflection.

From www.numerade.com

SOLVED Consider the round steel shaft below that has a transverse belt What Is Belt Deflection The number one cause of a power transmission belt failure is improper tensioning. Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. It is normally used to tension drives using banded belts that require a deflection force beyond the range of. What Is Belt Deflection.

From www.chegg.com

Solved Required information Use the general shaft layout What Is Belt Deflection It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. The number one cause of a power transmission belt failure is improper tensioning. In order to ensure a long and efficient belt operation, you must properly learn how to. Incorrect belt deflection can lead to belt slippage or excessive. What Is Belt Deflection.

From engineeringdiscoveries.com

How To Apply Conjugate Beam Method For Beam Rotations And Deflections What Is Belt Deflection It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. Measure the belt span length and calculate the desired deflection distance (1/64” per inch of. Incorrect belt deflection can lead to belt slippage or excessive tension, causing premature belt wear. Proper belt tension ensures optimum performance of a vehicle's. What Is Belt Deflection.

From teganburrows.z19.web.core.windows.net

V Belt Calculation Pdf What Is Belt Deflection Select from the dropdown options below to find the appropriate belt tension for. It is normally used to tension drives using banded belts that require a deflection force beyond the range of conventional equipment. Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. Deflection refers to the distance the belt sags or deflects when a force. What Is Belt Deflection.