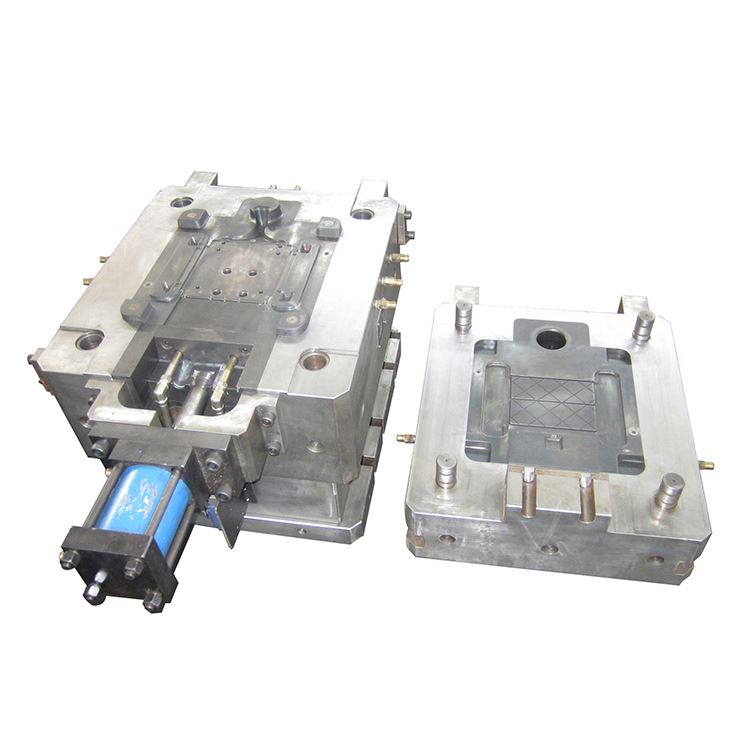

Die Casting Mold . Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements. Die casting is a process in which molten material is poured or forced into a mold cavity. The die casting mold is a vital part of the process, giving parts their desired features. Molten metal is poured or injected into. In gdc, molten metal is poured into the mould using gravity. This mold is designed to match. Learn how to design molds for die casting metal products with high precision and efficiency. The process begins with creating a mold, also known as a die, typically made from hardened steel. This negative shape approach is identical in principle to all molding and casting. Die casting is a metal casting process that uses metal dies to create metal parts. Here’s an article to introduce die casting mold. There are two main types of this process: Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. Gravity die casting (gdc) and pressure die casting (pdc).

from moldie.net

There are two main types of this process: Die casting is a process in which molten material is poured or forced into a mold cavity. The process begins with creating a mold, also known as a die, typically made from hardened steel. Die casting is a metal casting process that uses metal dies to create metal parts. Molten metal is poured or injected into. Gravity die casting (gdc) and pressure die casting (pdc). Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements. Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. In gdc, molten metal is poured into the mould using gravity. This negative shape approach is identical in principle to all molding and casting.

Die Casting Mold Design, Development and Production process Moldie

Die Casting Mold Molten metal is poured or injected into. Gravity die casting (gdc) and pressure die casting (pdc). Here’s an article to introduce die casting mold. Die casting is a process in which molten material is poured or forced into a mold cavity. In gdc, molten metal is poured into the mould using gravity. This negative shape approach is identical in principle to all molding and casting. Molten metal is poured or injected into. The die casting mold is a vital part of the process, giving parts their desired features. Learn how to design molds for die casting metal products with high precision and efficiency. Die casting is a metal casting process that uses metal dies to create metal parts. Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. There are two main types of this process: The process begins with creating a mold, also known as a die, typically made from hardened steel. This mold is designed to match. Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements.

From

Die Casting Mold Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements. There are two main types of this process: Die casting is a metal casting process that uses metal dies to create. Die Casting Mold.

From www.diecasting-mould.com

Die Casting Mold Manufacturer & Supplier Mold Making Service Junying Die Casting Mold The process begins with creating a mold, also known as a die, typically made from hardened steel. This mold is designed to match. Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements. Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed. Die Casting Mold.

From

Die Casting Mold Molten metal is poured or injected into. This negative shape approach is identical in principle to all molding and casting. Here’s an article to introduce die casting mold. Learn how to design molds for die casting metal products with high precision and efficiency. Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and. Die Casting Mold.

From blog.faradars.org

دایکاست چیست ؟ — دانستنی های مهم درباره ریخته گری تحت فشار فرادرس مجله Die Casting Mold Gravity die casting (gdc) and pressure die casting (pdc). In gdc, molten metal is poured into the mould using gravity. Learn how to design molds for die casting metal products with high precision and efficiency. There are two main types of this process: The process begins with creating a mold, also known as a die, typically made from hardened steel.. Die Casting Mold.

From

Die Casting Mold Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. This mold is designed to match. Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements. Learn how to design molds for die casting metal products with high precision and efficiency.. Die Casting Mold.

From

Die Casting Mold This mold is designed to match. Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements. The process begins with creating a mold, also known as a die, typically made from hardened steel. Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed. Die Casting Mold.

From

Die Casting Mold There are two main types of this process: Learn how to design molds for die casting metal products with high precision and efficiency. Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. Here’s an article to introduce die casting mold. Explore the key steps, factors, and techniques involved. Die Casting Mold.

From

Die Casting Mold Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements. Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. The process begins with creating a mold, also known as a die, typically made from hardened steel. This negative shape approach. Die Casting Mold.

From

Die Casting Mold The die casting mold is a vital part of the process, giving parts their desired features. Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements. Here’s an article to introduce die casting mold. Die casting is a metal casting process that uses metal dies to create metal parts. Die casting is. Die Casting Mold.

From insightsolutionsglobal.com

Die Casting Possible Manufacturing Problems and Their Fixes Insight Die Casting Mold Gravity die casting (gdc) and pressure die casting (pdc). Here’s an article to introduce die casting mold. In gdc, molten metal is poured into the mould using gravity. This negative shape approach is identical in principle to all molding and casting. Die casting is a process in which molten material is poured or forced into a mold cavity. Explore the. Die Casting Mold.

From www.indiamart.com

8x10 Inch Aluminum Pressure Die Casting Mould at Rs 140000 Goregaon Die Casting Mold Here’s an article to introduce die casting mold. Gravity die casting (gdc) and pressure die casting (pdc). The process begins with creating a mold, also known as a die, typically made from hardened steel. Die casting is a process in which molten material is poured or forced into a mold cavity. In gdc, molten metal is poured into the mould. Die Casting Mold.

From

Die Casting Mold The die casting mold is a vital part of the process, giving parts their desired features. Gravity die casting (gdc) and pressure die casting (pdc). The process begins with creating a mold, also known as a die, typically made from hardened steel. Die casting is a permanent mould casting process in which molten metal is poured into a mould and. Die Casting Mold.

From

Die Casting Mold Learn how to design molds for die casting metal products with high precision and efficiency. The die casting mold is a vital part of the process, giving parts their desired features. The process begins with creating a mold, also known as a die, typically made from hardened steel. Die casting is a permanent mould casting process in which molten metal. Die Casting Mold.

From

Die Casting Mold This negative shape approach is identical in principle to all molding and casting. In gdc, molten metal is poured into the mould using gravity. Die casting is a process in which molten material is poured or forced into a mold cavity. The process begins with creating a mold, also known as a die, typically made from hardened steel. Explore the. Die Casting Mold.

From www.chinametalcastings.com

Die casting mold Aluminum & Zinc Die casting China Die Casting Mold There are two main types of this process: In gdc, molten metal is poured into the mould using gravity. Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. This negative shape approach is identical in principle to all molding and casting. Molten metal is poured or injected into.. Die Casting Mold.

From

Die Casting Mold Die casting is a metal casting process that uses metal dies to create metal parts. In gdc, molten metal is poured into the mould using gravity. There are two main types of this process: Here’s an article to introduce die casting mold. Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements.. Die Casting Mold.

From

Die Casting Mold Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements. Here’s an article to introduce die casting mold. In gdc, molten metal is poured into the mould using gravity. The process begins with creating a mold, also known as a die, typically made from hardened steel. This negative shape approach is identical. Die Casting Mold.

From pacdiecast.com

Die Casting Mold Design & Fabrication Mold Making Die Casting Mold Die casting is a metal casting process that uses metal dies to create metal parts. There are two main types of this process: Here’s an article to introduce die casting mold. In gdc, molten metal is poured into the mould using gravity. The die casting mold is a vital part of the process, giving parts their desired features. This negative. Die Casting Mold.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Die Casting Mold Gravity die casting (gdc) and pressure die casting (pdc). Die casting is a metal casting process that uses metal dies to create metal parts. Learn how to design molds for die casting metal products with high precision and efficiency. Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements. There are two. Die Casting Mold.

From www.themouldinfo.com

Aluminum Die Casting Mold /Die Casting Mold Mould Products, Mould Die Casting Mold There are two main types of this process: In gdc, molten metal is poured into the mould using gravity. Molten metal is poured or injected into. Learn how to design molds for die casting metal products with high precision and efficiency. The process begins with creating a mold, also known as a die, typically made from hardened steel. Gravity die. Die Casting Mold.

From

Die Casting Mold The process begins with creating a mold, also known as a die, typically made from hardened steel. Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements. Molten metal is poured or injected into. Gravity die casting (gdc) and pressure die casting (pdc). Die casting is a metal casting process that uses. Die Casting Mold.

From www.inoxcast.com

Die Casting Mold Parts Manufacturer and Supplier Inox Cast Die Casting Mold This mold is designed to match. Learn how to design molds for die casting metal products with high precision and efficiency. There are two main types of this process: In gdc, molten metal is poured into the mould using gravity. Here’s an article to introduce die casting mold. Explore the key steps, factors, and techniques involved in creating molds that. Die Casting Mold.

From www.gang-mould.com

High Precision Rubber Mold Mould Die Casting Mold In gdc, molten metal is poured into the mould using gravity. This negative shape approach is identical in principle to all molding and casting. This mold is designed to match. Here’s an article to introduce die casting mold. Molten metal is poured or injected into. There are two main types of this process: Die casting is a metal casting process. Die Casting Mold.

From

Die Casting Mold This negative shape approach is identical in principle to all molding and casting. Die casting is a metal casting process that uses metal dies to create metal parts. The die casting mold is a vital part of the process, giving parts their desired features. This mold is designed to match. Die casting is a process in which molten material is. Die Casting Mold.

From

Die Casting Mold There are two main types of this process: Here’s an article to introduce die casting mold. Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements. Die casting is a process in which molten material is poured or forced into a mold cavity. Gravity die casting (gdc) and pressure die casting (pdc).. Die Casting Mold.

From

Die Casting Mold Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. This negative shape approach is identical in principle to all molding and casting. The die casting mold is a vital part of the process, giving parts their desired features. The process begins with creating a mold, also known as. Die Casting Mold.

From

Die Casting Mold Die casting is a process in which molten material is poured or forced into a mold cavity. Die casting is a metal casting process that uses metal dies to create metal parts. Molten metal is poured or injected into. This mold is designed to match. Gravity die casting (gdc) and pressure die casting (pdc). In gdc, molten metal is poured. Die Casting Mold.

From

Die Casting Mold The process begins with creating a mold, also known as a die, typically made from hardened steel. Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. Learn how to design molds for die casting metal products with high precision and efficiency. There are two main types of this. Die Casting Mold.

From

Die Casting Mold The process begins with creating a mold, also known as a die, typically made from hardened steel. This mold is designed to match. Gravity die casting (gdc) and pressure die casting (pdc). In gdc, molten metal is poured into the mould using gravity. Learn how to design molds for die casting metal products with high precision and efficiency. Die casting. Die Casting Mold.

From www.gabrian.com

What is Aluminum Die Casting? 5 Things You Need to Know Die Casting Mold Gravity die casting (gdc) and pressure die casting (pdc). Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. Die casting is a process in which molten material is poured or forced into a mold cavity. This mold is designed to match. The process begins with creating a mold,. Die Casting Mold.

From

Die Casting Mold In gdc, molten metal is poured into the mould using gravity. Explore the key steps, factors, and techniques involved in creating molds that meet the desired specifications and requirements. This mold is designed to match. There are two main types of this process: Die casting is a metal casting process that uses metal dies to create metal parts. Here’s an. Die Casting Mold.

From www.indiamart.com

Pressure Die Casting Mold at Rs 125000/set Casting Mould in Ludhiana Die Casting Mold Gravity die casting (gdc) and pressure die casting (pdc). Molten metal is poured or injected into. Die casting is a metal casting process that uses metal dies to create metal parts. There are two main types of this process: The process begins with creating a mold, also known as a die, typically made from hardened steel. The die casting mold. Die Casting Mold.

From

Die Casting Mold This mold is designed to match. The die casting mold is a vital part of the process, giving parts their desired features. Die casting is a metal casting process that uses metal dies to create metal parts. Molten metal is poured or injected into. Die casting is a permanent mould casting process in which molten metal is poured into a. Die Casting Mold.

From

Die Casting Mold Die casting is a permanent mould casting process in which molten metal is poured into a mould and removed after solidification. The process begins with creating a mold, also known as a die, typically made from hardened steel. This mold is designed to match. In gdc, molten metal is poured into the mould using gravity. Die casting is a metal. Die Casting Mold.

From hongyumolds.com

Die Casting Mold Hongyu Molds Die Casting Mold The die casting mold is a vital part of the process, giving parts their desired features. In gdc, molten metal is poured into the mould using gravity. Die casting is a process in which molten material is poured or forced into a mold cavity. Die casting is a permanent mould casting process in which molten metal is poured into a. Die Casting Mold.