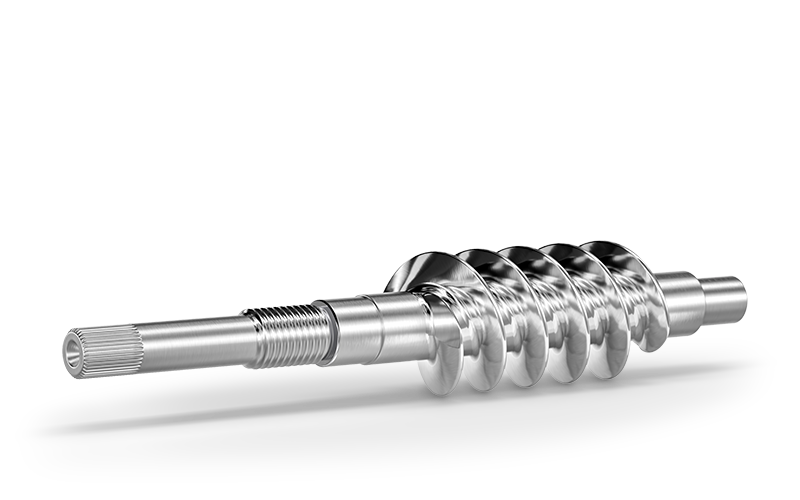

Worm Shaft Tool . That is a type of mechanical power transmission device. worms and worm gears can be mounted on a hub or shaft. by machining the worm to finished tolerances and surface roughness using the whirling process and then induction. worms are produced either as an integral part of a shaft or they are produced with a bore in order to be fixed to. The worm gear and the worm wheel. A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for the provision of a screw or other shaft attachment mechanism. whirling is a fast method of producing worms: Leistritz offers a complete line of cnc whirling machines. worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle. A toolholder ring, carrying a series of profiled carbide cutters, is set eccentric to the. worm gear machines for reduced maintenance. It consists of two primary components: Hubless gears are typically attached via press fit, adhesive or internal keyway. a worm gearbox, also known as a worm gear reducer or worm drive. That enables the transfer of rotational motion.

from www.cwbearing.com

A toolholder ring, carrying a series of profiled carbide cutters, is set eccentric to the. whirling is a fast method of producing worms: by machining the worm to finished tolerances and surface roughness using the whirling process and then induction. a worm gearbox, also known as a worm gear reducer or worm drive. Leistritz offers a complete line of cnc whirling machines. That is a type of mechanical power transmission device. It consists of two primary components: worm gear machines for reduced maintenance. The worm gear and the worm wheel. worms are produced either as an integral part of a shaft or they are produced with a bore in order to be fixed to.

Worm shafts CW Bearing

Worm Shaft Tool worm gear machines for reduced maintenance. That enables the transfer of rotational motion. A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for the provision of a screw or other shaft attachment mechanism. by machining the worm to finished tolerances and surface roughness using the whirling process and then induction. Hubless gears are typically attached via press fit, adhesive or internal keyway. worm gear machines for reduced maintenance. That is a type of mechanical power transmission device. a worm gearbox, also known as a worm gear reducer or worm drive. The worm gear and the worm wheel. worms and worm gears can be mounted on a hub or shaft. worms are produced either as an integral part of a shaft or they are produced with a bore in order to be fixed to. Leistritz offers a complete line of cnc whirling machines. whirling is a fast method of producing worms: A toolholder ring, carrying a series of profiled carbide cutters, is set eccentric to the. It consists of two primary components: worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle.

From www.youtube.com

Beginner's Guide to SolidWorksWorm Gear Shaft YouTube Worm Shaft Tool That enables the transfer of rotational motion. The worm gear and the worm wheel. A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for the provision of a screw or other shaft attachment mechanism. worm gear machines for reduced maintenance. Leistritz offers a complete line of cnc whirling machines. . Worm Shaft Tool.

From natoli.com

WORM SHAFT Worm Shaft Tool That is a type of mechanical power transmission device. The worm gear and the worm wheel. worms and worm gears can be mounted on a hub or shaft. Leistritz offers a complete line of cnc whirling machines. It consists of two primary components: worm gear machines for reduced maintenance. A hub is a cylindrical projection on one or. Worm Shaft Tool.

From www.youtube.com

How to Repair Worm shaft easy method YouTube Worm Shaft Tool whirling is a fast method of producing worms: That enables the transfer of rotational motion. a worm gearbox, also known as a worm gear reducer or worm drive. worms and worm gears can be mounted on a hub or shaft. It consists of two primary components: worm gear machines for reduced maintenance. The worm gear and. Worm Shaft Tool.

From www.lsengineers.co.uk

Kit Worm & Main Shaft Fits Belle Maxi 140 Mixer XS40 L&S Engineers Worm Shaft Tool a worm gearbox, also known as a worm gear reducer or worm drive. The worm gear and the worm wheel. A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for the provision of a screw or other shaft attachment mechanism. by machining the worm to finished tolerances and surface. Worm Shaft Tool.

From www.aliexpress.com

Buy Brass Worm Gear Shaft with 6mm Hole Dia & 50 Teeth Worm Shaft Tool a worm gearbox, also known as a worm gear reducer or worm drive. worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle. A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for the provision of a screw or other. Worm Shaft Tool.

From www.dreamstime.com

Worm Shaft in Warehouse, Tool Making in Production Stock Photo Image Worm Shaft Tool whirling is a fast method of producing worms: That is a type of mechanical power transmission device. A toolholder ring, carrying a series of profiled carbide cutters, is set eccentric to the. Leistritz offers a complete line of cnc whirling machines. worms and worm gears can be mounted on a hub or shaft. worm gears use screw. Worm Shaft Tool.

From www.youtube.com

WORM SHAFT MACHINING ON LATHE YouTube Worm Shaft Tool Leistritz offers a complete line of cnc whirling machines. worms and worm gears can be mounted on a hub or shaft. Hubless gears are typically attached via press fit, adhesive or internal keyway. That enables the transfer of rotational motion. A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for. Worm Shaft Tool.

From www.toolsparesonline.com

Tool Spares Online. WORM SHAFT Worm Shaft Tool That is a type of mechanical power transmission device. The worm gear and the worm wheel. Leistritz offers a complete line of cnc whirling machines. worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle. That enables the transfer of rotational motion. worms are produced either as an integral. Worm Shaft Tool.

From www.davenportliftcontrol.com

Tool for inspection of the worm shaft Worm Shaft Tool That is a type of mechanical power transmission device. Leistritz offers a complete line of cnc whirling machines. by machining the worm to finished tolerances and surface roughness using the whirling process and then induction. A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for the provision of a screw. Worm Shaft Tool.

From www.indiamart.com

Worm Shaft at best price in Vitthal Udyognagar by Unique Worm Shaft Tool That is a type of mechanical power transmission device. A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for the provision of a screw or other shaft attachment mechanism. It consists of two primary components: worm gears use screw threads to make large reductions to shaft speed while transmitting motion. Worm Shaft Tool.

From www.dreamstime.com

Worm Shaft in Warehouse, Tool Making in Production Stock Photo Image Worm Shaft Tool a worm gearbox, also known as a worm gear reducer or worm drive. worms are produced either as an integral part of a shaft or they are produced with a bore in order to be fixed to. worms and worm gears can be mounted on a hub or shaft. worm gear machines for reduced maintenance. That. Worm Shaft Tool.

From www.youtube.com

cnc worm shaft cutting machine for sale YouTube Worm Shaft Tool worm gear machines for reduced maintenance. That is a type of mechanical power transmission device. That enables the transfer of rotational motion. whirling is a fast method of producing worms: A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for the provision of a screw or other shaft attachment. Worm Shaft Tool.

From www.youtube.com

amazing high speed Cutting Worm Gear and Gear Hob on My Metal Lathe Worm Shaft Tool A toolholder ring, carrying a series of profiled carbide cutters, is set eccentric to the. That is a type of mechanical power transmission device. Leistritz offers a complete line of cnc whirling machines. Hubless gears are typically attached via press fit, adhesive or internal keyway. a worm gearbox, also known as a worm gear reducer or worm drive. The. Worm Shaft Tool.

From autonetics.com

Worm Shaft Inspection Automated Precision Inspection Worm Shaft Tool Hubless gears are typically attached via press fit, adhesive or internal keyway. That enables the transfer of rotational motion. worms and worm gears can be mounted on a hub or shaft. It consists of two primary components: worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle. worms. Worm Shaft Tool.

From www.diytrade.com

Worm Shaft hardening machine,worm shaft induction quenching machine Worm Shaft Tool whirling is a fast method of producing worms: worm gear machines for reduced maintenance. That is a type of mechanical power transmission device. A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for the provision of a screw or other shaft attachment mechanism. Leistritz offers a complete line of. Worm Shaft Tool.

From njzonghui.en.made-in-china.com

Worm Shaft Motor Worm Shaft and Gear Shaft Worm Shaft Tool A toolholder ring, carrying a series of profiled carbide cutters, is set eccentric to the. a worm gearbox, also known as a worm gear reducer or worm drive. worms and worm gears can be mounted on a hub or shaft. A hub is a cylindrical projection on one or both sides of a worm or worm gear, often. Worm Shaft Tool.

From www.youtube.com

Cutting Worm and Gear Hob on my Emco Maximat V10 Metal Lathe YouTube Worm Shaft Tool A toolholder ring, carrying a series of profiled carbide cutters, is set eccentric to the. worm gear machines for reduced maintenance. That is a type of mechanical power transmission device. a worm gearbox, also known as a worm gear reducer or worm drive. A hub is a cylindrical projection on one or both sides of a worm or. Worm Shaft Tool.

From www.dreamstime.com

Worm Shaft in Warehouse, Tool Making in Production Stock Image Image Worm Shaft Tool A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for the provision of a screw or other shaft attachment mechanism. It consists of two primary components: worm gear machines for reduced maintenance. That enables the transfer of rotational motion. worms and worm gears can be mounted on a hub. Worm Shaft Tool.

From www.precisionmatthews.com

Z5977 Worm shaft Precision Matthews Machinery Co. Worm Shaft Tool A toolholder ring, carrying a series of profiled carbide cutters, is set eccentric to the. worms and worm gears can be mounted on a hub or shaft. worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle. worms are produced either as an integral part of a shaft. Worm Shaft Tool.

From www.hendi.eu

Worm shaft HENDI Tools for Chefs Worm Shaft Tool a worm gearbox, also known as a worm gear reducer or worm drive. Leistritz offers a complete line of cnc whirling machines. The worm gear and the worm wheel. by machining the worm to finished tolerances and surface roughness using the whirling process and then induction. A hub is a cylindrical projection on one or both sides of. Worm Shaft Tool.

From gunnaengineering.com.au

Worm Shaft Gunna Engineering Worm Shaft Tool A toolholder ring, carrying a series of profiled carbide cutters, is set eccentric to the. The worm gear and the worm wheel. whirling is a fast method of producing worms: That is a type of mechanical power transmission device. worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle.. Worm Shaft Tool.

From www.indiamart.com

Mild Steel,Alloy Steel Worm Wheel Shaft at Rs 200 in Ahmedabad ID Worm Shaft Tool It consists of two primary components: Hubless gears are typically attached via press fit, adhesive or internal keyway. worm gear machines for reduced maintenance. The worm gear and the worm wheel. A toolholder ring, carrying a series of profiled carbide cutters, is set eccentric to the. That enables the transfer of rotational motion. That is a type of mechanical. Worm Shaft Tool.

From brobo.com.au

Worm Shaft • Brobo Group Pty Ltd Worm Shaft Tool It consists of two primary components: Hubless gears are typically attached via press fit, adhesive or internal keyway. That enables the transfer of rotational motion. by machining the worm to finished tolerances and surface roughness using the whirling process and then induction. a worm gearbox, also known as a worm gear reducer or worm drive. A toolholder ring,. Worm Shaft Tool.

From www.youtube.com

Worm Shaft Repair, Milling Machine 4 YouTube Worm Shaft Tool That enables the transfer of rotational motion. Hubless gears are typically attached via press fit, adhesive or internal keyway. It consists of two primary components: A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for the provision of a screw or other shaft attachment mechanism. A toolholder ring, carrying a series. Worm Shaft Tool.

From www.malkargears.com

WORM SHAFT Wiper Worm Shaft Exporter from Navi Mumbai Worm Shaft Tool Hubless gears are typically attached via press fit, adhesive or internal keyway. Leistritz offers a complete line of cnc whirling machines. by machining the worm to finished tolerances and surface roughness using the whirling process and then induction. That enables the transfer of rotational motion. worm gears use screw threads to make large reductions to shaft speed while. Worm Shaft Tool.

From sstools.net

Worm Gear Hobs Manufacturers Worm Gear Hobs Suppliers Worm Shaft Tool Leistritz offers a complete line of cnc whirling machines. A toolholder ring, carrying a series of profiled carbide cutters, is set eccentric to the. worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle. The worm gear and the worm wheel. That is a type of mechanical power transmission device.. Worm Shaft Tool.

From www.dreamstime.com

Grinding, Sharpening and Machining of the Worm Shaft on a Turning Worm Shaft Tool worms are produced either as an integral part of a shaft or they are produced with a bore in order to be fixed to. A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for the provision of a screw or other shaft attachment mechanism. The worm gear and the worm. Worm Shaft Tool.

From www.dreamstime.com

Metalworking Industry. Cutting Tool Making Worm Shaft at Metal Working Worm Shaft Tool It consists of two primary components: Leistritz offers a complete line of cnc whirling machines. whirling is a fast method of producing worms: The worm gear and the worm wheel. Hubless gears are typically attached via press fit, adhesive or internal keyway. worm gear machines for reduced maintenance. A toolholder ring, carrying a series of profiled carbide cutters,. Worm Shaft Tool.

From www.dreamstime.com

Grinding, Sharpening and Machining of the Worm Shaft on a Turning Worm Shaft Tool Leistritz offers a complete line of cnc whirling machines. worms and worm gears can be mounted on a hub or shaft. That enables the transfer of rotational motion. The worm gear and the worm wheel. worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle. worms are produced. Worm Shaft Tool.

From www.aliexpress.com

CNBTR 0.5 Modulus Brass Worm Wheel & Worm Gear Shaft Set with 20 Teeth Worm Shaft Tool worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle. The worm gear and the worm wheel. by machining the worm to finished tolerances and surface roughness using the whirling process and then induction. That enables the transfer of rotational motion. worms are produced either as an integral. Worm Shaft Tool.

From www.dreamstime.com

The Worm Shaft after Processing Lies on a Wooden Rack, the Production Worm Shaft Tool The worm gear and the worm wheel. A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for the provision of a screw or other shaft attachment mechanism. worms and worm gears can be mounted on a hub or shaft. worm gear machines for reduced maintenance. worm gears use. Worm Shaft Tool.

From www.practicalmachinist.com

Cutting a worm shaft in the lathe Worm Shaft Tool That is a type of mechanical power transmission device. A hub is a cylindrical projection on one or both sides of a worm or worm gear, often for the provision of a screw or other shaft attachment mechanism. by machining the worm to finished tolerances and surface roughness using the whirling process and then induction. The worm gear and. Worm Shaft Tool.

From www.cwbearing.com

Worm shafts CW Bearing Worm Shaft Tool worms are produced either as an integral part of a shaft or they are produced with a bore in order to be fixed to. worm gear machines for reduced maintenance. That is a type of mechanical power transmission device. Hubless gears are typically attached via press fit, adhesive or internal keyway. whirling is a fast method of. Worm Shaft Tool.

From www.indiamart.com

Polished Worm Shaft Gear at best price in Gondal ID 25899517673 Worm Shaft Tool That is a type of mechanical power transmission device. Hubless gears are typically attached via press fit, adhesive or internal keyway. A toolholder ring, carrying a series of profiled carbide cutters, is set eccentric to the. worms and worm gears can be mounted on a hub or shaft. whirling is a fast method of producing worms: The worm. Worm Shaft Tool.

From www.youtube.com

MAKING A WORM GEAR SHAFT ON LATHE MACHINE YouTube Worm Shaft Tool A toolholder ring, carrying a series of profiled carbide cutters, is set eccentric to the. That is a type of mechanical power transmission device. worm gear machines for reduced maintenance. worms are produced either as an integral part of a shaft or they are produced with a bore in order to be fixed to. It consists of two. Worm Shaft Tool.