Torque Wrench Bolts Cylinder Head . This indispensable tool allows you to apply the exact amount of torque specified by the. the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then. the amount of torque applied to the head bolt accomplishes two things. Proper tightening ensures a secure seal between the cylinder head and the engine block, preventing. torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. First, it overcomes friction between the threads in the block and the bolt. See below for torque specs and sequence. use a quality torque wrench and torque angle gauge.

from www.2carpros.com

use a quality torque wrench and torque angle gauge. torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. the amount of torque applied to the head bolt accomplishes two things. See below for torque specs and sequence. the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. This indispensable tool allows you to apply the exact amount of torque specified by the. First, it overcomes friction between the threads in the block and the bolt. the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then. Proper tightening ensures a secure seal between the cylinder head and the engine block, preventing.

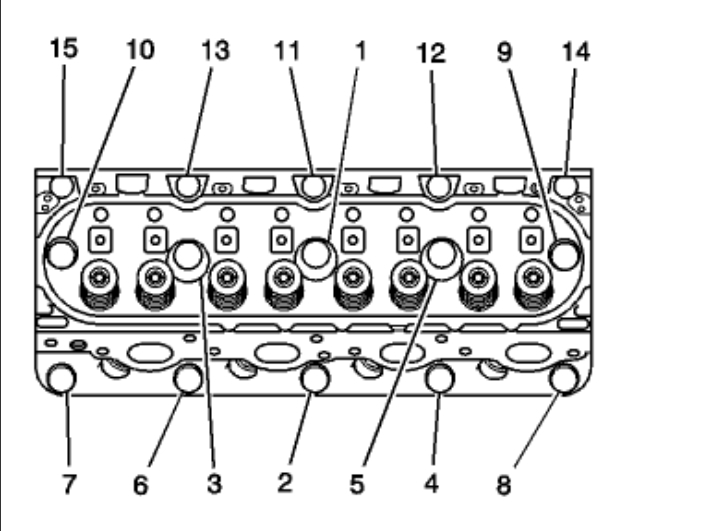

Torque Spec and Sequence for the Head Bolts

Torque Wrench Bolts Cylinder Head torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. the amount of torque applied to the head bolt accomplishes two things. First, it overcomes friction between the threads in the block and the bolt. use a quality torque wrench and torque angle gauge. Proper tightening ensures a secure seal between the cylinder head and the engine block, preventing. See below for torque specs and sequence. the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then. the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. This indispensable tool allows you to apply the exact amount of torque specified by the. torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity.

From www.youtube.com

How to Torque Cylinder Head Bolts, basic cylinder head torque sequence Torque Wrench Bolts Cylinder Head Proper tightening ensures a secure seal between the cylinder head and the engine block, preventing. use a quality torque wrench and torque angle gauge. First, it overcomes friction between the threads in the block and the bolt. torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. See below for torque. Torque Wrench Bolts Cylinder Head.

From mavink.com

Cylinder Head Bolt Torque Chart Torque Wrench Bolts Cylinder Head First, it overcomes friction between the threads in the block and the bolt. use a quality torque wrench and torque angle gauge. the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific. Torque Wrench Bolts Cylinder Head.

From www.2carpros.com

What Are the Cylinder Head Bolt Torque Specifications? Torque Wrench Bolts Cylinder Head the amount of torque applied to the head bolt accomplishes two things. First, it overcomes friction between the threads in the block and the bolt. torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. the torque spec for my tacoma says that cylinder head bolts should be torqued (in. Torque Wrench Bolts Cylinder Head.

From mavink.com

Cylinder Head Bolt Torque Chart Torque Wrench Bolts Cylinder Head use a quality torque wrench and torque angle gauge. See below for torque specs and sequence. the amount of torque applied to the head bolt accomplishes two things. First, it overcomes friction between the threads in the block and the bolt. This indispensable tool allows you to apply the exact amount of torque specified by the. torquing. Torque Wrench Bolts Cylinder Head.

From mavink.com

Cylinder Head Bolt Torque Chart Torque Wrench Bolts Cylinder Head torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. Proper tightening ensures a secure seal between the cylinder head and the engine block, preventing. First, it overcomes friction between the threads in the block and the bolt. See below for torque specs and sequence. the torque spec for my tacoma. Torque Wrench Bolts Cylinder Head.

From www.fixya.com

SOLVED Yamaha cylinder head torque specs and tightening Fixya Torque Wrench Bolts Cylinder Head See below for torque specs and sequence. torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. This indispensable tool allows you to apply the exact amount of torque specified by the. Proper. Torque Wrench Bolts Cylinder Head.

From mavink.com

Cylinder Head Bolt Torque Chart Torque Wrench Bolts Cylinder Head torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially. Torque Wrench Bolts Cylinder Head.

From www.equipmentworld.com

Bolt torque basics Understanding torque wrenches & more Torque Wrench Bolts Cylinder Head torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. Proper tightening ensures a secure seal between the cylinder head and the engine block, preventing. First, it overcomes friction between the threads in. Torque Wrench Bolts Cylinder Head.

From air-componentsinc.com

Torque Wrench Heads Air Components Inc Torque Wrench Bolts Cylinder Head This indispensable tool allows you to apply the exact amount of torque specified by the. the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then. Proper tightening ensures a secure seal between the cylinder head and the engine block, preventing. use a quality torque. Torque Wrench Bolts Cylinder Head.

From www.bikeexif.com

The nuts and bolts of torque Bike EXIF Torque Wrench Bolts Cylinder Head See below for torque specs and sequence. the amount of torque applied to the head bolt accomplishes two things. Proper tightening ensures a secure seal between the cylinder head and the engine block, preventing. the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then.. Torque Wrench Bolts Cylinder Head.

From www.2carpros.com

Torque Setting for Cylinder Head Specs I Need to Know Torque Torque Wrench Bolts Cylinder Head use a quality torque wrench and torque angle gauge. See below for torque specs and sequence. This indispensable tool allows you to apply the exact amount of torque specified by the. First, it overcomes friction between the threads in the block and the bolt. Proper tightening ensures a secure seal between the cylinder head and the engine block, preventing.. Torque Wrench Bolts Cylinder Head.

From diyquickly.com

How to Tighten Cylinder Head Bolts Without Torque Wrench Torque Wrench Bolts Cylinder Head the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then. the amount of torque applied to the head bolt accomplishes two things. See below for torque specs and sequence. First, it overcomes friction between the threads in the block and the bolt. This indispensable. Torque Wrench Bolts Cylinder Head.

From www.alamy.com

The procedure for tightening the cylinder head bolts. Part 5 of 6 Torque Wrench Bolts Cylinder Head Proper tightening ensures a secure seal between the cylinder head and the engine block, preventing. torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. First, it overcomes friction between the threads in. Torque Wrench Bolts Cylinder Head.

From diy-auto-repair.wonderhowto.com

How to Torque cylinder head bolts on a Honda Accord « Auto Maintenance Torque Wrench Bolts Cylinder Head Proper tightening ensures a secure seal between the cylinder head and the engine block, preventing. the amount of torque applied to the head bolt accomplishes two things. This indispensable tool allows you to apply the exact amount of torque specified by the. the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform. Torque Wrench Bolts Cylinder Head.

From www.youtube.com

1GR V6 4.0L Engine Cylinder Head Bolts Torque YouTube Torque Wrench Bolts Cylinder Head torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. use a quality torque wrench and torque angle gauge. First, it overcomes friction between the threads in the block and the bolt. See below for torque specs and sequence. the torque spec for my tacoma says that cylinder head bolts. Torque Wrench Bolts Cylinder Head.

From mavink.com

Cylinder Head Bolt Torque Chart Torque Wrench Bolts Cylinder Head First, it overcomes friction between the threads in the block and the bolt. See below for torque specs and sequence. the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. This indispensable tool allows you to apply the exact amount of torque specified by the. the amount of torque applied. Torque Wrench Bolts Cylinder Head.

From www.2carpros.com

Torque Spec and Sequence for the Head Bolts Torque Wrench Bolts Cylinder Head See below for torque specs and sequence. the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then. First, it overcomes friction between the threads in the block and the bolt. This indispensable tool allows you to apply the exact amount of torque specified by the.. Torque Wrench Bolts Cylinder Head.

From www.youtube.com

EP Tech Tip 3 Torque the Head Bolts YouTube Torque Wrench Bolts Cylinder Head the amount of torque applied to the head bolt accomplishes two things. the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then. First, it overcomes friction between the threads in the block and the bolt. Proper tightening ensures a secure seal between the cylinder. Torque Wrench Bolts Cylinder Head.

From www.youtube.com

Head bolt torque specs and pattern. YouTube Torque Wrench Bolts Cylinder Head See below for torque specs and sequence. the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. First, it overcomes friction between the threads in the block and the bolt. use a quality torque wrench and torque angle gauge. This indispensable tool allows you to apply the exact amount of. Torque Wrench Bolts Cylinder Head.

From automotorpad.com

Nissan cylinder head bolts perma torque Torque Wrench Bolts Cylinder Head the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. First, it overcomes friction between the threads in the block and the bolt. use a quality torque wrench and torque angle gauge.. Torque Wrench Bolts Cylinder Head.

From www.fixya.com

Torque specifications for cylinder head bolts of hr 15 de Fixya Torque Wrench Bolts Cylinder Head the amount of torque applied to the head bolt accomplishes two things. First, it overcomes friction between the threads in the block and the bolt. the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then. the primary reason for torquing cylinder head bolts. Torque Wrench Bolts Cylinder Head.

From www.youtube.com

How To Torque Small Engine Head Bolts Basic Pattern & Info on 3 Long Torque Wrench Bolts Cylinder Head This indispensable tool allows you to apply the exact amount of torque specified by the. the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. First, it overcomes friction between the threads in the block and the bolt. Proper tightening ensures a secure seal between the cylinder head and the engine. Torque Wrench Bolts Cylinder Head.

From truckguider.com

L83 Head Bolt Torque Specs Truck Guider Torque Wrench Bolts Cylinder Head use a quality torque wrench and torque angle gauge. torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. See below for torque specs and sequence. This indispensable tool allows you to apply the exact amount of torque specified by the. the amount of torque applied to the head bolt. Torque Wrench Bolts Cylinder Head.

From www.evolutionm.net

Head bolt torque specs and pattern Torque Wrench Bolts Cylinder Head torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. First, it overcomes friction between the threads in the block and the bolt. the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then. the primary reason. Torque Wrench Bolts Cylinder Head.

From mungfali.com

Cylinder Head Torque Sequence Torque Wrench Bolts Cylinder Head use a quality torque wrench and torque angle gauge. See below for torque specs and sequence. torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. Proper tightening ensures a secure seal between the cylinder head and the engine block, preventing. This indispensable tool allows you to apply the exact amount. Torque Wrench Bolts Cylinder Head.

From torquewrenchguide.com

Can You Use a Torque Wrench to Loosen Bolts? TorqueWrenchGuide Torque Wrench Bolts Cylinder Head First, it overcomes friction between the threads in the block and the bolt. See below for torque specs and sequence. the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then. the amount of torque applied to the head bolt accomplishes two things. use. Torque Wrench Bolts Cylinder Head.

From www.alamy.com

The procedure for tightening the cylinder head bolts. Part 2 of 6. The Torque Wrench Bolts Cylinder Head the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. See below for torque specs and sequence. the amount of torque applied to the head bolt accomplishes two things. First, it overcomes friction between the threads in the block and the bolt. the torque spec for my tacoma says. Torque Wrench Bolts Cylinder Head.

From www.windward.solutions

Torque wrench settings chart Torque Wrench Bolts Cylinder Head This indispensable tool allows you to apply the exact amount of torque specified by the. First, it overcomes friction between the threads in the block and the bolt. See below for torque specs and sequence. the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. torquing cylinder heads is a. Torque Wrench Bolts Cylinder Head.

From diyquickly.com

How to Tighten Cylinder Head Bolts Without Torque Wrench Torque Wrench Bolts Cylinder Head use a quality torque wrench and torque angle gauge. the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. See below for torque specs and sequence. torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. the amount of torque applied. Torque Wrench Bolts Cylinder Head.

From www.alamy.com

The procedure for tightening the cylinder head bolts. Part 6 of 6 Torque Wrench Bolts Cylinder Head torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine performance and longevity. the amount of torque applied to the head bolt accomplishes two things. the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then. Proper tightening ensures a. Torque Wrench Bolts Cylinder Head.

From www.youtube.com

How To Torque Cylinder Head Bolts YouTube Torque Wrench Bolts Cylinder Head the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then. Proper tightening ensures a secure seal between the cylinder head and the engine block, preventing. use a quality torque wrench and torque angle gauge. First, it overcomes friction between the threads in the block. Torque Wrench Bolts Cylinder Head.

From www.youtube.com

How to use a Torque Wrench YouTube Torque Wrench Bolts Cylinder Head the primary reason for torquing cylinder head bolts in a predefined sequence is to ensure uniform bolt loading. This indispensable tool allows you to apply the exact amount of torque specified by the. See below for torque specs and sequence. Proper tightening ensures a secure seal between the cylinder head and the engine block, preventing. the amount of. Torque Wrench Bolts Cylinder Head.

From caterpillarinformation.blogspot.com

2.0 Best Practice Description Torque Wrench Bolts Cylinder Head This indispensable tool allows you to apply the exact amount of torque specified by the. the amount of torque applied to the head bolt accomplishes two things. First, it overcomes friction between the threads in the block and the bolt. the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence). Torque Wrench Bolts Cylinder Head.

From mavink.com

Cylinder Head Bolt Torque Chart Torque Wrench Bolts Cylinder Head the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then. the amount of torque applied to the head bolt accomplishes two things. See below for torque specs and sequence. torquing cylinder heads is a crucial step in engine assembly that ensures optimal engine. Torque Wrench Bolts Cylinder Head.

From www.automobilecars.in

Hyundai Verna 1.6 CRDi Cylinder Head Bolt Tightening Torque and Torque Wrench Bolts Cylinder Head the torque spec for my tacoma says that cylinder head bolts should be torqued (in a specific sequence) to 27 ft/lbs initially and then. use a quality torque wrench and torque angle gauge. This indispensable tool allows you to apply the exact amount of torque specified by the. the amount of torque applied to the head bolt. Torque Wrench Bolts Cylinder Head.