Why Dual Mass Flywheel . With the same or even less installation space available, the classic torsion damper has proved inadequate to outbalance constantly increasing. The other works with the clutch and transmission. To save money and increase performance. A dual mass flywheel works by connecting two flywheels, connected by springs and complex machinery, to allow them to work independently from each other to absorb impact and vibrations from an engine that is in operation. There are two main reasons people convert to a single mass flywheel; The dual mass flywheel sits between the engine and the drivetrain, and is designed to stop the vibrations from the engine getting as far as the. One efficient and cost effective solution to reduce the rotational (torsional) vibrations is to use a dmf, which is the abbreviation for dual mass flywheel. While it might appear as if the flywheel on a running engine rotates at a constant angular speed, it does not actually do so, since. One flywheel is linked to the crankshaft. If their dual mass flywheel goes out, it can be much cheaper to replace it with a single mass. The component protects the driveline from such. The dual mass flywheel (dmf) is a. Why are dual mass flywheels required? Why convert to a single mass flywheel from a dual mass one?

from www.brakeandfrontend.com

If their dual mass flywheel goes out, it can be much cheaper to replace it with a single mass. Why are dual mass flywheels required? While it might appear as if the flywheel on a running engine rotates at a constant angular speed, it does not actually do so, since. One efficient and cost effective solution to reduce the rotational (torsional) vibrations is to use a dmf, which is the abbreviation for dual mass flywheel. The other works with the clutch and transmission. To save money and increase performance. The component protects the driveline from such. There are two main reasons people convert to a single mass flywheel; The dual mass flywheel (dmf) is a. One flywheel is linked to the crankshaft.

VIDEO How DualMass Flywheels Smooth Vibrations

Why Dual Mass Flywheel One flywheel is linked to the crankshaft. The other works with the clutch and transmission. While it might appear as if the flywheel on a running engine rotates at a constant angular speed, it does not actually do so, since. If their dual mass flywheel goes out, it can be much cheaper to replace it with a single mass. One efficient and cost effective solution to reduce the rotational (torsional) vibrations is to use a dmf, which is the abbreviation for dual mass flywheel. Why convert to a single mass flywheel from a dual mass one? Why are dual mass flywheels required? With the same or even less installation space available, the classic torsion damper has proved inadequate to outbalance constantly increasing. The dual mass flywheel sits between the engine and the drivetrain, and is designed to stop the vibrations from the engine getting as far as the. The dual mass flywheel (dmf) is a. To save money and increase performance. The component protects the driveline from such. There are two main reasons people convert to a single mass flywheel; A dual mass flywheel works by connecting two flywheels, connected by springs and complex machinery, to allow them to work independently from each other to absorb impact and vibrations from an engine that is in operation. One flywheel is linked to the crankshaft.

From www.automotivepowertraintechnologyinternational.com

Dualmass flywheels versus solid and dualmass flywheel conversions Why Dual Mass Flywheel There are two main reasons people convert to a single mass flywheel; To save money and increase performance. The dual mass flywheel (dmf) is a. The component protects the driveline from such. A dual mass flywheel works by connecting two flywheels, connected by springs and complex machinery, to allow them to work independently from each other to absorb impact and. Why Dual Mass Flywheel.

From www.youtube.com

Dual Mass Flywheel Design & Operation YouTube Why Dual Mass Flywheel The other works with the clutch and transmission. A dual mass flywheel works by connecting two flywheels, connected by springs and complex machinery, to allow them to work independently from each other to absorb impact and vibrations from an engine that is in operation. One flywheel is linked to the crankshaft. To save money and increase performance. Why convert to. Why Dual Mass Flywheel.

From innovationdiscoveries.space

Flywheel problems, symptoms, and repairs Why Dual Mass Flywheel Why convert to a single mass flywheel from a dual mass one? If their dual mass flywheel goes out, it can be much cheaper to replace it with a single mass. There are two main reasons people convert to a single mass flywheel; Why are dual mass flywheels required? While it might appear as if the flywheel on a running. Why Dual Mass Flywheel.

From www.researchgate.net

Schematic diagram of basic dual mass flywheel (DMF). 1 primary Why Dual Mass Flywheel If their dual mass flywheel goes out, it can be much cheaper to replace it with a single mass. Why are dual mass flywheels required? While it might appear as if the flywheel on a running engine rotates at a constant angular speed, it does not actually do so, since. There are two main reasons people convert to a single. Why Dual Mass Flywheel.

From www.my-cardictionary.com

Dualmass flywheel Why Dual Mass Flywheel Why are dual mass flywheels required? To save money and increase performance. The component protects the driveline from such. There are two main reasons people convert to a single mass flywheel; If their dual mass flywheel goes out, it can be much cheaper to replace it with a single mass. A dual mass flywheel works by connecting two flywheels, connected. Why Dual Mass Flywheel.

From www.theengineer.co.uk

Promoted content What is a Dual Mass Flywheel and how does it work? Why Dual Mass Flywheel The component protects the driveline from such. One efficient and cost effective solution to reduce the rotational (torsional) vibrations is to use a dmf, which is the abbreviation for dual mass flywheel. To save money and increase performance. The dual mass flywheel (dmf) is a. With the same or even less installation space available, the classic torsion damper has proved. Why Dual Mass Flywheel.

From www.carid.com

LuK® DMF074 Dual Mass Flywheel Why Dual Mass Flywheel There are two main reasons people convert to a single mass flywheel; The component protects the driveline from such. A dual mass flywheel works by connecting two flywheels, connected by springs and complex machinery, to allow them to work independently from each other to absorb impact and vibrations from an engine that is in operation. The dual mass flywheel (dmf). Why Dual Mass Flywheel.

From www.amsautomotive.com

Dual Mass Flywheels AMS Why Dual Mass Flywheel Why are dual mass flywheels required? While it might appear as if the flywheel on a running engine rotates at a constant angular speed, it does not actually do so, since. There are two main reasons people convert to a single mass flywheel; The dual mass flywheel (dmf) is a. A dual mass flywheel works by connecting two flywheels, connected. Why Dual Mass Flywheel.

From alfaworkshop.co.uk

Dual mass flywheels what they are for and how they work Why Dual Mass Flywheel The other works with the clutch and transmission. To save money and increase performance. The dual mass flywheel sits between the engine and the drivetrain, and is designed to stop the vibrations from the engine getting as far as the. Why convert to a single mass flywheel from a dual mass one? The component protects the driveline from such. While. Why Dual Mass Flywheel.

From blog.japanesecartrade.com

What is a DualMass Flywheel? Why Dual Mass Flywheel The component protects the driveline from such. The dual mass flywheel (dmf) is a. Why convert to a single mass flywheel from a dual mass one? The dual mass flywheel sits between the engine and the drivetrain, and is designed to stop the vibrations from the engine getting as far as the. There are two main reasons people convert to. Why Dual Mass Flywheel.

From www.researchgate.net

Dual mass flywheel (DMF)[4] Download Scientific Diagram Why Dual Mass Flywheel Why convert to a single mass flywheel from a dual mass one? One flywheel is linked to the crankshaft. With the same or even less installation space available, the classic torsion damper has proved inadequate to outbalance constantly increasing. The component protects the driveline from such. One efficient and cost effective solution to reduce the rotational (torsional) vibrations is to. Why Dual Mass Flywheel.

From www.brakeandfrontend.com

VIDEO How DualMass Flywheels Smooth Vibrations Why Dual Mass Flywheel One efficient and cost effective solution to reduce the rotational (torsional) vibrations is to use a dmf, which is the abbreviation for dual mass flywheel. The other works with the clutch and transmission. If their dual mass flywheel goes out, it can be much cheaper to replace it with a single mass. There are two main reasons people convert to. Why Dual Mass Flywheel.

From www.taziparts.com

Dual Mass Flywheel VS Single Mass Flywheel Dual Mass Why Dual Mass Flywheel Why are dual mass flywheels required? The component protects the driveline from such. Why convert to a single mass flywheel from a dual mass one? The other works with the clutch and transmission. The dual mass flywheel sits between the engine and the drivetrain, and is designed to stop the vibrations from the engine getting as far as the. A. Why Dual Mass Flywheel.

From x-engineer.org

Dual Mass Flywheel (DMF) Why Dual Mass Flywheel The dual mass flywheel (dmf) is a. The dual mass flywheel sits between the engine and the drivetrain, and is designed to stop the vibrations from the engine getting as far as the. To save money and increase performance. A dual mass flywheel works by connecting two flywheels, connected by springs and complex machinery, to allow them to work independently. Why Dual Mass Flywheel.

From www.youtube.com

How Does A Dual Mass Flywheel Work? DMF Explained In 90 Seconds YouTube Why Dual Mass Flywheel If their dual mass flywheel goes out, it can be much cheaper to replace it with a single mass. With the same or even less installation space available, the classic torsion damper has proved inadequate to outbalance constantly increasing. The other works with the clutch and transmission. A dual mass flywheel works by connecting two flywheels, connected by springs and. Why Dual Mass Flywheel.

From www.parkers.co.uk

What is a DMF (dual mass flywheel)? Parkers Why Dual Mass Flywheel While it might appear as if the flywheel on a running engine rotates at a constant angular speed, it does not actually do so, since. One efficient and cost effective solution to reduce the rotational (torsional) vibrations is to use a dmf, which is the abbreviation for dual mass flywheel. There are two main reasons people convert to a single. Why Dual Mass Flywheel.

From x-engineer.org

Dual Mass Flywheel (DMF) Page 2 Why Dual Mass Flywheel To save money and increase performance. Why are dual mass flywheels required? The other works with the clutch and transmission. While it might appear as if the flywheel on a running engine rotates at a constant angular speed, it does not actually do so, since. If their dual mass flywheel goes out, it can be much cheaper to replace it. Why Dual Mass Flywheel.

From x-engineer.org

Dual Mass Flywheel (DMF) Why Dual Mass Flywheel One flywheel is linked to the crankshaft. If their dual mass flywheel goes out, it can be much cheaper to replace it with a single mass. The dual mass flywheel (dmf) is a. There are two main reasons people convert to a single mass flywheel; The dual mass flywheel sits between the engine and the drivetrain, and is designed to. Why Dual Mass Flywheel.

From humblemechanic.com

How VW Dual Mass Flywheels Fail Video Humble Mechanic Why Dual Mass Flywheel While it might appear as if the flywheel on a running engine rotates at a constant angular speed, it does not actually do so, since. If their dual mass flywheel goes out, it can be much cheaper to replace it with a single mass. One efficient and cost effective solution to reduce the rotational (torsional) vibrations is to use a. Why Dual Mass Flywheel.

From www.carid.com

LuK® Dual Mass Flywheel Why Dual Mass Flywheel With the same or even less installation space available, the classic torsion damper has proved inadequate to outbalance constantly increasing. The component protects the driveline from such. A dual mass flywheel works by connecting two flywheels, connected by springs and complex machinery, to allow them to work independently from each other to absorb impact and vibrations from an engine that. Why Dual Mass Flywheel.

From www.congress-intercultural.eu

Simple Guide To The Dual Mass Flywheel And Why Your Vehicle, 60 OFF Why Dual Mass Flywheel The component protects the driveline from such. There are two main reasons people convert to a single mass flywheel; While it might appear as if the flywheel on a running engine rotates at a constant angular speed, it does not actually do so, since. The dual mass flywheel sits between the engine and the drivetrain, and is designed to stop. Why Dual Mass Flywheel.

From www.parkers.co.uk

What is a DMF (dual mass flywheel)? Why Dual Mass Flywheel A dual mass flywheel works by connecting two flywheels, connected by springs and complex machinery, to allow them to work independently from each other to absorb impact and vibrations from an engine that is in operation. One flywheel is linked to the crankshaft. Why convert to a single mass flywheel from a dual mass one? If their dual mass flywheel. Why Dual Mass Flywheel.

From www.halfords.com

LUK Dual Mass Flywheel Halfords UK Why Dual Mass Flywheel Why convert to a single mass flywheel from a dual mass one? While it might appear as if the flywheel on a running engine rotates at a constant angular speed, it does not actually do so, since. The dual mass flywheel (dmf) is a. The component protects the driveline from such. The other works with the clutch and transmission. A. Why Dual Mass Flywheel.

From www.theengineer.co.uk

Promoted content What is a Dual Mass Flywheel and how does it work? Why Dual Mass Flywheel While it might appear as if the flywheel on a running engine rotates at a constant angular speed, it does not actually do so, since. Why convert to a single mass flywheel from a dual mass one? With the same or even less installation space available, the classic torsion damper has proved inadequate to outbalance constantly increasing. The dual mass. Why Dual Mass Flywheel.

From eeuroparts.com

dual mass flywheel eEuroparts Why Dual Mass Flywheel If their dual mass flywheel goes out, it can be much cheaper to replace it with a single mass. Why convert to a single mass flywheel from a dual mass one? The dual mass flywheel (dmf) is a. A dual mass flywheel works by connecting two flywheels, connected by springs and complex machinery, to allow them to work independently from. Why Dual Mass Flywheel.

From en.wikipedia.org

Dualmass flywheel Wikipedia Why Dual Mass Flywheel With the same or even less installation space available, the classic torsion damper has proved inadequate to outbalance constantly increasing. There are two main reasons people convert to a single mass flywheel; One efficient and cost effective solution to reduce the rotational (torsional) vibrations is to use a dmf, which is the abbreviation for dual mass flywheel. Why are dual. Why Dual Mass Flywheel.

From trade.mechanic.com.au

Dual Mass Flywheels Explained Why Dual Mass Flywheel One efficient and cost effective solution to reduce the rotational (torsional) vibrations is to use a dmf, which is the abbreviation for dual mass flywheel. The component protects the driveline from such. The dual mass flywheel (dmf) is a. While it might appear as if the flywheel on a running engine rotates at a constant angular speed, it does not. Why Dual Mass Flywheel.

From blog.japanesecartrade.com

What is a DualMass Flywheel? Why Dual Mass Flywheel With the same or even less installation space available, the classic torsion damper has proved inadequate to outbalance constantly increasing. Why are dual mass flywheels required? A dual mass flywheel works by connecting two flywheels, connected by springs and complex machinery, to allow them to work independently from each other to absorb impact and vibrations from an engine that is. Why Dual Mass Flywheel.

From www.youtube.com

LuK Dual Mass Flywheel Flywheel Movement After Unpacking YouTube Why Dual Mass Flywheel The other works with the clutch and transmission. One flywheel is linked to the crankshaft. With the same or even less installation space available, the classic torsion damper has proved inadequate to outbalance constantly increasing. If their dual mass flywheel goes out, it can be much cheaper to replace it with a single mass. Why convert to a single mass. Why Dual Mass Flywheel.

From exedy.com.au

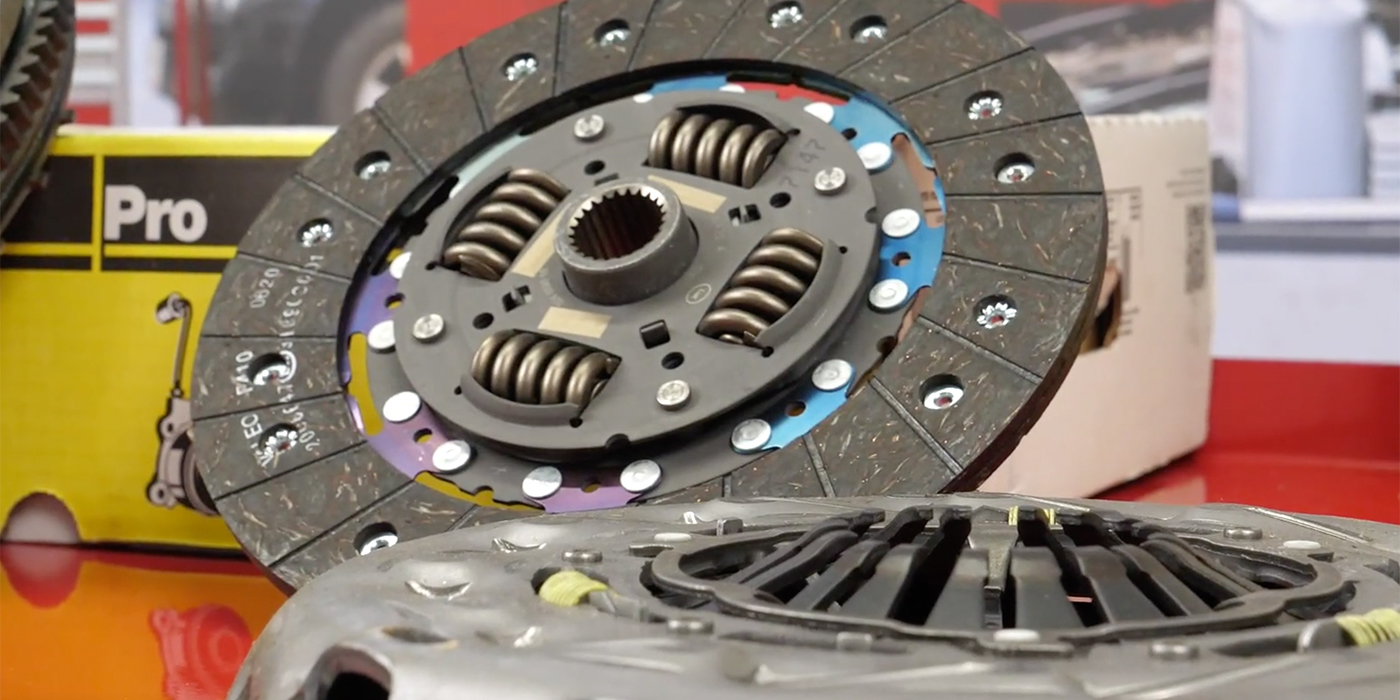

Clutch and Flywheel Dampening image.jpg Why Dual Mass Flywheel While it might appear as if the flywheel on a running engine rotates at a constant angular speed, it does not actually do so, since. One flywheel is linked to the crankshaft. There are two main reasons people convert to a single mass flywheel; The component protects the driveline from such. The dual mass flywheel sits between the engine and. Why Dual Mass Flywheel.

From haynes.com

Simple Guide to the Dual Mass Flywheel and Why Your Vehicle Has One Why Dual Mass Flywheel The other works with the clutch and transmission. If their dual mass flywheel goes out, it can be much cheaper to replace it with a single mass. To save money and increase performance. One flywheel is linked to the crankshaft. The dual mass flywheel sits between the engine and the drivetrain, and is designed to stop the vibrations from the. Why Dual Mass Flywheel.

From www.youtube.com

How To Check Your DMF Dual Mass Flywheel The Correct Way YouTube Why Dual Mass Flywheel One efficient and cost effective solution to reduce the rotational (torsional) vibrations is to use a dmf, which is the abbreviation for dual mass flywheel. Why convert to a single mass flywheel from a dual mass one? One flywheel is linked to the crankshaft. The component protects the driveline from such. There are two main reasons people convert to a. Why Dual Mass Flywheel.

From x-engineer.org

Dual Mass Flywheel (DMF) Why Dual Mass Flywheel Why convert to a single mass flywheel from a dual mass one? The dual mass flywheel sits between the engine and the drivetrain, and is designed to stop the vibrations from the engine getting as far as the. To save money and increase performance. The component protects the driveline from such. While it might appear as if the flywheel on. Why Dual Mass Flywheel.

From www.repxpert.com

Dual Mass Flywheel origins and development Why Dual Mass Flywheel The dual mass flywheel sits between the engine and the drivetrain, and is designed to stop the vibrations from the engine getting as far as the. There are two main reasons people convert to a single mass flywheel; The component protects the driveline from such. The other works with the clutch and transmission. While it might appear as if the. Why Dual Mass Flywheel.

From www.transmissiondigest.com

Installation of DualMass Flywheel Transmission Digest Why Dual Mass Flywheel With the same or even less installation space available, the classic torsion damper has proved inadequate to outbalance constantly increasing. One flywheel is linked to the crankshaft. The component protects the driveline from such. The dual mass flywheel (dmf) is a. A dual mass flywheel works by connecting two flywheels, connected by springs and complex machinery, to allow them to. Why Dual Mass Flywheel.