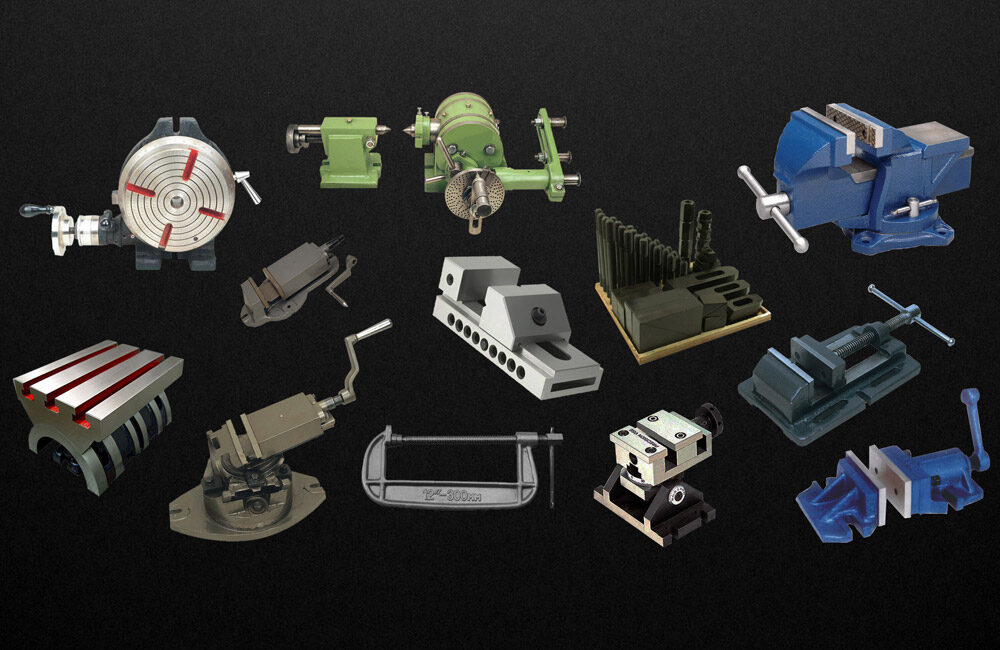

Types Of Holding Devices . Work holding devices in lathe machine. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Three jaws or four jaws? Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Here's everything you need to know about the most important workholding devices in. Types of cutting tool materials and their. Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Each type of device is designed for a specific. There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and fixtures. If the workpiece is not attached.

from www.abmtools.com

Each type of device is designed for a specific. Three jaws or four jaws? Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Work holding devices in lathe machine. If the workpiece is not attached. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Here's everything you need to know about the most important workholding devices in. Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and fixtures.

Work Holding Devices ABM Tools

Types Of Holding Devices Work holding devices in lathe machine. Three jaws or four jaws? Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Here's everything you need to know about the most important workholding devices in. Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and fixtures. Each type of device is designed for a specific. Types of cutting tool materials and their. If the workpiece is not attached. Work holding devices in lathe machine. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations.

From www.studypool.com

SOLUTION drilling machine work holding devices Studypool Types Of Holding Devices Work holding devices in lathe machine. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Three jaws or four jaws? Types of cutting tool materials and their. Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. Each type. Types Of Holding Devices.

From www.youtube.com

Lathe Work Holding Devices Types Chucks Part1 YouTube Types Of Holding Devices Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and fixtures. Each type of device is designed for a specific. Here's everything you need to know about the most important workholding devices in. These. Types Of Holding Devices.

From justinfozone.blogspot.com

Basic Elements of jigs and fixtures(Clamping & Bushes) Informational Types Of Holding Devices Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. Three jaws or four jaws? These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Work holding devices in lathe machine. Work holding device is a general term for devices. Types Of Holding Devices.

From www.birlaprecision.com

Exploring Work Holding Devices In Cutting Tools BPTL Types Of Holding Devices Types of cutting tool materials and their. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Work holding devices in lathe machine. If the workpiece is not attached. Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. Three. Types Of Holding Devices.

From www.youtube.com

Milling Tool and Work Holding Devices YouTube Types Of Holding Devices Three jaws or four jaws? Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Here's everything you need to know about the most important workholding devices in. Each type of device. Types Of Holding Devices.

From www.slideserve.com

PPT Introduction to the Lathe Machine PowerPoint Presentation ID Types Of Holding Devices Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and fixtures. Types of cutting tool materials and their. These tools serve as work holding devices, each with specific functions in securing and supporting the. Types Of Holding Devices.

From www.toolsengg.com

Work Holding Devices Types Of Holding Devices If the workpiece is not attached. Three jaws or four jaws? Types of cutting tool materials and their. Work holding devices in lathe machine. Each type of device is designed for a specific. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Workholding is a catchall term referring. Types Of Holding Devices.

From www.slideserve.com

PPT Milling Machines PowerPoint Presentation ID2263507 Types Of Holding Devices Work holding devices in lathe machine. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. If the workpiece is not attached. Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. These tools serve as work holding devices, each with specific functions in securing. Types Of Holding Devices.

From www.youtube.com

CNC Tool magazine and Work holding Devices YouTube Types Of Holding Devices There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and fixtures. Work holding devices in lathe machine. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Three jaws or four jaws? Here's everything you need to know about the most important workholding devices. Types Of Holding Devices.

From studylib.net

Tools and Holding Devices Types Of Holding Devices Each type of device is designed for a specific. There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and fixtures. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Work holding devices in lathe machine. Common accessories for a lathe machine include chuck,. Types Of Holding Devices.

From www.slideserve.com

PPT CLAMPING AND HOLDING DEVICES PowerPoint Presentation, free Types Of Holding Devices Types of cutting tool materials and their. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. If the workpiece is not attached. Work holding devices in lathe machine. Three jaws or four jaws? There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and. Types Of Holding Devices.

From www.slideshare.net

Holding Types Of Holding Devices If the workpiece is not attached. Each type of device is designed for a specific. Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. Three jaws or four jaws? Types of cutting tool materials and their. There are many different types of workholding devices used in manufacturing, including clamps, vises,. Types Of Holding Devices.

From dreamstime.com

Set Of Hand Holding Electronic Devices Stock Photography Image 19469742 Types Of Holding Devices Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and fixtures. These tools serve as work holding devices,. Types Of Holding Devices.

From www.slideserve.com

PPT The Bisecting Technique PowerPoint Presentation ID2337946 Types Of Holding Devices Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Work holding devices in lathe machine.. Types Of Holding Devices.

From www.youtube.com

Milling Machine Tool holding devices, Types of cutter, and Operations Types Of Holding Devices These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Here's everything you need to know about the most important workholding devices in. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Types of cutting tool materials and their. Three jaws or. Types Of Holding Devices.

From seisanzai-japan.com

Machining 08 What are work holding devices? Industry and Types Of Holding Devices Types of cutting tool materials and their. Each type of device is designed for a specific. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. These tools serve as work holding devices, each with. Types Of Holding Devices.

From qhunt.blogspot.com

Work Holding Devices in Drilling Machine Q Hunt Types Of Holding Devices Each type of device is designed for a specific. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Here's everything you need to know about the most important workholding devices in. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various. Types Of Holding Devices.

From www.youtube.com

4/7 Work holding Devices for Lathes Lathe Machine ASKAzad Types Of Holding Devices Three jaws or four jaws? If the workpiece is not attached. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Common accessories for a lathe machine include chuck, face. Types Of Holding Devices.

From www.cutwel.co.uk

Tool Holding Explained An Expert Guide Cutwel Ltd Types Of Holding Devices There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and fixtures. Three jaws or four jaws? Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations.. Types Of Holding Devices.

From www.abmtools.com

Work Holding Devices ABM Tools Types Of Holding Devices Three jaws or four jaws? Work holding devices in lathe machine. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Types of cutting tool materials and their. There are many different types. Types Of Holding Devices.

From informacionpublica.svet.gob.gt

Work Holding Devices In Lathe Machine Technology Types Of Holding Devices These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Work holding device is. Types Of Holding Devices.

From www.slideserve.com

PPT Drilling Machine… PowerPoint Presentation, free download ID1285969 Types Of Holding Devices Types of cutting tool materials and their. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Each type of device is designed for a specific. Work holding devices in lathe machine. There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and fixtures. Here's. Types Of Holding Devices.

From www.youtube.com

Tool and Work holding devices for CNC machines and their types with Types Of Holding Devices These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Here's everything you need to know about the most important workholding devices in. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Types of cutting tool materials and their.. Types Of Holding Devices.

From www.scribd.com

Work Holding Devices PDF Metalworking Tools Types Of Holding Devices Work holding devices in lathe machine. There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and fixtures. Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. Work holding device is a general term for devices that attach and fix a workpiece to a. Types Of Holding Devices.

From informacionpublica.svet.gob.gt

Lathe Machine Work Holding Device informacionpublica.svet.gob.gt Types Of Holding Devices Each type of device is designed for a specific. Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. Three jaws or four jaws? Here's everything you need to know about the most important workholding devices in. Work holding devices in lathe machine. Types of cutting tool materials and their. If. Types Of Holding Devices.

From www.slideserve.com

PPT Drilling Machine Accessories PowerPoint Presentation, free Types Of Holding Devices Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. If the workpiece is not attached. Work holding devices in lathe machine. Three jaws or four jaws? Workholding is a catchall term referring to any. Types Of Holding Devices.

From www.educationalstuffs.in

WORK HOLDING DEVICES EDUCATIONAL STUFFS Types Of Holding Devices Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. If the workpiece is not attached. Three jaws or four jaws? Types of cutting tool materials and their. Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. These tools serve as. Types Of Holding Devices.

From www.mechical.com

Work Holding Devices in Lathe Machine and Their Types Types Of Holding Devices Each type of device is designed for a specific. Work holding devices in lathe machine. There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and fixtures. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. If the workpiece is not attached.. Types Of Holding Devices.

From www.youtube.com

Drill holding device YouTube Types Of Holding Devices Types of cutting tool materials and their. Work holding devices in lathe machine. Three jaws or four jaws? Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. Work holding device is a general term. Types Of Holding Devices.

From www.biname.be

Insulated holding device BINAME Types Of Holding Devices Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Types of cutting tool materials and their. Work holding devices in lathe machine. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. If the workpiece is not attached. Here's everything you need. Types Of Holding Devices.

From www.youtube.com

Work and Tool Holding Devices for Lathes YouTube Types Of Holding Devices If the workpiece is not attached. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Types of cutting tool materials and their. Work holding device is a general term for devices that. Types Of Holding Devices.

From www.scribd.com

Workingholding Devices Types of Work Holding Devices PDF Types Of Holding Devices Here's everything you need to know about the most important workholding devices in. Each type of device is designed for a specific. Three jaws or four jaws? Work holding devices in lathe machine. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Common accessories for a lathe machine include chuck,. Types Of Holding Devices.

From www.harveyperformance.com

Workholding Styles & Considerations In The Loupe Types Of Holding Devices Types of cutting tool materials and their. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Three jaws or four jaws? Workholding is a catchall term referring to any device or apparatus used to keep a workpiece stable and immobile. If the workpiece is not attached. Common accessories for a. Types Of Holding Devices.

From www.tmsmith.com

The Importance of Tool Holders in Several Industries T.M. Smith Tool Types Of Holding Devices These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Work holding devices in lathe machine. Each type of device is designed for a specific. Three jaws or four jaws? Work holding device is a general term for devices that attach and fix a workpiece to a machine tool.. Types Of Holding Devices.

From newmachineparts.blogspot.com

Various Types of Work Holding Devices Types Of Holding Devices There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and fixtures. Types of cutting tool materials and their. These tools serve as work holding devices, each with specific functions in securing and supporting the workpiece during various lathe operations. Three jaws or four jaws? Each type of device is designed for a specific.. Types Of Holding Devices.