Spinning Flow Chart . The initial stage of the spinning process involves converting cotton in bales into the cone winding. spinning is a major part of the textile industry. cotton yarn spinning process: introduction to spinning: In this process, the fibers in the bale form will be loosened, opened, and cleaned. The process of converting fiber into yarn is called as spinning. In here we have discussed the process of cotton yarn manufacturing. The process of making the yarn from a textile fiber is called spinning. It is part of the textile manufacturing process where three types. ring spinning, the most widely used yarn manufacturing process for short staple spinning, uses several types of machinery. Combed and carded yarn spinning process. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. Bale opening ↓ blow room ↓ carding.

from textileeducationtips.blogspot.com

Bale opening ↓ blow room ↓ carding. ring spinning, the most widely used yarn manufacturing process for short staple spinning, uses several types of machinery. In this process, the fibers in the bale form will be loosened, opened, and cleaned. introduction to spinning: It is part of the textile manufacturing process where three types. The process of making the yarn from a textile fiber is called spinning. The process of converting fiber into yarn is called as spinning. spinning is a major part of the textile industry. The initial stage of the spinning process involves converting cotton in bales into the cone winding. In here we have discussed the process of cotton yarn manufacturing.

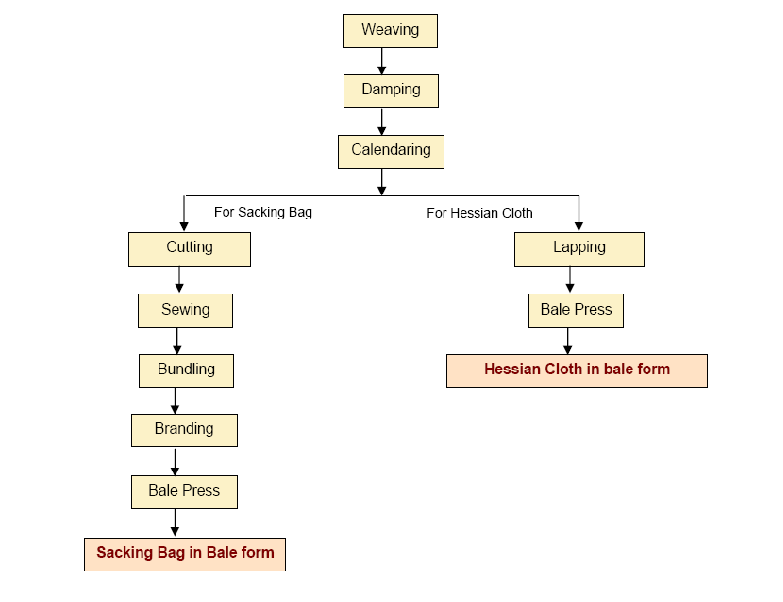

Finishing Flow Chart of Jute Spinning Textile Education Tips

Spinning Flow Chart In here we have discussed the process of cotton yarn manufacturing. The process of converting fiber into yarn is called as spinning. It is part of the textile manufacturing process where three types. spinning is a major part of the textile industry. Bale opening ↓ blow room ↓ carding. In this process, the fibers in the bale form will be loosened, opened, and cleaned. The initial stage of the spinning process involves converting cotton in bales into the cone winding. cotton yarn spinning process: ring spinning, the most widely used yarn manufacturing process for short staple spinning, uses several types of machinery. Combed and carded yarn spinning process. The process of making the yarn from a textile fiber is called spinning. In here we have discussed the process of cotton yarn manufacturing. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. introduction to spinning:

From www.chemtube3d.com

Symmetry Flowchart Assign Point Groups — ChemTube3D Spinning Flow Chart introduction to spinning: In here we have discussed the process of cotton yarn manufacturing. In this process, the fibers in the bale form will be loosened, opened, and cleaned. The process of converting fiber into yarn is called as spinning. Combed and carded yarn spinning process. It is part of the textile manufacturing process where three types. spinning. Spinning Flow Chart.

From textilestudycenter.com

Melt Spinning , Dry spinning and Wet Spinning Method Textile study center Spinning Flow Chart It is part of the textile manufacturing process where three types. Combed and carded yarn spinning process. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. ring spinning, the most widely used yarn manufacturing process for short staple spinning, uses several types of machinery. In this process, the. Spinning Flow Chart.

From www.lucidchart.com

The 4 Steps to SPIN Selling Lucidchart Blog Spinning Flow Chart ring spinning, the most widely used yarn manufacturing process for short staple spinning, uses several types of machinery. It is part of the textile manufacturing process where three types. cotton yarn spinning process: yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. The initial stage of the. Spinning Flow Chart.

From journals.sagepub.com

Mathematical modeling of the dynamic yarn path depending on spindle Spinning Flow Chart The process of converting fiber into yarn is called as spinning. It is part of the textile manufacturing process where three types. In this process, the fibers in the bale form will be loosened, opened, and cleaned. Combed and carded yarn spinning process. introduction to spinning: The initial stage of the spinning process involves converting cotton in bales into. Spinning Flow Chart.

From textileeducationtips.blogspot.com

Finishing Flow Chart of Jute Spinning Textile Education Tips Spinning Flow Chart Combed and carded yarn spinning process. In this process, the fibers in the bale form will be loosened, opened, and cleaned. In here we have discussed the process of cotton yarn manufacturing. introduction to spinning: It is part of the textile manufacturing process where three types. Bale opening ↓ blow room ↓ carding. The process of converting fiber into. Spinning Flow Chart.

From bceweb.org

Cotton Spinning Process Flow Chart A Visual Reference of Charts Spinning Flow Chart Combed and carded yarn spinning process. cotton yarn spinning process: yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. The process of converting fiber into yarn is called as spinning. Bale opening ↓ blow room ↓ carding. In this process, the fibers in the bale form will be. Spinning Flow Chart.

From textilesscholars.blogspot.com

Process flow chart of Spinning Process flow chart of carded yarn Spinning Flow Chart In this process, the fibers in the bale form will be loosened, opened, and cleaned. The initial stage of the spinning process involves converting cotton in bales into the cone winding. The process of converting fiber into yarn is called as spinning. ring spinning, the most widely used yarn manufacturing process for short staple spinning, uses several types of. Spinning Flow Chart.

From www.researchgate.net

flow chart of spin coating method of undoped and sliver doped TiO 2 Spinning Flow Chart introduction to spinning: The process of converting fiber into yarn is called as spinning. In this process, the fibers in the bale form will be loosened, opened, and cleaned. cotton yarn spinning process: Bale opening ↓ blow room ↓ carding. Combed and carded yarn spinning process. The initial stage of the spinning process involves converting cotton in bales. Spinning Flow Chart.

From textilecreativities.blogspot.com

Process flow chart of yarn spinning technology? TE Spinning Flow Chart The process of converting fiber into yarn is called as spinning. The process of making the yarn from a textile fiber is called spinning. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. The initial stage of the spinning process involves converting cotton in bales into the cone winding.. Spinning Flow Chart.

From awesomeenglish.edu.vn

Discover 138+ ring spinning process flow chart latest awesomeenglish Spinning Flow Chart Combed and carded yarn spinning process. The process of making the yarn from a textile fiber is called spinning. It is part of the textile manufacturing process where three types. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. In this process, the fibers in the bale form will. Spinning Flow Chart.

From www.csir.co.za

EoILakshmiRingFrame.jpg CSIR Spinning Flow Chart ring spinning, the most widely used yarn manufacturing process for short staple spinning, uses several types of machinery. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. spinning is a major part of the textile industry. Combed and carded yarn spinning process. The process of converting fiber. Spinning Flow Chart.

From www.youtube.com

Textile Spinning Process Overview Explained TexConnect YouTube Spinning Flow Chart introduction to spinning: spinning is a major part of the textile industry. It is part of the textile manufacturing process where three types. Combed and carded yarn spinning process. ring spinning, the most widely used yarn manufacturing process for short staple spinning, uses several types of machinery. Bale opening ↓ blow room ↓ carding. The initial stage. Spinning Flow Chart.

From www.textileproperty.com

All About Yarn Manufacturing Process Flow Chart! Textile Property Spinning Flow Chart Combed and carded yarn spinning process. In here we have discussed the process of cotton yarn manufacturing. The initial stage of the spinning process involves converting cotton in bales into the cone winding. ring spinning, the most widely used yarn manufacturing process for short staple spinning, uses several types of machinery. yarn properties are parameters to describe the. Spinning Flow Chart.

From www.textilesphere.com

Introduction to textile spinning process Flowchart Objectives Spinning Flow Chart The process of making the yarn from a textile fiber is called spinning. Bale opening ↓ blow room ↓ carding. The process of converting fiber into yarn is called as spinning. Combed and carded yarn spinning process. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. cotton yarn. Spinning Flow Chart.

From www.textilesphere.com

Introduction to textile spinning process Flowchart Objectives Spinning Flow Chart The process of converting fiber into yarn is called as spinning. It is part of the textile manufacturing process where three types. introduction to spinning: spinning is a major part of the textile industry. The initial stage of the spinning process involves converting cotton in bales into the cone winding. ring spinning, the most widely used yarn. Spinning Flow Chart.

From www.scribd.com

Process Flow Chart of Rotor Spinning PDF Spinning Flow Chart The process of making the yarn from a textile fiber is called spinning. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. In here we have discussed the process of cotton yarn manufacturing. Combed and carded yarn spinning process. introduction to spinning: ring spinning, the most widely. Spinning Flow Chart.

From textilesscholars.blogspot.com

Process flow chart of spinning Process flow chart of combed yarn Spinning Flow Chart Bale opening ↓ blow room ↓ carding. spinning is a major part of the textile industry. In this process, the fibers in the bale form will be loosened, opened, and cleaned. cotton yarn spinning process: In here we have discussed the process of cotton yarn manufacturing. The process of making the yarn from a textile fiber is called. Spinning Flow Chart.

From www.pinterest.com.au

Flowchart Samples Spinning Mill Process Flow Chart Cotton To Yarn Spinning Flow Chart spinning is a major part of the textile industry. The process of converting fiber into yarn is called as spinning. cotton yarn spinning process: yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. It is part of the textile manufacturing process where three types. The process of. Spinning Flow Chart.

From www.textilesphere.com

Introduction to textile spinning process Flowchart Objectives Spinning Flow Chart Combed and carded yarn spinning process. In this process, the fibers in the bale form will be loosened, opened, and cleaned. In here we have discussed the process of cotton yarn manufacturing. The initial stage of the spinning process involves converting cotton in bales into the cone winding. yarn properties are parameters to describe the yarn, such as fineness. Spinning Flow Chart.

From www.elmergmbh.at

Spinnerets products Elmer GmbH Spinning Flow Chart In this process, the fibers in the bale form will be loosened, opened, and cleaned. spinning is a major part of the textile industry. The process of making the yarn from a textile fiber is called spinning. ring spinning, the most widely used yarn manufacturing process for short staple spinning, uses several types of machinery. cotton yarn. Spinning Flow Chart.

From brainly.in

Make a flow chart showing various stages of production of woollen Spinning Flow Chart It is part of the textile manufacturing process where three types. The process of making the yarn from a textile fiber is called spinning. In here we have discussed the process of cotton yarn manufacturing. The initial stage of the spinning process involves converting cotton in bales into the cone winding. In this process, the fibers in the bale form. Spinning Flow Chart.

From www.scribd.com

Cotton Spinning Flow Chart Blow Room Cotton Mixing PDF Spinning Flow Chart Bale opening ↓ blow room ↓ carding. The process of making the yarn from a textile fiber is called spinning. ring spinning, the most widely used yarn manufacturing process for short staple spinning, uses several types of machinery. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. In. Spinning Flow Chart.

From vova.edu.vn

Discover 76+ ring spinning process flow chart super hot vova.edu.vn Spinning Flow Chart In here we have discussed the process of cotton yarn manufacturing. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. The initial stage of the spinning process involves converting cotton in bales into the cone winding. introduction to spinning: The process of converting fiber into yarn is called. Spinning Flow Chart.

From 4textile.blogspot.com

Wet Spinning Flow chart for singeing> dyeing 4Textile Spinning Flow Chart The initial stage of the spinning process involves converting cotton in bales into the cone winding. The process of converting fiber into yarn is called as spinning. In here we have discussed the process of cotton yarn manufacturing. introduction to spinning: cotton yarn spinning process: The process of making the yarn from a textile fiber is called spinning.. Spinning Flow Chart.

From www.pinterest.com

flow chart of yarn manufacturing process in 2021 Manufacturing Spinning Flow Chart Combed and carded yarn spinning process. The process of making the yarn from a textile fiber is called spinning. introduction to spinning: It is part of the textile manufacturing process where three types. The initial stage of the spinning process involves converting cotton in bales into the cone winding. In here we have discussed the process of cotton yarn. Spinning Flow Chart.

From www.ecowindow.com.vn

Discover 133+ ring spinning process flow chart best Spinning Flow Chart The initial stage of the spinning process involves converting cotton in bales into the cone winding. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. introduction to spinning: It is part of the textile manufacturing process where three types. In this process, the fibers in the bale form. Spinning Flow Chart.

From www.youtube.com

FLOW CHART OF SPINNING PROCESS Study With Param Parmanand YouTube Spinning Flow Chart In here we have discussed the process of cotton yarn manufacturing. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. The process of making the yarn from a textile fiber is called spinning. Bale opening ↓ blow room ↓ carding. It is part of the textile manufacturing process where. Spinning Flow Chart.

From www.victoriana.com

Imperialismus Hohl Universität ring spinning Sich unterhalten Spinning Flow Chart Bale opening ↓ blow room ↓ carding. The initial stage of the spinning process involves converting cotton in bales into the cone winding. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. In here we have discussed the process of cotton yarn manufacturing. introduction to spinning: Combed and. Spinning Flow Chart.

From awesomeenglish.edu.vn

Discover 138+ ring spinning process flow chart latest awesomeenglish Spinning Flow Chart Combed and carded yarn spinning process. In this process, the fibers in the bale form will be loosened, opened, and cleaned. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. spinning is a major part of the textile industry. Bale opening ↓ blow room ↓ carding. In here. Spinning Flow Chart.

From ordnur.com

Flow Chart of Spinning ORDNUR TEXTILE AND FINANCE Spinning Flow Chart It is part of the textile manufacturing process where three types. spinning is a major part of the textile industry. In here we have discussed the process of cotton yarn manufacturing. cotton yarn spinning process: Bale opening ↓ blow room ↓ carding. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness,. Spinning Flow Chart.

From www.pinterest.com

SPIN SELLING infographic is designed by our company to help salesmans Spinning Flow Chart introduction to spinning: spinning is a major part of the textile industry. In here we have discussed the process of cotton yarn manufacturing. The process of making the yarn from a textile fiber is called spinning. cotton yarn spinning process: The process of converting fiber into yarn is called as spinning. It is part of the textile. Spinning Flow Chart.

From ordnur.com

Visual Flow Chart of Spinning ORDNUR Spinning Flow Chart The initial stage of the spinning process involves converting cotton in bales into the cone winding. It is part of the textile manufacturing process where three types. ring spinning, the most widely used yarn manufacturing process for short staple spinning, uses several types of machinery. cotton yarn spinning process: In this process, the fibers in the bale form. Spinning Flow Chart.

From www.textilecoach.net

Spinning Flowchart Spinning Flow Chart Bale opening ↓ blow room ↓ carding. yarn properties are parameters to describe the yarn, such as fineness or titer, elongation, hairiness, tenacity, twist, and volume. In this process, the fibers in the bale form will be loosened, opened, and cleaned. spinning is a major part of the textile industry. The initial stage of the spinning process involves. Spinning Flow Chart.

From textileandinfo.blogspot.com

TEXTILE AND INFO open end spinning process Spinning Flow Chart The process of making the yarn from a textile fiber is called spinning. Bale opening ↓ blow room ↓ carding. It is part of the textile manufacturing process where three types. The process of converting fiber into yarn is called as spinning. The initial stage of the spinning process involves converting cotton in bales into the cone winding. Combed and. Spinning Flow Chart.

From www.youtube.com

Introduction to Textile Spinning Flow Chart Machine Objectives Spinning Flow Chart The process of converting fiber into yarn is called as spinning. Combed and carded yarn spinning process. ring spinning, the most widely used yarn manufacturing process for short staple spinning, uses several types of machinery. In this process, the fibers in the bale form will be loosened, opened, and cleaned. It is part of the textile manufacturing process where. Spinning Flow Chart.