Insufficient Solder Fillet . A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. How can i tell if a solder joint has insufficient solder? Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause cracks in. Insufficient solder joints often appear dull, grainy, or incomplete. This stress may cause pad lifting; A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. The appearance of this fillet is an indicator that you have properly soldered your board. Insufficient wetting of the surface mount component in soldering

from www.semanticscholar.org

Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause cracks in. Insufficient wetting of the surface mount component in soldering How can i tell if a solder joint has insufficient solder? Insufficient solder joints often appear dull, grainy, or incomplete. This stress may cause pad lifting; This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. The appearance of this fillet is an indicator that you have properly soldered your board. A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet.

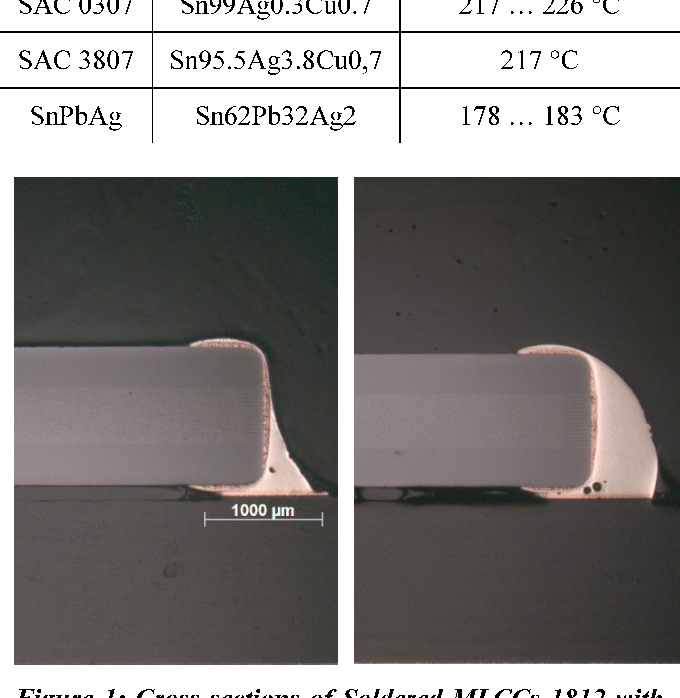

Figure 1 from Fracture probability of MLCC in dependence of solder

Insufficient Solder Fillet How can i tell if a solder joint has insufficient solder? A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. The appearance of this fillet is an indicator that you have properly soldered your board. Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause cracks in. Insufficient wetting of the surface mount component in soldering This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. Insufficient solder joints often appear dull, grainy, or incomplete. This stress may cause pad lifting; How can i tell if a solder joint has insufficient solder? A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads.

From www.researchgate.net

Six types of defects (a) Excessive Solder, (b) Insufficient Solder Insufficient Solder Fillet A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. This stress may cause pad lifting; Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause cracks in. This procedure includes figures and tables for solder joint acceptability criteria on. Insufficient Solder Fillet.

From www.researchgate.net

Six types of defects (a) Excessive Solder, (b) Insufficient Solder Insufficient Solder Fillet How can i tell if a solder joint has insufficient solder? Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause cracks in. A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. A protrusion formed after solder paste printing,. Insufficient Solder Fillet.

From www.finepowertools.com

9 Types of Soldering Defects and Their Solutions Insufficient Solder Fillet A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. Insufficient wetting of the surface mount component in soldering Insufficient solder joints often appear dull, grainy, or incomplete. A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. The appearance of this fillet. Insufficient Solder Fillet.

From www.qhsmt.com

SMT pick and place machine &Solder problems in PCB Soldering Insufficient Solder Fillet This stress may cause pad lifting; A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. Insufficient solder joints often appear dull, grainy, or incomplete. Insufficient wetting of the surface mount component in soldering How can i tell if a solder joint has insufficient solder? A properly applied solder joint will have a small. Insufficient Solder Fillet.

From www.ourpcb.com

Insufficient Solder What It Is and What to Do About It Insufficient Solder Fillet Insufficient wetting of the surface mount component in soldering How can i tell if a solder joint has insufficient solder? A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. Insufficient solder joints often appear dull, grainy,. Insufficient Solder Fillet.

From www.slideshare.net

SOLDER FILLET STANDARDS DEMO BOOKLET DEFINITIONS Insufficient Solder Fillet How can i tell if a solder joint has insufficient solder? Insufficient solder joints often appear dull, grainy, or incomplete. This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. This stress may cause pad lifting; Or, if the adhesion between pad and board is at that point stronger than the solder, it. Insufficient Solder Fillet.

From www.researchgate.net

Six types of defects (a) Excessive Solder, (b) Insufficient Solder Insufficient Solder Fillet A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. How can i tell if a solder joint has insufficient solder? This stress may cause pad lifting; Or, if the adhesion between pad. Insufficient Solder Fillet.

From www.keyence.com

Inspection and Measurement of Solder Cracks and Voids Electronic Insufficient Solder Fillet This stress may cause pad lifting; Insufficient wetting of the surface mount component in soldering The appearance of this fillet is an indicator that you have properly soldered your board. This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. How can i tell if a solder joint has insufficient solder? A protrusion. Insufficient Solder Fillet.

From www.researchgate.net

Six types of defects (a) Excessive Solder, (b) Insufficient Solder Insufficient Solder Fillet A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. Insufficient solder joints often appear dull, grainy, or incomplete. How can i tell if a solder joint has insufficient solder? A protrusion. Insufficient Solder Fillet.

From www.onestopndt.com

Fillet Weld Sizing Guidelines OnestopNDT Insufficient Solder Fillet The appearance of this fillet is an indicator that you have properly soldered your board. Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause cracks in. This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. Insufficient wetting of the surface mount component. Insufficient Solder Fillet.

From www.ourpcb.com

Insufficient Solder What It Is and What to Do About It Insufficient Solder Fillet Insufficient solder joints often appear dull, grainy, or incomplete. How can i tell if a solder joint has insufficient solder? A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. Or, if the. Insufficient Solder Fillet.

From engineersblog.net

What is Convex Fillet Joint? Explain in details step by step procedure Insufficient Solder Fillet Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause cracks in. The appearance of this fillet is an indicator that you have properly soldered your board. A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. This procedure includes. Insufficient Solder Fillet.

From www.slideshare.net

SOLDER FILLET STANDARDS DEMO BOOKLET DEFINITIONS Insufficient Solder Fillet Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause cracks in. A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. How can i tell if a solder joint has insufficient solder? The appearance of this fillet is an. Insufficient Solder Fillet.

From indiumblog.com

Indium 사의 블로그 Insufficient Solder Fillet A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. Insufficient wetting of the surface mount component in soldering A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. Insufficient solder joints often appear dull, grainy, or incomplete. Or, if the adhesion between. Insufficient Solder Fillet.

From www.ourpcb.com

Insufficient Solder What It Is and What to Do About It Insufficient Solder Fillet Insufficient solder joints often appear dull, grainy, or incomplete. This stress may cause pad lifting; A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. The appearance of this fillet is an indicator that you have properly soldered your board. This procedure includes figures and tables for solder joint. Insufficient Solder Fillet.

From www.pcbaaa.com

How to improve the welding reliability of QFN package bottom? IBE Insufficient Solder Fillet Insufficient wetting of the surface mount component in soldering The appearance of this fillet is an indicator that you have properly soldered your board. This stress may cause pad lifting; How can i tell if a solder joint has insufficient solder? This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. A protrusion. Insufficient Solder Fillet.

From www.ourpcb.com

Insufficient Solder What It Is and What to Do About It Insufficient Solder Fillet How can i tell if a solder joint has insufficient solder? Insufficient solder joints often appear dull, grainy, or incomplete. A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. This stress may cause pad lifting; Insufficient wetting of the surface mount component in soldering The appearance of this fillet is an indicator that. Insufficient Solder Fillet.

From www.reddit.com

[Tutorial] Soldering a Keyboard r/MechanicalKeyboards Insufficient Solder Fillet Insufficient solder joints often appear dull, grainy, or incomplete. This stress may cause pad lifting; This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. Insufficient wetting of the surface mount component in soldering Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause. Insufficient Solder Fillet.

From www.researchgate.net

Six types of defects (a) Excessive Solder, (b) Insufficient Solder Insufficient Solder Fillet Insufficient wetting of the surface mount component in soldering A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. The appearance of this fillet is an indicator that you have properly soldered your board. This procedure includes figures and tables for solder joint acceptability criteria on a variety of. Insufficient Solder Fillet.

From www.researchgate.net

Asymmetry of solder fillets at PCB is consequence of teardrop pads Insufficient Solder Fillet A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. Insufficient wetting of the surface mount. Insufficient Solder Fillet.

From www.ourpcb.com

Insufficient Solder What It Is and What to Do About It Insufficient Solder Fillet Insufficient wetting of the surface mount component in soldering Insufficient solder joints often appear dull, grainy, or incomplete. A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. The appearance of this fillet is an indicator that you have properly soldered your board. This stress may cause pad lifting;. Insufficient Solder Fillet.

From www.circuits-diy.com

Bad Solder PCB Soldering Issues and their Solution Insufficient Solder Fillet Insufficient wetting of the surface mount component in soldering A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. This stress may cause pad lifting; A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. Insufficient solder joints often appear dull, grainy, or. Insufficient Solder Fillet.

From www.slideshare.net

SOLDER FILLET STANDARDS DEMO BOOKLET DEFINITIONS Insufficient Solder Fillet Insufficient wetting of the surface mount component in soldering A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause cracks in. Insufficient solder joints often appear dull, grainy, or incomplete.. Insufficient Solder Fillet.

From www.semanticscholar.org

Figure 1 from Fracture probability of MLCC in dependence of solder Insufficient Solder Fillet Insufficient solder joints often appear dull, grainy, or incomplete. Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause cracks in. The appearance of this fillet is an indicator that you have properly soldered your board. A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent. Insufficient Solder Fillet.

From www.protoexpress.com

How to Design Correct PCB Footprints Sierra Circuits Insufficient Solder Fillet This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. The appearance of this fillet is an indicator that you have properly soldered your board. Or, if the adhesion between pad and board is at that point. Insufficient Solder Fillet.

From www.semanticscholar.org

Figure 1 from A hydrostatic model of solder fillets part I Insufficient Solder Fillet A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. Insufficient wetting of the surface mount component in soldering A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. This stress may cause pad lifting; How can i tell if a solder joint. Insufficient Solder Fillet.

From www.slideserve.com

PPT Aerospace Soldering & Electronic Assembly Techniques Randall Insufficient Solder Fillet Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause cracks in. The appearance of this fillet is an indicator that you have properly soldered your board. This stress may cause pad lifting; Insufficient solder joints often appear dull, grainy, or incomplete. How can i tell if a solder joint has. Insufficient Solder Fillet.

From www.ourpcb.com

Insufficient Solder What It Is and What to Do About It Insufficient Solder Fillet Insufficient solder joints often appear dull, grainy, or incomplete. This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause cracks in. This stress may cause pad lifting; A properly applied solder joint will have. Insufficient Solder Fillet.

From www.circuitbasics.com

Tips for Good Soldering Technique Circuit Basics Insufficient Solder Fillet A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. This stress may cause pad lifting; A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. Or, if the adhesion between pad and board is at that point stronger than the solder, it. Insufficient Solder Fillet.

From www.researchgate.net

Solder spread and fillet radius at different solder joint height with Insufficient Solder Fillet This stress may cause pad lifting; How can i tell if a solder joint has insufficient solder? The appearance of this fillet is an indicator that you have properly soldered your board. Insufficient wetting of the surface mount component in soldering Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause. Insufficient Solder Fillet.

From www.semanticscholar.org

Figure 2 from A hydrostatic model of solder fillets part I Insufficient Solder Fillet A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. Insufficient solder joints often appear dull, grainy, or incomplete. This stress may cause pad lifting; This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. How can i tell if a solder. Insufficient Solder Fillet.

From www.protoexpress.com

IPC JSTD001 Standard for Soldering Sierra Circuits Insufficient Solder Fillet The appearance of this fillet is an indicator that you have properly soldered your board. This stress may cause pad lifting; A properly applied solder joint will have a small amount of molten solder on it, called solder bloom or solder fillet. This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. How. Insufficient Solder Fillet.

From www.slideshare.net

Manufacturability & reliability challenges with qfn Insufficient Solder Fillet How can i tell if a solder joint has insufficient solder? Insufficient wetting of the surface mount component in soldering Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause cracks in. Insufficient solder joints often appear dull, grainy, or incomplete. The appearance of this fillet is an indicator that you. Insufficient Solder Fillet.

From www.slideshare.net

Manufacturability & reliability challenges with qfn Insufficient Solder Fillet Or, if the adhesion between pad and board is at that point stronger than the solder, it can cause cracks in. The appearance of this fillet is an indicator that you have properly soldered your board. This stress may cause pad lifting; Insufficient solder joints often appear dull, grainy, or incomplete. A protrusion formed after solder paste printing, resembling a. Insufficient Solder Fillet.

From www.slideshare.net

Manufacturability & reliability challenges with qfn Insufficient Solder Fillet A protrusion formed after solder paste printing, resembling a sharp tip that bridges between adjacent pads. Insufficient solder joints often appear dull, grainy, or incomplete. This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types. The appearance of this fillet is an indicator that you have properly soldered your board. How can i. Insufficient Solder Fillet.