How To Check Electric Motor Bearings . Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. The dimension at 14:32 should read 1.1816 inches not 0.1816 inches. Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. How to disassemble an electric motor to check and replace the bearings. Frosting of the bearings and raceways;. There are three main signs of electrical bearing damage: Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. This article describes a/c electrical motor troubleshooting:

from hecoinc.com

There are three main signs of electrical bearing damage: Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. How to disassemble an electric motor to check and replace the bearings. Frosting of the bearings and raceways;. The dimension at 14:32 should read 1.1816 inches not 0.1816 inches. Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. This article describes a/c electrical motor troubleshooting:

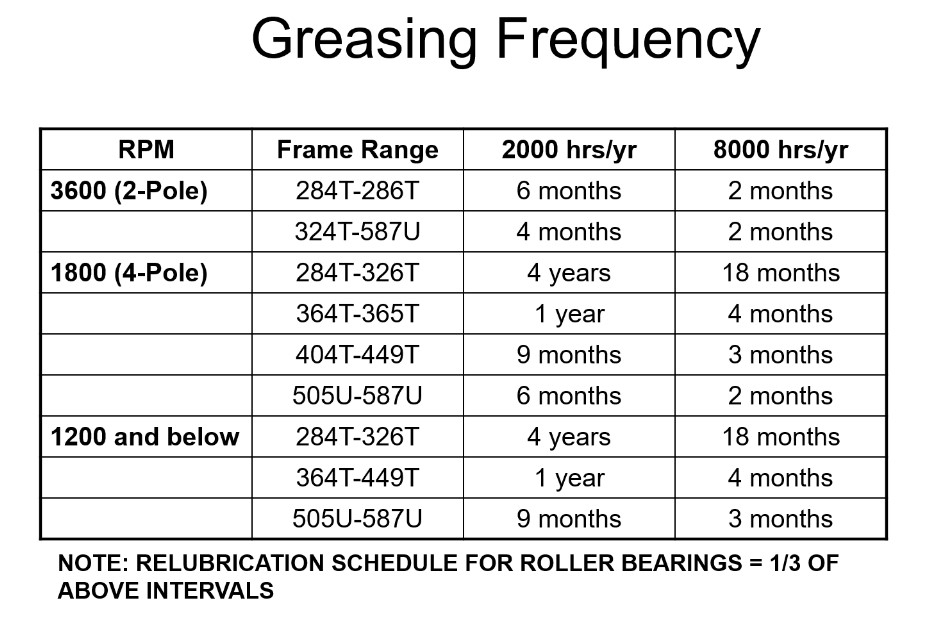

Greasing Electric Motor Ball Bearings HECO

How To Check Electric Motor Bearings Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. There are three main signs of electrical bearing damage: How to disassemble an electric motor to check and replace the bearings. Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. The dimension at 14:32 should read 1.1816 inches not 0.1816 inches. Frosting of the bearings and raceways;. This article describes a/c electrical motor troubleshooting: Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good.

From innovationdiscoveries.space

KnowHow To Read Bearings Specification How To Check Electric Motor Bearings Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. There are three main signs of electrical bearing damage: The dimension at 14:32 should read 1.1816 inches not 0.1816 inches. Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. How. How To Check Electric Motor Bearings.

From www.youtube.com

How to change motor bearing YouTube How To Check Electric Motor Bearings Frosting of the bearings and raceways;. Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. Here we provide an electric motor diagnostic table, a troubleshooting guide that helps. How To Check Electric Motor Bearings.

From blog.est-aegis.com

Electrical Bearing Protection Q&A Part 15 How To Check Electric Motor Bearings You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. Frosting of the bearings and raceways;. This article describes a/c electrical motor troubleshooting: There are three main. How To Check Electric Motor Bearings.

From hecoinc.com

Greasing Electric Motor Ball Bearings HECO How To Check Electric Motor Bearings You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. How to disassemble an electric motor to check and replace the bearings. Frosting of the bearings and raceways;. Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric. How To Check Electric Motor Bearings.

From www.youtube.com

How to Grease your Electric Motor Bearings YouTube How To Check Electric Motor Bearings How to disassemble an electric motor to check and replace the bearings. Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. There are three main signs of electrical bearing damage: Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings.. How To Check Electric Motor Bearings.

From www.slideshare.net

Bearing handbook for electric motor skf How To Check Electric Motor Bearings There are three main signs of electrical bearing damage: Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. The dimension at 14:32 should read 1.1816 inches not 0.1816 inches. Frosting of the bearings and raceways;. Here at precision zone, we closely inspect the bearings and housings on all motor work performed and. How To Check Electric Motor Bearings.

From powerlineelectricmotors.co.uk

Bearing Maintenance and Greasing Electric Motors How To Check Electric Motor Bearings Frosting of the bearings and raceways;. The dimension at 14:32 should read 1.1816 inches not 0.1816 inches. How to disassemble an electric motor to check and replace the bearings. Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. Here is how to look for signs of electrical damage when inspecting. How To Check Electric Motor Bearings.

From vdocuments.mx

Guide to Electric Motor Bearing Lubrication Guide to Electric Motor How To Check Electric Motor Bearings How to disassemble an electric motor to check and replace the bearings. You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. Frosting of the bearings and raceways;. Here. How To Check Electric Motor Bearings.

From www.youtube.com

How to Replace Electric Motor Bearings YouTube How To Check Electric Motor Bearings Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. How to. How To Check Electric Motor Bearings.

From www.electrical4uonline.com

How to Check Electric Motor? (A Complete Guide) How To Check Electric Motor Bearings Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. Here at precision zone, we closely inspect the bearings and housings on all motor work performed and. How To Check Electric Motor Bearings.

From www.china-bearing-manufacturer.com

Electric Motor bearing Application and Installation China Bearing How To Check Electric Motor Bearings Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. How to disassemble an electric motor to check and replace the bearings. There are three main signs of electrical. How To Check Electric Motor Bearings.

From www.youtube.com

how to electrical motor bearing change electrical 0.5 hp motor bearing How To Check Electric Motor Bearings You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. Here is how to look for signs of electrical damage when inspecting failed motor. How To Check Electric Motor Bearings.

From emadrlc.blogspot.com

Engineering Photos,Videos and Articels (Engineering Search Engine How To Check Electric Motor Bearings Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose. How To Check Electric Motor Bearings.

From www.ecmweb.com

Best Practices for Electric Motor Bearing Relubrication EC&M How To Check Electric Motor Bearings Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. There are three main signs of electrical bearing damage: This article describes a/c electrical motor troubleshooting: Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. Frosting of the bearings and raceways;. How to. How To Check Electric Motor Bearings.

From www.tekwellservices.com

Electric Motor Bearing Analysis Services Knoxville, TN Electric Motor How To Check Electric Motor Bearings The dimension at 14:32 should read 1.1816 inches not 0.1816 inches. Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. This article describes a/c electrical motor troubleshooting: How to disassemble an electric motor to check and replace the bearings. There are three main signs of electrical bearing damage: Here at precision zone,. How To Check Electric Motor Bearings.

From www.tekwellservices.com

Bearing Components for Electric Motor Service Knoxville, TN Electric How To Check Electric Motor Bearings Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. The dimension at 14:32 should read 1.1816 inches not 0.1816 inches. How to disassemble an electric motor to check and replace the bearings. You could assemble the motor, check the endplay as described above, then dismantle the motor. How To Check Electric Motor Bearings.

From www.wikihow.com

The Easiest Way to Check an Electric Motor wikiHow How To Check Electric Motor Bearings Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. How to disassemble an electric motor to check and replace the bearings. There are three main signs of electrical bearing damage:. How To Check Electric Motor Bearings.

From new.abb.com

How to extend the life of your motor bearings ABB How To Check Electric Motor Bearings You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. The dimension at 14:32 should read 1.1816 inches not 0.1816 inches. There are three main signs of electrical bearing damage: This article describes a/c electrical motor troubleshooting: Here at precision zone, we closely inspect the bearings. How To Check Electric Motor Bearings.

From www.youtube.com

Electric Motor Bearings wdbearing YouTube How To Check Electric Motor Bearings You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. Here at precision zone, we closely inspect the bearings and housings on all motor work performed and. How To Check Electric Motor Bearings.

From www.mmbbearings.net

Electric Motor Quality Bearings MMB Bearings How To Check Electric Motor Bearings There are three main signs of electrical bearing damage: Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. How to disassemble an electric motor to check and replace the bearings. Frosting of the bearings and raceways;. This article describes a/c electrical motor troubleshooting: Here is how to look for signs. How To Check Electric Motor Bearings.

From www.youtube.com

Motor bearing changehow motor bearing is changed? YouTube How To Check Electric Motor Bearings Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. There are three main signs of electrical bearing damage: How to disassemble an electric motor to check and replace. How To Check Electric Motor Bearings.

From dokumen.tips

(PDF) Guide to Electric Motor Bearing Lubrication DOKUMEN.TIPS How To Check Electric Motor Bearings You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. How to disassemble an electric motor to check and replace the bearings. Here we. How To Check Electric Motor Bearings.

From hecoinc.com

Electric Motor Ball Bearings Types & Options HECO How To Check Electric Motor Bearings Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. The dimension at 14:32 should read 1.1816 inches not 0.1816 inches. This article describes a/c electrical motor troubleshooting: Frosting. How To Check Electric Motor Bearings.

From www.youtube.com

How to check Bearings and Bearing Housing in Electric Motors YouTube How To Check Electric Motor Bearings Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. There are three main signs of electrical bearing damage: The dimension at 14:32 should read 1.1816 inches not 0.1816 inches. How to disassemble an electric motor to check and replace the bearings. Here at precision zone, we closely inspect the bearings and housings. How To Check Electric Motor Bearings.

From gibbonsgroup.blogspot.com

How to extend the life of electric motor bearings The Gibbons Group How To Check Electric Motor Bearings Frosting of the bearings and raceways;. There are three main signs of electrical bearing damage: Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. Here we provide an electric motor. How To Check Electric Motor Bearings.

From cesgeorgia.com

Changing electric motor bearings How To Check Electric Motor Bearings Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. There are three main signs of electrical bearing damage: This article describes a/c electrical motor troubleshooting: Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. The dimension at 14:32 should. How To Check Electric Motor Bearings.

From www.youtube.com

How to Remove Bearings from the Shaft of a Motor WITHOUT a Bearing How To Check Electric Motor Bearings Frosting of the bearings and raceways;. Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. This article describes a/c electrical motor troubleshooting: Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. How to disassemble an electric motor to check and replace the. How To Check Electric Motor Bearings.

From www.youtube.com

How to identify motor bearing size from Nameplate bearing size from How To Check Electric Motor Bearings Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. This article describes a/c electrical motor troubleshooting: Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. There are three main signs of electrical bearing damage: Frosting of the bearings and. How To Check Electric Motor Bearings.

From www.slideserve.com

PPT Electric Motor Bearing Lubrication PowerPoint Presentation, free How To Check Electric Motor Bearings Frosting of the bearings and raceways;. Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. How to disassemble an electric motor to check and replace the bearings. Here at precision zone, we closely. How To Check Electric Motor Bearings.

From www.youtube.com

Electric Motors Bearing Guide/ Motors bearing details/ Part 1 YouTube How To Check Electric Motor Bearings Frosting of the bearings and raceways;. Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. This article describes a/c electrical motor troubleshooting: Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. There are three main signs of electrical bearing damage: Here at. How To Check Electric Motor Bearings.

From motorcycle.bali-painting.com

Change Motor Bearings Motorcylce How To Check Electric Motor Bearings Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. This article describes a/c electrical motor troubleshooting: You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. Frosting of the bearings and raceways;. The. How To Check Electric Motor Bearings.

From mdmbearings.com

Electric Motors MDM Bearings Miami FL How To Check Electric Motor Bearings Here is how to look for signs of electrical damage when inspecting failed motor or equipment bearings. Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. There are three main signs of electrical bearing damage: This article describes a/c electrical motor troubleshooting: The dimension at 14:32 should. How To Check Electric Motor Bearings.

From www.gatewoodelectricmotors.com

Top Considerations When Selecting Electric Motor Bearings How To Check Electric Motor Bearings You could assemble the motor, check the endplay as described above, then dismantle the motor and do the appropriate machine work, but a good. The dimension at 14:32 should read 1.1816 inches not 0.1816 inches. Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. This article describes a/c electrical motor. How To Check Electric Motor Bearings.

From www.youtube.com

Electric motor bearing replacement YouTube How To Check Electric Motor Bearings Here at precision zone, we closely inspect the bearings and housings on all motor work performed and if needed, offer a sleeve. Frosting of the bearings and raceways;. There are three main signs of electrical bearing damage: Here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor. How to disassemble an. How To Check Electric Motor Bearings.